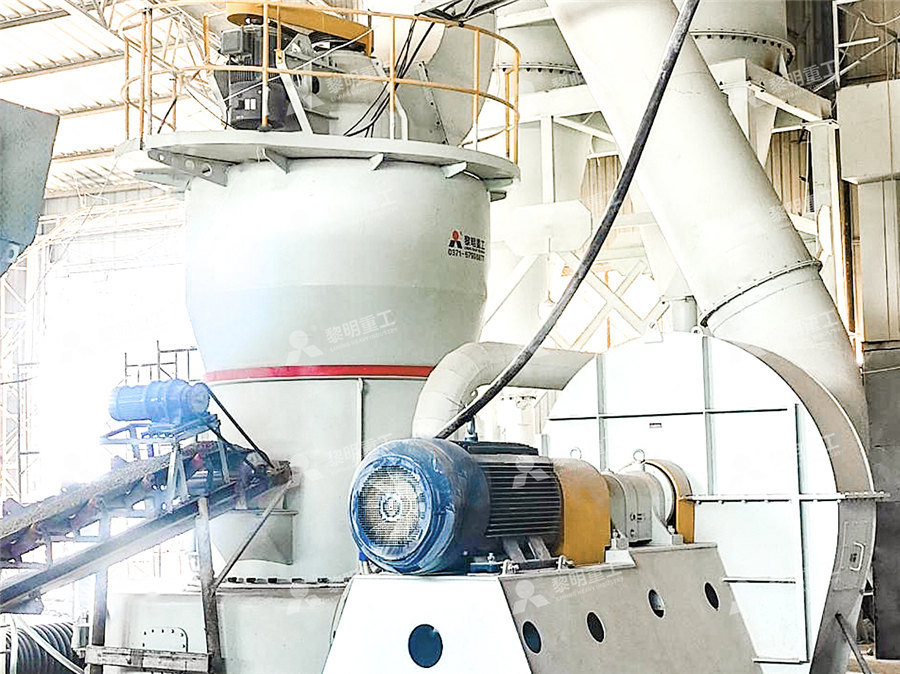

Cement grinding station equipment

Cement Grinding Unit Cement Grinding Plant

There are three common types of processing for cement grinding stations: opencircuit grinding system, closedcircuit grinding system, and combined grinding system At present, most of clients use a combined grinding system, and its Cement grinding equipment comprises cement vertical mills, cement ball mills, cement roller presses, cement separators, conveyors, and other cement machinery We offer free project design based on user requirements, Cement Grinding Plants Cement Grinding Unitcomplete equipment and accessories for cement grinding station; EPC services: complete solutions including design, research and development, manufacturing, transportation, installation, commissioning, training, and aftersalescement grinding stationCement clinker grinding unit, or called cement grinding plant, cement grinding station, is an individual grinding plant in the finished cement production Cement grinding plants are primarily used to produce finished cement products by Cement Grinding Plant CHAENG

Cement Grinding Plant Expert Cement Grinding

We master the construction and design schemes of various cement grinding plant systems such as vertical mill system, combined system, and ball mill system No matter what type and strength of cement you want to produce, and what 1) complete equipment and accessories for cement grinding station; 2) EPC services: complete solutions including design, research and development, manufacturing, transportation, installation, commissioning, training, and after Clinker Grinding Unit CHAENG25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND CEMENGAL Engineering, equipment and assembly for Fives delivers comprehensive grinding systems with toprated performance and low energy consumption Our FCB FLAG™ station is a modular, integrated grinding unit combining three separate process functionsFives Modular grinding with FCB FLAG™ station

.jpg)

Cement Grinding Station Solution Ball Mill and

The new cement grinding station adopts the pregrinding technology, on the one hand to reduce the particle size of the material into the grinding; On the other hand to promote the material particles inside the crack and defect, so as to The modular mobile grinding plant developed by AGICO CEMENT is a highly flexible system capable of producing any desired types of cement for local cement producers and market Modular Mobile Grinding Plant, Portable Grinding Plant Cement EVERYTHING YOU NEED TO KNOW ABOUT ESTABLISHING CEMENT GRINDING PLANT 1MTY THIS WAS FEASIBILITY STUDY MADE BY OUR COMPANY INFINITY FOR CEMENT EQUIPMENT IF YOU WANT ANY EVERYTHING YOU NEED TO KNOW ABOUT With 65 years of dedicated experience in cement equipment and fertilizer research, development, and manufacturing, we are your expert and reliable partner for The Green Building Material Cement Factory 600,000 TPY GGBFS vertical roller mill grinding station has a significant annual production capacity of 1 million tons of Ground Cement Fertilizer Equipment Manufacturer 65+ years Experience

modular and portable grinding station plug and grind vertical

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations 2024年6月14日 If the cement grinding station and clinker production line are set near the limestone mine, unnecessary transportation expenses of cement mixture will be incurred Therefore, the cement grinding station is built near the sales area, which can save about 40% of the freight Improved cement grinding technology Cement grinding hasNew Features of Cement Grinding Station DesignThere are two types of mills commonly used in the modular mobile grinding station: ball mill and vertical roller mill (VRM) We will select the appropriate mill module according to the specific needs of customers The mill is the core component of a grinding plant All other equipment in the grinding station serves the purpose of grindingModular Grinding Plant AGICO Cement MachineryTherefore, a cement grinding station is more suitable for the actual development of the local area Because it needs a smaller area and has no requirements for mine resources The main grinding equipment cement mills grind the clinker to finished cement powders Material – batching – Cement Mill Cement Grinding Units Cement Plant Equipment CNBM

.jpg)

Clinker Grinding Unit CHAENG

The whole system of cement grinding station mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so on In order to meet the customers' requirements on different granularity of auxiliary materials, it can be 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations CEMENGAL Engineering, equipment and assembly for the cement 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations modular and portable grinding station plug and grind verticalcemengal: engineering, equipment and assembly for the cement industry EXPERTS IN GRINDING STATION 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding CEMENGAL: INGENIERIA, EQUIPOS Y MONTAJE PARA LA INDUSTRIA DEL CEMENTO

.jpg)

Modular and portable grinding station Plug and

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND CEMENGAL has been awarded with a new contract for the supply of 2 nd Cement grinding station to ACICO Cement consisting of a complete cement mill workshop; Main equipment to be included within this new contract is related to a 5,200 Kws ball mill fully engineered by CEMENGAL with all the peripheral equipment and a 4 th generation classifier from Magotteaux XP4i130 for high Cemengal is a EPC contractor specialized in the Cement Industry Therefore, the clinker production line should be built near the mine, and the cement grinding station should be built near the market The cement grinding plant is an industry with green benefits There is no doubt that cement Cement Grinding Plant Overview Cement Grinding Previous Post Next Post Contents1 KILN ALIGNMENT ROLLER GRINDING2 1 Hot kiln alignment using electronic devices21 11 Advantages of this Technique22 12 Tools and Instruments Used23 13 Measurement Procedures Using Total Station24 14 General Notes3 2 Grinding of rollers tyres31 21 Grinding Method32 22 Grinding Machine33 23 KILN ALIGNMENT ROLLER GRINDING INFINITY FOR CEMENT EQUIPMENT

MODULAR AND PORTABLE GRINDING STATION PLUG GRIND

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations CEMENGAL Engineering, equipment and assembly for the cement 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Cemengal is a EPC contractor specialized in the Cement Industry Cement grinding station with annual output of 1 million tons Description The cement grinding station with an annual output of 1 million tons adopts the technology of separately grinding clinker and slag, among which the clinker grinding adopts the combined grinding process composed of two Φ 42m × 13m cement millsCement Production Line,Cement Machine,Rotary Kiln,Cement Equipment

.jpg)

Cement Production Equipment factory, Buy good price Cement Grinding

China quality Cement Production Equipment Cement Grinding Station supplier and Good price Cement Production Equipment for sale online Cement Production Equipment Cement Grinding Station Hydrated Lime Plant Rotary Kiln System 5125 jspflq@1262024年8月22日 Cement grinding plant or cement grinding unit, grinding station is a necessary section of the cement manufacturing plant What does cement AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment CONTACT INFO +86 s 19F, Suite B, Global Trade Mansion, Wenfeng equipment Archives AGICO Cement Plant25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Modular and portable grinding station Plug and Grind classicCement grinding station is one production unit of cement finished products, which doesn't include the last finished stage of the cement production process Home; Equipment in cement grinding plant Machines needed in cement grinding Cement Grinding Station FTM Machinery

.jpg)

modular and portable grinding station plug and

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations modular and portable grinding station plug and grind xtreme2024年5月31日 AGICO CEMENT is a trustable cement equipment supplier, we provide you with a budget template of a cement grinding unit, and help you better plan the cement grinding station Please feel free to contact us for more details! Skip to content +86 s about blog contact EN ES MenuHow much dose it cost to start a cement grinding plant?Cement grinding plant is the last station in the cement production line In order to reduce the power consumption of cement grinding plants, the application of cement pregrinding equipment is worthy of promotion Cement Roller Press Type: Roller Diameter(mm) Roller Width(mm) Feed Size(mm) Output(t/h) Power(kw) G14080: 1400: 800:Making Your Cement Grinding Plant Energy Saving Cement Grinding

.jpg)

Cement Grinding Plants Cement Grinding Unit Cement Grinding Station

Cement grinding equipment comprises cement vertical mills, cement ball mills, cement roller presses, cement separators, conveyors, and other cement machinery We offer free project design based on user requirements, providing suitable equipment to ensure smooth production with minimal investment and high profitabilityAt present, it has completed over 60 new dryprocess cement clinker production lines of various sizes (3008000 tons/d), more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and over Leading Supplier of Cement Plant Equipments Rotary CEMENGAL has been awarded with a new contract for the supply of 2 nd Cement grinding station to ACICO Cement consisting of a complete cement mill workshop; Main equipment to be included within this new contract is related to a 5,200 Kws ball mill fully engineered by CEMENGAL with all the peripheral equipment and a 4 th generation classifier from Magotteaux XP4i130 for high Cemengal is a EPC contractor specialized in the Cement Industry 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations CEMENGAL Engineering, equipment and assembly for the cement

.jpg)

Cement Manufacturing Process INFINITY FOR

Grinding: the material is ground between rollers and grinding table while passing from the center of the table to the nozzle ring The commnation method belongs to the most efficient grinding processes applied in the cement manufacturing The Superiority of the Cement Grinding Plant in Property: The cement grinding plant is of high efficiency, high quality, and energy conservation Besides, the resource can be made full use of with it, which can meet the requirement in environmental protection and sustainable development The Analysis of the Production Profit of the Cement Cement Grinding Plant,New Type Cement Grinding Station2023年11月1日 We give some tips for cement plant design, including cement site selection, mineral selection, raw material prehomogenizing, grinding station design, calcination system design, waste gas generating system design, 8 Tips For Cement Plant Design25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations modular and portable grinding station plug and grind XL

CEMENGAL Engineering, equipment and assembly for the cement

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Jiangsu Pengfei Group Co, Ltd is the national leading enterprise of building material industry, the manufacturing and exporting base for complete set of cement machinery equipment, the provincial abide by contracts and keep ones words enterprise Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement Jiangsu Pengfei Group Co,LtdZuari Cement is one of the leading cement producers in South India A owned subsidiary of the HeidelbergCement Group its, Commitment to customer satisfaction has seen Zuari Cement grow from a modest 05 million tonne capacity in 1995 to above 71 MnT in 2016 and has earned it amongst the leading innovative cement Brands in the countryZuari Cement Chennai Grinding UnitWe will elaborately create the most appropriate cement grinding station scheme for you according to your production demand, investment budget, market situation, site scale, etc other commonly used equipment in the cement grinding station include cement mill separators, bag filters and ESPs, cement silos, conveyors, bucket elevators, Cement Grinding Plant Expert Cement Grinding Solutions from

.jpg)

Cement grinding station with annual output of 1 million tons

The cement grinding station with an annual output of 1 million tons adopts the technology of separately grinding clinker and slag, Ltd is one of the leading manufacturers of rotary kiln and grinding equipment in China and the global market Follow Us Links Benjia,Ji,North Suburbs of Hai'an City,Jiangsu Province,PRC 0086513 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations CEMENGAL Engineering, equipment and assembly for the cement