vertical mill powder selector turning blade

.jpg)

Vertical Blade Classifiers (VBC) Bradley Pulverizer

The Bradley Vertical Blade Classifier (VBC) is designed to separate extremely fine powders direct from any airswept mill Dynamic classifiers such as the VBC, provide wide flexibility of operation by allowing for instant adjustment of The invention discloses a blade device of a vertical mill powder selection machine The blade device comprises an upper rotor blade, a lower rotor blade and two connecting elements,CNA Blade device of vertical mill powder selection 3 Airflow and Powder Selection After grinding, the broken materials continue to move towards the edge of the grinding plate They are carried away by the airflow and enter the powder selector Within the powder selector, blades separate CLUM Series Ultrafine Vertical Roller MillThe utility model discloses a novel vertical mill selection powder machine device, including casing one, casing two, flange, discharge gate, go up casing, guide vane, moving blade,CNU Novel vertical mill selection powder machine

Numerical Study of Flow Field and Particle Motion Characteristics

2024年11月1日 In order to improve the motion characteristics of particles in vertical roller mills (VRMs), the assumption that different structures of helical guide blades affect the internal flow 2020年11月4日 Deep understandings of the relationships and mechanisms between the blades and the mill performance could provide a theoretical basis for designing, running, controlling, Effects of Blade Parameters on the Flow Field and Classification 2020年11月4日 Based on the DPM (Discrete Phase Model) and continuous phase coupling model, the flow field characteristics in the vertical roller mill including the velocity and pressure Effects of Blade Parameters on the Flow Field and Classification The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized Vertical Mill Shanghai Zenith Company

.jpg)

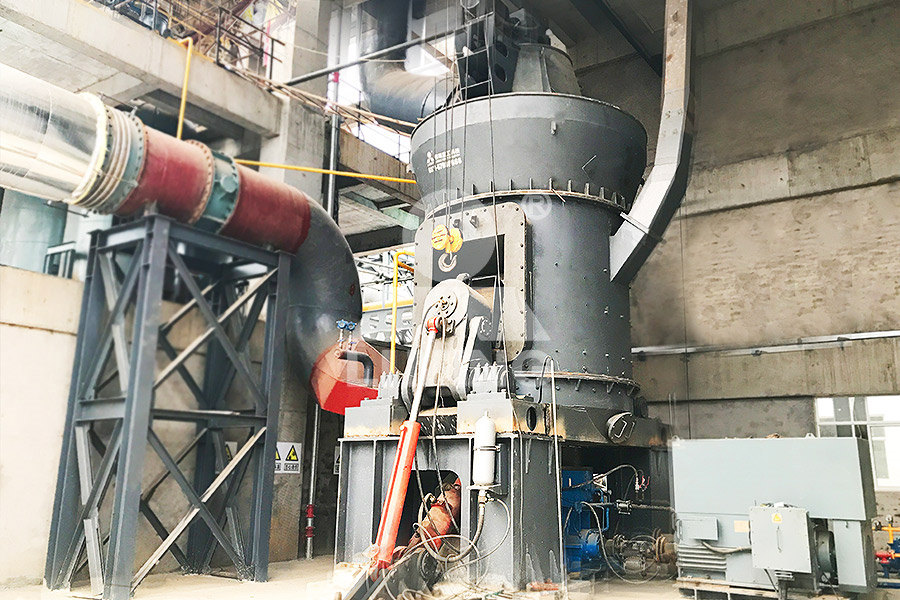

Solid Edge’s Application in Vertical Mill Design Springer

A complete set of vertical mills mainly includes foundations, transmissions, roll plates, pressurizing devices, rocker arms, housings, three lock air valves, sealed blower systems, this dissertation was to investigate the effect of coal feedstock property variation on the vertical spindle coal pulverising mill’s performance to facilitate optimal plant performance Plant design Performance optimisation of vertical spindle coal pulverisers2020年11月4日 1 Introduction The vertical roller mill, integrating various processes including crushing, grinding, drying, conveying, and powder selection [1, 2], is broadly employed in many fields like cement, electric power, metallurgy, chemical, and nonmetallic ore industriesHowever the vertical roller mill, as a common choice due to its multiple functions, always consumes Effects of Blade Parameters on the Flow Field and Classification 2023年11月16日 HRM vertical mill series vertical mills are widely used in different industries such as cement, electricity, metallurgy, chemical and nonmetal mineral for the grinding of cement raw meal, clinker, mining slag, steel slag, Vertical Roller Mill Vertical Roller Mill and Vertical

.jpg)

Blade mill VM series Mill Powder Tech Co, Ltd

Vertical type,so it only need a small space for installation The grain of powder uniform and easy to select the grain from mesh Treatment Grinder Material Properties Oily NonOily Fineness 3mm ~ 30mesh Capacity 20kg ~ 300kg The air flow through the mill is directed by the system fan The ground materials leave the mill after passing through the rotating cage of the highefficiency powder separator, which is integrated with the mill The product is collected by the dust collector behind the mill and sent to the storage warehouse for subsequent processesDetailed explanation of vertical mill grinding technologyVertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTL2024年1月5日 When choosing a mill, it is important to consider the following: 1 Particle size: The fineness of the powder required for your application will determine the type of mill you need 2 Production capacity: How much granite powder do you need to produce per hour or per day? This will influence the size and power of the mill you need 3Granite Powder Grinding Mill Machines

.jpg)

VF4 40Taper Mill Vertical Mills – Haas CNC Machines

CNC Vertical Mill with 50" x 20" x 25" travels Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needsStraight blade turbine impellers consist of two to eight flat vertical blades These turbine impellers generate a radial flow pattern and high shear They are used in solid suspension systems, heat transfer applications, and moving solutes from the bottom of the tank Pitched blade turbine impellers have flat angled bladesAgitators: Parts, Types, Flow Patterns, and Configurations IQS 1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal chemical industry, power plant desulfurization industry and coal powder preparation industry 2 The LRM type vertical roller mill integrates Supply Vertical Roller Mill Customized Factory SINOMALY Description Characteristics of Summit ® HeavyDuty vertical boring mill and milling (VBM) machines Summit ® HeavyDuty vertical boring mills and milling (VBM) machines offer smooth running, superior speed control, and maximum reliability in a costeffective solution Summit’s 48″ 60″ (single column) and 80″ – 120″ (double column) vertical boring mills feature closedgrain Vertical Boring Mill and Turning Machines Summit Machine Tool

.jpg)

A Comprehensive Guide to Vertical Turning – TMC

Vertical turning, also known as vertical turning lathe (VTL) or vertical boring mill (VBM), holds a significant advantage in various machining applications, particularly when dealing with large and heavy workpieces It offers a set of This vertical mill machine is applied in electric power, metallurgy, chemical and nonmetallic industries, such as portland cement and blended cements, limestone, slag, manganese, gypsum, coal, barite, calcite etc HLM vertical Best HLM Vertical Roller Mill Manufacturer and LM Vertical Grinding Mill What are the primary applications of the LM Vertical Grinding Mill? Moreover, a multihead cagetype powder selector can be tailored to meet specific user demands for output, fineness, and sieving rate This mill allows adjustment of product fineness within the range of 325 to 2500 meshes, Micro Powder Grinding MillNew standards in the field of vertical turning Vertical turning requires the utmost of economic efficiency and accuracy Moreover, highest cutting performance and the possibility to machine challenging workpieces on a single machine are essential in many industries and applicationsVertical Turning WaldrichSiegen

.jpg)

Vertical Blade Classifiers (VBC) Bradley Pulverizer Company

The Bradley Vertical Blade Classifier (VBC) is designed to separate extremely fine powders direct from any airswept mill Dynamic classifiers such as the VBC, provide wide flexibility of operation by allowing for instant adjustment of particle separation ranges2023年3月15日 The ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a better choice in the ultrafine powder grinding industry Product Features: Higher capacity, better powder quality, more excellent comprehensive performances Input Size: 010mm; Capacity: 518TPHLUM Ultrafine Vertical Grinding Mill SBM Mill CrusherCompared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding MillRanging from thinkerf single vertical saws to high speed wideband twin vertical saws, WoodMizer vertical sawmills are designed for highproduction The store will not Lucas Mill 616/618 Sawmill Blades $15100 Add to Cart Add to Compare Moulder Knives Moulder How to Increase Sawmill Blade Life Vertical Sawmills WoodMizer USA

Operation Manual: HRM1700M Vertical Roller Coal Mill

HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for At present, the market demand for nonmineral powder is increasingly strong, and the annual average growth rate of consumption of heavy calcium is nearly 95% It is predicted that the annual demand for nonmetallic mineral powder will still maintain a high growth rate in the next 10 years In the pursuit of stable product quality and uniform particle size distribution, the market News Application of HLMX Ultrafine Vertical Roller Mill for Non 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill Ultra fine vertical roller millUltra Fine Millultramill

.jpg)

Design and Testing of UMM Vertical Ball Mill (UVBM) for

2018年4月1日 UMM Vertical Ball Mill (UVBM) was intended to be the apparatus to produce metal powder with superior characteristic in production rate while retaining good quality of metal powder2022年5月16日 The WType Vertical Mixer for Food Ingredients Powder Mixing has a vertical axis mixing blade and a conical body The helicoid rotates to generate the upward product flow on the peripheries, which then descends to the center A geared motor unit is responsible for turning the mixing shaft having single bearing support on the topWType Vertical Mixer for Food Ingredients Powder Mixing2020年1月24日 The horizontal mill’s cutters resemble the blade of a circular saw somewhat, with a crucial difference being that they are generally thicker, smaller and their shape offers speedier milling than the spindles on their vertical counterparts Vertical turning centers are also called vertical turret lathes or VTLHorizontal vs Vertical Milling and Turning: What Are the PRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical mill

Water Mills and Wheels Tide Mill Institute

This page includes information on: Undershot Wheels Horizontal Wheels Overshot Wheels PitchBack Wheels Breast Wheels Flutter Wheels Turbines Water Wheel Ancestors Water Wheel Evolution There are many wheel configurations, vane/blade shapes and waterflow patterns Undershot wheels and horizontal wheels were the most common choices for tide mills Since Since 1875, Shibaura Machine Tools (Formally Toshiba) is the leading manufacturer in Vertical Turning and Boring Mills (VTLs) Shibaura builds their Vertical Boring and Turning Mills to last the test of time Shibaura offers table sizes ranging from 40” Vertical Boring and Turning Mills Great Lakes MachineryPURPOSE:To keep the accuracy of classification high and to effectively produce products stable in particle size in a classifier for a vertical roller mill for pulverizing coal, limestone, etc CONSTITUTION:To the outer peripheral end part of upper support plates 9a of classifying blades 10, of a rotary classifier incorporated in an inner cone 5, plural auxiliary classifying blades 11 JPHA Classifier for vertical roller mill Google PatentsVertical Roller SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d Vertical Roller Mill for Cement Raw Material

Millingturning center, Turningmilling machine All

The compact G350T millturn machining center enables machining of smaller parts from practically any material in just one setup Our VTM80YB 5axis combination lathe/machining center can perform turning, vertical, horizontal, 2017年4月1日 Separation operation of verticalrollermill will be modelled by application of current models The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treatedOperational parameters affecting the vertical roller mill Since 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production lineSlag Mill Vertical Slag Mill Provider SINOMALYVertical mill is an industrial mineral powder production equipment integrating five functions of crushing, grinding, powder separation the main mill consists of frame, air inlet volute, shovel blade, grinding roller, grinding ring and housing HLM vertical roller mill Max feeding size: 50mm Capacity: 5200t/h Fineness: 200325 mesh (75 News What Is Vertical Grinding Mill?

.jpg)

Smartcut EVS CNC Vertical Mills Summit Machine Tool

Description Designed for growing companies evolving from manual mill operations to computer numerical control (CNC), Summit ® SmartCut EVS Series CNC Vertical Mills are a perfect fit This CNC milling machine features the Fagor 8058 Control System – perhaps the most versatile CNC due to its dual operating systemThe You Ji VMT Vertical Mill /Turn Center Series combines 3axis 5face machining with vertical turning capabilities The machines provide 5sided or 4+1 axis milling and turning of medium size workpieces, producing complete parts in a single setup A full Caxis allows for 4axis simultaneous milling, making the machines ideal for aerospace and energy industry applicationsYou Ji VMT Series – Vertical Mill/Turn Centers Absolute Machine Turn / Mill Assist Flexloader Shortbar loader IRCO ILMUK 7012/10012 Vertical Turn VT high repeat accuracy and good operability are the convincing product features Emco Vertical VT 400 Max turning diameter 400 mm Max chuck diameter 400 mm Max spindle speed 4000 rpm Drive power main spindle 36 kW Drive power turret 8,5 kW;EMCO Vertical Turn VT: CNC Vertical Turning CentersWe have an extensive range of vertical milling machines for metalworking Heavy duty, reliable machines +44 (0)1543 Account; Cart; Menu Home; Machines CNC Machining Centres VMC; FTV; 5 Axis; DCM; Turning Milling; HMC; CNC Lathes 2 Axis Turning Centre; 3 Axis Turning Centre; Flatbed Lathe; Sub spindle; CHESTER LUX MILL DRILL Vertical Milling Machines Chester Machine Tools

.jpg)

Vertical Grinding Mill: How it Works, Application And Advantages

Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 The fine powder is then collected into the air cyclone collector and expelled from the outputpowder valve as the final product blade, grinding roller, and liner,