Coke limestone powder production line

Lime Coating Coke (LCC) for Reduction of Nitrogen Oxide

The lime coating coke method (LCC), where coke breeze is coated with CaO materials, has been developed to decrease the nitrogen oxide (NO x) emission from iron ore sintering plants The CaO coated on the coke surface melts with the iron ore existing around LCC in the sintering bed 2023年2月15日 The whole lime production line includes: mining, crushing, screening and calcinating First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are Lime Production Process and Required Equipment2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is Decarbonising the lime industry: Stateoftheart ScienceDirectLimestone powder production line Equipment: LM vertical roller mill Material: Limestone Capacity: 25TPH Output size: 200 mesh Location: Philippines Using time: 2024Limestone powder production lineLIMING HEAVY INDUSTRY CO,

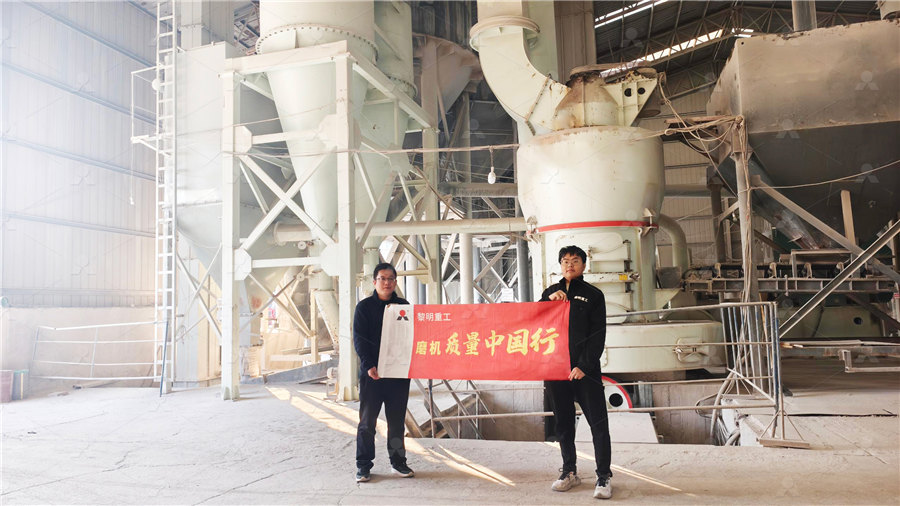

Shandong Coke Grinding Project建冶重工机械官网

In recent years, the price of coke powder rises, the user spends tens of millions of dollars to build a production line with an annual output of 60,000100,000 tonnes of highquality coke powder, 1977年5月3日 The basic processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) 1117 Lime Manufacturing US EPAThe limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields Limestone Grinding Mill Plant TAYMACHINERYLimestone production line mill is a national patent product developed by our company on the basis of absorbing modern grinding technology and concept This model adopts a series of new Limestone mill Hengtu Machinery

.jpg)

Development of Coating Granulation Process at Commercial

Coke breeze and limestone are injected from the end of the drum mixer by the belt convey or at high speed to achieve coating on the quasiparticles Because these two materials segregate description of the production process for lime, with discussions of individual lime products, limestone inputs, and costs of production Section 3 describes the characteristics, uses, and Lime Production: Industry ProfileLimestone can be used as coating material and brick and tile adhesive; it can be directly processed into stone and fired into quicklime; mixed with clay, etc, and calcined at high temperature to obtain cement; mixed with quartz sand, soda Limestone Mobile Crushing Production Line2017年7月7日 Limestone is also a very important industrial mineral Its chemical properties make it a valuable mineral for a wide range of industrial/manufacturing uses Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weightLimestone – Its Processing and Application in Iron and

Limestone Powder SHC Group Vietnam SHC

2017年7月9日 No18 Son Ha Minerals Co, Ltd is one of the leading manufacturer and supplier limestone powder at Vietnam We are pleased to introduce limestone powder production process to customers to more Industrial Mineral Processing Machine Coal Drum Rotary Dryer for Gypsum, Sand, Cement, Slag, Slurry, Limestone, Ore Powder, Ferromanganese Slag, Coke Coal US$19,80000 1 Set (MOQ)Industrial Mineral Processing Machine Coal Drum Rotary Dryer for 2020年3月7日 The complete limestone powder production line Successful cases: 1 316tph limestone powder in Pakistan Material: limestone; Feeding size:030mm; Discharging granularity:200 mesh; Use for: Road ore powder and asphalt mixing station; Needed machines: PE jaw crusher, PF impact rock crusher, Φ1500*5700 ball mill;Limestone Powder: Uses, Price and Production HongXing 2024年10月17日 In this article, we discuss the basic stages in the production of castiron Raw Materials Cast iron is produced with pig iron along with coke, limestone and often other such as grinding, cutting, and drilling as required Surface finishing techniques, including painting, galvanising, or powder coating, are applied to improve Cast iron production Architextures

.jpg)

Steel Production American Iron and Steel Institute

The blast furnace uses coke, iron ore and limestone to produce pig iron Coal traditionally has been a key part of the cokemaking process The coal is crushed and ground into a powder and then charged into an oven where it is heated to approximately 1800°F in the absence of oxygen114 Calcium Carbide Manufacturing 1141 General Calcium carbide (CaC2) is manufactured by heating a lime and carbon mixture to 2000 to 2100°C (3632 to 3812°F) in an electric arc furnace At those temperatures, the lime is reduced by114 Calcium Carbide Manufacturing US Environmental 2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLink2018年8月30日 Limestone powder is a byproduct of the limestone quarry, and it has been used in cementbased materials for many years In 1938, Bessey [6] first reported that CaCO 3 could react with cement to form calciumcarboaluminate The formation of calciumcarboaluminate was influenced by the amount and fineness of LS, but it had little effect on the compressive A review on use of limestone powder in cementbased materials

.jpg)

Simulation of calcium acetylide and acetylene production Sciendo

is the production of calcium acetylide This substance is obtained from coke and limestone in an electric arc furnace at elevated temperatures Raw materials used in this process contain relatively large amounts of impurities that are converted and entrapped in the desired product of the above reaction Some of theLimestone can be divided into four different specifications according to the pulverization fineness: single fly powder (95% through 200 mesh), double fly powder (about 99% through 325 mesh), and three fly powder (about 999% Limestone mill Hengtu MachineryThe limestone fertilizer production line is to make lim Fertilizer Machine Production Line Phone Whatsapp: +86 Home; About us; Fertilizer Equipment Fertilizer Product Line; Mixing: The limestone powder can be mixed with other components such as ammonium nitrate, Limestone Fertilizer Production Line2017年12月9日 As shown in Fig 42 most of the Portland limestone and composite cements conform to the 325 and 425 strength classes, although “very high strength” 525 Portland limestone cements are also produced Most countries around the world specify similar chemical and physical requirements for the limestone that can be used, including a minimum CaCO 3 Limestone Powder SpringerLink

.jpg)

(PDF) i) Direct Reduced Iron: Production ResearchGate

2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New Yorkrials including iron ore and limestone Two types of coated coke were prepared: CaO coating (LCC) and mixedpowder coating of CaO and iron ore fines (CFCC) To understand the appropriate coating layer height and quantity, the blending ratio of the coating materials to the coke breeze was changed from 0 to 20 wt% (CaO/coke)Lime Coating Coke (LCC) for Reduction of Nitrogen Oxide The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of limestone powder as a partial cement replacement, in order to reduce energy consumption and CO2 emissions This study utilizes limestone powders, with different particle sizes, to replace Evaluation of the Efficiency of Limestone Powder in Concrete and HCH1395 Limestone Ultrafine Grinding Mill for Powder Production 10μm 45TPH HC1700 limestone grinding mill plant project, 300mesh 1318TPH 5R4119 Raymond Roller Mill for Bentonite Powder Making 200 Mesh 8TPHPowder Processing Equipment Production Line HongCheng

122 Coke Production

122 Coke Production 1221 General Metallurgical coke is produced by destructive distillation of coal in coke ovens Prepared coal is "coked", or heated in an oxygenfree atmosphere until all volatile components in the coal evaporate The material remaining is called coke42 Energy use and emissions The lime production process is energy intensive and results in CO 2 emissions from both mineralogical transformation process and energy used The production of one tonne of lime entails the emission of around 12 tonne of CO 2 (Ochoa George et al, 2010; Sagastume Gutiérrez et al, 2012)This makes lime one of the products with the highest Lime Production an overview ScienceDirect TopicsPetroleum Coke Composition The specific chemical composition of Petcoke depends on the composition of the petroleum feedstock used in refining Petcoke is primarily carbon based but other elements, such as nitrogen, sulphur, nickel are also captured within Petcoke’scarbon matrix Petroleum Coke PropertiesPetroleum Coke in the Cement IndustryHistory Patch 0829: Some improvements to Pipe SFX causing hitches/stuttering in factories with a lot of Refineries/Blenders built; Patch 0820: Fixed an Audio issue leading to performance hitches in factories with Refineries, including audio optimizations for the Refinery; Patch 036: New visuals Slightly smaller size (width from 12 m to 10 m and height from 30 m to 21 m), can Refinery Official Satisfactory Wiki

Understanding the Steel Making Process: A Flow

2024年3月20日 The article provides an overview of the steel making process, detailing how raw materials like iron ore, coke, and limestone are transformed into versatile and durable steel through a complex series of steps depicted in a 2024年4月25日 Phase I: tetragonal, stable between 25 and 440 °C (dominant in commercial carbide) Phases II and III: lower symmetry, stable below 440 °C Phase IV: facecentered cubic, stable above 440 °C The heat of transformation at 440°C is 868 J/g Notably, the CaC 2CaO phase diagram exhibits a simple eutectic behavior, with no compound formation or solid Calcium Carbide: Properties, Production and Uses2016年10月28日 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slagforming elements and coke The purpose of sintering is to obtain a product with suitable Iron Ore Sintering: Raw Materials and Granulation ResearchGateIn cement production line, most of the cement raw materials must be broken, such as limestone, clay, iron ore and coal cement, limestone, titanium iron powder, alum ore, activated carbon, coke, mineral powder, alumina, magnesium oxide, Rotary Cooler Clinker Cooler In Cement Plant AGICO CEMENT

.jpg)

Cement Clinker Production an overview ScienceDirect Topics

As an alternative replacement of clay, sewage sludge is also combined with other solid waste in cement production Lin and Lin (2004; 2005) used different types of waste sludge ash, including sewage sludge ash, water purification sludge ash and steel slag and limestone, as raw components for the production of ecocement clinkers by burning at 1400 °C for 6 hThe whole grinding line is used for limestone powder production, the capacity is 4t/h, 15TPH LM1300 Petroleum Coke Grinding Mill; 10 Microns 4TPH Limestone Micro Powder Pr; Contact Us Tel: 0086371; WhatsApp: 50; : mill@liminghi 10 Microns 4TPH Limestone Micro Powder Production Plant China Limestone Powder Processing Machine wholesale Limestone Slag Coke Gangue Coal 1 / 6 Favorites Mining Outlet Powder Coating Equipment Machine for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line US$ 100050000 / set 1 set (MOQ) Shanghai Clirik Machinery Co, Limestone Powder Processing Machine MadeinChina333 I SUMMARY This profile envisages the establishment of a plant for the production of 10,000 tonnes of lime per annum The present demand for the proposed product is estimated to be 28,000 tonnes per annum and it is33 PROFILE ON LIME PRODUCTION

Limestone Pellets Granulating Production Line

If you need a plan for turn limestone into granules in a small scale, which is about 15 t/h Disc granulation line is an ideal choice for you For one thing, it can fully meet your requirement to prepare 15 tons of limestone pellets per hourpowder so the waste material called gangue can be removed The remaining ironrich powder is rolled into balls and fired in a furnace to produce strong, marblesized pellets that contain 60% to 65% iron Sinter is produced from fine raw ore, small coke, sandsized limestone and numerous other steel plant waste materials that contain some ironHOW A BLAST FURNACE WORKS Foundry Gate2015年11月26日 Coproduction of DRI Powder and Semicoke from Siderite Ore and Low Rank Coal by Excessive Coalbased Direct Reduction in Rotary Kiln November 2015 ISIJ International 56(1)(PDF) Coproduction of DRI Powder and Semicoke Benefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the lifetime of its wearing Limestone Powder Grinding Mill Machinery

Clinker Production an overview ScienceDirect Topics

In another study by Her et al [151], eggshell powder was used as an alternative to limestone for the production of OPC clinker Similar to municipal and industrial wastes, the application of ASW in clinker and cement production is an emerging technology that needs comprehensive research to realize its engineering performance and carbonsaving potentialThe limestone is removed from the earth by blasting with explosives It is then crushed and screened to a size that ranges from 05 inch to 15 inch to become blast furnace flux This flux can be pure high calcium limestone, dolomitic limestone containing magnesia or a blend of the two types of limestoneThe Blast Furnacecoke ovens, known as batteries During this process, byproducts are removed and coke is produced Blast Furnace The raw materials – iron ore, coke and fluxes (minerals such as limestone which are used to collect impurities) – are fed into the top of the blast furnace Air is heated to about 1200°C and is blown into the furnace throughSECTION FOUR HOW IS COAL USED?Introduction The production of iron from its ore involves a redox reaction carried out in a blast furnace The furnace is filled at the top with the iron ore oxide most commonly hematite (\(Fe2O3\)) but can also magnetite (\(Fe3O4\)), carbon Iron Production Chemistry LibreTexts

cases

Limestone powder making plant – 10 TPH limestone; 200 mesh D90; glass industry; Calcined petroleum coke powder making plant – 7 TPH Calcined coke; 200 mesh D70; SOLUTION Ground Calcium Carbonate(GCC) Grinding Mill; Coal powder preparation project; Gypsum Powder Production Line; Grinding mill for Calcium carbonate; Limestone powder 2021年8月16日 Suitable coke selection enhances the steel production line, saves coke utilisation, minimises dust generation, reduces the significant amount of greenhouse gases discharged into the atmosphere Particle Size Distribution Models for Metallurgical Coke Grinding