The principle of steam mill

Steam mill Wikipedia

A steam mill is a type of grinding mill using a stationary steam engine to power its mechanism And did those feet in ancient time, Albion Flour Mills, first steam mill in London from around 1790; Aurora Steam Grist Mill, a historic grist mill located in Aurora, Cayuga County, New York, Steam is an important feed manufacturing input but is often poorly understood and often mismanaged Steam generation and use is a major cost for most feed manufacturing facilities Steam generation, control, and quality for feed manufacturing2016年9月6日 The principle of roller milling is the gradual reduction of grain by breaking it open and reducing the particle size between successive pairs of rolls At every stage of the process From Quern to Computer: The history of flour milling Mills ArchiveThe principle of steam management is to ensure that losses are made zero Our research shows that Pulp and paper mills can reduce steam demand anywhere between 1525% just be04 Innovations In Steam IPPTA

Brief History of the Steam Engine Michigan State University

2013年5月21日 However, one of the fundamental principles used in the development of steambased power is the principle that condensation of water vapor can create a vacuum This brief 2023年2月8日 The first important principle is that heated water produces steam which is 1500 times more voluminous The steam, when it cools and condenses back to water, then dramatically reduces in volume and creates a partial The Steam Engine in the British Industrial RevolutionFrom Englishman Thomas Newcomen 's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine Steam power during the Industrial Revolution WikipediaSteam power, the use of water in gaseous form to power mechanical devices Steam power was first popularized in the 18th century and reached its peak importance in the late 19th century, when it became the main source of power Steam power History, Uses, Facts Britannica

.jpg)

Steam Turbine: Working, Types, Components, and Applications

Steam Turbine Working Principle A steam turbine works on the basic principle of the Rankine cycle The basic principle of a steam turbine involves the expansion of highpressure steam through a series of stages, where it passes over sets of stationary and rotating blades Image source: schoolworkhelperWorking Principle of Fluid Energy Mill Fluid energy mill is also known as jet mill It works on the principle of impact and interparticle attrition to achieve the desired particle size Construction of Fluid Energy Mill It consists of a grinding What is Fluid Energy Mill? Working Principle, 2022年4月27日 Principle The principle of the roller mill is breaking and crushing actions are achieved mechanically with the application of pressure Stress is applied by rotating heavy corrugated wheels (mullers or rollers) The oil is Roller Mill Principle, Construction And Working2023年6月14日 The crushing chamber of the flat jet mill is in the shape of a horizontal disc, and it is also called a horizontal disc jet mill It is composed of grinding chamber, separation device, feeding device, air duct, etc (Fig 1)The working principle is like this: the compressed gas (air, superheated steam, or inert gas) generates a highspeed jet through the feeding ejector, and Jet Mill SpringerLink

.jpg)

Review of Literature on Steam Accumulator Sizing in Palm Oil Mill

The principle of steam accumulation used in the system was limited for the pressure range of up to 2 bars and automatic regulation was not yet incorporated Ruths2015年3月5日 The uncondensed steam in the condensate is called ‘blowthrough steam’ The cascade system, cascades the blowthrough steam through succeeding dryer sections to a small group of dryers at the wet end This last group discharges to a condenser and depending on the minimum pressures required, it might discharge to some other mill processHow steam is used at paper mills in paper production2023年8月30日 Possessing a basic knowledge pertaining to the properties of steam, engineering principles, and was instrumental in the use of steam power at the Albion mill, the first corn mill to do so; William Creighton who was employed as engine fitter before becoming the head of the drawing office; Engineering Skills and the Efficiency of Steam Engines During High energy utilization rate, low operating cost, grinding particle size range D50: 0510μm The revolution of dry milling technology, the milled particle size can reach submicron or nanometer level, which greatly improves the energy utilization efficiency and realizes low carbon, energy saving, environmental protection and resource recycling by supersonic steam jet millSupersonic Steam Jet Mill ALPA Powder Equipment

.jpg)

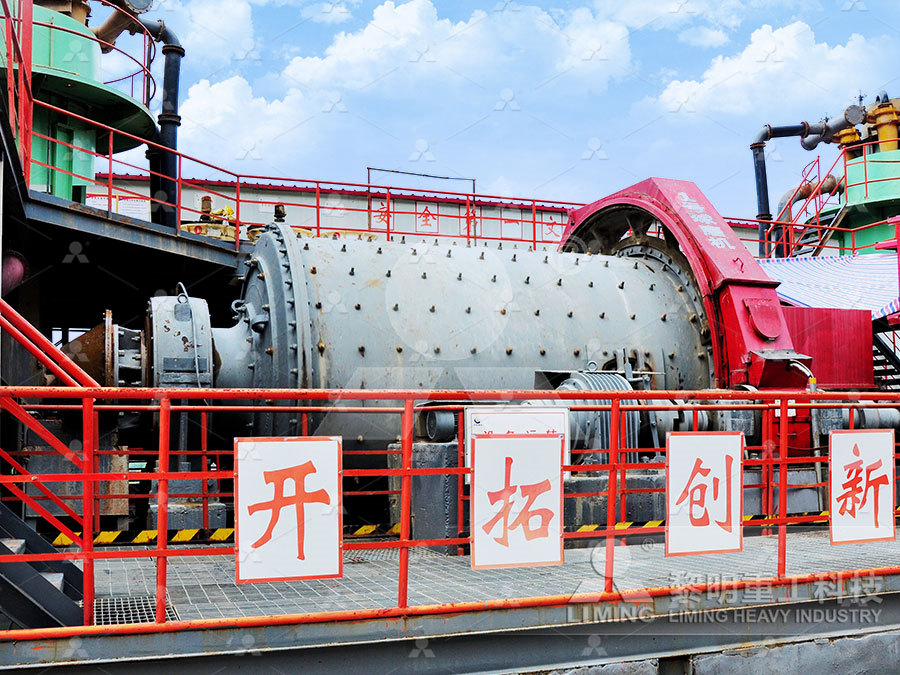

The working principle of ball mill Meetyou Carbide

2019年5月22日 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal forceSteam is an important feed manufacturing input but is often poorly understood and often mismanaged Steam generation and use is a major cost for most feed manufacturing facilities Given current energy costs, attention should be paid to optimizing the operation of the steam system and the feed mash conditioning processSteam generation, control, and quality for feed manufacturing2 How does a jet mill work ? The working principle of jet mills is explained in this part 21 High velocity impact The principle of size reduction applied in a jet milling machine is to have high velocity impact, in between the particles, and in Jet mills : what is it ? How jet milling works2023年2月8日 The principles of vacuums and atmospheric pressure were known in the 17th century by such scientists as Galileo (15641642) and Evangelista Torricelli (16081647), but the problem was building an engine The Steam Engine in the British Industrial Revolution

How Do Wind Turbines Work? Department of Energy

Wind turbines work on a simple principle: instead of using electricity to make wind—like a fan—wind turbines use wind to make electricity Wind turns the propellerlike blades of a turbine around a rotor, which spins a generator, Jet mill works on fluid energy Consider a pancake spiral jet mill as an example Micronizing and classification take place in a shallow, cylindrical chamber High pressure air or steam is injected in this chamber through the specially designed nozzles placed at regular distance, on the peripheral wall The axis of each jet is tangential toHOW IT WORKS2023年4月17日 The principle of the steam engine was that heated water produces steam, which is 1500 times more voluminous which was the first large factory entirely powered by steam Manufacturers were invited to the mill to see the impressive Watt and Boulton engines working and then make an orderWatt Steam Engine World History Encyclopedia2021年7月27日 The working principle and main purpose of jet mill 27/07/2021 Some jet mills use steam as kinetic energy, which we call “steam jet mill” Particle size could be up to 02μm, with stronger kinetic energy It is usually used to treat power plant fly ash, The working principle and main purpose of jet mill

(PDF) John Stuart Mill's Harm Principle and Free Speech

This article advocates employing John Stuart Mill's harm principle to set the boundary for unregulated free speech, and his Greatest Happiness Principle to regulate speech outside that boundary This first steam engine ever documented was the aeolipile, invented by Greek geometer and engineer Heron of Alexandria in the 1st century ceIn 1698 British engineer Thomas Savery invented the atmospheric pressure engine, revolutionizing the efficiency of steam power The Newcomen steam engine, invented in 1712 by British engineer Thomas Newcomen, improved Steam power History, Uses, Facts BritannicaSteam blowing is one of the initial cleaning operations before starting any power plant or steam lines Steam blowing of MS lines, CRH, HRH, SH, RH, HP, LP bypass pipelines of the turbine is carried out in order to remove welding slag, weld bead deposits, loose foreign materials, iron pieces, rust, etc from the system, generated during manufacturing, transportation, erection What is Steam Blowing? Steam Blowing Procedure2021年4月20日 In year 1785, the first directly driven steam mill was built in London and it became operational in 1786 having 10 millstones for grinding while cylindrical sieves were used for sieving Actually, the milling was still performed by the millstones which dominated the process until the invention of the roller mills [1, 7, 8]The Evolution of Milling Process SpringerLink

Steam Distillation Principle The Engineer's Perspective

2022年6月4日 Steam distillation functions on the principle that steam (water) forms an immiscible, nonideal mixture with the components to be separated Each component in the mixture will, as a result, establish its own vapor 2024年9月23日 Even today Mill's essay "Utilitarianism," which was published in 1861, remains one of the most widely taught expositions of the doctrine There are three principles that serve as the basic axioms of utilitarianism the Three Basic Principles of Utilitarianism ThoughtCo2023年8月2日 gen fertilizer rates, sowing density, and plant growth regulator application on the quality and mill ing value of Triticum durum Desf grain Agronomy, 12 (7), 1622The Latest Innovations in Wheat Flour Milling: A Review2021年9月8日 More Resources: Heat Tracing in Piping: Types, Working, Use, Installation, Comparison (Steam Tracing vs Electrical Tracing) Principle of Steam blowing During steam blowing, the Piping network should be blown with enough velocity of steam to ensure sufficient cleaning force for the removal of debris, rust, and scaleWhat is Steam Blowing? Steam blowing Type, procedure, and Principal

How Steam Engines Work HowStuffWorks

2023年7月18日 The Jacobite Express crosses a curved viaduct at Scotland's Glenfinnan David Cation / Getty Images Steam engines played a pivotal role in shaping the modern world They were the first engine type to see widespread use First invented by Thomas Newcomen in 1705, steam engines saw big improvements in 1769, courtesy of James Watt (who we remember Attrition mills use the hammermill principle to a certain extent; ie, shattering by/impact However, they also impart a shearing and cutting action Between this valve and the steam generator or boiler are a strainer and trap to remove condensate, providing only dry steam in the millChapter 18 Feed Milling Processes Food and Agriculture 2024年4月17日 Fluidized bed dryer (FBD) is well known and widely used equipment in granulation area of pharmaceutical manufacturing It is used in the granulation process for drying the material to get desired moisture content in the tablet formulation granules required for perfect compression of tabletsPrinciple and Working of Fluidized Bed Dryer (FBD)2023年11月30日 This chapter conducts a thorough examination of current and emerging palm oil milling technologies, emphasizing their role in enhancing efficiency while addressing environmental concerns Structured into four sections, it begins by evaluating traditional milling methods and equipment, considering their effectiveness and environmental impact in Advances in Sustainable Palm Oil Milling Technologies: Enhancing

Bead Mill Technology Bead Mill maker Ashizawa Finetech Ltd

Principles of Bead Mill Technology Dry Bead Mills Dry bead mills employ a system to produce fine particles in air or inert gas atmosphere With beads of relatively large diameter inside, large and coarse particles can be ground easily There are two types of dry bead mill operations: continuous or batch operations2024年10月21日 Working Principle of Steam Turbine The Rankine cycle is a fundamental principle in the operation of steam turbines The Rankine cycle is an idealised thermodynamic cycle of a heat engine that transforms heat into mechanical work during a phase transition Here the frictional losses are neglected By expanding through the turbine, steam energy is Steam Turbines: Working, Construction, Parts, Types, Applications Steam can and is also used to convey energy, but unlike electricity, steam conveys heat energy, and is a fluid Because steam is a fluid, and is used to convey energy, it is termed an energy fluid A fluid has no fixed shape and yields when external pressure is applied ie fluids flow easily Fluids may be a liquid, or a gasIntroduction to Steam, Boilers, and Thermodynamics PDHLibrarySteam Boilers play a very important role as a very important Unit Operation categorized as Utilities in any Process IndustryThe complete Principle of WorkinSteam Boilers Principle of Working

Rice Milling Manual International Rice Research Institute

Engleberg mill has led some governments to discourage its use and in many Asian countries, the Engleberg mills can no longer be licensed to operate as service or commercial mills 32 Two Stage Milling Compact Mill Two stage mills are often called compact rice mills and in many countries have superseded the Engleberg mill The twostage mill2016年2月26日 Hammer Mill Operating Principle We have never subscribed to the idea that the hammermill is suited to the primary breaking of shovelloaded, slag, and cement rock The larger sizes are built to take steam shovel size limestone, crushing it into pieces 1″, 2″, 3″, or 4″ and under, in one operation, Hammer Mill Operating Principle 911Metallurgist2015年7月22日 Material input into the pelleting chamber Regulated material input into the pellet mill is important for maintaining consistent pellet quality During the pellet production process moisture is released as steam If the rate of material feed is greater than the productivity rate of the pellet mill, problems may occurIf the steam generated from pelletization cannot escape Working Principles of pellet mill Pioneer:FeedWood 66 THE BARROW STEAM CORN MILL, 18701972 OH!Prax f~ ll'lJrJ~s FIG 8 Ordnance Survey Map, c l873 showing the corn mill and its surroundings THE BARROW STEAM CORN MILL, 18701972 67 The original office buildings and kiln within Building 13 were replaced with a fivestorey addition, matching that originally built to the southThe Barrow Steam Corn Mill, 18701972 Academia

Process control variables, instrumentation and automation of

Steam is the primary variable controlled to properly condition the incoming product Steam adds heat and moisture Heat and moisture activate the starches and other adhesives in the ingredients in the feed to bind the pellet together as it passes through the specially steam usage In many mills due attention is given to the steam and condensate system However, the importance of hood balance and pocket air ventilation is quite often ignored This could result in excessive energy consumption in the dryer section and/or reduction in drying efficiency with consequential loss in productivity Fundamentals of Paper Drying Theory and Application from 2020年9月23日 This article advocates employing John Stuart Mill's harm principle to set the boundary for unregulated free speech, and his Greatest Happiness Principle to regulate speech outside that boundary because it threatens unconsentedto harm Supplementing the harm principle with an offense principle is unnecessary and undesirable if our conception of harm John Stuart Mill's Harm Principle and Free Speech: Expanding the Notion A section cutthrough of ball mills A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shellBall mill Wikipedia