Vertical mill lm170 use

.jpg)

en/163/building vertical mill lm170md at main

Contribute to lbsid/en development by creating an account on GitHubLM series vertical mill is mainly composed of classifier, roller device, grinding disk device, pressure device, speed reducer, electric motor and housing Classifier is a kind of efficient and LM series vertical millWrite better code with AI Code review Manage code changessbm where to use vertical mill lm170mdLM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, stone industry, nonmetallic mineral It is used to grind granular and powdered LM Series Vertical Mill Liming Heavy Industry

.jpg)

Vertical Mill Tutorial 1 : The Basics YouTube

2019年7月6日 This is Mill Skills, a multipart series to help you learn basic machine shop work Exclusive videos, drawings, models plans available on Patreon!https://wUBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your UBE Vertical Mill UBE Machinery Corporation, LtdMACHINING OPERATIONS AND MACHINE TOOLS VerticalUniversalRamBed type mill14Machining Centers • Machining center highly automated machine tool capable of sbm/sbm vertical mill lm170 maintenance proceduresmd at Load an end mill or face mill into the milling machine Generally a tool that will accomplish the cut in one pass Calculate the spindle speed and feed rate for the tool selected Turn on the Chapter 9 Part 7: Manual Vertical Milling Machines

.jpg)

Introduction to the vertical Milling Machine YouTube

2018年1月27日 Mr Riggs explains the parts and functions of the vertical milling machineWrite better code with AI Code review Manage code changessbm/sbm how to do the vertical mill lm170 without powdermd at 全国销售热线: 黎明重工科技最具价值的粉磨装备供应商 通过其他装载设备将干物料堆放原料仓中,带式输送机按照系统设定的速度将存放在在原料仓中的物料经斗式提升机和锁风喂料机,喂入到立磨中进行粉磨。LM VERTICAL MILL 工业磨粉行业首选品牌The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith Company

.jpg)

Vertical roller mill, Vertical roller grinding mill All

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesLMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years’ mill experiences It can crush, dry, grind, and classify the materials LM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, stone industry, nonmetallic mineralLM Series Vertical Mill Liming Heavy IndustryLMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years' mill experiences It can crush, dry, grind, and classify the materials LM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, stone industry, nonmetallic mineralLM Series Vertical Mill Liming Heavy IndustryLM Series Vertical Roller Mill is used to pulverize materials, material can be pulverized into 80400Mesh with this mill Feed particle size: 070mm Production capacity: 4300 tons / hour Applicable materials: limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, phosphate rock, graphite, quartz, slag, etcLM Vertical Roller Mill, Vertical Mill Manufacturer

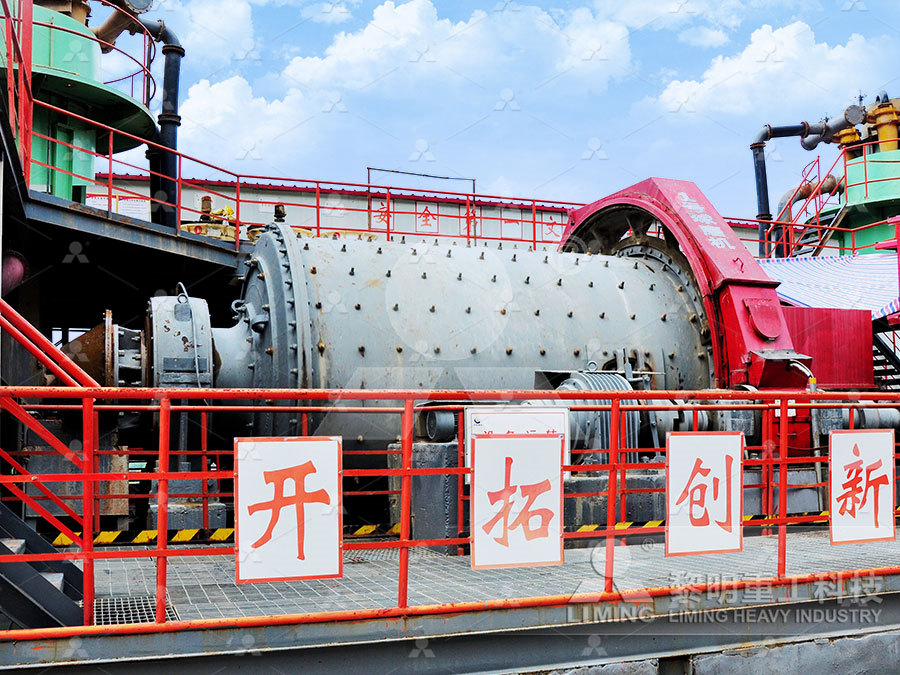

LM Vertical Grinding Mill Vertical Roller Mill sbmchina

LM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open air with less comprehensive investmentLM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is LM Vertical Mill – Stone Crushers Grinding Mills for Mines and LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, nonmetallic mineral It is used to grind granular and materials into powders with required finenessLM Series Vertical Mill LIMING(Shanghai)2017年1月1日 Schmitz, T: Quadropol QMCRD World's First Vertical Roller Mill with Driven Rollers Presentation 7 th International VDZ Congress 2013, 2527 September 2013, Düsseldorf/Germany(PDF) Drives for large vertical roller mills ResearchGate

Slag Vertical Roller Mill

2023年1月10日 Advantages of Slag Vertical Roller Mill 1 Costeffective, less comprehensive investment Large functions are integrated in one, occupying an area of about 50% of the ball mill system, and can be arranged in the open air, greatly reducing investment costs; the system design is simple and reasonable, saving the total investment in equipment LM Vertical Grinding Mill Under the situations that related technologies about vertical grinding mill gradually become mature and the technical advantages of vertical grinding mill become prominent, SBM releases LM Series Vertical LM Vertical Grinding MillSBM Industrial Technology Sand Mill related knowledge: 1The Working Principle of LM Vertical Grinding Mill 2Milling machine is widely used in the production of silicon carbide powder 3Raw material LM Vertical Grinding Mills technology Sand Mill technical data:Lm Series Sand Mill for Making Powder in Product introduction:The LM vertical roller mill is a highly efficient and energysaving product has realized the localization of highlevel vertical mills, which combines 30 years of mature vertical mill technology from foreign successful experience LM Vertical Roller Mill vanguardtec

.jpg)

LM Vertical Roller Mill

Vertical Roller mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds The materials fall into the center of device through lock air feeder, and hot air comes into mill through air inlet under the function of centrifugal force, the materials when they come by the annular chuteOne more large vertical roller mill in modular construction with a capacity of 40 t/h will be used in the grinding of coal to a fineness of 10 % and R 90 μm sieving residue Loesche’s contractual partner and plant constructor is the renowned Sinoma International Engineering Co from Nanjing/China, specialised in the design of cement plantsLoesche supplies four vertical roller mills (VRM) ZKGLM Vertical Grinding Mill LM series vertical roller mills are a excellent grinding equipment, which have the capacity of 24hours constant running Because of this automatic operation, this VRMs are popular in the condition, which needs easy monitor, large capaity, constant running, stable product quality, like large mineral powder plant, cement plant, GGBS powder plant, coal LM Vertical Grinding Mill Vertical Roller MillLM series vertical mill is an efficient equipment which combines crushing ,drying, milling , separating and transporting together It is wildly used in field of cement, metallurgy, electricity, chemical,ceramics, glass, nonmetal ores,etc It can also grind water slag, ore slag, stove slag, LM Vertical MillGreat Wall Company

.jpg)

Vertical Mills for sale, New Used MachineSales

The # 1 place to find new used vertical mills for sale Buy or sell machinery equipment quickly easily MachineSales Toggle navigation MachineSales Sell; Wanted; Directory; Contact; ACER EMILL 3VKH VERTICAL MILL Model eMill 3VKH, S/N NS9, New 2004 Stock # Q11776 EQUIPPED WITH: Newall C80 DRO SPECIFICATIONS: LM vertical roller mill is a kind of high efficiency and energy saving product perfectly combined with 30 years of mature vertical grinding technology, foreign successful experience and our company's technical innovation and upgrading It has realized the localization of worldclass vertical grindingLM VERTICAL MIVipeak Heavy Industry Machinery Group 1 LM Vertical slag mill integrates drying, grinding, powder selection and conveying together, simple system, compact layout, the area is about 50% of the ball milling system Reduce the cost of investment, low energy consumption, LM Vertical slag mill2011年3月1日 Download Citation Trials on high quality cement with a Loesche vertical roller mill Loesche GmbH from Düsseldorf supplied the grinding plants for producing raw meal and pulverized fuel as Trials on high quality cement with a Loesche vertical roller mill

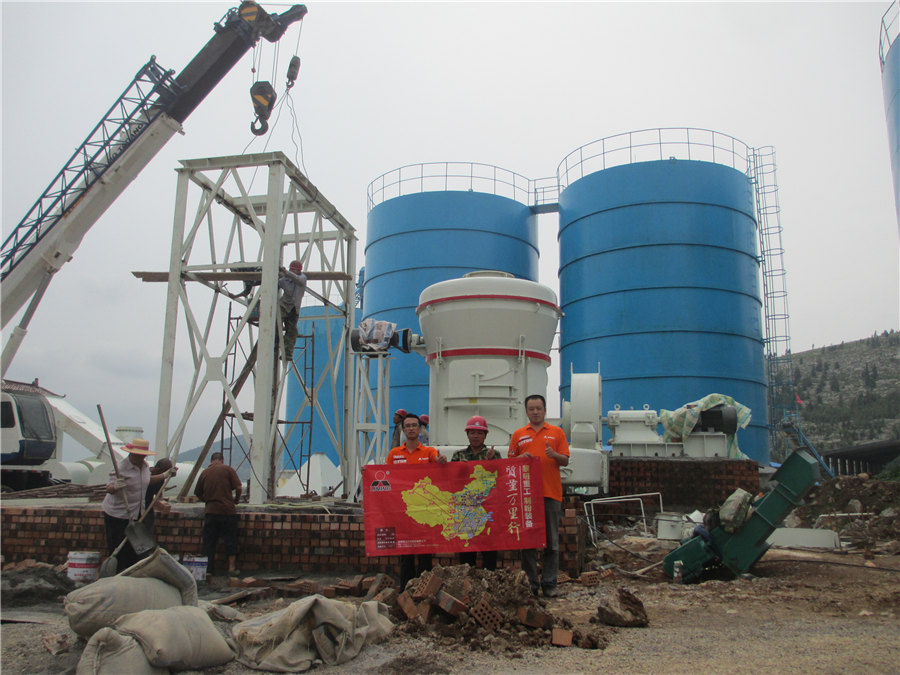

LM Vertical Roller Mill, slag vertical mill, coal

LM130K Vertical Mill For Dolomite In Sichuan Output size:150200 mesh, D95 LATEST EQUIPMENT MTW European Type Trapezium Mill LM Vertical Roller Mill Raymond Mill LUM series superfine vertical roller grinding mill ORE UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Information about UBE Vertical Mill services Repair Service Restoring your equipment to its original performance Consulting ServiceUBE Vertical Mill UBE Machinery Corporation, LtdGrinding roller bearings are lubricated with forced thin oil, longer bearing life;Using an independent oil station,and there is an automatic protection system for oil pressure and oil temperature, which makes the whole set of equipment safe and reliable;Use hydraulic control system to apply and control its force on materials and pressure can be adjusted automatically LUM series superfine vertical roller grinding millA Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there’s a Haas to do the workVertical Mills VMC Haas CNC Machines Haas Automation

.jpg)

Working principle and characteristics of vertical mill

Working principle and characteristics of vertical mill Working principle The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The ground materials are then blown by hot air through an outlet in the mill's LM Vertical Grinding Mill Based on the absorption of advanced technologies of famous international corporations and 30 years' experience in grinding mill production, SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, powder selection, drying and material conveyingLM Vertical Grinding MillSBM Industrial Technology GroupThe first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an2 µm 5 µm LoescheVertical Roller mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds The materials fall into the center of device through lock air feeder, and hot air comes into mill through air inlet under the function of centrifugal force, the materials when they come by the annular chuteLM Vertical Roller Mill

.jpg)

LM Vertical MillGreat Wall Company

LM series vertical mill is an efficient equipment which combines crushing ,drying, milling , separating and transporting together It is wildly used in field of cement, metallurgy, electricity, chemical,ceramics, glass, nonmetal ores,etc It can LM Vertical Grinding Mill Features Small Occupational Area Its occupational area is about 50% of that of the ballmilling system Better Final Powder Materials linger in the mill for a short time, which can reduce repeated grinding LM Vertical Grinding Mill Zenith Crusher• Mill motor speed • Mill air flow/mill differential pressure • Temperature after the mill • Pressure before the mill • Grinding stock feed • Classifier speed • Mill fan speed • Water spraying • Hot gas • Fresh air Manipulated variables Disturbance variable Process measured value RelauchLMmaster 6 250814 11:47PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSVertical Roller Mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high consumption of industry mills With a decade of years research of mills, Vertical Roller Mill is designed and manufactured based on our advanced design idea, and in combination with the European technology and the market demandZenith Large Capacity Lm Series Vertical Roller Mill

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI 2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor support The overarm is a Vertical Milling Machines vs Horizontal: Differences Explained2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its Regular inspection is a fundamental aspect of vertical mill maintenance This includes checking the condition of the grinding rollers, the grinding table, and the liners for signs of wear or damage Any wornout components should be replaced promptly to prevent further deterioration and ensure optimal grinding performanceKey points for maintenance and care of vertical mills

LM Vertical Mill

LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industries Structural Features Of Vertical Ball Mill The barrel of the vertical ball mill is a welded structure, and a protective lining is attached to the inner wallVertical Ball Mill