Zhejiang graphite carbon powder processing Shenzhong threering micro powder mill

.jpg)

Graphite spheroidization production lineZhejiang Leap

Graphite Mill is ideal energysaving micro powder producing equipment with good performance and high efficiency 1General Description ACM series air classifying mill, compared to current 2006年6月1日 Particle shape is a result of the manufacturing technology, the milling process and the anisotropy of the particles The particle shape can vary from spherical (graphite and Graphite and carbon powders for electrochemical applications2021年1月28日 Reported data shows that carboncontaining composites could be manufactured using graphite powder, graphene, and carbon nanotubes by SLAlike 3D printing 10Novel hybrid method to additively manufacture denser graphite 2021年8月30日 Here, we report the development of colloidal ink from commercial graphite powders that allows the fabrication of any complex architectures with tunable geometry and Threedimensional printing of complex graphite structures

Graphitic Carbon Powders for Polymer Applications

2015年1月1日 The use of synthetic graphite as main filler and carbon black and carbon fibers as minor fillers has been suggested in order to create thermally conductive pathways between 2019年9月1日 Hence, this study extensively describes a current purification method for producing highquality graphite material with impurities reaching about 10–100 mg/kg, Purification, application and current market trend of natural 2022年7月21日 Sheet carbon materials such as graphite powder (GP), graphite nanosheet (GS) and graphene (GE) would improve the performance of paste using only UC as conductive Using “intercalation bridging” to effectively improve the Applications: Calcium carbonate pulverization processing, gypsum powder processing, power plant desulfurization, nonmetallic mineral powder production, coal powder preparation, etc E JoyalThreering Micro Powder Mill,Threering Micro Powder Mill

.jpg)

Green and facile production of highquality graphene from

A novel, simple and efficient method by the combination of hydroxyl radicals and electrical exfoliation of graphite for the green production of highquality graphene from graphite was first Graphite Mill is ideal energysaving micro powder producing equipment with good performance and high efficiency ACM series air classifying mill, compared to current comminution mills, Synthetic Graphite Spheroidization Grinding Mill ACM LEAP PDF On Sep 26, 2018, Prashantha Kumar HG and others published Processing of Graphene/CNTMetal Powder Find, read and cite all the research you need on ResearchGateProcessing of Graphene/CNTMetal PowderOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] Focus on the field of micro powder grinding CLUM Series SBM Ultrafine Powder Technology Industrial

.jpg)

(PDF) Multiwalled Carbon Nanotube/Graphite Powder Film for

2022年7月30日 walled carbon nanotube/graphite powder (MWCNT@Gp) film, which has high sensitivity and great linearity and is more oriented to flexible piezoresistive sensors The sensor consists of two parts: aBrief introduction Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water Micro Powder Roller Mill for Getting Ultrafine Powder DASWELLHGM series Micro Powder Grinding Plant is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under sixSuch as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, HGM series Micro Powder Grinding Plantgrinding mill/ultrafine mill A look into the next steps of the processes involved in carbon graphite production highlights the complexity and importance of maintaining strict controls sales@metcar +19149413738; about us we will split postprocessing up into two categories, Graphitization and Impregnation, although these two processes are certainly not mutually From Powders to Parts: Carbon Graphite manufacturing Process

Micro Powder Mill Kefid

Micro Powder Mill Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for processing gypsum, calcspar, talc, and other materials used in painting, pigment and cosmetics industryPiao ZHONGYU, Professor Cited by 910 of Zhejiang University of Technology Read 77 publications Contact Piao ZHONGYUPiao ZHONGYU Professor PhD Zhejiang University of Realize powder surface modification by changing inner vortex with three rotating rotors Mature technology, low investment, suitable for stearic acid coating Selffriction generates heat, no heating device is needed, less auxiliary machine, and low operating cost Suitable for powder coatings of 325~3000 meshThreeRoller Coating Machine EPIC PowderGraphite powder manufactured by processing select natural graphite using a proprietary special refining process In addition to a purity equivalent to artificial graphite, this powder possess highly superior electrical conductivity and lubricity 003: 9997: 226: 03355: SNEFine Powder SEC CARBON,Ltd

Home Hosokawa Micron Powder Systems

2024年9月27日 Hosokawa Micron Powder Systems designs and manufactures size reduction systems and powder processing solutions for the chemical, mineral, pharmaceutical, cosmetic, food and plastic industries Hosokawa 2006年6月1日 Graphite and carbon powders occur in many different forms and emanate from many different sources A systematic classification is given based on the degree of crystallinity, from lowstructured Graphite and carbon powders for electrochemical applications HCM Machinery has whole production line for Raymond Mill, Vertical Roller Mill, Micro Powder Mill Welcome to Guilin HCM Machinery Official WebSite! mkt@hcmilling English Espanol Русский язык 简体中文Grinding Mills, Ultrafine Mills, Powder Processing EquipmentCarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine grinding mill is also called (threering fourring) mediumspeed ring roller microgrinding machineCarbon Black Ultrafine Grinding Mill

.jpg)

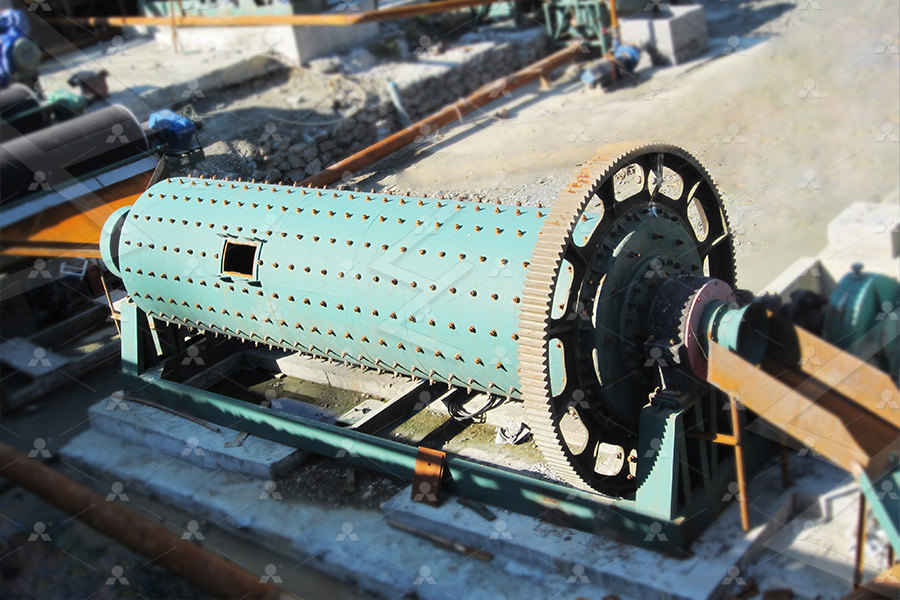

Synthetic Graphite Spheroidization Grinding Mill ACM LEAP

Synthetic Graphite Spheroidization Grinding Mill ACM LEAP Products Made In China, China Manufacturer Graphite Mill is ideal energysaving micro powder producing equipment with good performance and high efficiency 1General Description ACM series air classifying mill, compared to current comminution mills, has superior performances and is applied for varies of material Graphite Mill is ideal energysaving micro powder producing equipment with good performance and high efficiency 1General Description ACM series air classifying mill, compared to current comminution mills, has superior performances and is applied for varies of material processing, especially for thermalsensitive and fibrous materialsGraphite spheroidization production lineZhejiang Leap Models of Ultrafine Mill: HGM80, HGM90, HGM100, HGM125and HGM1680L finished production fineness: 3003000mesh(574 micron) the capacity (ton/hour) ranges: 05 to 45 ton per hour Ultrafine Mill is a device that breaks solid materials into powder by grinding, Such comminution is an important unit operation in many processesHGM Series Grinding Mill,Stone Powder making machine ,UltraFine Mill Located in Weifang city, Qinzhou Micropowder Co, Ltd Shandong is a special manufacturer of superfine black and green silicon carbide powders After several years development, our company has become one of the largest producers in the abrasive industy of ChinaSilicon Carbide Powder Manufacturer, Silicon Carbide Powder

.jpg)

Yu Zhong's research works Zhejiang University and other places

Yu Zhong's 118 research works with 8,465 citations, including: Toward Ultralow Temperature Lithium Metal Batteries: Advancing the Feasibility of 1,3‐Dioxolane Based Localized High 2018年9月26日 In recent days, the demand for powder metallurgy components has increased due to unusual combination of properties Carbon allotropes such as graphene and CNT are the novel material to enhance the properties of powder metallurgy component However, processing of such materials is in infancy stage due lack of advance processing technique This can be Processing of Graphene/CNTMetal Powder IntechOpenHas now formed three series (fluoride membrane, modified fluorinated polymer superfine powder, containing fluorine highend products) of 20 kinds of products The products are mainly applied in the field of aerospace, automotive, solar energy, energy saving and environmental protection building materials, new energy, new materials instead of shale gasPVDF Film Manufacturer, PTFE Oil Sealed Lip, PTFE MicroPowder 2019年9月1日 This study focuses on the powder processing methodology (PPM) for the fabrication of metal matrix composite using Graphite flakes (Grf) reinforced Copper (Cu)Powder processing methodology for fabrication of Copper/Graphite

.jpg)

(PDF) Spark plasma sintering of graphitealuminum

2015年7月1日 An attempt is made in this work to investigate the electrical conductivity of unreinforced graphite aluminum (Gr–Al) powder and graphite aluminum (Gr–Al) powder reinforced with 10 wt% SiC and 2022年7月30日 With the continuous progress of artificial intelligence and other manufacturing technologies, there is promising potential for wearable piezoresistive sensors in human physiological signal detection and bionic robots Here, we present a facile solutionmixing process to fabricate a multiwalled carbon nanotube/graphite powder (MWCNT@Gp) film, which has Multiwalled Carbon Nanotube/Graphite Powder Film for Work Principle of Three Ring Micro powder Grinding Machine: HGM series Three Ring Micro powder Grinding Machinemainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feeder Videos of Work Principle: https://shclirikenmadeinchinaChina Three Ring Micro Powder Grinding Machine by Audited 2017年3月1日 This chapter will review the manufacturing processes and properties of graphitic carbon powders (section “Manufacturing Processes and Properties of Graphitic Carbon Powders”), the preparation of graphitefilled polymer composites (section “GraphiteFilled Polymer Composites Processing”), and the mechanism of conduction (section “Conduction Graphitic Carbon Powders for Polymer Applications

From Powders to Parts: CARBON Graphite MANUFACTURING

Since the material needs to spend a certain amount of time in each temperature zone, it takes up to several weeks for a part to enter the oven and come out as plain carbon graphite The diagram above shows a microscopic view of “green” carbon graphite The diagram above shows carbon graphite that has been sent through the baking processJiangnan SHEN, Professor (Full) Cited by 5,240 of Zhejiang University of Technology Read 172 publications Contact Jiangnan SHENJiangnan SHEN Professor (Full) Doctor of Engineering Zhejiang 2015年1月1日 This chapter will review the manufacturing processes and properties of graphitic carbon powders (section “Manufacturing Processes and Properties of Graphitic Carbon Powders”), the preparation of graphitefilled polymer composites (section “GraphiteFilled Polymer Composites Processing”), and the mechanism of conduction (section “Conduction Graphitic Carbon Powders for Polymer ApplicationsIt mainly includes superfine powder mill, air vortex micro powder mill, soft plastic and rubber crushing, vertical screenless, turbine crushing, etc and a series of supporting equipment, crushing equipment classifier, conveyor, elevator, collector, dust collector Machine (pulse, simple), negative electrode material production line, graphite pulverizer, graphite shaping About Us Zhejiang Jacan Technology Co, Ltd

.jpg)

Effect of grain size of graphite powder in carbon paper on the

2022年11月15日 When the grain size of graphite powder increases to more than 10 μm, the thickness of carbon paper increases significantly The pyrolysis of phenolic resin and the escape of noncarbon elements during carbonization, resulting in the shrinking along the thickness direction of carbon paper Graphite powder is bonded by resin carbon in carbon paper2020年11月6日 In the early 1990s, Hemley et al theoretically predicted that C 3 N 4 has five structures, namely αC 3 N 4, βC 3 N 4, c C 3 N 4, p C 3 N 4 and gC 3 N 4 in graphite phase []Among them, organic pollutant degradation and photocatalytic hydrogen production have good prospects [2–6], graphitephase gC 3 N 4 is widely used as a nonmetallic photocatalyst in Preparation of graphite phase carbon nitride (gC3N4) micro 2022年7月21日 21 Material Ultrafine carbon powder (UC) with particle size of 100 nm was purchased from Shanghai Xiangtian nano materials Co, Ltd Graphene (GE) below 10 layers was purchased from Changzhou Sixth Element Co, Ltd Graphite nanosheet (GS) was purchased from Zhengzhou Sanyo Chemical Co, Ltd 2000 mesh graphite powder (GP) was purchased Using “intercalation bridging” to effectively improve the 2020年6月2日 Threedimensional graphene network is a promising structure for improving both the mechanical properties and functional capabilities of reinforced polymer and ceramic matrix composites However A powdermetallurgybased strategy toward threedimensional graphene

.jpg)

Titanium Powder Sintering in a Graphite Furnace and Mechanical

2017年1月23日 Recent accreditation of titanium powder products for commercial aircraft applications marks a milestone in titanium powder metallurgy Currently, powder metallurgical titanium production primarily relies on vacuum sintering This work reported on the feasibility of powder sintering in a nonvacuum furnace and the tensile properties of the assintered Ti The main hallmarks of fine impact mills are that they achieve a small particle size and have a wide range of possible applications The aim here is to ensure costeffective production and offer mills with high throughputs and optimised energy efficiency for a lot of applicationsFine Impact Mills Hosokawa AlpineGP is a powder form graphite which is easier to manufactured compared to other forms with the properties outlined in Table 5GP has been used as a functional filler for ECCC development [18,83] since it possesses low electrical resistivity around 10 –4 Ω∙cm due to its high carbon content (above 98%) and a density around 21 g/cm 3 [17]GP has also been studied as a Graphite Powder an overview ScienceDirect Topics2023年10月22日 The sp 2 hybridized allotropes of carbon are typically formed by processing graphite on commercial scale to SEM of micro graphite Full size image Fig 44 Crystal structure of graphitization at temperatures above 1000 °C the polymer segments fuse into small graphene dots which build up into graphite and finally carbon Comparison of the Synthesis, Properties, and Applications of Graphite

.jpg)

Separation and recovery of carbon powder in anodes from

2019年7月8日 Based on the structural characteristics of the anodes of lithiumion batteries, an improved Hummers’ method is proposed to recycle the anode materials of spent lithiumion batteries into grapheneAfter the raw coke materials are crushed and pulverized into a microfine powder, the next step in the graphite manufacturing process is to mill the powder in a centrifuge system This is typically the first stage of the particle size separation and selection processGraphite Manufacturing Process Flowchart MWI, Inc