Ore grinding machine installation safety technology briefing

.jpg)

Grinding Safety Precautions and Control Measures

2023年10月11日 In this article, we will explain what grinding safety precautions are and how they can be identified and implemented using a grinding risk assessment and provide you with grinding safety tips to keep your workers 2021年7月22日 We understand the importance of a safe work environment, and how training is the first step to a safe operation of any machine Grinding is a job that has to be taken Safety checklist for working with grinders Atlas Copco2024年7月21日 In this article, we’ll explore essential safety tips and best practices to ensure you stay safe while achieving highquality results From proper protective gear to correct handling Grinding Machine Safety: Essential Tips for OperatorsVSM shows the safety aspects that need to be taken into account when grinding and the precautions to be taken Grinding with handheld and stationary machines is a central process Safety during grinding: Avoid hazards and risks VSM Abrasives

.jpg)

Gamechanger in mill relining safety Safe To Work

2024年4月19日 Bradken’s MillSafe Solutions are keeping personnel safer during mill relining A grinding mill is a critical asset to a mining operation Capable of breaking down ore, these Grinding machines are used daily in a machine shop To avoid injuries follow the safety precautions listed below Wear goggles for all grinding machine operations Check grinding GRINDING MACHINES Carnegie Mellon University2021年4月16日 Visit the Crushing and Grinding sections on the Emerson Mining, Minerals Metals page for more on the technologies and solutions that can drive greater reliability, Safe, Reliable and Efficient Crushing and Grinding in Mining grinderrelated safety practices An abrasive wheel grinder is one of the most common pieces of machinery utilized in maintenance shops and in manufacturing These machines are used for PeerReviewed Working Safely With Grinders American Society

.jpg)

High Pressure Grinding Rolls for Minerals AusIMM

This paper discusses wear and the measures taken to overcome this problem; availability and the procedures implemented to reduce downtime for replacement of the rolls; criteria for selection 2017年9月27日 Safety regulations for grinding prepared by a number of national and international bodies are reviewed, and factors affecting safety in grinding are presented, Safety in Grinding SpringerLinkProtection for grinding machines, operator protection, work protection, grinding machine protection for retrofitting, buy now at Mowotas! Our safety guards for grinding machinesamp;nbsp;can be easily mounted/retrofitted on most grinding machines of the different manufacturers:Safety Guards for Grinding Machines MOWOTASWith over a century of experience, Metso designs and manufactures the most comprehensive line of grinding mills and entire grinding systems for mining companies around the world The comprehensive offering provides reliable and energy efficient technology and solutions across wet, dry, horizontal, and vertical grinding operationsGrinding Metso

.jpg)

Our Dynamic HPGR Technology for Mineral Grinding

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore When it comes to feed material characteristics, the 5 VERTICAL ROLLER MILL KTM Main data Type Min motor power Max motor power Min capacity Max capacity [kW] [kW] [t/h] [t/h] KTM 400 11 18,5 0,1 0,8 KTM 800 37 55 2 5 KTM 1000 55 90 4 8 KTM 1200 90 132 6 12 KTM 1400 132 200 9 18 KTM 1600 200 315 12 24 KTM 1800 315 400 20 38 KTM 2000 400 500 29 50 KTM 2200 500 630 39 64 KTM 2400 630 800 GRINDING AND SEPARATING TECHNOLOGY SYSTEMS2016年7月14日 As a largely volumetric machine, the comminution specific energy in an HPGR is a function of the power drawn by the machine at a given rolls pressure setting, divided by the throughput This has two related effects: firstly, HPGR throughput has relatively little variation based on ore hardness, but it also implies that the specific power input for the HPGR stage is HPGR 911Metallurgist2024年11月21日 A brief history of extracting of tin from tin ores In nature, the tin ore are existing in sand or alluvial raw material, this kind tin ore called sand tin or alluvial tin, those raw material may be with stone, sand, gravel, soil, sticky clay, some times with other magnetic iron, tungsten, ilmenite, hematite, monazite, zircon sand and other mineralsHow to extraction tin from tin ores JXSC Machinery

.jpg)

Vale to automate iron ore mine to improve safety and production

2018年9月13日 The operation currently employs around 1,700, and is now the secondlargest mine in Brazil, behind the Carajás iron ore mine in Pará Mining Technology’s Mining Safety content is supported by USA mining safety specialists Carroll Technologies Groupapparent for fine products Though it is ore dependant, as a general guide sub 10 micron applications will be limited to about 4550% feed solids Power and Energy Efficiency Grinding energy is one of the major costs of mineral processing Choosing the right grinding machine and the best media are certainly importantFine Grinding as Enabling Technology – The IsaMillFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchasesOre mill, Ore grinding mill All industrial manufacturers2010年3月24日 The first commercial shipment of 58t of hematite direct shipping ore occurred in October 2012 Processing The ore is processed in an onsite facility Processing includes crushing, grinding, magnetic separation, reverse flotation and thickening to produce 12Mt/y of magnetite concentrate Approximately 85% of ore is delivered to the crusherKarara Iron Ore Mine Mining Technology

.jpg)

Beneficiation of Gold and Silver Ores SpringerLink

2019年12月15日 However, the demand for finer grinding has set new challenges for grinding technology; new technological advancements in mineral processing, including stirred milling, have opened the door for many new opportunities Lowergrade ore and finely distributed ore require finer grinding than the traditional mill circuit product size (P80) of 75 μmThe extraction technology for platinumgroup metals (PGMs) has changed dramatically in the last 80 years, and the changes are likely to continue for years to comeThe extractive metallurgy of South Africa's platinum 2023年10月11日 One of the main causes of harm while grinding is improper operation of machinery This is why employee training is so important To reduce the risk to health and safety when operating grinding machines, operators Grinding Safety Precautions Hazards Control 2022年9月6日 In 2019, Weir Minerals received a £100 million order for 12 Enduron® HPGR machines and GEHO® Positive Displacement pumps for a magnetite iron ore application in Australia Installation is underway, and once complete, this will be the world’s biggest HPGR installation in an iron ore applicationEnduron® HPGR – the principal choice in iron ore

Mineral Processing Equipment Ore Grinding Machine CITIC HIC

CITIC Heavy Industries Co Ltd (CITIC HIC), formerly known as Luoyang Mining Machinery, was one of the national key construction projects of China's First FiveYear Plan (Ma'aden) 6 wet grinding rod mills, Ø46×67m Vedanta Project in South Africa 1 2022年3月30日 Another contribution regarding grinding kinetics of a Ta ore was the research objective in Nava et al []Some variations to classical population balance model methodologies and functional operational correlations were found among the feed size; the specific breakage rate; and the Sn, Ta, and Nb contentsGrinding and Concentration Technology of Critical Metals MDPI2023年10月2日 Derrick Corporation has been at the forefront of iron ore processing since the 1950s “The SuperStack technology is more than just a technical solution,” Hay saidRevolutionising iron ore processing Australian MiningSBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/HSBM Ore Ultrafine Grinding Mill

.jpg)

Latest Advances in High Capacity, Fine Screening for the Iron Ore

2021年7月1日 Leading iron ore producers are already implementing SuperStack screening technology in innovative applications Vale SA, one of the world’s largest iron ore is installing SuperStacks for fine iron recovery at the Carajás mining complex to transform their tailings into positive cash flow with a by making a highvalue “green ore” product from what was previously 2024年10月25日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider Most advanced gold ore treatment technology; Enviromental equipment manufacturing, construction, equipment installation, commissioning, operation, and a series of onsite EPC/turnkey production Dasen: all in one ore mining machinery, equipment, solution 2021年7月6日 As such, we provide demonstrations for our clients who are unfamiliar with the machines we hire To help you stay safe when using a floor grinding machine, we’ve created a brief guide on some safety bestpractice How to Stay Safe Using a Floor Grinding Machine2015年3月12日 Today, the ironore industry uses HPGRs to prepare pellet feed for finishing grinding after wetball milling and filtering The wetball mill product is more readily filtered without the need to grind it to the final product size Since Developments in HPGR technology Mining Magazine

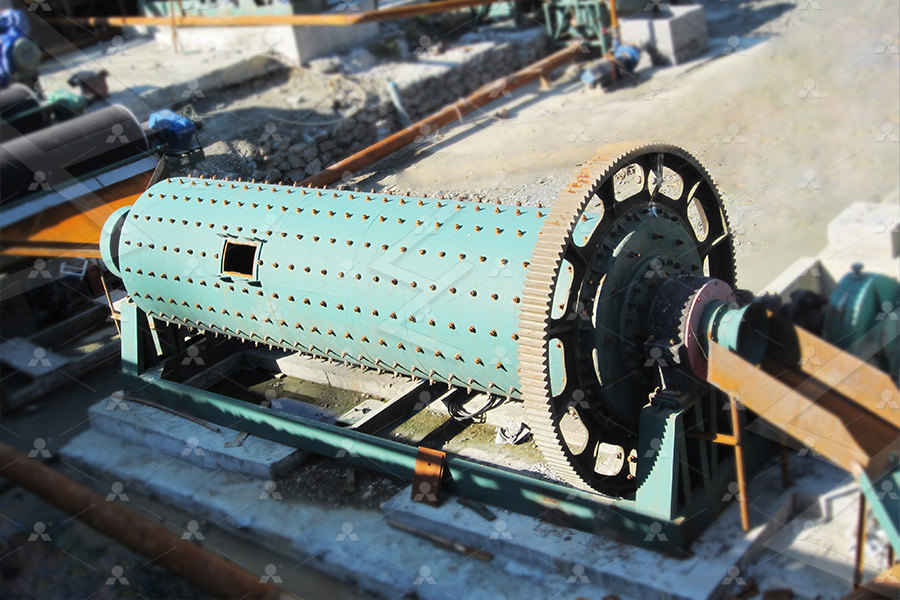

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 Ball mill is a common grinding equipment in concentrator Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball mill2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices The demand for new metals and materials has also arisen concurrently This necessitates Future of Mining, Mineral Processing and Metal Extraction 2023年10月17日 Factors for choosing a suitable ore powder grinding mill 1 Raw material characteristics: Different raw materials have different hardness, humidity and grinding and crushing properties, and the corresponding ore powder grinding mill needs to be selected to meet the processing requirements 2 Production capacity: Determine the required processing How to choose a suitable ore powder grinding mill?This video shows the big, midum and small ball millsOre Grinding Machine Ball Mill YouTube

.jpg)

Grinding Machines SpringerLink

2019年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; 2024年8月15日 Although flotation machines require fine grinding and can be costly, they are efficient and can process most types of ore Magnetic separator: Magnetic separators come in two types: dry and wet Dry magnetic separators do not need water or liquid, making them simpler and cheaper to maintain, and more ecofriendlyMineral Processing Plants: What You Need to Know Fote MachineryAt Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence converge Ore Crushing, Sand Making, Grinding Machinery Bellian Mining 2020年7月23日 Innovation plays a critical role in the mining industry as a tool to improve the efficiency of its processes, to reduce costs, but also to meet the increasing social and environmental concerns among communities and authorities Technological progress has also been crucial to allow the exploitation of new deposits in more complex scenarios: lower ore Innovation in the Mining Industry: Technological Trends and a

.jpg)

Modern Grinding Technology and Systems MDPI

This specialist edition features key innovations in the science and engineering of new grinding processes, abrasives, tools, machines, and systems for a range of important industrial applications Topics written by invited, internationally JFE, Metso, Kobe Steel, POSCO, and Vale are among the leading patent filers in ore pretreatment Metso has a Feed Pretreatment System (FPS) that expands the range of sulphide concentrates and residue materials that can be treated Leading innovators in ore pretreatment for the mining 2019年2月5日 High Pressure Grinding Roll ("HPGR") technology is applied is a broadening range of applications In the last few years, increasing numbers of HPGR units have been or are being installed in HPGR Grinding Technology and its Application to the 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Grinding Machines SpringerLink

Mineral Processing Equipment for Mining Industry

2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to separate particles by size and density, and separation to isolate valuable minerals from waste materials2015年3月15日 The total energy consumption for ore comminution will further increase within the next decades One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principleResearch of iron ore grinding in a verticalrollermill2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra Principles of Modern Grinding Technology ResearchGate2024年6月26日 The Canadabased company says it is committed to using its technology to “make a positive impact on the world around us, whether on Earth or beyond” With the grinding process in mining globally equating to as much as 4% of energy consumption, Rockburst CEO Oscar Malpica and his team have set out to innovate and transform ore processingOre processing innovation: Rockburst sets out to cut energy use

Ore Grinding SpringerLink

2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation It’s all about volume In the iron ore industry, you want the largest possible throughput of iron ore through your processing equipment That’s why you need the most reliable and proven equipment that never lets you down, even though it handles large tonnages every day of the yearReliable equipment for iron ore mines FLSmidth