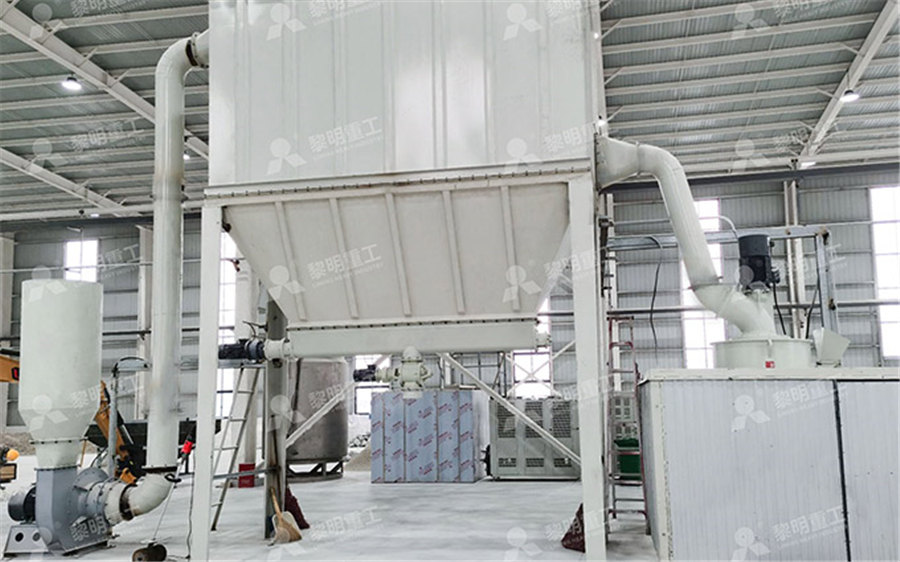

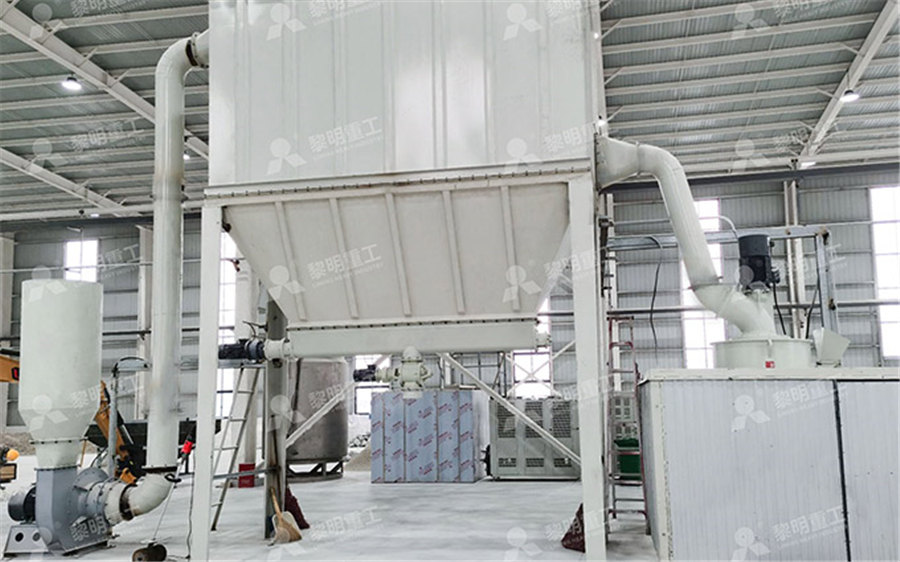

Calcium carbide mud Qinhuangdao decarbonized coal gangue processing grinding equipment

Case studyOptimization of proportions and solidification

2024年7月1日 In order to reduce carbon emissions and consume a large amount of lowquality solid waste, CFBFARMCS has been developed by utilising the synergistic effect of 2023年10月1日 CO 2 cured building materials prepared from calcium carbide residue are CO 2 negative Integrating pozzolanic reaction and lime carbonation in one autoclave is industrially Carbon dioxide cured building materials as an approach to 2021年10月25日 In this study, DS from Taihu Lake, together with calcium carbide slag (CCS) and ground granulated blastfurnace slag (GGBS), was used as supplementary cementitious Recycling sediment, calcium carbide slag and ground granulated 2022年5月1日 For the chloralkali industry, CCS can regenerate massive CaO through purification, molding, calcination Thus, CCS can be used as raw material for CaC2 Recycling and utilization of calcium carbide slag ScienceDirect

Study on the Properties and Hydration Mechanism of Calcium

2024年4月30日 In order to overcome the defects of traditional strong alkaline activators and realise the high valueadded use of calcium carbide residue (CCR), this paper adopts CCR as 2024年1月5日 This study presents an indepth evaluation of calcium carbide residue and coal fly ash as alternative binders The assessment of raw materials emphasized their chemical Evaluation of calcium carbide residue and fly ash as sustainable 2024年6月6日 Calcium carbide slag (CS) is an industrial solid waste produced via the coalbased poly (vinyl chloride) process, and its main component is calcium hydroxide (Ca (OH) 2) An Innovative Approach to Prepare Calcium Oxide from Calcium 2023年8月14日 To solve the disposal problems of carbide slag (CS), soda residue (SR), and red mud (RM) solid wastes, a new type of cemented paste backfill (CPB) was prepared with CS, Production of a new type of cemented paste backfill with

Sustainable application of calcium carbide residue as a filler for 3D

2023年3月17日 CCR is an active chemical, and rain washes away alkali from sludge, changing the pH of soils and water and damaging the environment In this work, we explored new Diversified development of calcium carbide industry, resource utilization of solid waste carbide slag and its application of carbon emission reduction have been fully reviewed In 2020, the Resource utilization of solid waste carbide slag: a brief review of 2016年12月12日 In preparing geopolymer based on red mud (RM), preactivation processes that are generally energyintensive are employed, including two indispensable steps, namely, calcination and fine grinding A novel cogrinding preactivation method without calcination was proposed in this study RM was pretreated by mix grinding with blended coal gangue (CG) Preparation of blended geopolymer from red mud and coal gangue Request PDF On Feb 13, 2019, Nevin Koshy and others published Synthesis and characterization of geopolymers derived from coal gangue, fly ash and red mud Find, read and cite all the research Synthesis and characterization of geopolymers derived from coal gangue

.jpg)

Representative coal gangue in China: Physical and chemical

2024年2月1日 Coal is not only the most abundant fossil fuel on earth, but also an indispensable energy source in the industrial age According to the data of “2021 National Mineral Resources Reserve Statistics Table”, the cities with the most coal reserves in China's energy minerals are Inner Mongolia, Xinjiang, Shanxi, Hebei, Chongqing, Gansu, Shaanxi and other regions2023年9月25日 This study investigates the feasibility of two industrial byproducts, ie, coal gangue (CG) and calcium carbide residue (CCR), as a sustainable CG–CCR geopolymer binder for soil stabilizationMultiscale experimental analysis of marine clay stabilized with coal 2016年11月1日 With the increased global depletion of bauxite reserves and the concurrent growth in the demand for alumina resources, it is important to search for the alternatives to bauxite [1], [2], [3]Coal gangue produced from coal mining and coal processing is one of the largest amounts of industrial solid wastes in China [4], [5]The current simple disposal method Improved extraction of alumina from coal gangue by surface 2022年11月25日 China’s total coal production in 2021 exceeded 413 billion tons, 52% of the world’s total Coal gangue, a solid waste of coal mining accounts for 15–20% of coal production, when directly discharged on the ground surface as waste heaps, it occupies large areas of land and cause environmental pollution This paper summarizes the existing gangue backfilling Underground Disposal of Coal Gangue Backfill in China MDPI

Calcium Carbide an overview ScienceDirect Topics

Calcium carbide has the nominal formula of CaC 2 and the molecular weight of 640992 g/mol The pure material is colorless, but most samples have a color ranging from black to grayishwhite, depending on the grade Its density is 222 g/cc and it melts at 2160 °C with a boiling point (under an inert atmosphere) of 2300 °C, where it decomposesIts main use industrially is in the In order to comprehensively utilize coal gangue, we present fluidized calcination as a new thermal technology for activating coal gangue and systematical study was conducted in comparison with static calcination The calcined products obtained by different calcination methods under various temperatures were characterized by the means of Xray diffraction (XRD), thermal gravimetry Investigation on Calcination Behaviors of Coal Gangue by 2023年11月1日 This study investigates the feasibility of two industrial byproducts, ie, coal gangue (CG) and calcium carbide residue (CCR), as a sustainable CG–CCR geopolymer binder for soil stabilizationMechanics, durability, and microstructure analysis of marine soil 2020年4月14日 22 Experiment The chemical composition measured by Bruker S8 TIGER XRF analysis; the mineralogical composition measured via Bruker D8 ADVANCE XRD analysis; thermal analysis conducted with Mettler Toledo analyzer in a temperature range of 30–1000 °C at a heating rate of 10 °C/min and N 2 or O 2 atmosphere Mortar strength test: prismatic mortar Identification and Activation of Coal Gangue and Performance

.jpg)

Aluminum extraction from activated coal gangue with carbide slag

2022年3月1日 A new coal gangue(CG) activation additive was studied in this paper, carbide slag(CS) was used as an auxiliary agent on the extraction of Al2O3 from coal gangue activated by Na2CO3 through acid 2014年5月1日 In order to deep understand the hydration characteristics of red mudcoal gangue based intermediatecalcium cementitious materials, XRD, IR, TGDTA and MIP techniques were used to investigate the Hydration characteristics of intermediatecalcium based 2024年5月23日 Optimization of proportions and solidification mechanism of allsolid waste cementitious materials based on circulating fluidized bed fly ash, calcium carbide slag, and red mud May 2024 Case Optimization of proportions and solidification 2023年9月25日 An ecofriendly way to improve the engineering properties of lowerstrength soils becomes attractive This study investigates the feasibility of two industrial byproducts, ie, coal gangue (CG) and calcium carbide residue (CCR), as a sustainable CG–CCR geopolymer binder for soil stabilization The geomechanical properties, compressibility, and microstructure of Multiscale experimental analysis of marine clay stabilized with coal

Frontiers Microstructure and Composition of Red MudFly Ash

2020年11月5日 In the mix design of geopolymer samples, the sandbinder ratio was 3:1, the liquid solid ratio (L/S) was fixed at 07 and the different percentages of the geopolymer materials were shown in Table 4Solid particles (fly ash, red mud) and wetbased carbide slag were firstly mixed for 3 min, then the upper clear solution of carbide slag was poured into the mixture and 2019年12月1日 The accumulation of considerable coal gangue not only occupies a great deal of land resource, but also results in serious environmental problems, eg, soil pollution, air pollution, and geologic hazards (Stracher and Taylor, 2004)The heat continues to accumulate during the accumulation process, which leads to spontaneous combustion with the oxidization of coal Comprehensive utilization and environmental risks of coal gangue: A 2022年12月1日 Coal gangue, a waste produced during coal mining, has been regarded as the largest source of industrial waste in China It is estimated that the production of 1 t coal generates 01–025 t coal gangue [1], and the total stockpile of coal gangue exceeds 6 billion tons in China [2], [3]The coal gangue not only occupies agricultural land in large areas but triggers Exploring calcined coal gangue fines as the total substitute of fly 2022年6月1日 Request PDF Experimental study of microorganisminduced calcium carbonate precipitation to solidify coal gangue as backfill materials: mechanical properties and microstructure The treatment of Experimental study of microorganisminduced calcium carbonate

.jpg)

Experimental study on calcium carbide residue as a combined

2021年12月20日 This study investigates the use of calcium carbide residue (CCR) as a potential alternative to NaOH for activating coal gangue (CG) geopolymers, both of industrial waste A series of experiments were carried out to evaluate the effects of CCR content, NaOH:Na 2 SiO 3 mass ratios, liquid to solid ratio (L/(CG + CCR)), and curing time on the strength development 2024年7月12日 Coal gangue (CG), which accounts for about 10–20 % of coal output, is a kind of solid waste generated during the coal mining and washing processes According to Fig 2 , the annual output of CG in China fluctuates between 600–800 million tons, with a utilization rate hovering around 70 %Review Highcapacity utilization of coal gangue as supplementary 2024年9月7日 The persistent reliance on coal has resulted in the accumulation of substantial coal gangue, a globally recognized problematic solid waste with environmental risks Given the coal gangue properties and global land degradation severity, the resourceful utilization of coal gangue as soil conditioners is believed to be a universally applicable, costeffective, high Opportunities, challenges and modification methods of coal gangue 2024年7月16日 With the continuous development of the textile industry, a large amount of dye wastewater is continuously produced Dye wastewater readily causes allergic reactions and cancer risks, which seriously threaten the health of aquatic organisms and humans Aiming at the pollution problem of dye wastewater, the preparation conditions of calciumbased coal gangue Preparation of CalciumBased Coal Gangue Based on Response

Comparison of red mud and coal gangue blended geopolymers

2017年10月30日 The main mineral phases of kaolinitebased coal gangue is kaolinite At present, research on geopolymer directly manufactured from coal gangue is extremely scarce Composite cementitious materials based on red mud and coal gangue mixtures have been studied systematically [28], [29], [30], [31]114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by carbon to calcium carbide and carbon monoxide (CO), according to the following reaction: CaO+3C→CaC2 +CO114 Calcium Carbide Manufacturing US EPA2023年11月6日 Recognition and separation of Coal/Gangue are important phases in the coal industries for many aspects This paper addressed the topic of Coal/Gangue recognition and built a new model called (CGR A review of intelligent coal gangue separation technology and equipment 2023年2月28日 In this paper, the influence of calcium on coal gangue and fly ash geopolymer is explored, and the problem of low utilization of unburned coal gangue is analyzed and solved(PDF) Investigation on the Effect of Calcium on the Properties of

Aluminum extraction from activated coal gangue with carbide slag

2022年5月1日 A new coal gangue(CG) activation additive was studied in this paper, carbide slag(CS) was used as an auxiliary agent on the extraction of Al 2 O 3 from coal gangue activated by Na 2 CO 3 through acid leaching The dissolution rate of Al 2 O 3 was determined by Inductively Coupled PlasmaAtomic Emission Spectrometer(ICPAES) and calculated using 2023年9月25日 An ecofriendly way to improve the engineering properties of lowerstrength soils becomes attractive This study investigates the feasibility of two industrial byproducts, ie, coal gangue (CG) and calcium carbide residue (CCR), as a sustainable CG–CCR geopolymer binder for soil stabilization The geomechanical properties, compressibility, and microstructure of Multiscale experimental analysis of marine clay stabilized with coal 2023年5月24日 This paper proposes a modified YOLOv4 model, named GYOLO, for coal gangue recognition with the aim of reducing model parameters, improving calculation speed, and reducing equipment requirements To achieve this, the paper optimizes the feature extraction network structure by using linear operation instead of traditional convolution to obtain A fast recognition method for coal gangue image processing2009年2月1日 Request PDF Earlyage characteristics of red mudcoal gangue cementitious material This experimental research was to investigate the possibility of incorporating red mud and coal gangue as raw Earlyage characteristics of red mudcoal gangue

Microstructure and Composition of Red MudFly AshBased

wetbased carbide slag, and the fly ash, red mud and carbide slag were prepared as the proportion of 4:3:3 Through scanning electron microscope, back scattered electron,2021年12月20日 This study investigates the use of calcium carbide residue (CCR) as a potential alternative to NaOH for activating coal gangue (CG) geopolymers, both of industrial waste A series of experiments were carried out to evaluate the effects of CCR content, NaOH:Na 2 SiO 3 mass ratios, liquid to solid ratio (L/(CG + CCR)), and curing time on the strength development Experimental study on calcium carbide residue as a combined 2021年10月25日 The carbide slag was involved in the activation process of coal gangue by Na2CO3 at 740847 °C, which destroyed the SiO structure and AlOH structure in coal gangue, generated calcium silicate Recycling sediment, calcium carbide slag and ground granulated 2018年3月30日 Earlier studies explored the geopolymer synthesis using fly ash [2], red mud [22], coal gangue [25], fly ashred mud [8,26] and coal ganguered mud [15] However, there are lacunae in the available literature with respect to the simultaneous use of coal gangue and fly ash to complement each other for strength development and also for waste valorizationImproving strength of calcinated coal gangue geopolymer mortars

Experimental study of microorganisminduced calcium carbonate

2022年2月12日 The treatment of coal gangue solid waste and microbially induced calcium carbonate precipitation (MICP) consolidate technology is a focus of research at home and abroad MICP technology was used to solidify and cement coal gangue particles and endows them with a certain strength The process does not use the traditional cementitious material (Portland Calcium carbide, also known as calcium acetylide, is a chemical compound with the chemical formula of Ca C 2Its main use industrially is in the production of acetylene and calcium cyanamide [3]The pure material is colorless, while pieces of technicalgrade calcium carbide are grey or brown and consist of about 80–85% of CaC 2 (the rest is CaO (calcium oxide), Ca 3 P Calcium carbide Wikipedia2021年10月14日 Both the accumulation of coal gangue and potentially toxic elements in aqueous solution have caused biological damage to the surrounding ecosystem of the Huainan coal mining field In this study, coal gangue was used to synthesize calcium silicate hydrate (CSH) to remove Cr(VI) and Cu(II)from aqueous solutions and aqueous solution The optimum Synthesis of Calcium Silicate Hydrate from Coal Gangue for Cr 2009年5月21日 To recycle industrial wastes and reduce SO2 pollutant emission in coal combustion, the mineralogical compositions, porosity structures, surface morphologies, and desulfurization properties of Physicochemical Characterizations and Desulfurization Properties

Characterization studies on coal gangue for sustainable geotechnics

2020年2月5日 Global rise in greenhouse gas emissions (GHG) is triggered mainly due to the consumption of fossil fuels for power generation and domestic usage Among the fossil fuels, coal is a primary contributor to global GHG with substantial emissions generated during its mining and combustion process Coal gangue, a residue produced during the coal mining process, has 2017年10月30日 DOI: 101016/JCONBUILDMAT201707045 Corpus ID: ; Comparison of red mud and coal gangue blended geopolymers synthesized through thermal activation and mechanical grinding preactivationComparison of red mud and coal gangue blended geopolymers