Can smokeless Raymond mill process coal powder

Raymond® Bowl Mill Coperion

Handles variety of fuels–accepts bituminous, subbituminous and lignite coals and petroleum coke with initial moisture content as high as 40% for lignites Flexibility–available with both dynamic and static classifiers, spring or 2024年11月20日 The Raymond mill is widely used for grinding coal into fine powder, making it ideal for use in industries such as power generation, cement manufacturing, metallurgy, and Raymond Grinding Mill for Coal Powder Making PlantThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersRaymond® Roller Mills CoperionMaterials: Raymond mill is used to process gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black powder, coal powder, various rubber powder, alum and other chemical powdersKaolin Raymond Mill SBM Ultrafine Powder Technology

RAYMOND® ROLLER MILLS Thomasnet

Each roller mill system is custom designed to achieve the best solution for your processing application The mill, feeder, classifier, fan, cyclone, dust collector and other system 2012年10月19日 The whole Raymond grinding mill is of the standard structure It attributes tiny occupying area and powerful integration capacity It could possibly form an independent Raymond Mill Utilized For Coal Powder Manufacturing Plant 博客园It can process a wide range of materials, including calcite, limestone, dolomite, and coal, into fine powders with a consistent particle size High Precision: The machine is equipped with Raymond mill: A pioneer in the grinding industryAs a production line for grinding nonmetallic minerals, the Raymond mill machine is commonly used in coal mines, metallurgy, and mines with a Mohs hardness of less than 93 and a humidity below 6% In addition to its simplicity, convenient Raymond Mill Machine Manufacturing Dura Mortar

.jpg)

Kaolin Raymond Mill SBM Ultrafine Powder

Kaolin Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 135 t/h Materials: Raymond mill is used to process gypsum powder, talc powder, titanium dioxide powder, bone meal, shell powder, carbon black Choosing the Right Vertical Mill for 200 Mesh Coal Powder Preparation 1 Type of Vertical Mill There are several types of vertical mills used in coal powder preparation, each with its own characteristics and advantages The key types include: Raymond Mill: Known for its versatility and reliability, the Raymond mill is suitable for the Choosing the right vertical mill for 200 mesh coal powder Mills Powder Engineering RM Raymond Mill Manufacturer Widely applied to various nonflammable and explosive ores with Mohs hardness below 7 and moisture below 6%, such as calcium carbonate, graphite, bentonite, RM Raymond Mill – Jinghua Powder Engineering2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill Machine

.jpg)

Raymond Mill,Raymond Roller Mill,Raymond Grinding Mill,Raymond Mill

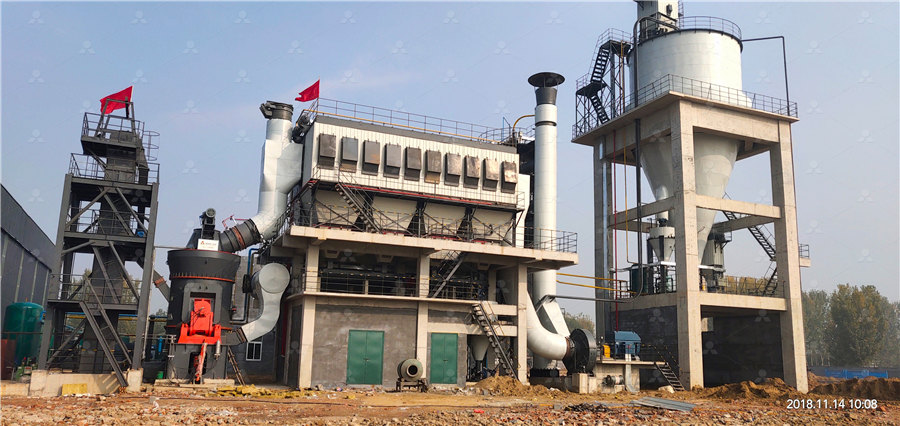

Raymond Mill Price Shanghai Clirik Machinery, 25 years on Raymond mill producing You are alwyas warmly welcomed to contact or visit us Our engineers will design the most suitable solution for your project If you want to know the Raymond mill price,please leave you and tel,We wlll send the raymond mill details and price【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC MachineRaymond mill, widely used in minerals grinding process of metallurgy, building gypsum crushing processing, power plant desulfurization, nonmetallic ore pulverizing, pulverized coal preparation Capacity: 0895T/H Input LM130N Vertical Mill, Process slag, 325mesh, 6tph Output size:150200 mesh LM130N Vertical Mill, Process slag Raymond mill, raymond mill price, raymond mill manufacturer, raymond Charcoal Raymond mill is a heavyduty mill with extremely strong crushing powerIt can process all kinds of nonflammable and nonexplosive raw materials with Mohs hardness of less than 7 Including ores, coal, charcoal, ceramics, etcPabrik Arang Raymond Mesin Penggilingan Bubuk Batubara

.jpg)

How Is Smokeless Coal Made? Pearson Fuels

2018年9月12日 The benefits of smokeless coal and what not to do Smokeless coal is a solid fuel that doesn’t emit any visible smoke or emits a very minimal amount of smoke This type of fuel is very popular for open fires, or places where there is a fuel ban on unseasoned wood and coal etc What not to do when burning smokeless coal Never burn wet []Through crushing and processing, raw materials are converted into fine powder to meet the production needs of various industries In addition, by adjusting the analyzer’s speed and air volume, the produced powder’s fineness can be precisely controlled JXSC raymond mill is a complete set that can form a production system independentlyRaymond Mill JXSC Machinery2023年2月15日 Main parts of Raymond roller mill Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, Raymond mill pendulum, star stack, etc Main Raymond Roller Mill PartsUltimate Guide Fote What Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is Raymond Mills Raymond Roller Mill Grinding Mill

Coal mill manufacturer ChinaCoal pulverizer design in powder

In thermal power plant, coal mill pulverizer is used in the milling process to crush and grind coal into powder Raymond mill can be used grinding coal into powder with finess from 100 mesh to 325 mesh according to the requirements Raymond roller mill is also used in mining, construction, chemical industry, Mill connection: the circulating fan is connected to the explosionproof bag dust collector and the inert gas supplement pipe: the inert gas supplement pipe is connected to a heat source system that supplements the low oxygen content heat source gas to the pulverized coal vertical mill to control the low oxygen in the extracorporeal circulation system The limiting oxygen content What is the process flow of vertical mill to produce pulverized coal?Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, It is an upgraded Raymond mill for making micro powder and fine powder Widely applied in metallurgy, mining, chemical, it can process materials with 15% humidityPowder Grinding Mills Engineered by FTM Fote MachineryRaymond Mill Raymond mill is suitable for preparation of various mineral powder and pulverized coal, also called high pressure roller mill After longterm research and development, Zenith has developed the upgrading products of Raymond mill MTM series medium speed trapezium mill and MTW series trapezium mill Feed Size: 035mmRaymond Mill, Raymond Mill Technical Innovation

Highefficient Raymond Mill Fote Machinery

The powder production process of Raymond mill is feedingcrushinggrindingselectingcollecting, 10 – 15 TPH gypsum powder grinding process Yes! I'm interested 2 Coal slag grinding plant in Thailand Output 300 kiloton/annually Finished particle size 100 mesh (0149 mm) Raw material 2023年8月29日 Powder Fineness: 50400 mesh The high pressure mill, also known as the high pressure overhang roller mill or swing mill, is an upgraded version of the Raymond mill It utilizes closed circulation to process fine powder and enhances output and What is The Secondary Application of Industrial Waste Fly Ash?The coal powder produced by Fote Raymond mill meets the fineness requirements well Our clients keep placing orders with us Besides, thanks very much to engineer, Alan Lee for his patience Applications of Raymond Grinding Mill Raymond grinding mill can process over 200 kinds of nonflammable and nonexplosive materialsRaymond Roller Mills Fote Machinery (FTM)2021年6月16日 This article will introduce to you 400 mesh alumina powder Raymond vertical mill Home; The microcomputer system controls the entire process of material grinding, and can automatically configure an ideal three roller mill It is suitable for the preparation of ore powder and coal powder, such as the fine powder 400 Mesh Alumina Powder Processing Machine CLIRIK Raymond

.jpg)

Raymond Ultrafine Mill Qlar

The Raymond Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate products as fine as 50% passing 2 microns or as coarse as 50% passing 10 microns2024年1月11日 The 5step process to pulverize coal efficiently The coal pulverization process involves a precise sequence of steps Each is systematically designed to convert raw coal into a fine, efficient powder But How to Process Coal into Pulverized Coal in 5 Steps?Raymond mill is suitable for the preparation of various mineral powders and coal powder Henan Wood Machinery Co, Ltd the Raymond mill can meet the requirements of and it is also easy to block during the feeding and conveying process, which causes the ability of Raymond to reduce Parameters of Raymond mill Model: WDRM3R1410: WD Raymond Mill Superfine Charcoal Powder Grinding Machine2023年9月18日 Raymond mill is a type of stone grinder to grind several types of such as mineral processing and powder milling They can be used to process various kinds of materials, including limestone, gypsum, coal, talc, quartz stone, and other minerals In addition to this, they can also be used for grinding and polishing hard Raymond Grinding Mill: The Ultimate Guide From SMAT Machinery

Coal mill pulverizer in thermal power plants PPT SlideShare

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill hot air inlet temperatures should never be more than 600 ° F and the outlet temperature should not exceed 200°F on Raymond coal mills If the flow of raw coal to the coal mill is interrupted for any reason (for example: plugging, failure of the coal feeder, etc), the outlet temperature of the coal mill can quickly climb to coal feeders and coal mill CapabuildRaymond roller grinding mill is mainly applicable to the grinding and processing of mineral product materials such as metallurgy, building materials, chemicals, and mines Raymond mill can process various nonflammable and nonexplosive mineral materials with Mohs hardness below 6 and humidity less than 6%Raymond Roller Grinding MillReview of control and fault diagnosis methods applied to coal mills V Agrawal, PMV Subbarao, in Journal of Process Control, 2015 1 Introduction Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for Coal Mill an overview ScienceDirect Topics

.jpg)

Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

The introduction of hot air helps to improve the drying effect of coal powder and carries coal powder into the coal mill shell during the coal grinding process Coal Powder Conveying System The pulverized coal conveying system is used to transport pulverized coal from the pulverizer to the target location, such as a combustion furnace or a pulverized coal storage bin2024年7月31日 Raymond mill is mainly used as a piece of common mining equipment, which is mainly suitable for grinding various minerals, chemicals, construction, and other industries of more than 300 kinds of materials with Raymond Mill For Making Fine Charcoal Powder2024年1月30日 Raymond mill maintenance focuses on the following aspects: Lubrication: Regularly inspect and replace lubricating oil to ensure proper lubrication of all components and reduce wear Inspection: Regularly inspect all parts of the Raymond mill, such as grinding rollers, grinding rings, and analyzers, and promptly replace worn or damaged parts to prevent Failure Raymond Mill Maintenance Guide: Prolonging Service Life, Output: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt Raymond mill, Raymond grinding mill All industrial

.jpg)

CLRM series Raymond mill SBM Ultrafine Powder Technology

CLRM series Raymond mill Discharge fineness: 80500 mesh Feed size: 35 mm Output: 135 t/h Materials: Quartz, feldspar, barite, carbonate calcite, limestone, talc, ceramics, iron ore, emery, bauxite, phosphate rock, coal and other materials, a total of about 400 kinds of materials2015年7月6日 1 Fly ash Raymond Mill,Fly ash Powder Processing Plant Fly Ash Applications Fly ash is a fine powder recovered from coalfires electric generation power plants Fly ash could be an expensive replacement for Portland cement in concrete and using it, improves strength, segregation and ease of pumping concreteFly ash raymond mill,fly ash powder processing plant PDFIndustrial Raymond mill, also known as YGM Raymond mill and Raymond machine, is a high efficiency pulverizing mill that replaces ball mills to process ore powder +17 [ protected]YGM Industrial Raymond Mill SBM Ultrafine Powder Technology2019年1月27日 But like any fuel, smokeless needs to be used properly in order to get the best from it Here’s five common issues/hints and tips with smokeless fuel: Always Clear The Grate and Ashpan Before Lighting a Smokeless Fire Mineral fuels such as coal need air from below to combust, so it’s important air can flow through the fire5 Common Mistakes When Using Smokeless Fuel Mr Soot Chimney Sweep

Raymond Roller Mill airswept vertical ringroll

A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardness There are a few limitations, but the most practical are soft to medium hard materials They can also be used to prepare feed for systems producing ultrafine materials, such as a Raymond Vertical mill, ball mill or JetStream Classifier system2024年3月22日 The Raymond mill offers versatility in grinding as it can effectively process a diverse range of materials including limestone, gypsum, calcite, dolomite, barite, marble, talc, coal powder, and more This broad applicability makes it a valuable tool for various industries requiring finely ground materials for their processesHow Does a Raymond Roller Mill Work Raymond Grinding Mill The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY