5500 tons per day diabase steel plant steel slag mill vertical mill Raymond mill

An overview of utilization of slag and sludge from steel industries

2007年3月1日 This paper analyzes the characterization, beneficiation and utilization aspects of blast furnace flue dust, blast furnace sludge, LD sludge and LD slag generated at modern 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1] China's crude steel output in 2021 was Comprehensive utilization of steel slag: A review ScienceDirect2021年9月24日 This paper takes a critical look at the developments toward steel slag recycling and utilization, leading to resource conservation and greenhouse emission control Various BOF Steel Slag: Critical Assessment and Integrated Approach for 2002年7月1日 Hot metal desulfurization slag is a highmetallic iron content slag produced at a typical steelmaking facility and is currently considered waste Each year, 50,000 tons of this Pelletizing steel mill desulfurization slag ScienceDirect

.jpg)

Chemical, Mineralogical, and Morphological Properties of Steel

2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basic This article presents a review of the slag energy potential on a global scale, and a proposal for a recovery plant in the factories of ArcelorMittal in Asturias (Spain), based on a steam Rankine Steel mill slags energy potential: the case of the steel factory of 2016年5月16日 The generation rate of slag produced from steel industries is found to be in the range of 150–200 kg per ton of steel production The LD slag generated by the basic oxygen Sustainable Approaches for LD Slag Waste Management in SteelThis dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes: Efficient and costeffective metal recovery in the Steel Slag Loesche

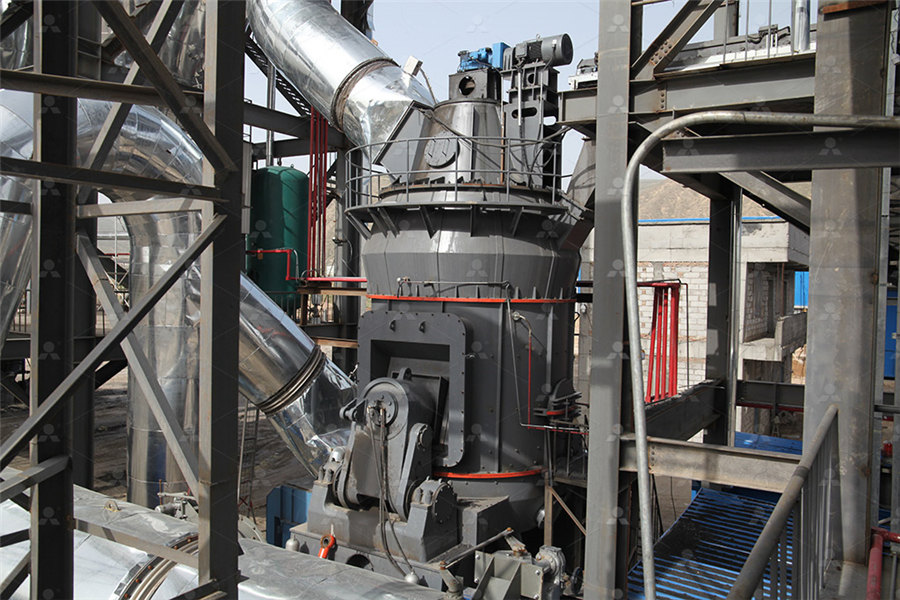

Steel Slag Grinding Plant CHAENG

Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect13 Utilization of steel slag Utilization of steel slag in various industries as raw material can provide environmental sustainability and therefore ensure the reduction in exploitation of natural resources (Yüksel, 2017)Toward the sustainable environment, the use of industrial waste can minimize the disposal of wastes to the environment which helps the environmental regulations Recent applications of steel slag in construction industry2022年2月3日 Steel is the most important ingredient in modern development, specifically infrastructural development The World Steel Association has projected growth of Indian steel demand by 73% in 2019 while the global demand is projected by 14% in 2019 (Steel Statistical Yearbook 2018)Per capita steel consumption in India is 68 kg which is far below the world Steel plant slag dumps: A potential source of groundwater

A Review on Environmental Concerns and Technological

2023年11月20日 In the twentyfirst century, steel has become one of the most utilized engineering materials, from house utensils to the automotive sector According to the World Steel Organization, the world produced a total of 1951 million tons of crude steel in 2021, in which China is the top producer of crude steel with 10328 million tonnes, followed by India and 2021年9月24日 During steel production, the impurities in the hot metal react with the fluxes forming the steel slag Chemical constituents of this steel slag (SS) are relevant to iron/steelmaking or blended cement manufacture Harmful impurities present in it, however, limit its recycling to these applications Japan, Europe, and the US consume a significant amount of BOF Steel Slag: Critical Assessment and Integrated Approach for Steel Slag Road: A Sustainable Gujarat Around 1 lakh tonne of processed steel slag aggregates developed at AMNS steel plant, Hazira, Axle Repetition) design traffic for 20year design life period and subjected on 1000 to 1200 commercial vehicles per day carrying 30 to 40 ton load for past two yearsSteel Slag Road: A Sustainable Valorization of Steel Slag as Road The Global Steel Plant Tracker (GSPT) provides information on global crude iron and steel production plants, and includes every plant currently operating with a capacity of five hundred thousand tonnes per year (ttpa) or more of crude iron or steel The GSPT also includes all plants meeting the five hundred ttpa threshold that have been ContinuedGlobal Steel Plant Tracker Global Energy Monitor

.jpg)

Review Steel slag and its applications in cement and concrete

2021年5月10日 Steel slag's usage is related to its physicochemical characteristics The density of steel slag is 33–36 g/cm 3 Steel slag is hard because of its high Fe amount and is highly resistant to corrosion The grindability index of steel slag is 07 [38] Steel slag primarily consists of SiO 2, CaO, Fe 2 O 3, FeO, Al 2 O 3, MgO, MnO, and P 2 O 5 The Company is also providing steel mill services for handling BOF Slag, etc During the year 201617, reported production of 748,836 tonnes of slag Bhilai steel plant reported production of 1,557,343 tonnes of 3 lakh fly ashbased products per day by utilising fly ash and slag generated from integrated steel plantSlagIron and Steel 2017 (2) IBM2022年2月1日 Steel slag (SS), accounting for about 15–20% of the total steel amount, has been produced in huge quantities worldwide (Han et al, 2015; Shi, 2004)Initially, SS was treated as a waste material and disposed of as landfill, which not only took up land resources but also severely impacted the natural environment and human health due to the highly alkaline leachates Environmental benefit assessment of steel slag utilization and 2011年10月26日 Multiserv Ltd, Harsco Corporation, which performs slag processing operations at the Mittal Steel Plant, supplied representative samples of BOF slag consisting of particles smaller than 15 mm The Whitesville Steel Chemical, Mineralogical, and Morphological Properties

.jpg)

Use of steel slag as sustainable construction materials: A review

2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total and , ,Recent trends in slag management utilization in the steel industry2023年11月17日 An example of slag chemistries during stainless steel production from Holappa et al (2021) is given in Table 23 where significant quantities of chromium oxide are found in the EAF slag; however, due to the high reactivity of chromium with FeO and the addition of slag reducing agents such as silicon and aluminum in the EAF, there are low levels of FeO and Electric Arc Furnace Steelmaking and Slag Formation, 2016年5月16日 In this study, aqueous mineral carbonation of Linz–Donawitz (LD) slag waste from Rourkela, Bokaro, and Tata steel industries was undertaken at a room temperature of 30°C and elevated CO2 (PDF) Sustainable Approaches for LD Slag Waste Management in Steel

.jpg)

Application of Steel Slag as an Aggregate in Concrete Production

2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the continuous use of residue yards have led to vast occupation of land resources and caused severe environmental concerns Steel slag particles can potentially be 2021年9月1日 The steel slag used in this study with a specific surface area of 1173 m 2 /kg was obtained from Hebei Jianye Steel Plant (Tangshan, China) and was classified as a basic oxygen furnace (BOF) slag Environmental benefit assessment of steel slag utilization and 2015年3月17日 Steel slag is a byproduct of the steel industry Understanding of the chemical, mineralogical, and morphological properties of steel slag are necessary for its use in sustainable practicesSteel Slag; Chemistry, Mineralogy and Morphology ResearchGate2014年7月15日 A second port basin, two new unloaders in Schwelgern, a new ore crushing and screening facility and a second sinter unit: At Schwelgern port in 1964 these were milestones marking a leap forward not just for the port but for the growth of the entire ThyssenKrupp Steel Europe mill 50 years ago today the expansion of the port was completed, increasing the mill's Schwelgern port: Major logistics hub on the Rhine handles 23

.jpg)

An Overview of Utilization of Steel Slag ScienceDirect

2012年1月1日 Benxi Iron and Steel Company produces 78,000 tons of slag steel and 89,000 tons of iron concentrate with the advanced slag hot disintegrating treatment technique and crusingscreeingbar mill dissertation) Xian: Xian University of Architecture and technology; 2005 [18] Ozeki S Properties and usage of steel plant slag 2016年5月16日 The average rate of generation of LD slag is approximately 150–180 kg per ton of crude steel in India []Researchers also found that this rate of production of LD slag somtimes reaches a high of 200 kg per ton of crude Sustainable Approaches for LD Slag Waste 2017年3月5日 Typically, the fi nal products from an integrate d mill plant are large structural sections per ton steel production) [2] 400,000 tons of steel slag are annually used as aggregates for (PDF) Iron and Steel Slags ResearchGate2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, Shi, C (1999) “Corrosion resistant cement made with steel mill byproducts” Proc, Int Symp on the Utilization of Metallurgical Slag, Steel Slag—Its Production, Processing, Characteristics, and

.jpg)

Steel slag in China: Treatment, recycling, and management

2018年8月1日 In recent years, common applications of steel slag have been road construction, concrete aggregate, cement production, and landfill materials [2, 3,5,6] 80,000 tons of steel slag was used in the Raymond mill is a common type of cement mill used in cement plant and lime calcination plant, and generally apply for the production of mineral powder or coal powder, such as the fine powder processing of raw ore, gypsum, coal and other materials Why choose Raymond mill from AGICO? AGICO Cement is one of leading raymond mill suppliers in China, we can offer any Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant2016年3月8日 It is estimated that between 70 and 75 million metric tons (77 to 83 million tons) of steel slag is used each year in the United States The primary applications for steel slag in the United States are its use as a granular base or as an aggregate material in construction applications DisposalSteel Slag Material Description User Guidelines for Waste and It is a twopurpose Production Line with two parts One is a steel slag production line with annual capacity of 300,000 million tons slag powder, and the other one is a GGBFS production line with annum capacity of 12 million tons GGBFS The main grinding equipment is designed with 2 GRMS vertical roller mills and 1 steel slag ball millSteel Slag Vertical Roller Mill

News Can steel slag Raymond mill be used to processed steel slag

If you want to further understand the characteristics and structural principles of steel slag vertical mill, please contact mkt@hcmilling or call at +86773, HCM will tailor for you the most suitable steel slag grinding mill program based on your needs, more details please check hcmilling2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water Research on the Properties of Steel Slag with Different MDPI2020年9月24日 With the rapid development of China’s steel industry, rising rates of steel production have led to the increase of steel slag emissions Steel slag is a kind of industrial solid waste produced in the process of iron and steel smelting, and its emission is about 15 wt%–20 wt% of crude steel output []According to the data released by the World Iron and Steel Sustainable Utilization of Steel Slag from Traditional Industry and Steel slag is one of the most common waste products from the steelmaking industry Conventional methods of slag disposal can cause negative impacts on humans and the environment In this paper, the process of steel and steel slag Assessment of Electric Arc Furnace (EAF) Steel Slag

Use of steel slag as sustainable construction materials: A review of

2021年6月8日 By optimizing the temperature, pressure, humidity, CO 2 concentration, reaction time, and steel slag particle size, the CO 2 capture capacity of steel slag per kilogram can reach 475169 g [16 The Raymond mill adopts a compact vertical structure, which rotate around the grinding ring As the wearing part of Raymond mill, it adopts more wearresistant alloy steel or highquality alloy carbon steel 2 Coal slag grinding plant in Highefficient Raymond Mill Fote MachineryThe Company is also providing steel mill services for handling BOF Slag, etc During the year 201415, VISL, of 3 lakh fly ashbased products per day by utilising fly ash and slag generated from integrated steel plant IISCO Steel Plant BF 3260 2330 3370 760 Slag Iron Steel 2015 IBMPlan of the Lackawanna Steel plant in Buffalo, New York ca 1903, showing the various elements of an integrated steel mill Blast furnaces of Třinec Iron and Steel Works Interior of a steel mill An integrated steel mill has all the functions for primary steel production: iron making (conversion of ore to liquid iron),; steel making (conversion of pig iron to liquid steel),Steel mill Wikipedia

Steel mill slags energy potential: the case of the steel factory of

2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants 2019年1月8日 Iron and steel manufacturing industry has been capturing CO 2 from its flue gas with carbontrapping technologies (eg: amine scrubbing, electrostatic precipitator) and recycling their waste products within the plant itself to limit excess handling and transportation of waste to disposal facilities The iron and steel slags, which are byproducts of iron and steel making Critical review of applications of iron and steel slags for carbon production data for slag were unavailable, but iron slag from blast furnaces may be estimated to be 25% to 30% of crude (pig) iron production and steel furnace slag may be estimated to be 10% to 15% of raw steel production In 2020, world iron slag production was estimated to be between 310 million and 380 million tons, and steel slagIron and Steel Slag USGS Publications Warehouse2017年12月8日 where D CO2 (m 2 /s) is the diffusivity of CO 2 species which is a function of temperature 17, δ is the film thickness (m), and k CO2 is the mass transfer coefficient (m/s) According to our CO2 Mineralization and Utilization using Steel Slag for

.jpg)

SLAG IRON AND STEEL Indian Minerals Yearbook 2017 IBM

The Company is also providing steel mill services for handling BOF Slag, etc During the year 201617, The information regarding plantwise capacity of iron and steel slag in the country is given in Table 1 163 SLAG of 3 lakh fly ashbased products per day by utilising fly ash and slag generated from