Cement ball mill equipment

Cement Ball Mill Cement Grinding Machine Cement

Cement ball mill is a cement grinding machine used in the cement production line for cement clinker grinding AGICO supplies the cement ball mills for processing limestone, cement clinker, gypsum, slag, ore, etcThe best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just thatBall mill for cement grindingBall mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best Ball Mill In Cement Plant Cement Ball Mill AGICO This method features large investment and relatively complex process but it can increase the output of cement ball mill by up to 50% The equipment used for pregrinding mainly includes rod mill, cement roller press, etc Cement Ball Mill Ball Mill For Cement Grinding – Cement Ball Mill

Improvements in New Existing Cement Grinding

Types of cement mills There are basically 4 types of cement mills in use today: Ball Mill (BM) Ball Mill (BM): predominant despite higher energy consumption partly because of historical reason but partly also because it still offers What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprisesIt has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easytoadjust the Cement Ball Mill Cement Grinding Machine Cement MillBALL MILL INSPECTION PROCEDURE source : thecementgrindingoffice Introduction This document is intended to help the staff of the cement plants On a process point of view, a mill inspection is only representative if the grinding mill circuit is in a steady working condition with a representative cement productCement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENTThe installation of liners Length Diameter Ratio The lengthdiameter ratio of the cement ball mill is relatively large For mills of opencircuit grinding system, the lengthdiameter ratio is usually between 35 and 6 to ensure that the product fineness is qualified through single grinding; For ball mills in closedcircuit grind system, in order to increase the material flow rate, the length Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

.jpg)

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsBall mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, Switzerland BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL CEMENT BALL MILLS Ball mill optimisation Holzinger ConsultingBall mill Ball mill is the key equipment for material crushing Tongli ball mill is widely used in cement clinker, Portland cement, new building materials, refractory materials, fertilizers, ferrous and nonferrous metal beneficiation, glass and ceramics and other production industriesBall mill CEMENTLBall mill for cement grinding An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness Girth Gear Heavyduty comminution requires heavyduty equipment – and our Girth Gears are up to the task Manufactured using stateoftheart processes Ball mills FLSmidth Cement

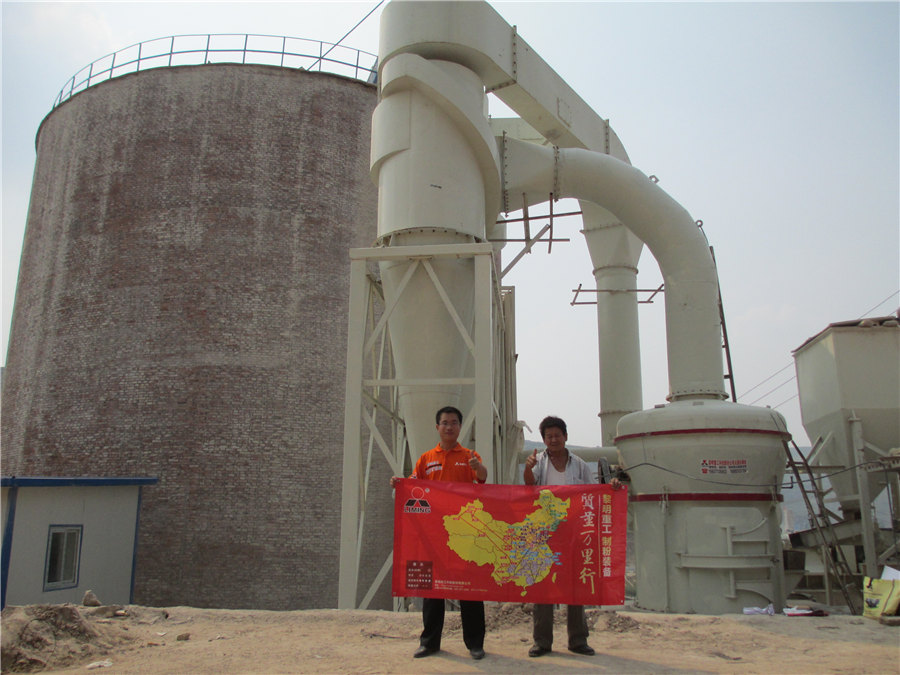

CFB石灰石脱硫剂制备96.jpg)

Cement Separator Ball Mill Optimization

Cement Separator Ball Mill Optimization Update May/2021 , when you buy the package from here , you will get books + complete Courses + Manuals and Notes from very Reputable companies + confedential Guides and Drawings for Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media andlined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLSPrevious Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball charge Ball charge optimization INFINITY FOR CEMENT EQUIPMENTBALL MILL OPERATION Ball mills for finish grinding cement usually consist of two compartments An intermediate diaphragm separates both compartments from each other The 1 compartment is filled with coarser balls and lifting liners and is supposed to pre Process Training Ball Mill INFINITY FOR CEMENT EQUIPMENT

.jpg)

Ball mill for cement grinding

An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just thatA 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaCement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill AGICO vertical roller mills can be used as cement mills, raw mills, and slag mills AGICO also supplies vertical roller mill components and parts, we can customize machines according to customers’ needs Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish []Vertical Roller Mill for Sale AGICO Cement Plant

Ball Mill Grinding Machines: Working Principle, Types, Parts

Cement Industry: Ball mills are extensively used in the cement industry for grinding raw materials, clinker, and additives to produce cement The ability to finely grind materials and control the grinding process makes ball mills crucial equipment in cement manufacturing2020年11月5日 We compare 3 cement milling and cement mill processes, including cement ball mill, vertical roller mill, and rod mill Find your answer here! Skip to content +86 s about ball mill, classifier, and other equipment cement equipment Raw Material Production Crusher;3 Necessary Cement Milling Comparison Ball Mill, Vertical Roller MillWide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc Strong production ability : AGICO CEMENT has a Cement Mill Cement Ball Mill Vertical Cement Mill 2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other What Are the Parts of a Cement Mills? Cement Ball

.jpg)

Rod Mill Ball Mill Cement Milll AGICO Cement

Rod mill is a kind of cement ball mill used in cement plants MBS series rod mills are used for further grinding after the raw material is broken while only the wet overflow type rod mill is usually used as the pregrinding equipment in the The largest planetary gears for ball mill drives in the cement industry supplied at this writing by the Maag Gear Wheel Co, have a transfer capacity of 8 MW The mill can for a limited time be operated at very low speeds for positioning the manholes of Mill drives INFINITY FOR CEMENT EQUIPMENT2019年11月21日 Cement ball mill Cement ball mill is core equipment for cement grinding It has own advantages in operation, application, and structure, at present, cement ball mill has widest applications High working efficiency, the cement ball mill produce uniform particles, increases the production capacity by 25%Cement Plant Equipment Cement Crusher, Cement Mill, Cement Choose the right cement manufacturing machine is an important influence factor to produce highquality cement The cement making machine frequently used in cement plants includes cement rotary kiln, shaft kiln, cement vertical mill, cement ball mill, cement roller press, etcCement Manufacturing Machine Cement Making Machine Cement

.jpg)

BALL MILL FLSmidth Cement

Cement ball mills have to achieve the desired grinding fineness with maximum grinding efficiency and minimal wear and tear It’s a tough job when you consider the operating conditions of the mill – but our equipment is built to last Hard wearing kit A ball mill is a traditional grinding machine that has been used in the cement industry for decades It consists of a rotating cylinder filled with steel balls that crush and grind the material as the cylinder rotates Ball mills are known for their reliability and ability to grind materials to a fine consistency Advantages of Ball Mills:Vertical roller mill vs ball mill for cement grinding: Comparison BALL MILL INSPECTION PROCEDURES CLICK HERE NOW TO DOWNLOAD MOST IMPORTANT BOOKS IN CEMENT INDUSTRY + PRACTICAL EXCEL SHEETS TO HELP YOU IN YOUR DAILY WORK General: The process engineer should be the doctor of the system The “doctor” is required for: implementation of “Health checks” > Regular actionBALL MILL INSPECTION PROCEDURES INFINITY FOR CEMENT EQUIPMENTAGICO Provides comprohensive equipments for Cement Production lines of different output, customers can choose whole cement plant or single equipmentCement Equipment Sale Cyclone PreheaterRotary

Roller Press Install For PreGrinding Before Cement

Why install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to HighEfficiency Cement Separators and Classifiers has been supplied by AGICO for 15 years, this equipment is mainly used to improves cement grinding sCement Seperator Improves Cement Grinding SystemAGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillTongli Steel slag Ball Mill Tongli slag ball mill is an industrial equipment for processing steel slag, mainly used to grind steel slag into the required fineness for recycling and reuse Steel slag is a byproduct of steel production, and its main components include iron oxide, calcium oxide and other metal oxidesSteel slag Ball Mill CEMENTL

Cement Ball Mill CHAENG

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section It is the ideal grinding equipment for cement clinker, limestone, gypsum, slag, ore, and other grindable hardness materialsball mill BÜHLER TYPE Nova 2000 SRX with Bühler control type ERD used Manufacturer: Bühler The Nova S ball mill is the optimal solution for the fine grinding of various masses such as compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatcontaining massesUsed Ball Mills for sale in Germany MachinioIt is also called cement grinding equipment or cement mill AGICO provides the cement ball mill, rod mill, cement vertical mill, Raymond mill, air swept coal mill, etc Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment CALL US +86 Grinding Mill Grinding Equipment Cement Mill AGICOball mill performance efficiency formulas if you work in a cement plant and you need courses and manuals like this manual and books and excel sheets and notes i spent 23 years collecting them you should click here to download them nowBall Mill Performance Efficiency Formulas INFINITY FOR CEMENT EQUIPMENT

.jpg)

Improving Mill Shoe Bearing Reliability and Productivity

2020年6月14日 So, this week we’ll discuss mill shoe bearings and how to enhance their reliability and productivity Cement Ball Mills A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives It is a component in the cement making process Today’s Ball Mills are typically designed with a slide shoe bearing