Desulfurized limestone powder composition standard

Optimization and characterization of highvolume limestone

2020年5月10日 The limit contents of limestone powder (25%35% by mass) in various standards seem to be conservative in UHPC system, 50 vol% is suggested as the optimum content for the limestone powder with comparable size and morphology to cement, by considering both 2018年12月20日 It has been welldocumented that limestone powder in concrete mainly showed filler, nucleation, dilution and chemical effects, and they were influence by the particle size, A review on effects of limestone powder on the ScienceDirect2018年8月30日 Limestone powder (LS) has been widely used in cementbased materials; and reportedly, can influence their properties by filler, nucleation, dilution and chemical effects The A review on use of limestone powder in cementbased materials 2017年1月27日 This paper introduces an investigation into limestone powder waste as a potential microfiller of polymer composites Physical characteristics such as the granulation the (PDF) Chemical and Physical Properties of Limestone Powder as a

.jpg)

Development of engineered cementitious composites with

2009年9月17日 Engineered cementitious composites (ECC) is a class of ultra ductile fiber reinforced cementitious composites, characterized by high ductility, tight crack width control standard calibration curve has been developed on the ARL OPTIM’X for the five elements (Ca, Si, Mg, Al, Fe) in limestone as a pressed powder The resulting calibrations for lime, magnesia, Analysis of limestone for flue gas desulfurization in a power plant2017年12月9日 Fine limestone is commonly included in Portland cement by intergrinding, resulting in an optimal particle size distribution of the modified cement In other applications, Limestone Powder SpringerLink2022年7月14日 The composition of CS and limestone slurry before and after desulfurization is shown in Table 3 The main component of CS gypsum is CaSO 3 05H 2 O Calcium sulfite Desulphurization mechanism and engineering practice of carbide

.jpg)

Recent advances in process and materials for dry desulfurization of

Limestone and lime are predominantly utilized in the desulfurization process within circulating fluidized bed boilers at the forefront of furnaces Under hightemperature conditions, limestone Flue gas desulfurization gypsum (FGDG) is an industrial byproduct generated during the flue gas desulfurization process in coalfired power plants Due to its abundance, chemical and Recent advances in flue gas desulfurization gypsum processes and 2024年6月15日 The limestone powder composition changes based on where it comes from and how it’s made and physical traits This careful checking makes sure every batch of powder is up to the high standards needed The limestone powder industry follows both international and national standards These standards cover things like chemical Limestone Powder – Essential Mineral for Various Uses2022年3月14日 To further explore the effects of limestone powder (LP) on the hydration of Portland cement as well as the formation and transformation mechanism of calcium carboaluminate phases, the hydration reaction between LP and tricalcium aluminate (C3A) is thoroughly studied in this paper Due to the crucial influence of gypsum on the hydration of Effects of limestone powder on the early hydration of tricalcium

.jpg)

composition and physical properties of limestone

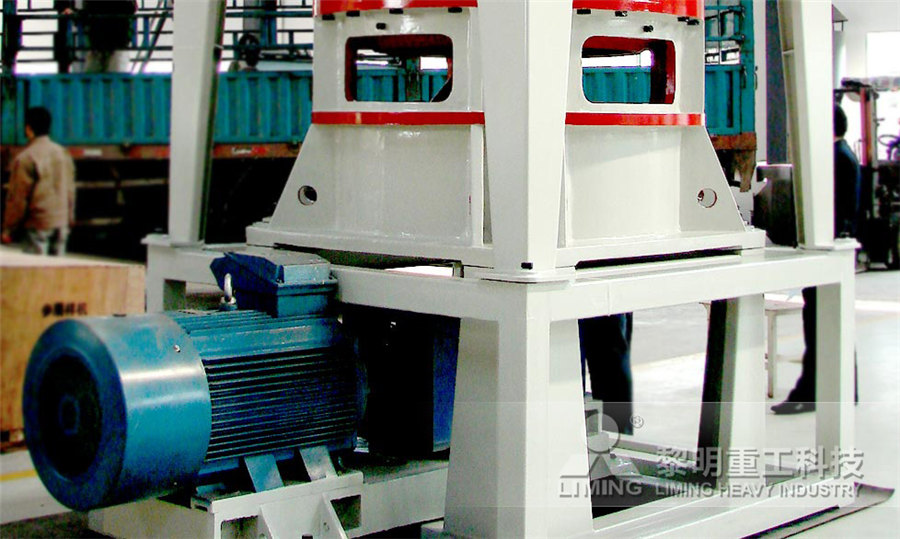

I, Type II and Type V complying with ASTM C150 were used in this work The chemical composition and physical properties of limestone powder are presented in Table 1Usually, limestone (CaCO 3) and lime (CaO) are used as Ca(OH) 2 sources thanks to their abundance and low cost Due to its low solubility, limestone needs to be pulverized in order to be used in the FGD process, adding cost and energy expenditure to the process Kikkawa et al (2002) tried to scrub SO 2 from FGD without limestone size reductionRecent advances in flue gas desulfurization gypsum processes and Raymond limestone grinding mill plays a vital role in the preparation of desulfurized limestone powder The quality of Raymond limestone grinding mill directly affects the quality, fineness and particle size distribution of limestone powder The following will explain the Limestone Raymond mill produces desulfurized limestone powder11 This standard prescribes the requiremerrts and the methods of sampling and test for limestone for chemical industry It also covers sea shells and calcite, a crystalline form of naturally occurring calcium carbonate 111 This standard IS 3204 (1978): Limestone for chemical industry Law

Feasibility Analysis and Key Issues of Using Limestone Sludge in

2021年1月14日 Comparative analysis of limestone sludge in recycled water and desulfurization limestone is made in the chemical composition, reaction activity, crystallization properties and pH of Slurry2020年11月5日 XRD SEM and BSEEDS were used to test the factors including microstructure, mineral composition, and gel composition which affects the microscopic characteristics of fly ashbased geopolymers Followed the test method mentioned in the literature ( Aughenbaugh et al, 2016 ), each set of proportions in Table 4 was made into the 20 mm × 20 mm × 80 mm Frontiers Microstructure and Composition of Red MudFly Ash 2023年10月21日 Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO3) in the form of mineral calcite or aragoniteIt is one of the most common and widely distributed rocks on Earth, with a wide range of uses in various industries and natural settings Limestone forms through the accumulation and compaction of marine organisms, primarily the Limestone Types, Properties, Composition, Formation, Uses2021年2月25日 Powder type of selfcompacting concrete (SCC) needs high cement content to achieve selfcompactibility, this will be undesirable in tropical climate of Sudan due to implication of high hydration heatEffects of Limestone Powder on Selfcompacting Concrete Properties

.jpg)

VWHP IOPscience

2021年1月16日 Then, the reclaimed water limestone sludge and desulfurized limestone samples were used respectively, and the 06 mol/L CaCl2 solution was replaced by the equivalent of calcium ion concentration to analyze the difference of reaction crystallization properties between the reclaimed water limestone sludge and the desulfurized limestone2023年9月18日 Results showed that dolomitic limestone powder can substitute cement by 16% by weight, using a concrete mix of 523g cement, 936g sand, 1,868g gravel, 100g dolomitic limestone powder, and 166g Dolomitic Limestone Powder: Cement Substitute in 2023年3月22日 Effective use of limestones to reconstruct seawater Li isotope compositions A community standard proposal March 2023; Chemical Six arti cial samples were prepared by mixing limestone powderEffective use of limestones to reconstruct seawater Li 2018年6月1日 In this study, limestone samples (a total of 58 sample) were investigated in terms of their grindability and chemical composition Grindability tests were carried out on standard HGI millThe possibilities of analysis of limestone chemical composition

.jpg)

Optimization design of lowcarbon hybrid concrete containing

2022年9月9日 Slag and limestone powder are common mineral admixtures to produce environmentally friendly concrete This paper presents an optimal design method for lowcarbon concrete containing slag and limestone powder that considers the influence of strength (30, 40, 50 MPa), carbonation service life (50, 100 years), and CO2 concentration of microclimate (004% 2010年1月1日 The laboratory test results revealed that up to 15% replacement of clinker by fine limestone powder having blain fineness values in the range of 4000 to 4500 cm 2 /gm result in comparable THE USE OF LIMESTONE POWDER AS AN ALTERNATIVE CEMENT The natural gypsum powder is a white powder, and the chemical composition is similar to that of desulfurized gypsum Impurities are mainly composed of clay minerals Formation process The formation process of desulfurization gypsum is completely different from natural gypsum Natural gypsum is formed in a slow, longterm geological processDesulfurization gypsum uses and properties take it as cement 2020年1月1日 This study investigated the mechanical properties and durability of mortar specimens containing various quantities of waste limestone powder (0%, 10%, 20%, and 30% of the weight of cement)(PDF) Effect of limestone powder on strength and permeability of

.jpg)

Performance and inorganic fume emission reduction of desulfurized

2022年6月1日 Request PDF Performance and inorganic fume emission reduction of desulfurized rubber powder/styrene–butadiene–styrene composite modified asphalt and its mixture Rubber asphalt (RA) and 2024年7月29日 Materials Figure 2 presents the physical appearance of the materials used for mixing and their respective particle size distributions The cement utilized in this study is Ordinary Portland cement (OPC), according to the guidelines outlined in the Sri Lankan standard []In the present study, limestone powder is a common precursor material in geopolymer mortarsAlkaliactivated limestone powder and groundnut shell ash based 2017年4月19日 Plain cement concrete (employed as reference) and three concretes containing limestone powder (replacement ratios of 10, 20, and 30%) were designed The compressive strengths of the four concretes were close to each other by adjusting the water to binder ratios The longterm (as long as 5 years) properties of hardened paste and concrete were Longterm properties of concrete containing limestone powderAdditionally, many factories in Erbil city in the Iraqi Kurdistan Region produce limestone powder for filler in the composition of asphalt mixture [39]It can benefit from these factories for soil Physical properties of the limestone and their

A review on effects of limestone powder on the ScienceDirect

2018年12月20日 Incorporating LS to replace fine aggregate didn’t reduce other cementitious compositions, the drying shrinkage of concrete increased as the LS content increased, as shown in Fig 9 [47] Properties of highvolume limestone powder concrete under standard curing and steamcuring conditions Powder Technol, 301 (2016), pp 1625Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime 1 × Close Log In Log in with Facebook Log in with Google or of last reapproval A superscript epsilon (e) indicates an editorial change since the last revision or reapproval This standard has been approved for use by agencies of the (PDF) Standard Test Methods for Chemical Analysis of Limestone 2022年10月17日 Desulfurized rubber powder and SBS were used as asphalt modifiers to study the rheological properties and performance of desulfurized rubber powder/SBS Machinemade sand and mineral powder were processed by crushed limestone from a company in This is because the gradation composition of the SMA13 mixture is Research on Rheological Properties by Desulfurized Rubber Powder2024年9月23日 This study explores the performance of asphalt mixtures modified with North American rock asphalt and desulfurized rubber particles at varying rubbertoasphalt ratios ranging from 18% to 36% by weight A comprehensive set of laboratory tests, including hightemperature rutting tests, lowtemperature bending tests, indirect tensile tests, and Performance of Asphalt Mixtures Modified with Desulfurized

A comprehensive review of flue gas desulphurized gypsum:

2023年8月22日 The admixture of slag powder and FGDG calcined at 200 °C with 35 % SO 3 content was mixed to obtain typeG slag powder TypeG slag powder influences the compressive and flexural strength as it is more activated and modified, resulting in more cohesion between the interfaces with improved porosity and pore structure of concrete2020年7月8日 21 Research Assumptions For the purpose of the study a reference mix (B800/LP0) was chosen The highperformance concrete mix has total of 800 kg/m 3 of binder, including fly ash and silica fume The mix design was a modification of a mix found in [7, 22]Mix performance and applicability in 3D printing was tested previously []For the purpose of the Properties of Composite Modified with Limestone Powder for 2024年11月6日 The decarbonization of the concrete industry is an ongoing pursuit One solution towards this goal is the use of limestone powder in portland cement Waste eggshell has tremendous potential as an alternative calcite filler in cement due to its similarities with limestone In this research, the feasibility of adding 15% and 35% ground eggshell in portland cement to Assessment of waste eggshell powder as a limestone alternative 2014年6月1日 The mining and processing of limestone in the state of Rio de Janeiro, southeast of Brazil, generates a considerable amount of small particles, like a powder ,which is commercialized as a by productCharacterization of a Limestone Powder Residue for Recycling

.jpg)

(PDF) The Influence of Limestone Powder on Fluidity,

2010年12月1日 For this purpose, prismatic mortar samples (40 mm 3 40 mm 3 160 mm) were prepared with limestoneblended cements (0, 10, 20, 30, 40 and 50% limestone powder was replaced by cement) and cured under 2023年2月11日 Its optimal formulation was 18% CDA, 15% fly ash, 5% mirabilite, 3% quicklime, 15% sodium hydroxide, and 575% slag micronized powder The compressive strength of this cementitious material under this formulation at 3, 7, and 28 d was 156, 364, and 712 MPa, respectively, all of which meet the requirements of the standard in ChinaResource utilization of flue gas calciumbased desulfurization ash: 2023年1月1日 Download Citation Carbonation of limestone powder concrete: Stateoftheart overview Recently, research into finding longterm solutions to CO2 mitigation in the cement and concrete sectors Carbonation of limestone powder concrete: Stateoftheart 2020年8月1日 Use of limestone as one of the main constituents in the manufacturing of cement has already been permitted in many standards such as European standard EN 1971 [8], Canadian standard CSA A3000 [9 Performance comparison of cement replacing materials in

Effect of Limestone Powder on Microstructure of Ternary

granulated blast furnace slag (BFS), Limestone powder (LP) 10 mixtures were designed The details of mixtures and chemical composition of each material are shown in able 1 The COT 2 content in each mixture was obtained by thermogravimetric analysis The mainly crystal phases in pozzolanic additives are2021年2月26日 Limestone was included in this research to explore its effect on the fresh and hardened properties of SCC as an alternate material A number of studies on using limestone in concrete, mortar, and Effect of limestone powder on selfcompacting concrete2009年11月1日 The benefits of limestone as a partial replacement for Portland Cement (PC) are well established Economic and environmental advantages by reducing CO2 emissions are well knownInfluence of various amounts of limestone powder on Download scientific diagram Water vapour adsorption isotherm for limestone powder a) raw, b) hydrophobized in stearic acid vapour, c) hydrophobized in silicone solution ( – sorption Water vapour adsorption isotherm for limestone powder a) raw,

Properties of highvolume limestone powder concrete under standard

2016年11月1日 1 Introduction Limestone powder has been recognized as one of the common mineral admixtures with low reactivity [1], [2]The primary constituent of limestone powder is calcium carbonate (CaCO 3), whose content is usually more than 95%It also contains SiO 2, Fe 3 O 4, MgO and Al 2 O 3 as minor constituents [3], [4], [5]Because limestone has low strength Since the lowest water demand, for a given workability of a binary limestone powderPortland cement, was obtained for a limestone powder content lower than the one corresponding to the highest packing density, Jones et al (2003) suggested two criteria to determine the optimum powder content for minimum water demand in plasticized mixes: a voids ratio reduction of 002 (PDF) Limestone Powder Duncan Herfort Academia