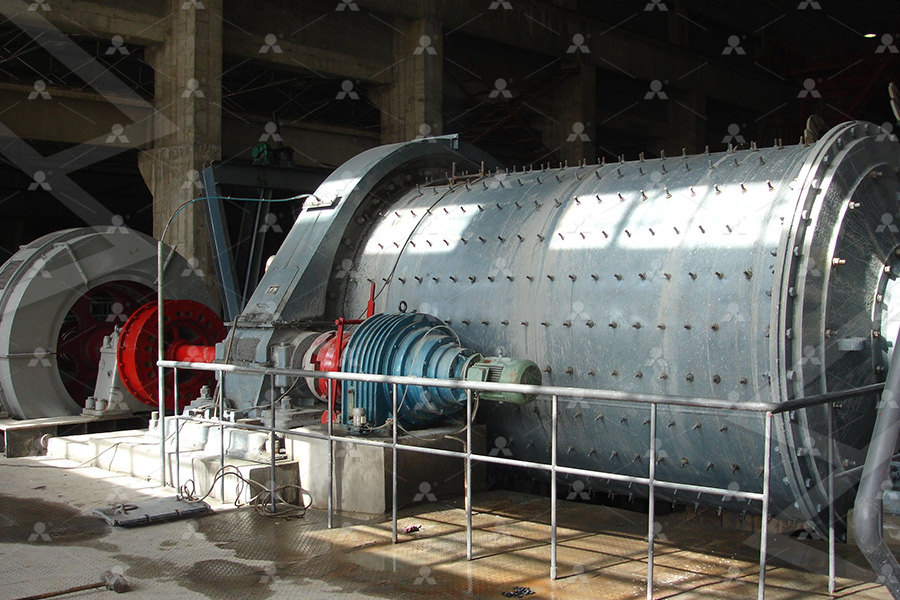

Ore mill mill

.jpg)

Mills for minerals and ores Loesche

The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been 2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validated The model makes use of Analysis and validation of a runofmine ore grinding mill circuit Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 UNDErsTaNDINg MINE TO MILL 911 Metallurgist2024年1月1日 Ore grinding is completed in the cylinder of the grinding mill With a certain amount of grinding medium in the cylinder, when the cylinder rotates, the grinding medium is Ore Grinding SpringerLink

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the Grinding mills operate on the principle of breaking down ore particles into smaller sizes through the action of abrasion The primary types of grinding mills include ball mills, rod mills, Understanding the operation of grinding mills in the mining and 2009年6月1日 Four different laboratory ball mills and stirred mills have been tested to grind seven ore samples with feed sizes ranging from 335 mm to 150 μm A case study on full Comparison of energy efficiency between ball mills and stirred 2018年11月21日 Effort and insights from mineralogical and processing characterisation (eg ore hardness) of subore body domains allows sequencing for processing to ensure consistency Dynamic concepts for mine to mill operation and optimisation

Development of ore sorting and its impact on mineral processing

2014年10月15日 The goal of ore sorting is to reduce the total amount of material sent to the high energy milling circuit, while not significantly impacting total metal recovery In general, ore 2023年10月17日 Type of Ore powder grinding mil 1 Raymond mill Raymond mill feed particle size ≤30mm, production capacity 8176 tons/day, production fineness 80325 mesh, the main transmission device adopts sealed gearbox How to choose a suitable ore powder grinding mill?HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: 2023年4月23日 Comminution includes the blasting, crushing, and grinding of ore to liberate valuable mineral particles One of the most used tumbling mills is the ball mill(PDF) Grinding Media in Ball MillsA Review ResearchGateNestled in the heart of “Ontario’s most beautiful village”, the Elora Mill Hotel Spa is a oneofakind destination that offers our guests access to bespoke accommodation and worldclass comfortElora Mill Hotel Spa Anything but Ordinary2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911Metallurgist

.jpg)

Monitoring ore loss and dilution for minetomill integration in

However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this study that the MCF should be seen as a method that identify the real problems underground and when these are addressed, the profitability of SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore GrindabilityThe ore ball mill designed by our company, which is represented by gold ore ball mill and iron ore ball mill, is manufactured with highquality materials and advanced technology They have the characteristics of high efficiency, energy Buy Ore Ball Mill for Mineral Processing Iron Gold 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911Metallurgist

.jpg)

Recycling of steel plant mill scale via iron ore sintering

The raw materials used for the preparation of the green pellets are iron ore, mill scale, limestone, bentonite and Corex sludge and their chemical composition is given in Table 1 Iron ore fines of –10 mm size and mill scale of –6 mm were mill n (printer) 번역할 수 없음 : The federal reserve ran some more money out of the mill to keep interest rates low mill n: figurative, pejorative (school) (학교를 일컫음, 비방, 비유) 공장, 찍어내는 곳 명 : That school is a worthless diploma mill mill n (fight) 주먹질 명 : mill WordReference 영한 사전The Ore Sawmill is a Reborntier utility upgrader added in the Reincarnation Update It was first revealed in a screenshot on Foxy's Twitter The Ore Sawmill has a unique hybrid function that duplicates ore, but also halves both their value and size Ores may be duplicated again with the Ore Replicator The description is a parody of a nowinfamous infomercial for Flex Tape, a Ore Sawmill The Miner's Haven Wikia FandomWith 20 years of experience in the industry, we are excited to present our vision to you and all our guests Our caring and committed staff strive to ensure you have a fantastic experience with usOre Mill Bar Grille

Black Mill, Ore – The Mills Archive

Mill: Black Mill, Ore A windpowered corn mill in the historic county of Sussex, England See related images and documents See images only Full details Power source : Wind: Mill type : Smock mill: Mill function : Corn mill: Archive ID :2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration in CRC ORE and Mine to Mill expert Don McKee released a publication entitled Understanding Mine to Mill The publication documents the history of Mine to Mill, explaining the concept in simple terms along with the elements and keys to successful implementationUnderstanding Mine to Mill CEEC (Coalition for Eco Efficient The costeffectiveness of SAG and AG mills will depend on various factors, including the size of the mill, the ore properties, and the required throughput Generally, AG mills have lower capital and maintenance costs, but SAG mills may offer higher efficiencies for larger operationsWhat is the difference between SAG and AG mill? ball mills

SAG Mill Testing Test Procedures to Characterize Ore

ball mill index values for a given ore type (McKen, Verret, Williams, 2006) On average, the rod and ball mill indices are essentially equal, but the ratio between the two can be quite variable High RWI/ BWI ratios indicate competent ores with low ball mill hardness, while low ratiosWater Mill Residence, New York Photo by Paul Domzal ORE was commissioned to design a multigenerational home for a family, sited at the edge of a natural swale, on six acres in Water Mill, New York ORE’s first groundup project is sited adjacent to ORE Design + Technology » WATER MILL2023年11月24日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Ores have different abrasiveness owing to their mineralogical composition Quartz is one of the most pervasive abrasive materials in Grinding Media in Ball Mills for Mineral Processing2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral Processing

Ore Crushing, Sand Making, Grinding Machinery Bellian Mining

Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your Horizontal ball mill and vertical Raymond mill can be used for milling of 200+ ores, with a fineness of 1002500 mesh View Now Mobile Crushers Mining Crusher SBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine grinding mill, Our main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial Grinding Mill, If a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than Ball Mill (Ball Mills Explained) saVRee saVRee2023年6月7日 In the grinding mill, the ore blocks sized >100 mm function as grinding medium The ore particles smaller than 80 mm but bigger than 20 mm have poor grindability and they cannot be easily ground by big lump ore, so such material Autogenous Mill SpringerLink

Common Basic Formulas for Mineral Processing Calculations

2016年3月21日 Mill Water to Ore Ratio Requirements Resistance of Various Materials to Crushing Pulp Calculations W—Tons of solids per 24 hours R—Ratio of weights: solution/solids V—Ratio of volumes: solution/solids L—Specific gravity, solution P—Specific gravity, pulp2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill management2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O3Recycling of steel plant mill scale via iron ore ResearchGate2023年1月1日 Further, ball mill and stirred mill experiments were performed at different grinding time intervals to optimize the grinding mill for lowgrade PGE bearing chromite ore The primary aim of the present study is to optimize an energyefficient grinding circuit for lowgrade PGE bearing chromite oreSize reduction performance evaluation of HPGR/ball mill and

Thermal Analysis Study on the Carbothermic

2015年7月1日 This paper presents a fundamental study on the carbothermic reduction of chromite ore with the addition of mill scale, which forms the basis for designing an alloying precursor, “chromite ore 2016年4月22日 In all ore dressing and milling processes, including flotation, cyanidation, gravity concentration, and amalgamation, it is necessary to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mill Rod Mill Design 911Metallurgist2013年7月15日 For any circuit, whether a crushing circuit, a rod mill, or a closed ball mill circuit, the Work Index always means the equivalent amount of energy to reduce one ton of the ore from a very large size to 100 um The sample was received crushed appropriately for the ball mill testBond Work Index FormulaEquation 911Metallurgist2012年4月1日 During the processing of steel in steel mills, iron oxides will form on the surface of the metal These oxides, known as mill scale, occur during continuous casting, reheating and hot rolling operations Mill scale is a valuable metallurgical raw material since it contains 65–70% iron JSW Steel Ltd is a 7 Mtpa integrated steel plant and generates 270 t of mill scale per day Recycling of steel plant mill scale via iron ore sintering plant

.jpg)

What’s the difference of Ball mill, SAG mill, AG mill? Baichy

2023年6月6日 Attrition mill is a type of grinding mill by kinds of media to crush lump to powderlike substances The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod Mills2021年9月23日 Recommended barite grinding mill: In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a professional manufacturer of milling equipment for the ore industryBarite Industrial Ultrafine Grinding Mill SBM Ultrafine Powder 2021年4月19日 PDF Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, increased volumes of primary ores need to be mined(PDF) Feasibility and necessity of mine to mill ResearchGate2022年4月8日 NO and SO2 are representative harmful gases generated in steel works, and iron ore sintering process accounts for more than 50 pct of total generation The current study investigated the effects of adding CaO and FeO, which are the components contained in raw materials to sinter mix on the formation of NO and SO2 The addition of CaO to sinter mix Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix