Basic conditions for starting an industrial grinding mill manufacturer

Grinding Mill an overview ScienceDirect Topics

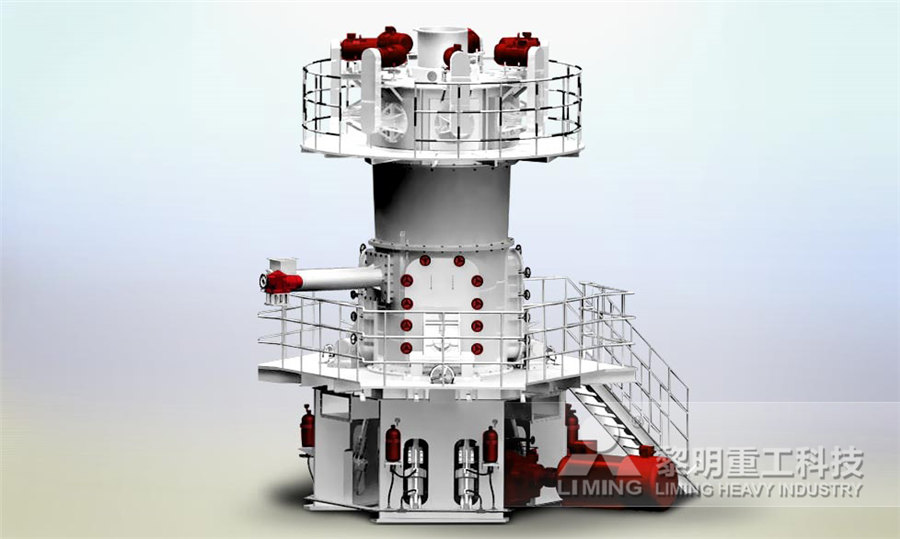

Roller mills can have grinding elements of various shapes In some mills they are cylindrical rollers, in others these are of truncatedconical shapes or have a flat lateral face and a convex circumferential surface Some leading manufacturers equip their mills with balls as the grinding Tough economical conditions and high grade but finegrained ore processing have forced the mining industry to look for more efficient processes IsaMill Technology for ultrafine and fine ISAMILL FINE GRINDING TECHNOLOGY AND ITS INDUSTRIAL To ensure high margins in the face of rising energy costs, manufacturers must develop production methods which are highly efficient and which achieve the highest values even in the case of PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSWEG offers the most reliable and efficient solutions for milling plants for ferrous and nonferrous products with their experience of mill drive systems In the heart of a processing plant, the ball Mining Grinding and Processing WEG

Grinding Mill Design Ball Mill Manufacturer 911Metallurgist

2017年2月20日 Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder SKF solutions for grinding mills protect pinions and trunnions from harsh conditions Helping prevent failure for better reliability and safety with lower costs In mineral processing, grinding Grinding mills SKFPalamatic Process UM grinding mills offer flexibility and ease of operation Due to the wide variety of raw materials, where each particle reduction demand requires a customized solution, How to choose the right industrial mill? Palamatic ProcessSelecting the right grinding mills for your operation requires the serious consideration of a variety of factors, far beyond “what do I want to grind?” and “How fine do I want it?” A starter list of Selection Tips for Grinding Mills Union Process

.jpg)

How grinding mill design changed over the last 30 years

2020年6月3日 During the last 30 years, mill manufacturers have not been able to convince customers or their engineering consultants to purchase completely standard or existing size The Attritor’s versatility is gained by the ability to operate under a broad range of conditions For example, grinding media type, size, and amount; different machine speeds; variable loading or ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS Union Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used Mill, Grinding mill All industrial manufacturers2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls (PDF) Performance optimization of an industrial ball

Barite Industrial Ultrafine Grinding Mill SBM

2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill These grinding media are crushing and grinding fresh product due to impact and friction The lining as well as the grinding media can be made out of hard wear resistant high manganese/chromium steel, ceramic or silexTaurus Ball Mill NETZSCH Grinding DispersingDownload scientific diagram Definition of Mill Diameter D, Mill Length L, and Effective Grinding Length EGL from publication: P a g e AUTOGENOUS AND SEMIAUTOGENOUS MILLS 2010 UPDATE This Definition of Mill Diameter D, Mill Length L, and Effective Grinding Rotational speed: 7,500, 5,550, 12,000 rpm Output: 5 kg/h 500 kg/h Motor power: 3 kW 15 kWPrinciple Advantages The material is evenly sent to the grinding chamber by the feeding system, and receives the strong impact of the highspeed rotating grinding movable disk At the same time, it receives the action Impact mill, Impact grinding mill All industrial manufacturers

CFB石灰石脱硫剂制备96.jpg)

Coal grinding mill, Coal grinding grinding mill All industrial

Find your coal grinding mill easily amongst the 48 products from the SBM, a Chinese grinding mill manufacturer, has researched and developed the fifthgeneration of rolling ball type mill (E type mill) 1960's Production of plate type mill 1970's Manufacture of rolling ball type mill (ZQM series) 1980 Start to Compare this product 2015年4月9日 Grinding Mills and Their Types satyendra; April 9, 2015; 12 Comments ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operationGrinding Mills and Their Types – IspatGurudepending on the type of the mill, the operating conditions and the type of the material being ground Several basic concepts are commonly used in modeling of the grinding process The starting material naturally consists of particles which differ significantly in size which makes it necessary to define different size classesGrinding in Ball Mills: Modeling and Process Control SciendoProduction of industrial and professional stone mills for industrial mills Industrial production processes are increasingly required to meet a wide variety of requests from customers and thus from final consumers, who are now demanding different food products to suit today’s major changes in lifestyle The BioStoneMill industrial and professional electric stone mill is able to Industrial Electric Stone Grinding Mill Manufacturer BioStoneMill

Grinding Characteristics of Wheat in Industrial Mills

2013年1月16日 An industrial wheat mill has several technological phases, starting with coarse grinding of seeds to fine grinding of the resulted milling products, after their sorting in fractions of dif 2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial Manufacturers B; Baileigh Industrial (1) Blaser Swisslube (1) D; Dr Fritch (1) E; the basic condition for productive and quality cutting on any bandsaw mill The stone grinding wheel is Compare this product Remove from comparison Cutting tool grinding machine All industrial Keep in mind that no single mill will grind large particles to a very fine size efficiently by repeating or prolonging the process in the same unit A specific type of mill (with fixed media, operating conditions or equipment parameters) is most efficient in grinding a particular material with a certain feedsize range A ratio of feed size to Solids Choose the Right Grinding Mill Chemical Processing

.jpg)

Ore mill, Ore grinding mill All industrial manufacturers

The Retsch Disc Mill DM 200 is used for grinding mediumhard, hard and brittle materials Thanks to its robust design it is suitable for usage under rough conditions in pilot plants and laboratories A major area of Laboratory disc mill The grinding vessels can hold sample batches of 101000 cm³ (thick suspensions with high shear tension) in laboratory conditions, for such purposes as bitumen as the FNG, he allows however the processing of more consequent batches than FNG0000 or BLX This mobile grinding unit is used for small industrial Laboratory mill, Laboratory grinding mill All industrial manufacturersFind your large mill easily amongst the 47 products from the leading brands (Fritsch GmbH, Liming, LONGI, ) on DirectIndustry, the industry specialist for your professional purchasesLarge mill, Large grinding mill All industrial manufacturersHammer Mills In machinery manufacturing and milling industries there is a saying that if you have a hammer mill, you have a business Drotsky says: “If you have a Drotsky hammer mill, you are guaranteed a successful business” Milling is the process of breaking up or crushing material into smaller pieces to make it more palatable for human and animal consumptionHammer Mills for Sale South Africa Drotsky

Grinding Mill an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L welded mechanic, it is intended for the small installations of grinding in laboratory Coarse powder mill, Coarse powder grinding mill All industrial Shanghai Clirik is a professional grinding mill machines manufacturer in China, Limestone Industrial Grinding Mill Raymond Mill Fineness:80600 mesh Yield:130 t/h read more >> + ultra fine grinding mill Build a "green mine", starting from ClirikGrinding Mill Manufacturer,Grinding Mill for Sale,Industrial grinding China Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaGrinding Mill MadeinChina

A guide to grinding mill installation: Ensuring efficient and

A guide to grinding mill installation: Ensuring efficient and troublefree operation Grinding mills are critical components in many industrial processes, responsible for reducing the size of materials and achieving desired particle sizes The successful installation of a grinding mill is essential for ensuring efficient and troublefree The mill is driven by an electric motor via a flexible coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the gearbox absorbs the grinding forces Before the mill motor is started, the grinding rollers are Loesche Mills for industrial mineralsOutput: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt Raymond mill, Raymond grinding mill All industrial manufacturersRequest PDF On Jul 31, 2015, Xiaoli Wang and others published Hybrid modeling of an industrial grindingclassification process Find, read and cite all the research you need on ResearchGateHybrid modeling of an industrial grindingclassification process

Industrial Roller Mills Williams Crusher

Williams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed modulation varies the centrifugal force of the grinding rollsFinal grain size: 250 µm 800 µm Rotational speed: 1,500 rpm 6,000 rpm Output: 650 kg/h 13,000 kg/h any type of dry of soft products with average hardness THEORY OF OPERATION: The product is loaded in the center of the mill by a feeding chute The product is so moved by centrifugation and milled by impacts Limestone mill, Limestone grinding mill All industrial manufacturersThe Retsch Disc Mill DM 200 is used for grinding mediumhard, hard and brittle materials Thanks to its robust design it is suitable for usage under rough conditions in pilot plants and laboratories Disc mill, Disc pulverizer All industrial manufacturersLabor laws in India govern various aspects of employment, including working conditions, wages, social security, and industrial relations Some of the key labor laws applicable to manufacturing businesses include the Factories Act, Minimum Wages Act, Employees' Provident Funds and Miscellaneous Provisions Act, and the Employees' State Insurance ActLegal and Regulatory Requirements for Starting a Manufacturing

Europemill Industrial Stone Grinding Mill Engsko

Both the Standard and the Industrial grinding mills simply do the job through the optimum milling process using the proven and wellknown Engsko millstones The adjustment of stones has an adjustment gear for fine tuningEngsko 2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two Effects of Mill Speed and Air Classifier Speed on 2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGateIf stop/start is a frequent occurrence then the gearbox must be sized accordingly 3 Those rigid type couplings can transmit shock more easily to the gearbox than can flexible or gear type couplings, and the application factor selected accordingly To select the basic size, the nominal torque must be multiplied by a service factor (see Table 2)DESIGN BASIC OF INDUSTRIAL GEAR BOXES Łódź

.jpg)

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

• All grinding tanks are jacketed for cooling or heating • A torque meter can be equipped to measure the energy input, and by using the total power consumption, one can monitor the grinding process • Cover seals can be provided for processing under inert atmosphere III THREE BASIC TYPES OF WET GRIND ATTRITORS Fig22012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the Energy conservation and consumption reduction in grinding 2023年3月15日 Richland Hills, Texas, September 12, 2024 AML, a USbased manufacturer of barcode data collection products, announces the launch of its latest Android ® product, the StrikerX mobile computer StrikerX is the evolution of its predecessor, the Striker, but comes equipped with the most powerful processing architecture available for devices in its class, the The Evolution and Importance of Grinding Mills in Modern Industry

.jpg)

Grinding Machines Grinding Mills and Industrial Grinding

Grinding Machines We offer grinding mills, industrial grinding machines, paint grinding machines, wet grinding mills, dry grinding mills, chemical grinding machines, grinding equipment at Manu Enterprises, ChennaiRotational speed: 120 rpm 240 rpm Output: 400 kg/h 30,000 kg/h Machine length: 13,900, 14,700 mm inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow: the unqualified particle size will fall and return Ultrafine mill, Ultrafine grinding mill All industrial manufacturers