Coal crusher model parameters, twoway

Performance assessment of the coal crusher machine using the

This analysis is carried out by comparing the effect of the six big losses and the overall equipment effectiveness (OEE) value on the coal crusher machine2016年7月11日 In order to model particlebreakage behavior in a crusher, breakage parameters and HGI of material should be taken into consideration Coal grindability has long been studied Coal Grindability and Breakage Parameters Taylor Francis Online2012年12月1日 The model utilizes a fair combination of individual models for two distinct phenomena, the breakage and the agglomeration which occur simultaneously in the double Modeling of coal breakage in a doubleroll crusher considering 2012年12月1日 A discrete element method (DEM) model of the crushing process of a toothed doubleroll crusher (TDRC) is established using the bonded particle model DEM results and Modeling of coal breakage in a doubleroll crusher considering

.jpg)

Modeling of coal breakage in a doubleroll crusher considering

2012年12月1日 Model parameters were estimated from experimental data from singlesize crushing tests Using these parameters, product size distributions with distributedsize feed 2012年12月1日 ABSTRACT Comparison of breakage behavior of coals is conducted between the industrial sieving crusher (SC) and ordinary teeth roll crushers in different breakage flow Modeling of coal breakage in a doubleroll crusher considering 2024年4月15日 This paper presents the investigation of the dynamic mechanical properties of coal rock under complex stress conditions at depth, based on the improved Separate Dynamic mechanical response and crack evolution law of raw coal 2023年10月25日 This research delineates the energy dissipation characteristics in coal crushing under impact loads, leveraging the capabilities of Separated Hopkinson Pressure Bar An analysis of impact load and fragmentation dimension to

.jpg)

Mathematical Modeling and MultiCriteria Optimization of Design

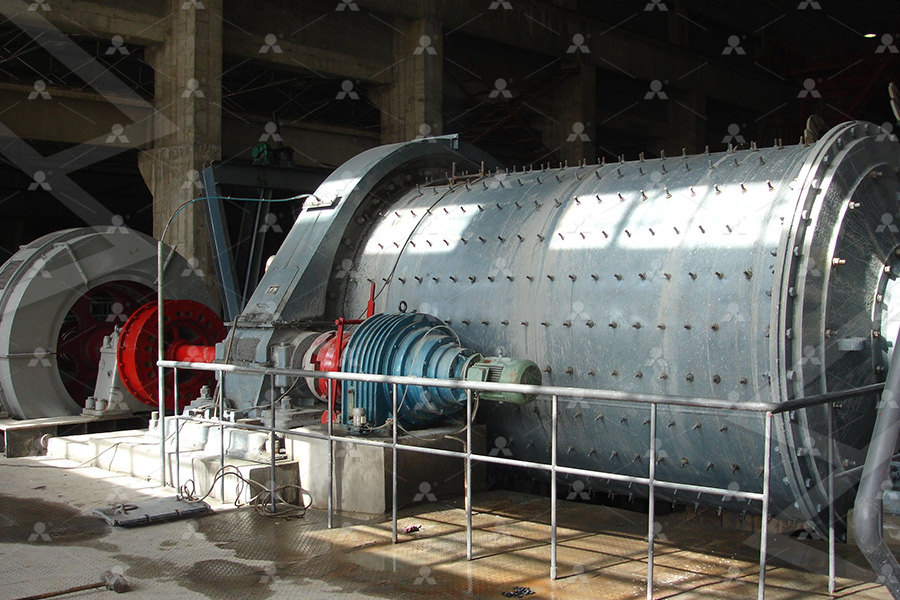

2023年5月17日 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a singleroll gyratory shaft crusher, designed Coal is one of the essential resources in an industry that requires energy One of the industries that use coal as a source of energy is a steam power plant In an industry that uses large numbers of coal with a certain size, it requires a coal crusher to change the shape of the coal into the desired shape A coal crusher is a machinePerformance assessment of the coal crusher machine using the 2023年5月17日 Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a singleroll gyratory shaft crusher, designed for crushing strong rocks Mathematical Modeling and MultiCriteria feedsize distributions, two blasting parameters, ie, burden and spacing, were considered The crusher parameters that affect energy consumption were also identifiedGyratory crusher model and impact parameters related to

.jpg)

Optimization of particle size distribution in circulating fluidized

2019年4月1日 Properties of coal gangue feed, especially its particle size distribution (PSD) and variable hardness, result in considerable impacts on both the efficiencies of the circulating fluidized bed (CFB Download Table Performance Parameters of Jaw Crushers from publication: A Study on the Effects of Coal Feed Size and Coal Type on the Performance of a Laboratory Jaw Crusher In this study, the Performance Parameters of Jaw Crushers Download Table2022年9月15日 Secondly, based on the physical domain entities contained in the intelligent mining face, the data perception models of coal shearer, scraper conveyor, stage loader, crusher, hydraulic support Construction of digital twin system for intelligent mining in coal 2023年10月8日 Jaw crusher + impact crusher + vibrating screen: Suitable for factories that have high requirements for output size and capacity Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

.jpg)

Optimization of particle size distribution in circulating fluidized

2019年6月15日 The model predicted the PSD parameter of coal gangue with excellent accuracy It was concluded that a reasonable roll gap and teeth length should be 75 mm and 23 mm, respectively A physical model of a twotoothed roll crusher was established to obtain an optimized roll diameter and was found to be >660 mm2021年7月1日 The emission of inhalable particulates (PM 10) from coal comminution processing is detrimental to the air qualityHowever, limited works have been carried out for the estimation of emission and dispersion of PM 10 from coal crushers and its ancillary operations In this study, fieldbased measurements and regulatory dispersion model coupled with Weather Research Assessment of emissionsource contribution to spatial dispersion Coal is one of the essential resources in an industry that requires energy One of the industries that use coal as a source of energy is a steam power plant In an industry that uses large numbers of coal with a certain size, it requires a coal crusher to change the shape of the coal into the desired shape A coal crusher is a machinePerformance assessment of the coal crusher machine using the 2012年12月1日 To represent the particle behaviors and to predict the product size distributions of coal breakage products by a doubleroll crusher, a new combined breakage–agglomeration model has been constructedThe model utilizes a fair combination of individual models for two distinct phenomena, the breakage and the agglomeration which occur simultaneously in the Modeling of coal breakage in a doubleroll crusher considering

Study on the crushing mechanism and parameters of

2022年3月31日 Crushing mechanism and parameters of the twoflow crusher 11 lowest, that is to say , the crushing effect is the worst, so the rotating speed of 795 rpm requires further analysis2023年6月30日 ] proposed a twoobjective optimization model for this task, taking into account the effect of workforce training and equipment wear The failure rate increases as the crusher ages and wears [Modeling and Improving the Efficiency of Crushing 2024年11月3日 Construction of typical coal and rock particle models To enhance the realism of the particle models in the discrete element model of the coal wall, three primary shapes of coal and rock particles Research on coal rock parameter calibration based on discrete precision for reporting coal parameters such as ash, moisture, sulphur, and heating value, by determining the concentration of primary elements (France, 1999) Coal quality management model for dome storage (DSCQMM) by MA BadaniPrado*, V Kecojevic*, and D Bogunovic† 03)6 Coal quality (ash, sulphur, moisture, and heating value) is one v116n7a12 Coal quality management model for dome storage

Coal Crushers, 16mm / 475mm Final Particle Size Gilson Co

Small Holmes Hammermill Coal Crusher (230V/50Hz or 230V/60Hz) Two sample collection containers – 10 and 35lb (45 and 16kg) capacity; Two screen plates – 3/16 1/16in (16 and 48mm) or other customerspecified sizes, or; Large Holmes Hammermill Coal Crusher (230V/50Hz or 230V/60Hz) Two screen plates in customerspecified sizes2024年3月25日 The low loading rate of the thin coal seam shearer drum is a severe obstacle to the efficient mining of thin seam resources, and the auxiliary drum loading through the cowl is an effective measure Influence of coal cowl parameters on the coal loading process of 2021年8月13日 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque accurately The discrete Torque Analysis of a Gyratory Crusher with the Discrete Element DOI: 101016/JPOWTEC201208021 Corpus ID: ; Modeling of coal breakage in a doubleroll crusher considering the reagglomeration phenomena @article{Kwon2012ModelingOC, title={Modeling of coal breakage in a doubleroll crusher considering the reagglomeration phenomena}, author={Jihoe Kwon and Heechan Cho and Myoungwook Mun and Kihong Kim}, Modeling of coal breakage in a doubleroll crusher considering

.jpg)

Characterization of 10 nm – 10 μm coal dust particles Springer

2023年12月19日 Nanotomicronsized coal dust can cause coal workers’ pneumoconiosis (CWP), and cutting and drilling are the main coal dustgenerating processes Based on a selfdeveloped simulated coal cutting and drilling dust generation system, the effects of cutting parameters (tooth tip cone angle, impact angle, roller rotary speed, cutting speed) and drilling 2011年11月1日 In this study, the effects of three different choke feed level (1/1, 1/2, and 1/4) and four different effective reduction ratios (25, 5, 10, and 20) depend on the capacity of the crusher of the Effects of Two Important Parameters on Capacity of a 2016年12月10日 1 Introduction The population balance model has been widely used as a basic structure in modelling of grinding mills for the mineral and coal industries (Kelsall and Reid, 1965, Herbst and Mika, 1970, Austin, 19711972, Herbst and Fuerstenau, 1973, Herbst and Fuerstenau, 1980, Whiten, 1974, Austin et al, 1984)The population balance model is based on a ratesize A review of the applications of the JK sizedependent breakage model 2020年6月1日 The parameter study is evaluated using mechanical and geometrical tests for aggregate properties In order to keep the focus on the gradation and crusher parameters, the study is limited to one rock type The aggregates produced during Influence of jaw crusher parameters on the quality of primary

Numerical modelling of gas outburst from coal: a review from

2023年11月28日 21 Gas properties 211 Gas content One of the factors affecting the energy release potential of coal is gas content Gas content is the summation of free and adsorbed gas in coal and is recognized as the key parameter used for determining outburst propensity (Lama 1995)In Australia, gas content is used alone to define a Threshold Limit Value (TLV) in coal 2020年12月1日 The slag model proposed by Ye et al [8] was modified and linked to the commercial CFD solver (ANSYS FLUENT) as a submodule Fig 1 illustrates the key input and output parameters between the CFD solver and the slag model Based on the wall heat flow rate, Q gas, and ash deposition rate, m dep, from the CFD solver, the slag model calculates the Slagging behavior modeling in coal gasifiers using twoway Metaverse (2022) Volume 3 Issue 2, 16 pages doi: 1054517/metv3i22130 Original Research Article Construction of digital twin system for intelligent mining in coal mines Bing MiaoConstruction of digital twin system for intelligent mining in coal 2023年7月21日 The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models Join the GrabCAD Community today to gain access and download!COAL CRUSHER PLANT 3D CAD Model Library GrabCAD

.jpg)

Mechanical Design and Analysis of Automatic Coal Crushing

A Coal Crusher Machine Coal Crusher Machine is to utilize the high turn speed mallets to smash the waste Coal coming into the devastating council of the Coal crusher machine as shown in Fig3 Fig3 Coal crusher machine The standard of little Coal crusher machine is as per the following: In the devastating assembly of the Coal crusher machine,2015年11月17日 To gain some perspective on the situation, Coal Age spoke to two leading crusher manufacturers TerraSource Global has been crushing RoM coal in the PRB with its breakers since the late 1970s MMD began marketing the sizer to the coal business in the late 1980s and operators have embraced the technologyCrushing and Sizing Systems for Surface Applications Coal Age2021年7月22日 The crusher was running in a coal handling plant in steel plant A simple schematic diagram of coal crusher with sensor orientation on bearing housing, a 3D crusher model and a photograph of Crusher NDE bearing with two sensors fixed in radial and horizontal direction are shown in Figs 4, 5 and 6 respectivelyRubImpact Fault Diagnosis of a Coal Crusher Machine by2016年7月11日 In order to model particlebreakage behavior in a crusher, breakage parameters and HGI of material should be taken into consideration Coal grindability has long been studied and empirical equations evaluating coal characteristics data have been proposedCoal Grindability and Breakage Parameters Taylor Francis

Coal falling trajectory and strength analysis of drum of shearer

2024年4月24日 The cutting and crushing of coal and rock containing gangue is the result of the coupling effect of multiple factors The geometric parameters of the working mechanism, the kinematic parameters of Minerals, 2021 This paper reports the calibration and validation of a cone crusher model using industrial data Usually, there are three calibration parameters in the condensed breakage function; by contrast, in this work, every entry of the lower triangular breakage function matrix is considered a calibration parameter(PDF) Simulation — the modern costeffective way to solve crusher 2021年11月11日 This paper reports the calibration and validation of a cone crusher model using industrial data Usually, there are three calibration parameters in the condensed breakage function; by contrast, in (PDF) Calibration and Validation of a Cone Crusher Model with A standard approach for modeling the oating roller has been to apply a spring damper model to describe its 55 motion This approach has been utilized by Quist, BarA Time Dynamic Model of a High Pressure Grinding Rolls Crusher

.jpg)

A method to determine the bondedparticle model parameters

2024年3月1日 While these three breakage models each have their own strengths in describing crushing behaviour, experiments by JimenezHerrera, Barrios, and Tavares (2018) have shown that the FBM and PRM have limitations in capturing the forces and deformations involved in particle breakage However, the BPM has parameters directly related to the material’s 2021年5月1日 Request PDF Assessment of emissionsource contribution to spatial dispersion for coal crusher agglomeration using prognostic model The emission of inhalable particulates (PM10) from coal Assessment of emissionsource contribution to spatial dispersion Due to their significant influence on feedsize distributions, two blasting parameters, ie, burden and spacing, were considered The crusher parameters that affect energy consumption were also identified A case study of an operating dolomite mine was performedA Review Study on the Proposed Model for a Multilevel 2023年11月28日 Among all methods for investigating the complex phenomenon of the coal and gas outburst, numerical modelling is the most comprehensive one that can consider all involved parameters and simulate Numerical modelling of gas outburst from coal: a review from

A unified thermomechanical model for coal mill operation

2015年11月1日 In this paper, a dynamic coal mill model is developed using conservation laws and empirical relations The physical processes occurring inside the mill such as grinding, pneumatic transport, drying, heat transfer, and classification are modeled Differential Evolution is used to estimate the model parameters