Calcite anthracite lignite mill accessories

Reprint from ZKG 3 Gebr Pfeiffer

mill performance data between the different solid fuels such as anthracite, hard coal, lignite and pet coke Even within a single fuel type the deviation is quite high for grindability, ash The MPS coal grinding mill with a high drying capacity is very suitable for grinding lignites with feed moistures of as much as 45 per cent Depending on this high feed moisture, the mill COAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer2022年1月1日 Most of the grinding plants for calcite are equipped according to the setups of tumbling mills such as ball mills However, it would be much more logical to replace such The effects on the grinding parameters of chemical, morphological 2003年8月1日 The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 μm has been determined using a laboratory (PDF) Breakage Parameters of Some Minerals and Coals Ground in

.jpg)

Lignite an overview ScienceDirect Topics

Lignite is the least calorific of all categories of coal (anthracite, bituminous, subbituminous, brown coal/lignite): this is due to its high moisture and volatile content and to its low carbon content 2023年8月1日 The usage of grinding aids prevents particle pelleting and leads to reduced energy consumption The work aims to research the impacts of three pure grinding aids from Effective role of grinding aids in the dry grinding performance of The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 /Lm has been determined using a laboratory scale ceramic ball Breakage parameters of some minerals and coals ground in a African Pegmatite is a leading supplier of anthracite, calcined anthracite and electrically calcined anthracite for a variety of foundry applications Many modern foundries rely on anthracite (and Anthracite for Castings and Refractory Applications African

.jpg)

Firstorder plots for dry and wet grinding of 425+300 JLm (a)

Download scientific diagram Firstorder plots for dry and wet grinding of 425+300 JLm (a) calcite, (b) bari te, (c) quartz, (d) lignite and (e) anthrac ite2003年8月1日 The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 μm has been determined using a laboratory scale ceramic ball mill(PDF) Breakage Parameters of Some Minerals and Coals Ground in DOI: 101016/jfuel2020 Corpus ID: ; Effect of moisture on energysize reduction of lignite coal in Hardgrove mill @article{Yang2020EffectOM, title={Effect of moisture on energysize reduction of lignite coal in Hardgrove mill}, author={Yong Yang and Yaqun He and Xiaotao Tony Bi and John R Grace and Haifeng Wang and Farzam Fotovat and Weining Xie Effect of moisture on energysize reduction of lignite coal in 2002年6月1日 The kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 μm has been determined using a laboratory scale ceramic ball millKinetics of wet versus dry grinding of lignite by a

.jpg)

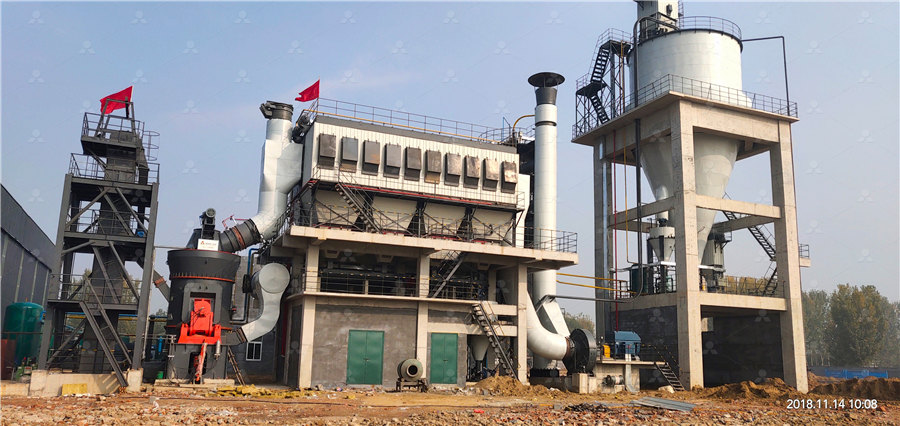

MRN Pendulous Hanging Grinding Mill Zenith Crusher

The limestone, calcite, marble, barite, feldspar, talc, bauxite, phosphate ore, iron oxide red, dolomite, granite, bituminous coal, anthracite, lignite, kaolin, bentonite and other noncombustible and nonexplosive brittle mineral products whose Moh’s hardness are below Grade 7 and water content below 6% could all be ground2023年8月27日 The influence of metal nitrates—KNO3, NaNO3, and Ca(NO3)2—as activating additives on the oxidation and combustion of lignite and anthracite is investigated The additives (5 wt %) are introduced in the samples by impregnation, according to the moisture capacity By thermal analysis and highspeed video recording of combustion, it is established that the Adding Metal Nitrates to Intensify Lignite and Anthracite COAL MILLppt Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses coal mill equipment, including the names, functions, and working principles of different types of equipment It focuses on vertical roller mills (VRM), describing the three main sections of VRM separation, drying, and grindingCoal Mill PDF Coal Lignite2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate

.jpg)

Geological Characteristics of Coal SpringerLink

2015年1月1日 As shown in Table 15 (Anthracite, Bituminous Coal and Lignite Classification), the main difference among anthracite, bituminous coal, and lignite is the volatile content on a dry and ashfree basis, V daf Carbonate minerals are mainly calcite and sideriteChoose from our selection of machine vises, locators, supports, and stops, milling machine accessories, and more In stock and ready to shipMilling Machine Accessories McMasterCarrMaterial: Anthracite, lignite Capacity: 300,000 tons per year Feed particle size: ≤25 mm Output particle size: 200 mesh Equipment: 3 sets of HLM1900M coal vertical mill Auxiliary equipment: Jaw crusher, conveyor belt, quantitative feeder, dust collectorEnergysaving and Efficient Vertical Roller Mill Fote Machinerycoal types like anthracite, bituminous coal or lignite and also various kinds of petcoke are processed Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills that have achieved a share of almost 90 per cent and, on the other, ball mills whoseCOAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer

Earth Science Chapter 3 Quiz Flashcards Quizlet

Study with Quizlet and memorize flashcards containing terms like Anthracite is the soft, brown form of coal; lignite is the hard, black form of coal, Coquina limestone consists of shell fragments; and therefore, has a biochemical origin, The faster magma cools, the larger the size of the crystals that form and moreMill Accessories including boring heads, collet sets, clamping kits, DRO’s, end mill holders, fly cutters and more at LittleMachineShop term (800) 981 9663 (800) 981 9663; Orders; Cart; type term Mini Lathe Sale ends November 30th !!! ProductsMini Mill Accessories LittleMachineShop2020年3月1日 In this paper, energy split phenomenon for the coarse grinding of super clean anthracite coal (SCAC)/calcite mixture of 28–2 mm in the ballandrace mill is investigatedEnergysize reduction of mixtures of anthracite and coking There are four major types (or “ranks”) of coal Rank refers to steps in a slow, natural process called “coalification,” during which buried plant matter changes into an ever denser, drier, more carbonrich, and harder material The four ranks are:Anthracite: The highest rank of coal It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high What are the types of coal? US Geological Survey

SED GEOL 1121 Flashcards Quizlet

Study with Quizlet and memorize flashcards containing terms like Which is most progressed in the formation of coals? a) anthracite b) bituminous coal c) lignite d) peat, What environments are often associated with the production of peat and coal? a) Stream Channel b) Swamp c) Desert d) Coral Reef, Organic sedimentary rocks are composed of: a) evaporated carbon b) carbonate 2022年1月1日 Calcite, in other words, calcium carbonate (CaCO 3), is a glassy shimmer, transparent, easily breakable, large crystal marble mineralIts Mohs hardness is 3 and specific gravity is in the range of 26–28 It is micronized by grinding then classification processes are applied, and offered to the user as natural ground or ground and coated calcite according to The effects on the grinding parameters of chemical, morphological 1 Bulk material first with a broken jaw or impact crusher crushing To fit into the grinding mill size; 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment;coal grinding mill, coal pulverizer machine, coal powder making Study with Quizlet and memorize flashcards containing terms like a is an economically important material that cannot be replenished in a reasonable time frame, so once it has been consumed, there will not be any more, which naturally occurring substance in coal is released through combustion to create acid rain?, how does the burning of fossil fuels affect the geology ch23 Flashcards Quizlet

.jpg)

Relationship between the breakage and wetting characteristics of lignite

2002年10月1日 Figure 22shows the firstorder disappearance plot for dry and wet grinding of À600+425 mm lignite using the same laboratory size ceramic ball mill as used before (in Table 2[23] and thereafter)2018年6月12日 Properties of coal surface and pore structure are important aspects to be investigated in coal preparation and utilization In order to investigate the limits of different probe methods, a comprehensive approach Surface Properties and Pore Structure of Anthracite, 2023年8月15日 Coal has a variety of physical properties, including: Color: Coal can range in color from black to brown to grayish; Hardness: Coal can range in hardness from very soft and crumbly, like graphite, to very hard, like Coal Properties, Formation, Occurrence and UsesDownload Table Size distributions of TiO 2 , calcite and their mixtures obtained from different mill types from publication: Interaction Between TiO2 and CalciteCalcined Kaolin Mixture During Table 2 Size distributions of TiO 2 , calcite and their

What is Lignite? Lignite Energy Council

Quick Facts: Lignite is abundant and accessible Lignitegenerated electricity is reliable Lignitegenerated electricity is environmentally compatible Lignitegenerated electricity is lowcost Lignite is used in an environmentallyresponsible manner by power plants Lignite is a dark brown to black combustible mineral formed over millions of years by the partial decomposition of plant Quiz yourself with questions and answers for Geology Final, so you can be ready for test day Explore quizzes and practice tests created by teachers and students or create one from your course materialGeology Final Quizlet17 Lignite Combustion 171 General15 Coal is a complex combination of organic matter and inorganic ash formed over eons from successive layers of fallen vegetation Coals are classified by rank according to their progressive alteration in the natural metamorphosis from lignite to anthracite Coal rank depends on the volatile17 Lignite Combustion US Environmental Protection Agencygrinding lignite with feed moistures of as much as 45 % Depending on this high feed moisture the mill rating is determined by the drying process whereas for anthracite, hard coal and petcok e the rating of the mill is determined by the grinding process The great variety of solid fuel properties,Reprint from ZKG 3 Gebr Pfeiffer

Flotation separation of fluorite from calcite using sulfonated lignite

2020年7月1日 FTIR results illustrated that sulfonated lignite was selectively absorbed on the calcite surface and NaOL could still be absorbed on fluorite surface with depressant sulfonated lignite Contact angle analysis demonstrated that depressant sulfonated lignite could significantly increase the hydrophilicity of calcite surface with NaOL as the collector2022年7月1日 Atomic force microscopy results indicated that the anthracite–anthracite adhesion force is greater than that of lignite–lignite, and the adhesion force dominates particle interactions The surface electrostatic potential range of lignite (8557–8767 kcal/mol) is much higher than that of anthracite (6368–5960 kcal/mol) and the lignite surface provides more polar regions Insight into the selfaggregation behavior of lignite and anthracite Vertical mill advantages Low energy consumption, 2030% lower compared with ball mill Much smaller footprint compared with ball mill Regulation within 15100% load Fast response to boiler load requirement, better ability to match with power grid regulation It could grind lignite coal with moisture content Mar; 40% as received basisVertical mill for coal pulverizing in power plant GeckointechStudy with Quizlet and memorise flashcards containing terms like T or F: Seafloor massive sulfide (SMS) deposits often contain metals such as iron and copper, T or F: Polymetallic mineral nodules could be mined from the seafloor to obtain iron and manganese, T or F: Chemautotrophic organisms would be put at risk if SMS deposits were mined and othersGeology Final Flashcards Quizlet

.jpg)

Insight into the selfaggregation behavior of lignite and anthracite

2022年7月1日 Atomic force microscopy results indicated that the anthracite–anthracite adhesion force is greater than that of lignite–lignite, and the adhesion force dominates particle interactions The surface electrostatic potential range of lignite (8557–8767 kcal/mol) is much higher than that of anthracite (6368–5960 kcal/mol) and the lignite surface provides more polar regions 2020年4月24日 Selecting lignite from the Mile area a s an experiment, samples of lignite, bitu minous coal and anthracite were dried in a blastdrying oven at 105 for 2 hours before the experiment, after drying Study on the industrial feasibility of adding lignite for blast Electrically calcined anthracite coal or ECA coal is manufactured by heating highgrade anthracite coal to temperatures as high as 2000⁰C in a DC Electric Calciner obtaining a depolarized and semigraphitized product ECA has a higher carbon content and relatively higher thermal and electrical conductivity than conventional anthracite coalElectrically Calcined Anthracite Coal Dev Energy2016年7月1日 In this paper, energy split phenomenon for the coarse grinding of super clean anthracite coal (SCAC)/calcite mixture of 28–2 mm in the ballandrace mill is investigated Before the analysis of experimental results, accuracy of energy split function in terms of timedependent breakage rate is first discussedAn analysis of the energy split for grinding coal/calcite mixture in

Beater Wheel Mill PDF Lignite Mill (Grinding)

This document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within the mill 2 Diagrams of beater wheel mills with different configurations, such as with or without a separating classifier or with a precrusher 3 Photos of 2020年2月1日 In this study, sulfonated lignite (SL) was studied as the depressant in the separation of fluorite and calcite with sodium oleate (NaOL) as the collectorFlotation separation of fluorite from calcite using sulfonated lignite The Anthracite Mill The Anthracite Mill Quality Cast Iron Salt Pepper Grinders Regular price £10999 GBP Accessories Double Mill Rest Double Mill Rest Vendor: IronMills Regular price £2999 GBP Regular price The Anthracite Mill Quality Cast Iron Salt Pepper GrindersThe kinetics of batch dry and wet grindings of calcite, barite, quartz, lignite and anthracite from feeds of sieve size 425+300 /Lm has been determined using a laboratory scale ceramic ball mill The 51 values obtained were the highest (0294 minl ) for anthracite and the lowest (0071 minl ) for quartz whenBreakage parameters of some minerals and coals ground in a

Energysize reduction of mixtures of anthracite and coking

2020年3月15日 In this paper, anthracite and coking coals of low ash are ground together in a Hardgrove mill, and resistance to be broken is compared based on the classical breakage model Product t 10 of component after mixture breakage are determined by the relation between characteristic ratio (ratio of height and full width at half maximum of 002 peak) and yield of