How long can the lining of the grinding production line be used

.jpg)

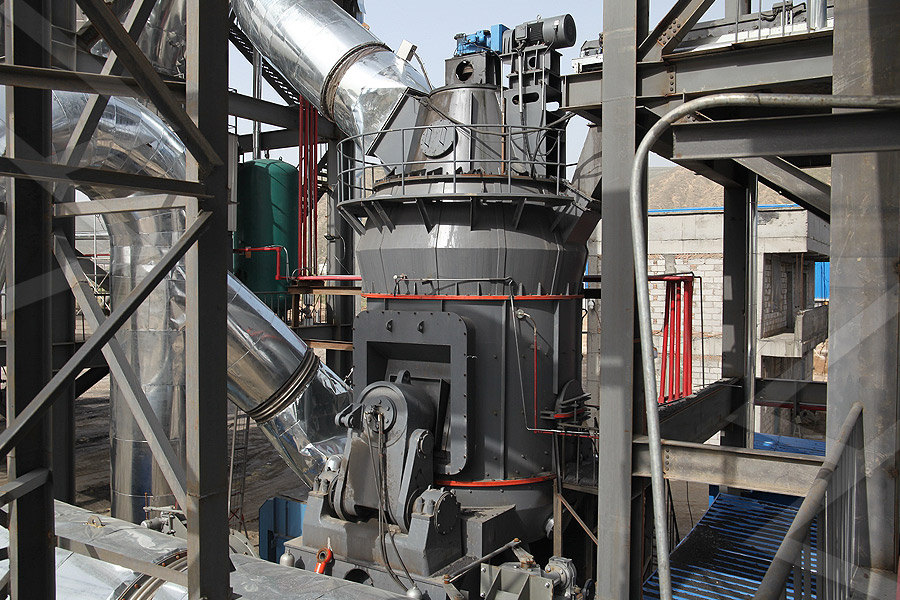

Sustainable and highperforming mill liners Metso

2023年4月17日 For instance, liners can be designed to last longer and to use less material This reduces waste and means less production, transportation, and replacement of products The liners, or even the entire grinding circuit, can be 2015年11月1日 In this study, five different relining scenarios were simulated and compared against the reference reline (ie current liner design) to accurately estimate the time required Relining efficiency and liner design for improved plant performanceShell linings Long wear life and balanced design to maximize mill availability The shell lining has a major influence on grinding efficiency It transforms the mill rotation into charge motion, and Mill lining solutions for horizontal Mill2006年1月1日 The main roles of liners are to protect the mill shell and promote effective ball motion for grinding For this reason the liner profile is carefully selected to ensure that the productivity(PDF) Selection and design of mill liners ResearchGate

Grinding Mill Liners 911Metallurgist

2015年8月6日 There are basically two groups of Grinding Mill Liners Ones with a HIGH PROFILE and those with a LOW PROFILE The high profile liner is designed to give the media the higher lift This type will be used in mills that In this study, five different relining scenarios were simulated and compared against the reference reline (ie current liner design) to accurately estimate the time required for relining This is the Relining efficiency and liner design for improved plant performancethe impact of shell liners on the grinding action and of grates and pulp lifters on pulp discharge In recent years, the trend in large SAG mills has been to use widespaced shell lifters with large Semiautogenous grinding (SAG) mill liner design and developmentA mill lining should be optimized to suit each specific mill Choosing an appropriate type of lining and design in terms of lining material, thickness and profile is vital for optimizing mill Three factors that determine the wear life and performance of mill

Improving liner design for efficiency and life

2015年9月20日 The results presented indicated that liners with a reduced mass and shorter life outperform their longer life counter parts in all key production parameters of throughput, energy consumptionOptimised liner design can be used to strike the best economic balance between liner life and mill grinding performance, thus enhancing the profitability of a mining operation Protection of the The Selection and Design of Mill Liners 911 Metallurgist2024年9月15日 Too much estrogen can overstimulate the endometrial lining to become overly thick Obesity: Fat tissue is responsible for the production of hormones, including estrogen Additional body fat can increase your estrogen production causing overstimulation of the endometrial lining, and may increase your risk for endometrial cancerEndometrial Lining: Remedies for Abnormal Thickness Verywell Indepth, practical, comprehensive grinding education for hardcore grinders working in production grinding Overview: The Book of Grinding is the most indepth, comprehensive, practical resource in existence for engineers, machine The Book of Grinding

How to configure the cristobalite grinding production

2022年8月30日 1 The cristobalite production line has a good connection between the equipment, which enhances the stability of the equipment in operation and makes the cristobalite grinding production line more durable 2 CNC brake lining production line is full automatic is mainly used for the post processing of brake lining after hot pressing, including grinding inner and outer arcs, drilling holes, grinding limit lines, etc 2 Our Advantages: The entire production line consists of six main workstations, all controlled by CNC automation C Brake Lining Production Line Armstrong2020年1月1日 The paper represents the results of investigation of magnetite quartzite centrifugal disintegrators crushing It is demonstrated that when crushing quartzites of ingoing size 100 mm, it is The study of the lining layer abrasing wear in the semiautogenous 2007年7月30日 The grinding heads are specially designed to grind points, stock rails, frogs and close to guard rails Grinding is effective from 075 degrees gauge side and 045 degrees field side of the rail A range of different size grinding stones can be used to suit customer specification Typically 6” stones are used for SCRegular grinding is the key to long rail life

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as 2021年7月6日 In these expressions, \(\eta\) stands for production line balance rate in %, \({T}{i}\) stands for the standard operation time element, PT stands for Takt time, m stands for a given number of work stations, SI stands for section index, ω1 and ω2 stand for weight constants for optimization and ω1 + ω2 = 1 This Balancing of the Production Line Process in the Manufacturing Mill liners are an essential component in grinding mills, providing a protective surface to minimize wear and extend the lifespan of the mill In this article, we will explore what mill liners do, their importance, and the different types available Mill liners are protective components that shield the interior of a grinding mill from the abrasive forces generated by grinding media and oreWhat Does Mill Liner Do? ball mills supplier2024年2月26日 Considerations When Setting Up an Efficient Production Line While implementing the above practices, consider the following: Employee Training: Even the most efficient production line won’t be effective if employees don’t know how to use it Invest in regular training to ensure your team can operate new machinery or software effectivelySetting Up an Efficient Production Line: Best Practices and

Precision Metal Grinding Metal Cutting Corporation

2020年6月14日 Depending on the method, grinding can be well suited to highvolume production for applications requiring thousands of parts In addition, some grinding processes can be used to rapidly rough out large volumes of metal2024年8月16日 Figure 4 Automatic production line for tandem stamping (2)Features It has a wide range of applications and can be used in the production of various stamping components There are no strict requirements Automatic Stamping Production Line BasicsGujarathi et al (2004) have reported that production rate can be obtained without increasing direct labour, there by achieved 32% increase in gross profit in an OEM industry via simulation modeling Multiskilling of operators in assembly line can be very much useful for achieving the desired results underSimulation Analysis of Brake Lining ManufacturingBased on the model of mining and processing equipment, the design, putting into production, joint tests of lining with the customer are carried out Warranty is provided Generic Lining Products Overall wearresistant plates Used for cladding large areas of the mill They can also be used to protect the surface of ore passes, trolleys and dump Rubber Lining for Ore Grinding Mills and Mining and Processing

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):年8月28日 As we have mentioned repeatedly in our articles, the right choose of lining plate is very important 1015 years ago there was only one main purpose of lining plates was protection of the mill hull from mechanical damage To date, the design of the lining plates is based on the need to form a grinding line, which will ensure the maximum efficiency of the LINING PLATE: THE MOST IMPORTANT THINGS Energosteel Grinding 2024年2月7日 In the work, as an object of modeling, we selected mill type MSHTS 5500 × 6500, used for grinding apatitenepheline ore, with the following technical characteristics: mill capacity Q = 300–310 t/h, drum diameter without lining D = 5500 mm, drum length L = 6500 mm, the working volume of the mill V = 140 m 3, ball loading m = 275–285 tons, degree of ball loading φ = Development MPC for the Grinding Process in SAG Mills Using The refractory lining on the interior of the cement rotary kiln is a crucial component in ensuring the kiln’s working efficiency and protecting the kiln shell from melting down There are many refractory materials that can be used to form the refractory lining of cement rotary kilnsCement Rotary Kiln Refractory Lining Selection Principles

Improving the efficiency of the material grinding process

2020年10月27日 This content was downloaded from IP address 173211110207 on 27/11/2020 at 19:51minerals, used as is Grinding is often done in steps: a primary mill grinds the largesized ore and then a secondary mill grinds the ore from a small size to the desired size The breakage mechanisms that mills use are impact (for coarse grinding), and attrition and abrasion (for finer sizes) These forces not only grindEBOOK Three factors that determine the wear life and 2024年2月7日 The discrete element method (DEM) was used to simulate the grinding of apatitenepheline ore in a mill using different types of linings and determining the process parametersDevelopment MPC for the Grinding Process in SAG Mills Using 2023年3月29日 Optimizing Production Efficiency: A Case Study on Machine Downtime Analysis and Implementation of Quality Control Tools and Action Plans(PDF) Optimizing Production Efficiency: A Case Study

.jpg)

How to calculate the life of the grinding wheel? Binic

Two trimming methods of calculating grinding wheel can be used during the creep feed grinding process: 1 Noncontinuous finishing in which an elevated or tabletop mounted diamond dresser intermittently inserts or laterally trims the 2021年4月20日 It is supposed that the mills consisting of two grindstones appeared in ancient Egypt but the archaeological finds from 1000 BC at the Boden Lake in modern Switzerland and around Dresden and Leipzig in modern Germany also reported similar grinding stones [7, 12]Very important feature of this grinding instrument is a shift from impact (mortar and pestle) to The Evolution of Milling Process SpringerLink2023年4月23日 used for grinding media only,13% for liners and about 50 % is used for energy Grinding is the final stage of comminution, which reduces particle size to micron size level The size re duction is(PDF) Grinding Media in Ball MillsA Review ResearchGate2023年5月25日 While traditional grinding techniques require manual labor and can be timeconsuming, the use of grinding automation systems has revolutionized the production line In this article, we will explore the benefits of using grinding automation systems, the types of systems available, and how to implement them in your production lineREVOLUTIONIZE YOUR PRODUCTION LINE WITH GRINDING

.jpg)

The 7 Core Strategies to Heal Leaky Gut and Fuel the Biome

2024年10月24日 The gut lining is the last defense between the outside and inside worlds of the body Protect your immune system and gut lining with these core strategies These natural strategies will maintain your gut mucosa More importantly, these steps give you a blueprint for maintaining health longterm2021年11月27日 Made in the USA Season 2 Episode 6: Why, and How, Hardinge is Reshoring Machine Tool Production In this episode of Made in the USA, several executives and senior staff at Hardinge give their firstperson account of how they formulated the plan to shift the manufacturing of its milling and turning product lines from its Taiwan plant to its plant in Elmira, 7 Key Factors in Choosing a Grinding Wheel2021年5月5日 The Grinding Machine is used in various industries for grinding The first and foremost industry where this machine is used in Manufacturing Industry The Grinding Machine is used for finishing the cylindrical and flat surfaces In other words, we can say it is used for grinding various materials Internal Resources:Grinding Machine: Definition, Parts, Working Principle, Operation 2021年1月16日 Tool and cutter grinding machines are used for sharpening cutting tools Surface grinding machines are used for grinding flat surfaces Now, let us dive into the world of Surface Grinding Machines Surface Grinding Machines You can do surface grinding of the components in any of the following types of machines Why we use Surface Grinding MachineSurface Grinder Types of Grinders How They Work Fine

5 Grinding Considerations for Improving Surface

2021年8月20日 This can happen in more aggressive grinding or when grinding certain metals that tend to stick to the grinding wheel In these applications, scrubber nozzles might need to be implemented Scrubber nozzles are 2019年7月29日 They are common in horses, with the prevalence estimated between 50 and 90% They can affect any horse at any age but occur most frequently in horses that perform athletic activities such as racing, endurance, Equine Gastric Ulcer Syndrome School of Veterinary would be a length of 135 m and a diameter of 25 m, with a speed of approximately 20 revolutions per minute Such a mill would normally have a load of approximately 90 tons of grinding media, graduated from 90 mm to 60 mm An Introduction to Clinker Grinding and Cement Storage2022年5月1日 The solutions that can be used for immersing the grinding wheels might be Mo2S [17], solgel alumina, and a synthetic organosilicon polymerbased impregnate [18] In fact, impregnating(PDF) Improving the Efficiency of Grinding Process Using the

.jpg)

Grinding in Ball Mills: Modeling and Process Control Sciendo

55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xjThus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j The mechanism of breakage is illustrated in [23] by a diagram shown in Fig 32019年11月1日 However, higher temperatures are generated during the grinding process, so it is not appropriate for pulverizing heatsensitive materials, especially herbs and spices [9]Intensification of the grinding process in vibration mills2020年9月8日 The screwin depth (e ≥ 15 x thread diameter of the grinding wheel flange) is a standardized value and must not be changedNote: The grinding wheel must be properly clamped (distance b)If necessary, a distance ring must be mounted Mounting and Balancing Grinding Wheelswearresistant alloys of iron and steel can be used, as the rubber substantially dampens the impact forces Low weight and long wear life Orebed mill linings The Orebed™ magnetic lining system consists of a series of powerful permanent magnets embedded within a matrix of highly abrasionresistant rubber Magnetic force ensures thatMill lining solutions for horizontal Mill

Grinding Processes SpringerLink

Grinding is the common collective name for machining processes that utilize hard, abrasive particles as the cutting medium The grinding process of shaping materials is probably the oldest in existence, dating from the time prehistoric humans found that they could sharpen their tools by rubbing them against gritty rocks2020年4月28日 Successful cylindrical grinding creates geometrically accurate results that meet the defined dimensions for each individual part In contrast to easily identifiable grinding issues that become obvious after a quick visual inspection of the surface quality, a host of issues can be harder to identify as they affect the overall shape of the workpiece and not just its surface How to prevent form errors in cylindrical workpieces UNITED GRINDING