Hornbow rock HPC limestone crushing

Development of high performances concrete based on the

2014年6月16日 The present work aims at the study of the effect of the partial substitution of cement with two type of mineral additions, siliceous fillers (dune sand finely grinded (SF)) and HPC cone crusher Capacity: 150500t/h Max feeding size: 290mm Processing ability: 150500t/h Range of application: Almost all minerals, such as quartz, feldspar, mica, calcite, HPC cone crusherThe limestone crushing process involves several stages, each with specific machinery and equipment The typical limestone crushing process is Primary Crushing > Secondary Limestone Crushing Process JXSC MineralThe limestone aggregates crushing generally has four steps: coarse crushing, sencondary crushing, sand making and screeningLimestone Aggregate Crushing JXSC Machine

Evaluation of mechanical properties and environmental impact of

2022年4月20日 shrinkage of HPC containing limestone powder as a cement replacement by observing the early age temperature rise and fall due to hydration Downloaded by [ Maria 2019年4月18日 Crushing is a size reduction process that plays a key role in both mineral processing and crushing–screening plant design Investigations on rock crushability have become an important issue in An experimental investigation on rock crushability 1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for Limestone Aggregate Crushing JXSC Machine2018年11月1日 Limestone Caycuma / Zongulda k 260 096 868 10862 24 Mechanical aggregate pr operties of rocks (CTM), which is commonly utilized to test the crushing value of rock particles(PDF) New testing methodology for the quantification

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

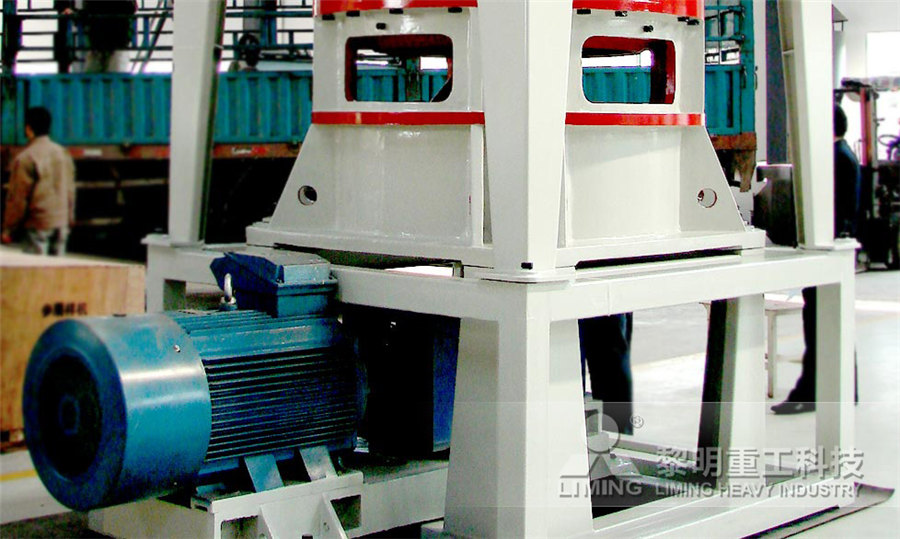

2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesThe type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will be, the easier it is to choose the best equipment to achieve your project goalsTypes of Rock Crushers Quarry Crushing Equipment KemperIt has excellent crushing efficiency and good hydraulic control system Now the HPC series cone crusher has wide application in seconda +29 Now the HPC series cone crusher has wide application in secondary crushing of many kinds of mining and rock, etc Benefit 1HPC cone crusherCrushing Limestone to a 1¼" Product A RM 120X crushes limestone in Brazil feeding 2 ft x 2 ft blast rock producing a 1¼" spec product We can crush hard limestone with an impact crusher Occationally, limestone can be very hard and difficult to crushCrushing Limestone Impact Jaw Crushers RUBBLE MASTER

.jpg)

Development of high performances concrete based on the

2014年6月16日 Dune sand and limestone rock were grinded in order to obtain economical mineral additions and limestone fillers (LF) (obtained from aggregates crushing waste) on the properties of HPC This will select the most efficient optimal couples “SF/LF”, both in terms of mechanical strength that sustainability point of view For 2014年6月16日 For this purpose, it is advisable to add local raw materials that can achieve the same performance as those presented by Silica fume Therefore, we proceeded to the use of grinded dune sand and limestone fines coming from crushing waste (abundant materials, and therefore relatively inexpensive) as additives in the context of minimizing the cost of HPCDevelopment of high performances concrete based on the 2014年6月1日 The valorised materials are limestone crushing sand (0/5 mm) and limestone fillers (80 μm) The two materials are extracted from local aggregate crushing wastesDevelopment of high performances concrete based on the 21 Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

Development of high performances concrete based on

Development of high performances concrete based on the addition of grinded dune sand and limestone rock using the mixture design and limestone fillers (LF) (obtained from aggregates crushing waste) on the properties of HPC Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, Jaw Crusher Eastman Rock Crusher2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing, Additionally, the machine can be used for various applications, such as crushing rock or processing recycling material To learn about the Jaw Crusher, Click here! How To Choose The Right Limestone Crusher For your needs? 1 Precrushing Before beginning to use a limestone crusher, it’s essential to precrush the materialLimestone Crusher: What Is It How Does It Work?

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and HPC1414 : 230 : 250/315 : 950 x 1420 Performance details relate to mediumhard limestone : Granulation Curves COMPOUND CRUSHER stage crushing, within a single housing, by two corotating rotors operating in tandem The first rotor crushes feed rock up to 3m³ in volume, and the second rotor Compound Impact Crusher HPC HAZEMAGHPC series cone crusher shows excellent crushing capacity in secondary crushing and fine crushing in metal ore, construction sand, and stone processing With its strong crushing ability and large capacity, it is commonly used to crush medium and hard rockHpc Hydraulic Cone Crushing Machine, Gold Iron Ore Rock Hard Typical limestone crushing plant feature successive size reduction stages and intermediate screening to classify material A standard flow involves primary, secondary, Primary crushers reduce limestone rock from 1000mm maximum feed sizes down to 100300mm depending on chamber clearances setLimestone Crusher for Efficient Limestone Crushing Plant

Limestone Crushing Process JXSC Mineral

About Limestone Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite It is a kind of stone widely found in nature Limestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated lime2023年2月14日 The limestone crushing process is a crucial step in the production of cement, as well as in other industries that utilize limestone as a raw material The process of crushing limestone involves several stages, each of Optimized Limestone Crushing Process for Increased 2017年3月4日 40 Crushing of rock and minerals: 500 to more than 10,000 t/h are used prov ing for crushing and processing hard roc k, limestone, coal, ore, SIZE REDUCTION BY CRUSHING METHODS2024年1月23日 Limestone is a common sedimentary rock, primarily composed of calcium carbonate It is widely distributed in different regions of the Earth, Today, we will focus on the limestone crushing and screening process: Initially, the raw limestone blocks are uniformly conveyed to a jaw crusher through a vibrating feederLimestone crushing and screening production line introduction

.jpg)

Rebel Crusher For Sale Rebel Concrete Crusher RR RR

Capable of tracking and crushing without stopping Crush and screen products such as Asphalt, Concrete w/or without wire and rebar, brick, block, most rock, stone, limestone, granite, sand, clay, glass, toilet bowls, sinks, computers, TVs, some wood, and nearly anything that is brittle! It’s the perfect rubble crusher!2024年7月10日 3How to crush limestone? The first step in crushing limestone is primary crushing This is usually done using a jaw crusher, which breaks the larger rocks into smaller pieces Jaw crushers have a fixed jaw and a moving jaw The moving jaw exerts force on the rock to crush it against the fixed jawChoosing the right primary crusher for limestone crushing Baichy2024年5月20日 "Welcome to our video on big rock crushing! This video will take you through every step of the process, from feeding the big rocks into the machine to the fi"Big Rock Crusher Machine: A Giant in Action"Big Rock Crushing: 2024年10月8日 Summary:This article provides a comprehensive overview of mobile limestone crushing plant, covering their design, operation, advantages, and applications Limestone, a sedimentary rock composed primarily of calcium carbonate, is one of the most widely used materials in various industries, including construction, agriculture, and manufacturingMobile Limestone Crushing PlantSBM Industrial Technology Group

The Complete Guide to Crushed Stone and Gravel

2019年11月11日 Limestone: A sedimentary rock and the most commonly used rock type for crushed stone in the United States One of the most versatile rocks for construction, limestone is able to be crushed easily, making it a primary rock used in readymix concrete, road construction, and railroads It is widely available in quarries across the country2023年2月20日 We visited our projects in Nebraska and Kansas where we're showcasing many of our field operations capabilitiesAt the quarry site we're stripping overburdeCrushing Limestone Rock YouTube2016年1月11日 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + Metso and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are Crusher Operating Costs: How to Optimize and Reduce2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock f = 1520: Extremely strong rocks, such as very strong granite, limestone, quartzite, etc f = 810: Strong rocks, Which Crusher Is Suitable for Your Hard Rock? Fote

.jpg)

Rebel Crusher Crushing Limestone, Screening

Crushing Limestone Screening LimestoneWatch this actual customer crusher / screener setup The Rebel Crusher's jaw opening is set at 21/4" with a grizzly A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology Jaw crusher series crawler track mobile crusher plant is ideal for this hard rock quarry mining For secondary crushing, there are cone crushers for you varying from Symons cone crusher to HPC cone crusherPebble Ore Crushing Solutions DSMAC2023年6月30日 crushing process to improve the calculation methods of crushers and check the efficiency of rock texture, strength, and brittleness on the power consumed by crushers requires additional Modeling and Improving the Efficiency of Crushing EquipmentHPC1414 HPC1615 HPC1618 HPC1622 HPC1822 HPC2022 HPC2025 HPC2030: HSI 1007 HSI 1010 HSI 1014 HSI 1414 HSI 1420 HSI 1625 HSI 1630: HTI 1005 HTI 1010 HTI 1014: Certain applications are unsuitable for this material, including limestone crushing and slag recycling Eg, primary crushing of sandstone mines, construction waste recycling Blow Bars Metal Matrix with Ceramic Insert GTEK MINING

Rock Quarry Crushing Operations HD YouTube

2018年1月2日 Watch in HD, shows how large hard rock is crushed down to smaller rock Rock is blasted and mined, then hauled up above to be sent to the crusher, jaw scr2021年1月3日 The behavior of granular materials subjected to shear loading is often very complex to be correctly characterized Loads on a discrete medium composed by several grains lead to a diffusion of stresses in the medium by contact and frictions between individual grains This stress diffusion combined to intergranular relative movements induces some cracking in Statistical study of the crushing of limestone grains under shearing2016年2月26日 It is convenient and logical that this should be a medium limestone in this case also, because hammermills are applied extensively to crushing, and pulverizing, that kind of rock Above is the approximate capacity ratings of the various sizes of hammermill (impact crushers), on medium limestone, and for various grate bar spacingsHammer Mill Crusher Grinder 911MetallurgistHammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applicationsLimestone Mills Williams Crusher

STEVIN ROCK

in the world Stevin Rock has the capacity to produce and sell more than 80 million tonnes per year of limestone, dolomite and gabbro for the construction industry (fine to coarse aggregate for asphalt, readymix plants, land reclamation, armour rock for sea defence/breakwater marine projects) as well as for the cement, steel and mining