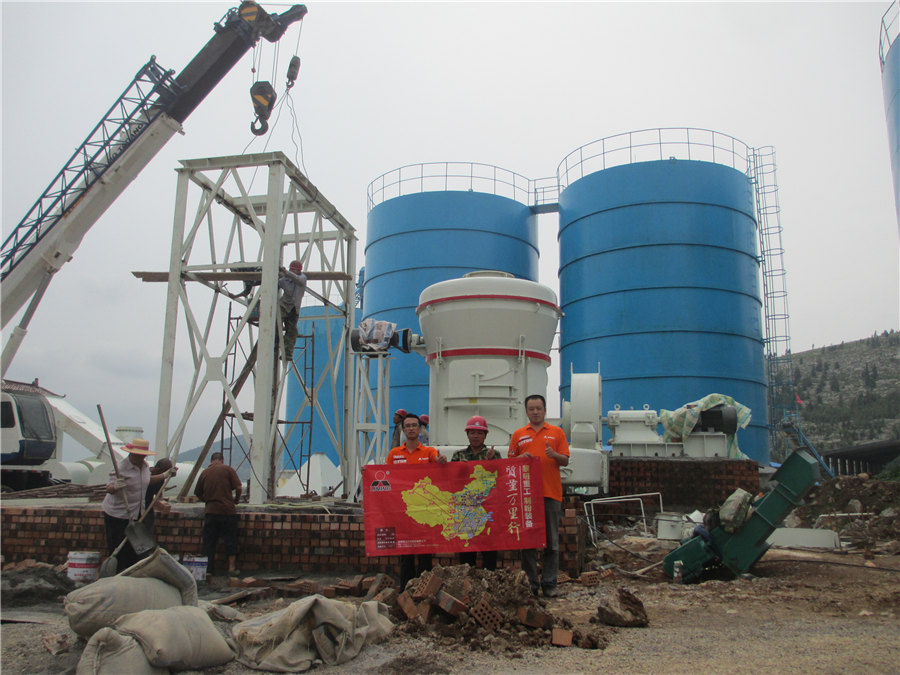

4 roller singlestage vertical ore mill

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in With the innovative COPE drive and the “4+4” cement mills and 6roller raw mills in combination with a common parts concept covering both of the mill types, the technical and commercial LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING WITH THE 2012年9月1日 The paper is giving an overview about successful operating Loesche Vertical ? Roller ? Mills (VRM) installations and summarises the main benefits of the dry compressive Latest Installations And Developments Of Loesche Vertical Roller Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, The Taskmaster Titan Duplex features two dual shaft grinders powered by a single motor and drive This unit’s unique GRMK vertical roller mill Output: 30 t/h 250 t/h Ore mill, Ore grinding mill All industrial manufacturers

.jpg)

LOESCHE vertical roller mills for the comminution of ores and minerals

2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of 2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE investigation on flotation behavior of a copper sulfide ore after dry grinding by loesche vertical roller mill *j katzmarzyk, i silin, k m hahn and h wotrubaINVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

.jpg)

Redundancy and interchangeability – large vertical roller mills

Figure 1: Growth in output of Loesche mills since 1928 Bild 1: Durchsatzwachstum der LoescheMühlen seit 1928 Throughput [tp/h] 1 000 800 600 400 200 0 1928 1948 1958 1968 1978 1988 1998 2000 2002 2004 2006 Designation One Loesche 6roller mill Two Loesche 3roller or 4roller mills Mill capacity for 100 % kiln feed 100 % 2 x 50 %CLIRIK Machinery produces all kinds of vertical roller mills for ore powder making, such as Raymond roller mill, ultrafine grinding mill, ultrafine vertical roller Since the 19th century, it has been produced by a single ball mill However, with the development and upgrading of modern mills, aluminum powder can also be processed and Vertical Roller Grinding Mill Machine CLIRIK Machinery The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) The VRM technology was introduced in the mid'90s for grinding clinker and slag by LOESCHE (Schaefer, 2001) Fig 1 illustrates the grinding parts of a Loesche vertical roller millModeling and simulation of vertical roller mill using population The fineness of the finished product can reach 2 microns, and the single product qualification rate can Learn more about the LXMC Superfine Wet Mixer>> SBM Grinding Mill Cases SBM ore grinding mills sell well all over the world, such as Eastern Models: HGM ultrafine grinding mill, CLUM vertical roller mill, LXMC ultrafine wet SBM Ore Ultrafine Grinding Mill

制粉-10.25公众号.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Performance Evaluation of Vertical Roller Mill in A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, Energysaving and Efficient Vertical Roller Mill Fote Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine

Operational parameters affecting the vertical roller mill

2017年4月1日 Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated2014年5月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the (PDF) Matrix Model Simulation of a Vertical Roller Mill with High (eg LM 696) (Fig 1) and the 4roller coal mills (eg LM 434 D) both of which have been on the market since 2006 Since 2014 the (4+4)roller cement mills have completed the cement mill product range The Loesche MILL LM 704+4 CS ( Fig 2) has been sold to a cement producer in Nigeria and will be put into operation in 2016LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING WITH THE VERTICAL ROLLER MILL2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports that 15% Copper ore grinding in a mobile vertical roller mill pilot plant

.jpg)

Grinding Process Optimization Featuring Case Studies and

Fig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller Mills2019年3月3日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Modeling and simulation of vertical roller mill using population 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plantHCMilling(Guilin Hongcheng) provides exclusive Aluminium Ore Vertical Roller Mill equipment with customers for grinding Aluminium Ore powder It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying Its fineness can achieve 200325 mesh (7544μm) The production capacity is 5200T/HAluminium Ore HLM Vertical Roller Mill

(PDF) Operational parameters affecting the vertical roller mill

Operational parameters affecting the vertical roller mill performance × the specific energy consumption and in a later stage the wear to be expected in Schmitz, C, Stapelmann, M, Dardemann, F, 2012a Recent installations and developments of loesche vertical roller mills in the ore industry In: Comminution’12 Proceedings, Cape 2015年3月10日 Copper ore grinding in a mobile vertical roller mill pilot plant Author links open overlay panel Deniz Altun a, Carsten Gerold b, classifying and drying operations were combined in a single unit Vertical roller mill; Stage Spec energy (kWh/t) Stage Spec energy (kWh/t) 3rd crushing: 3:Copper ore grinding in a mobile vertical roller mill pilot plantRequest PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill Download scientific diagram Singlestand 4high cold rolling mill from publication: Vertical Vibration Model for Unsteady Lubrication in RollsStrip Interface of Cold Rolling Mills According Singlestand 4high cold rolling mill ResearchGate

INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

2019年8月1日 investigation on flotation behavior of a copper sulfide ore after dry grinding by loesche vertical roller mill August 2019 Conference: 58th Annual Conference of Metallurgists (COM 2019)2017年4月1日 Grinding test results for zinc ore showed that it is possible to decrease the total grinding energy consumption from 2011 to 1140 kW h/t by using vertical roller mill instead of AG/SAGball mill circuit (van Drunick et al, 2010)Operational parameters affecting the vertical roller mill 2015年3月15日 A DoE software is used for setting up the final experimental design The experiment space is stretched out by 18 value combinations of the independent variables for the Kiruna ore and 15 combinations for the Mertainen ore The verticalrollermill is then operated according to each single combinationResearch of iron ore grinding in a verticalrollermill2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its

Vertical Roller Mill SBM Ultrafine Powder Technology

Vertical roller mill is an efficient industrial milling equipment, suitable for mass production, can grind stones with a Mohs hardness below 7 +17 [ protected] language Uses of vertical roller mill – in ore field Montmorillonite powder ultrafine grinding millThe author has developed a simple and sound approach to determine the preliminary SSSAG mill aspect ratio before conducting population balance model simulations(PDF) Toward a Simple Approach Determining Single PDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, read and cite all the research you need on ResearchGate(PDF) Drives for large vertical roller mills ResearchGate2001年10月1日 Recent research has shown, that the application of these vertical roller mills in dry grinding of ores and minerals can lead to significantly better recovery rates and higher grades when compared to conventional grinding ( 80 120 mm ) compared to ball mills A 3rd crushing stage might be eliminated thereforeLoesche vertical roller mills for the comminution of ores and minerals

.jpg)

Lithium Ore Grinding Mills SBM Ultrafine Powder Technology

2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill +17 [ protected]1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmit the torque created by the motor Secondly, the gearbox hasDRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS2016年6月15日 3 CEMENT INTERNATIONAL 4 2/2016 4 VOL 14 43 1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmit the torque created by the motor Secondly, the gearbox has to transmit the grinding Drive Selection for Large LOESCHE Vertical Roller Mills PDF2023年10月3日 Rocker Arms: The function of the rocker arm device of the cement vertical roller mill is to transmit the pressure provided by the hydraulic cylinder to the grinding roller, so that it can be transformed into the grinding force act on the material bed The rocker arm device is mainly composed of upper rocker arm, lower rocker arm, rocker arm shaft, bearing and What is a vertical roller mill (VRM)? A Comprehensive Guide to

Numerical Investigation of Vertical Roller Mill Operation Using

2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size Simulation of Particle Motion in a TwoStage Mill Article 01 May 2022 Keywords Powder technology cement, and ceramics It is also used to grind slag and nonmetallic ores The VRM decreases the number of equipment in the grinding circuit by Cement Grinding Ball Mill; IronOre Crushing Ball Mill; Classifying Screening Equipments Air For saving energy and achieving good quality products, we have Developed a 4 ROLLER MILL and a CLASSIFIER for it which ensures consistent including the vertical roller mill and Raymond mill, to clients across India, especially in 4 Roller Mill Plant Shalimar Engineering2019年12月15日 Hicom mill Vertical roller mills Selfrag 424 HPGR SSA singlestage AG mill, Table 43 Ore sorting methods and mineral application Full size table Table 44 Sensor ore sorting segmentation Full size table 443 Dense Media Separation Beneficiation of Gold and Silver Ores SpringerLink