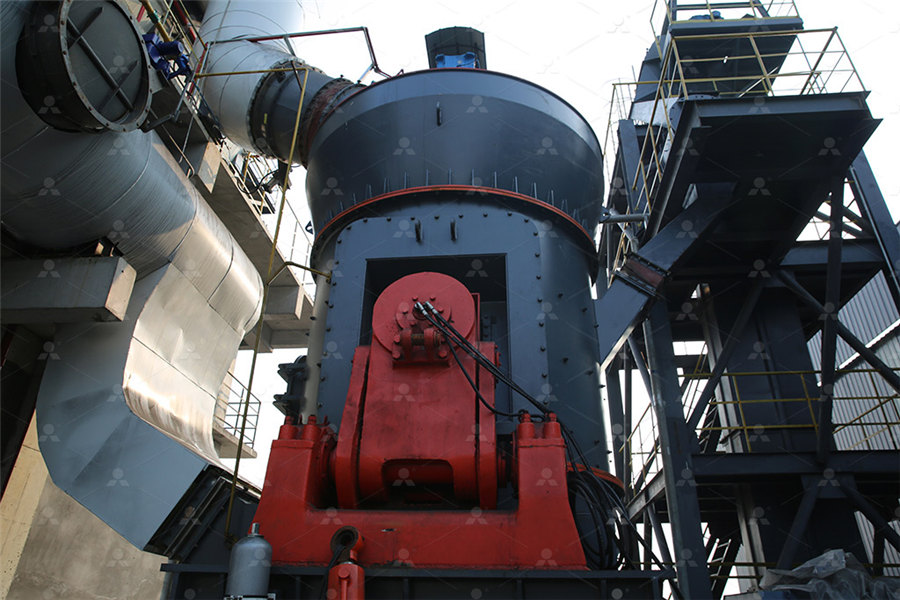

Rare earth ore ore powder making process

Rareearth element Processing Ores Britannica

2024年11月21日 All rareearth ores contain less than 10 percent REO and must be upgraded to about 60 percent in order to be processed further They are first ground to a powder and then 2017年9月10日 The purpose of this paper is to comprehensively review and summarize the rare earth processing routes, the mostly employed rare earth separation methods, supply and demand of rare(PDF) A Review of Rare Earth Mineral Processing 2023年11月9日 The screened rare earth ore enters a ball mill for dry grinding, improving mineral powder fineness and uniformity Overgrinding can waste resources and reduce recovery of brittle minerals FTM Machinery offers ball Unlocking Potential: Rare Earth Elements Processing 2017年8月1日 After mining, comminution and ore beneficiation, hydrometallurgical and pyrometallurgical processes are carried out to recover REE compounds The concentrate A review on the cracking, baking and leaching processes of rare

Rare Earth Elements: A Review of Production, Processing,

2012年5月21日 • Introduction to the Rare Earth Elements • Why are we interested in them and where are they found in the US? • How are they acquired and what are potential 2015年12月25日 This chapter is about mineral processing of the rare earths (making the mined ore into a concentrate of the valuable minerals), and extractive metallurgy of the rare earths (how to get the metals out of the concentrate) Mineral Processing and Extractive Metallurgy of the 2020年3月26日 In the present chapter, an attempt has been made to collate world rare earth reserves and production, various kinds of ores, processing strategies, plant practices, and Mineral Processing of Rare Earth Ores SpringerLink2024年4月1日 With the continuous depletion of rare earth (RE) resources, developing highefficiency beneficiation and ecofriendly metallurgical processes has attracted widespread Recent process developments in beneficiation and metallurgy of

.jpg)

Research progress of rare earth separation methods and

2023年2月1日 Each method for separating and extracting agents is individually revised in terms of the mechanism and interaction of providing rare earth elements This paper also evaluates 2017年8月1日 JOURNAL OF RARE EARTHS, Vol 35, No 8, Aug 2017, P 739 Foundation item: Project supported by the Research Initiation Grant of Queen’s University, Canada (#) and Ontario Centers of Excellence VIP fund (#25394) * Corresponding author: Ahmad Ghahreman (Email: [ protected]; Tel: +16135333294) DOI: 101016/S1002 A review on the cracking, baking and leaching processes of rare earth Unliberated or partly liberated rare earth minerals are associated closely mainly with other rare earth minerals and gangues These theoretical data could be employed to further comprehensively utilize the rare earth ore Keywords: process mineralogy, rare earth, Bayan Obo ore, MLA 1 IntroductionProcess mineralogy of Bayan Obo rare earth ore by MLA2023年11月9日 In order to maximize the extraction of these valuable metal elements, these four rare earth minerals are mainly mined and processed industrially: bastnaesite, monazite, xenotime and ion absorpt deposit Unlocking Potential: Rare Earth Elements Processing

.jpg)

Rare earth mining may be key to our renewable energy future

2023年1月11日 Australian company Lynas built a plant near Kuantan, Malaysia, (shown in 2012) to separate and process the rare earth oxide ore mined at Mount Weld in Western AustraliaChen et al Formate Salts TABLE1Main chemical composition of the rare earth ores (wt%) Component REO Al2O3 MnO2 ZnO CaO MgO K2O SiO2 Content 014 1523 001 001 002 062 354 6648Leaching Process of Weathered Crust ElutionDeposited Rare Earth Ore rare earth ore bodies and its mechanism has not been reported In this paper, a comparative experiment was designed to reveal the e ect of the leaching process on the permeability of rare earth ore bodies The mechanism of changes in the permeability coe cient was also discussed The objectives are to improve the leaching ability of ion of Rare Earth in Laboratory Leaching TestsMedia Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 82: Mining and Ore Processing Geosciences LibreTexts

Rare Earth Ore: From Mining to Application JXSC Mineral

2023年7月28日 Beneficiation of rare earth ore is a process that aims to separate and concentrate the valuable rare earth elements from the ore, making it suitable for further processing and use in various applications It is then ground into a fine powder to liberate the rare earth minerals from the gangue minerals2020年7月4日 The maximum recovery of rare earth resource from the Bayan Obo ore deposit is a difficult task, especially without the sufficient data of mineralogy In this paper the mineralogy of Bayan Obo ore deposit by comprehensively research with the application of mineral liberation analyzer (MLA) is reported The MLA was applied to quantitatively analyze the complicated Process mineralogy of Bayan Obo rare earth ore by MLAdosage on iontype rare earth ore leaching process is examined, as show in Figure 4 HEPENG ZHOU et al: STUDY OF OPTIMIZATION CONTROL OF IONTYPE RARE EARTH ORE LEACHING DOI 105013/IJSSSTa172524 243 ISSN: 1473804x online, 14738031 print Fig (4) Effect of Leaching Agent Dosage On Process As can be seen Study of Optimization Control of Iontype Rare Earth Ore Leaching Process2024年1月7日 The StepbyStep Process of Tungsten Production (Overview) From Ore to Metal: Once tungsten ore is extracted, it undergoes a series of processes to transform from a raw material into a usable metal It’s like a How is Tungsten made: From Ore to HighTech Metal

The Effect of Fulvic Acid on the Leaching of a Weathered RareEarth Ore

2015年7月14日 The effect of fulvic acid on the leaching of a weathered crust elutiondeposited rareearth ore, using ammonium sulfate as lixiviant, has been investigated The results show that fulvic acid can enhance the leaching process effectively With the addition of fulvic acid to the lixiviant at a concentration of 01 wt pct, the leaching extraction of rareearth elements 2023年9月17日 Weathered crust elutiondeposited rare earth ores are key strategic resources and the main source of medium and heavy rare earths This paper summarizes the development of leaching technology of rare earth ores, Development Review on Leaching Technology and Unliberated or partly liberated rare earth minerals are associated closely mainly with other rare earth minerals and gangues These theoretical data could be employed to further comprehensively utilize the rare earth ore Keywords: process mineralogy, rare earth, Bayan Obo ore, MLA 1 IntroductionProcess mineralogy of Bayan Obo rare earth ore by MLA2024年11月1日 Left: Models for formation of the Bayan Obo REE deposit (Liu et al, 2020) ((a) original orehosting dolomite formation, (b) carbothermal stage, (c) hydrothermal stage, (d) geological tectonic movement) and Right: oreforming fluid evolution and mineralization process in the Maoniuping REE deposit (Zheng and Liu, 2019)Global rare earth element resources: A concise review

.jpg)

Analysis on the Advancement of Mining Process of Magnesium

PDF On Jan 1, 2021, 有霖 王 published Analysis on the Advancement of Mining Process of Magnesium Salt System of IonAdsorbedRareEarth Ore Find, read and cite all the research you need on 2019年8月8日 With the rapid development of advanced technology, the demand for rare earth (RE) for the international market is quickly growing, especially the demand for middle and heavy RE []Almost 80% of the middle and heavy RE exists in weathered crust elutiondeposited RE ore, also called ionadsorbed RE ore []Owing to its great commercial value, exploitation of Leaching Process and Mechanism of Weathered Crust ElutionDeposited Among 250 recognized REEs minerals, only three are considered to be the major ore that is most viable for REMs extraction: bastnasite, monazite and xenotime However, weathered crust elutiondeposited rare earth ores commonly known as ionadsorbed rare (PDF) Process development to recover rare earth metals from 2020年6月28日 The test results of the automated mineral identification and characterization system (AMICS), including the mineral composition, particle size distribution, dissemination state and degree of liberation of the target minerals, could be used to improve the beneficiation process Taking the Dalucao rare earth ore located in Dechang, Sichuan Province, China (with Process mineralogy of Dalucao rare earth ore and design of

.jpg)

Rare Earth Magnet Manufacturing Process MPCO Magnets

2017年12月22日 Rare Earth Magnet Manufacturing Process There are several processes for making magnets, but the most common method is called Powder Metallurgy In this process, a suitable composition is pulverized into fine powder, compacted and heated to cause densification via “liquid phase sintering”2023年9月5日 Powder’s Process Performance The process performance of powder includes flowability, filling characteristics, compressibility, and formability (1) Filling Characteristics This refers to the degree of looseness or Powder Metallurgy: A Comprehensive Guide for The rareearth elements (REE), also called the rareearth metals or rare earths, and sometimes the lanthanides or lanthanoids (although scandium and yttrium, which do not belong to this series, are usually included as rare earths), [1] are a set of 17 nearly indistinguishable lustrous silverywhite soft heavy pounds containing rare earths have diverse applications in Rareearth element Wikipedia2024年8月2日 The Mining Process: Extracting Iron Ore The first step in making iron is mining Iron ore is extracted from the earth through various methods, depending on the location and the type of ore The most common methods are openpit mining and underground mining OpenPit Mining In openpit mining, large pits are dug into the earth's surface to The Process of Making Iron: From Ore to Product

.jpg)

A Review of RareEarth Elements Extraction with Emphasis on

2020年9月23日 A Review of RareEarth Elements Extraction with Emphasis on Nonconventional Sources: Coal and Coal Byproducts, Iron Ore Tailings, Apatite, and Phosphate Byproducts2018年6月15日 Ionic rare earth (RE) ores, which are also known as ionadsorption RE ores or weathered crust elutiondeposited RE ores, are resources of strategic importance They are mainly distributed across China's Jiangxi, Fujian, Guangdong, Guangxi, Hunan, and other southern provinces, of which the middle and heavy RE reserves accounted for 80% of the Compound leaching behavior and regularity of ionic rare earth ore2024年7月30日 The smaller pieces are ground into a fine powder in a ball or rod mill This process increases the surface area of the ore, allowing for better copper extraction The grinding mills use steel balls or rods to crush the ore into a fine consistency, similar to The Process of Making Copper From Ore to Product2023年2月24日 In the process of ionadsorbed rare earth (RE) ore leaching and mining, the injected chemical agent and rare earth particles have a strong chemical reaction, resulting in changes in the structure of the rare earth, and thus affecting the macroscopic mechanical properties and permeability of soil To investigate the evolution of the pore structure during the Evolutionary Law of Pore Structure of IonAdsorbed Rare Earth Ore

.jpg)

(PDF) Economic analysis of rare earth element processing

2022年8月22日 Although rare earth deposits are found on all continents, China produces more than 90% of all globally used rare earth metals Besides its economic dominance, China has also gained a monopolistic 2020年5月1日 The rare earth elements have been primarily absorbed into the clay minerals in the form of hydrated ions or hydrated hydroxyl ions in the weathered crust elutiondeposited rare earth ore Rare earth resources are indispensable raw materials widely utilized in steel, glass, ceramics, and other industries [[1], [2], [3]]Swelling of clay minerals during the leaching process of 2023年8月1日 The magnesium sulfate (MgSO 4)–ascorbic acid (Vc) compound leaching technique can extract rare earth elements (REEs) existing in ionexchangeable phase and colloidal phase from ionadsorption type rare earth ore through the synergy effect of coordination and reductionIn this paper, the coordination–reduction leaching mechanism was analyzed Coordination–reduction leaching process of ionadsorption type rare ERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sinaCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION

Rare Earth Magnets: Manufacturing and Applications

2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materialsThe ore is crushed and then ground to powder Copper ore enrichment The ore is enriched by a process called foam flotation Rare earth and metal prices on ISE Quotes January 2023; ISE Newsletter April 2023; ISE AG opens open Copper mining and production Institute for Rare 2020年12月3日 To strengthen the rare earth leaching process and weaken the hydration of clay minerals for preventing landslides, it is of great importance to adopt a green and sustainable leaching agent in the Leaching Process of Weathered Crust ElutionDeposited Rare Earth Ore 2017年9月1日 Hence, an alternative process would be provided for the leaching of rare earth from ionadsorption type rare earth ore The process could reduce the consumption of MgSO4 and would have great Effects of organic acids on the leaching process of ion

Production of mixed rare earth oxide powder from a thorium

2021年2月1日 Over the past two decades, the combination of pyro and hydrometallurgical method via acid roasting that is followed by leaching and precipitation has been the most common processing route for extracting REE not only from bastnasite but also monazite and xenotime [[14], [17], [38], [49]]In Malaysia, The Malaysian Rare Earth Corporation (MAREC) separated 2021年3月1日 The rare earth ore was provided by Niobec Inc from a deposit in the Saguenay region of Quebec, Canada The mineral and elemental composition of the ore were determined by QEMSCAN and Neutron Activation Analysis (NAA), respectively (Table 1)Due to the heterogeneous mineral composition of the sample, only minerals with a concentration above Kinetic study of calcination of a rare earth ore ScienceDirect2023年12月12日 Weathered crust elutiondeposited rare earth ores (WCEDREO) is a new type of exogenous rare earth ore first discovered in Jiangxi Province, China in 1969 1 Through geological exploration and experimental research, the new deposit is found to be composed of granite and volcanic rocks that have undergone biological and chemical reactions, so that the Enhancement of weathered crust elutiondeposited rare earth ores 2019年3月1日 Heavy REEs occur in weathered crust elutiondeposited rare earth ores 6, 7 It is noted that the supplying proportion of light REEs (containing lanthanum, cerium, praseodymium and neodymium) is relatively large, accounting for approximately 85% of the total REEs 8 The light REEs are produced mainly by mineraltype rare earth deposits such as Baiyan Obo, Process mineralogy of Weishan rare earth ore by MLA

Recycling rare earths: How a Canadian city is making its mark

2024年5月28日 Yet, mining and extracting rare earths is a complex process since the ore isn’t found in concentrated deposits Recycling them isn’t any easier – only around 1% of rare earths are currently recycled from old products Cyclic Materials has ambitious plans to change that