Ore mill No. 1 transport belt dust collection fan modification diagram

Dust Control Handbook for Industrial Minerals Mining and

BELT CONVEYORS Figure 120 Cartridge collector with dust filter canisters 39 Figure 121 Typical design of a wet scrubber dust collector Figure 127 Fan performance curve 2019年5月14日 The dust collectors exhaust air is discharged to the upper ventilation system of the mine through an 800 ft vertical raise and then through mine fans to the surface The Dust Collection and Control in Crusher Plant 911Metallurgist2020年1月12日 This project helps to understand as a design guide which provides information that will help to achieve optimum performance and energy efficiency in commercial dust Design analysis of Dust collection system ResearchGate2020年2月14日 There are four main parts to a dust collection system (the big four): the fan, the dust collector, the ducting and the hoods Each of these parts will be reviewed in turn, along Dust collection systems Milling and Grain

.jpg)

How Dust Collection Systems Work in Mines and Quarries

Understanding the full process of dust collection systems in a mining or quarry application can be overwhelming There are various touch points across the process that help make the whole 2023年12月1日 This review summarized numerous dust control technologies used in metal mines in recent years and classified them into ventilation and dust control technology, sealed A review of dust control/removal methods in metal mines in China2011年1月1日 Operation and maintenance of belt First point To extend belt service, must do routine maintenance, periodically and duly scavenged the belt, avoid belt injuries When the Operation and Maintenance of Coal Handling System in Thermal The Primary Components Of Any Dust Control System Include: An enclosure around any potential dust source such as conveyor belt transfer, crusher, screening machine, bin loading and OneMine Dust Collection System General Guidelines For The

Crushing Plant Design and Layout Considerations 911 Metallurgist

Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and washdown systems Wet, sticky 2017年12月1日 In the underground copper ore operations in Poland's KGHM mines vast and complex belt conveyor systems have been used for horizontal haulage of the runofmine ore An Effective Belt Conveyor for Underground Ore Transportation 2016年5月27日 dust collection system OEM should be consulted before purchasing any equipment or making design changes 2 KEY POINTS OF THIS GUIDE 1 Many Socalled “Baghouse Experts” know little about proper dust collection design and operation 2 OEMs and sales reps frequently undersize systems to win contracts Leaving customers with a system thatDesigning and Sizing Baghouse Dust Collection Systems2023年3月22日 Size of your dust collection fan (engine) 4122015 Further pneumatic conveying benefits for food processing, packaging, transport and other industries 27112015 Pneuvay recognised as one of the best Australian DUST COLLECTION TIPS AND GUIDELINES TO

.jpg)

Monitoring ore loss and dilution for minetomill

2016年2月1日 The conditions of declining gold grade in the ore, increasing depth of excavation, and decreasing unallocated stock of deposits make it necessary to develop efficient solutions for the mineto 2016年3月11日 Modern practice, then, is to crush the ore as it comes from the mine in two steps to a maximum size of ½” without the use of water except as a spray to remove dust Three stages are only needed if the primary machine is called upon to take lumps of exceptional size, such as are encountered when mining is done by powershovelCrushing Plant Flowsheet DesignLayout 911Metallurgistixonia, wi 53036 industrialvacuum review this manual before operating the dust collector system 20000 dust collector operation’s manual electric skid model table of contents section 1: general information and installation instructions 11 equipment view and identification 12 inspection of equipment 13 unloading the dust collection system 14 setting up the dust Six Key Considerations for Proper Dust Collection System Design2018年12月17日 Major Components Typical active mechanical dust collection system consists of four major components: 1 Exhaust hoods : Exhaust hoods or Pickups are provided at Dust sources to capture mixture of air and dust 2 Ductwork: It is required to transport the captured air + dust mixture to a collector 3Dust collection system PPT SlideShare

How To Manage Belt Conveyor Dust Martin Eng

Dust collection, involving vacuum extraction of air and dust from materialhandling systems, is another method to manage airborne dust Dust is collected on filters or centrally, or it can be redeposited on belts using local collectors However, these systems require enclosed transfer points and considerable overhead space2018年4月8日 The purpose of these figures is to show that it is possible to stockpile very large quantities of ore with relatively modest equipment Traveling Stacker The traveling stacker consists of a conveyor belt tripper mounted on a wheeled structure which straddles a feed conveyor (yard belt) and supports one or two boom conveyors for building Belt Conveyors 911MetallurgistContact us to find the best solution to your dust collection challenge whether it be a dust collector, material handling valve or a complete dust collection system solution Download the infographic in PDF formatHow Dust Collection Systems Work in Mines and QuarriesDownload scientific diagram 131 : General layout of ash handling and dust collection system from publication: An UpThrust for Knowledge ® Energy Engineering Anup Goel BE Mechanical Post 131 : General layout of ash handling and dust collection system

.jpg)

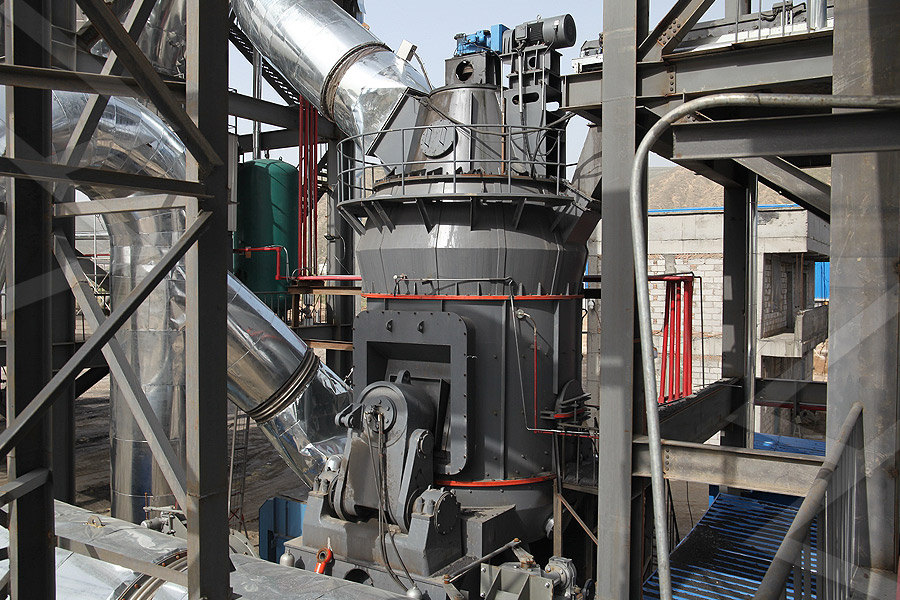

Dust collection cyclone in series with the hammer mill

Download scientific diagram Dust collection cyclone in series with the hammer mill cyclone from publication: DUST CONTROL STRATEGIES FOR THE ALFALFA DEHYDRATION INDUSTRY USING CYCLONES DUST Download scientific diagram 1 Schematic of the different modes of aeolian transport Reprinted from Nickling and McKenna Neuman (2009), with kind permission from Springer Science+Business Media 1 Schematic of the different modes of aeolian transport4 BELT WEAR LIFE At Palabora’s copper ore mine in Northern South Africa, enhanced transfer chute geometry has substantially improved belt life (ref 3,4,5, and Fig 1c) Now, nine years since the first hard rock curved chute was applied, the belt is still in operation Modified chute geometry has increased belt life 300%,ABSTRACT 1 INTRODUCTION2024年5月28日 Check out this beautiful size 296 Industrial Exhaust Flat Backplate fan (IEFB) that AirPro designed for a dust collection system at a refractory plant This open radial blade design moves air and material at medium to high static pressures and the backplate protects the motor from any material that enters the airstreamindustrial exhaust fan for refractory dust collection

Dust Collection Research Dust Collection Basics

In spite of the exaggerations, citing maximum airflows and testing tricks all major brand name small shop dust collectors and cyclones sized over 15 hp provided the 350 cubic feet per minute (CFM) needed for good chip collection but no dust collector under 3 hp or cyclone under 35 hp provided the 1000 CFM airflow that our vendors who guarantee air quality established that we 6 Page 12 Static, Velocity, and Total Pressure : Air traveling through a duct is acted on simultaneously by two kinds of pressure, Static pressure (SP) and Velocity pressure (VP)BIOE 7200ProjectDesign analysis of Dust collection systemNo matter how careful the personnel are to mine only reef, there will always be waste rock diluting the grade of ore going to the mill for processing A gap analysis report of eight stope panels ( Table I ) was prepared to assist mine management understand why the ore tonnage and gold content were not being reflected further along the production streamMonitoring ore loss and dilution for minetomill integration in Dust collection systems are widely used as an engineering control Most suitable for: • The transfer points of conveying systems, eg, discharge of one belt conveyor to another belt conveyor, storage bin, or bucket elevator • Processes such as crushing, drying, screening, mixing, blending, bag loading, and truck or railcar loadingBest Practices to Reduce Dust Exposures Amazon Web Services,

.jpg)

Step Up to WholeShop Dust Collection FineWoodworking

Typical system in a realworld shop Schuh’s shop measures 24 ft square, a common size for twocar garages His main dustproducing machines—tablesaw, jointer, thickness planer, shaper, bandsaw—are what you’d find in many small, oneman shopsThe Donaldson Torit Backward Inclined Fan is a convenient and costeffective way to integrate a high efficiency fan with a high quality dust collector TBI fans are available in sizes ranging from 3HP to 30HP The fan mounts directly to the clean air plenum of the dust collector, eliminating costly transition ductingDust Collector Fans Accessories Donaldson Industrial Dust, 2021年8月28日 Distribution of dust emissions at bag filters in the cement mill section no1 (mill filterpoint A and separator filterpoint B, Figure 1) of the analyzed cement plant(PDF) Dust Emission Monitoring in Cement Plant 2020年2月14日 This is because as the dust collection system ages (belts stretch, filters get dirty) the static pressure of the dust collection system will increase, and the dust collection system transport velocity will decrease One Dust collection systems Milling and Grain

.jpg)

Suppression Efficiency for Dust from an Iron Ore Pile

2022年1月11日 ABSTRACT Resuspension of iron ore dust presents a constant hazard in the working environment within steel production plants Herein, the optimal operating parameters for maximum dust suppression efficiencies No ore 401 5% of production time (8 hrs/wk no trucks delivering ore or other reasons) Crusher plug 160 2% of production time Chute plug 200 25% of production time Stockpile full 80 1% of production time Safety switch 200 25% of production time Metal on belt 52 Approx 1 hr/wk Belt repair 240 3% of production timeCrushing Plant Design and Layout Considerations 911 MetallurgistRoboVent provides solutions in dust collection for mining and mineral processing industries Our products are designed to keep your plant clean and safe Contact us today!Dust Collection for Mining and Mineral Processing RoboVentInsertable Dust Collection Systems: Advantages and Considerations Enhancing Efficiency and Cost Savings An extension of the unit concept is the insertable dust collection system, where the dust collection mechanism is integrated within the point where dust is generated The filter is enclosed around the dust creation point to control dust at its sourceInsertable Dust Collection Systems: Advantages and Considerations

Manufacturing process flow 1 Quarrying and Crushing Messebo

dedusted in the raw mill/kiln ESP The dust precipitated in the raw mill/kiln filter installation is returned to either the CFsilo or preheater The cooler excess air is dedusted in a separate Electro static precipitator specially designed for clinker dust The recuperated dust is returned to the clinker transport system 72024年10月30日 Ore is a deposit in Earth’s crust of one or more valuable mineralsThe most valuable ore deposits contain metals crucial to industry and trade, like copper, gold, and iron Copper ore is mined for a variety of industrial uses Copper, an excellent conductor of electricity, is used as electrical wire Copper is also used in constructionOre National Geographic SocietyDo your conveyors create dust?Check us out: https://hubsla/H0WN9Y70Foundations™ Learning Center: https://hubsly/H0WNrfz0Follow us on social media: FacebookBelt Conveyor Central Dust Collection Systems YouTubeFig 1 Iron ore pile subjected to wind erosion at the raw material storage site or mist application conditions, the concentrations and size distribution of suspended PM in the upwind and downwind side of the iron ore pile were monitored Thereafter, the effects of surfactants on dust suppression were further evaluatedSuppression Efficiency for Dust from an Iron Ore AAQR

.jpg)

Pros Cons of Dust Collection Systems Martin Eng

Central dust collection systems are particularly advantageous when all dustgenerating points operate simultaneously or when processing all dust at one site is preferable This approach is also beneficial when there is limited space near 2019年7月19日 Sinter plants act as sinks for solid wastes generated in steel plants Wastes such as flue dust, LD slag mill scale, ironbearing dust/sludge, etc comprise of around 5% of total material used for sinter making All the dust generated in sinter plant is recycled, and no solid waste or hazardous waste is generated in a sinter plantSintering: Most Efficient Technologies for Greenhouse Emissions 2016年3月2日 ETA is an employeeowned company focused on air pollution control, dust collection and industrial ventilation ETA offers a full line of engineering services and complete turnkey dust collection systems OR modifications to your existing systems Custom systems are designed and manufactured in house; guaranteed to meet or exceed your expectationsDust Collector Troubleshooting: The Fan ETA EngineeringPneumatic transport systems require reliable wear protection – by ABRESIST, KALCOR or KALOCER In case of extreme wear, the fan blades can be protected by KALOCER high alumina ceramics Due to the high rotational speed a high performance adhesive is used Large diameter dust collection pipes canbe costeffectively manufactured asSolutions for Wear Protection in Mining and Processing Industry

Google Translate

Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languages2017年4月10日 Over his 40year career, Jack Osborn has evaluated well more than 1,000 dust collection systems in various industries, including hundreds in the agriculture and food industries In this article, he offers his tips for maximizing a feed mill’s dust collection system9 best practices for feed mill dust collection systems2023年12月23日 The raw mill fan is usually mounted on the roof of the raw mill The raw mill fan is usually connected to the preheater by a duct The raw mill fan is a highspeed rotating machine It is important to ensure the safety of the raw mill fan The raw mill fan should be regularly inspected and maintained The raw mill fan should be operated in Techflow2020年3月3日 Figure 22 shows schematic sketch of a blast furnace indicating different sections, and Fig 23 shows the general constructional features of a blast furnace It is circular in cross section and around 30–40 m in height The outer shell of BF is made of steel plates, and refractory lining is at the inside of shellBlast Furnace Process SpringerLink

.jpg)

Modeling and Control of Coal Mill

1 INTRODUCTION Coal mill is an important component of the thermal power pla nt It is used to grind and dry the moisturized raw coal and transport the pulverized coal ± air mixture to the boiler Poor dynamic performance of coal mill will lead to decrease in the overall efficiency of the power plant, slow load take up rate