How many meshes are generally used for tailings limestone

.jpg)

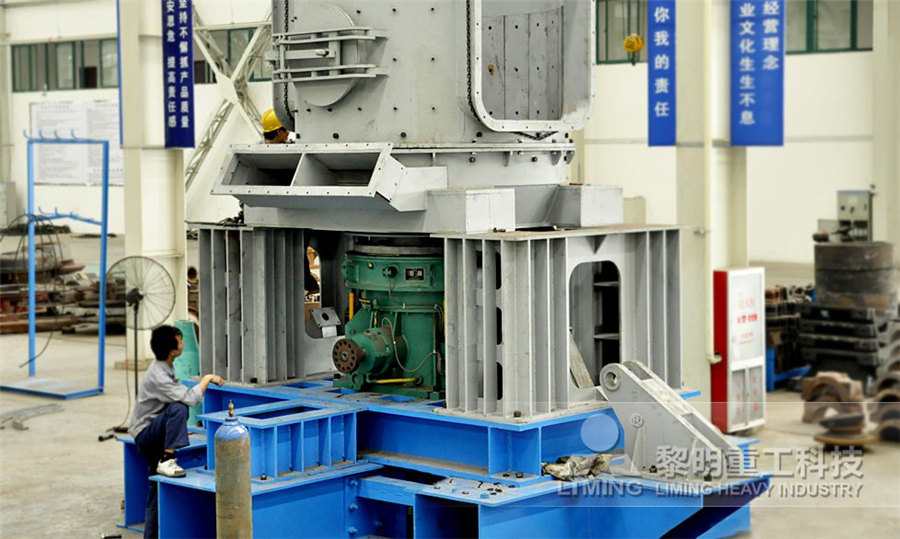

Highefficiency utilization of limestone tailings: Used as

2022年1月17日 To increase the utilization rate of limestone tailings and desulfurization gypsum and reduce the cement clinker and sodium hydroxide admixture, the optimal proportion is selected within the range of 50%70% of limestone tailings, 6%10% of desulfurization gypsum, 4% 2016年12月19日 Mine tailings include processaffected water, containing dissolved metals and ore processing reagents and finegrained groundup rocks after minerals of value have been Process effluents and mine tailings: sources, effects and 2018年10月15日 Generally, there are three categories of uses: first, reprocess to concentrate and recover valuable metals or minerals from tailings; second, use as a filler to backfill mined An extensive review on restoration technologies for mining tailings2024年1月1日 Kim and Park (2020) report on an advanced synthetic process that produces wearresistant glass ceramics from mining wastes and smelting byproducts (mixing gold Mine tailings ScienceDirect

A review on different methods of activating tailings to improve

2020年9月15日 Activation methods have been used for both tailings and slags Depending on the type of tailing and slag, an appropriate activation method is selected and used The main tailings are most commonly stored on site in a tailings storage facility Storage methods for conventional tailings include crossvalley and paddock (ringdyke) impoundments, where the CHAPTER II Global Tailings Review2010年1月1日 More than 99% of the original material mined may finally become tailings when lowgrade metal ores are utilized Tailings represent, therefore, the most voluminous waste at Tailings SpringerLinkTailings are the materials left over following the processing of mined ore that separates the valuable metals or minerals from the host rock Tailings are not the same as waste rock, the TAILINGS FACTSHEET Anglo American plc

制粉-10.25公众号.jpg)

Sustainable use of mine waste and tailings with suitable admixture

Utilization of mine waste rocks and tailings in concrete as aggregates will help in sustainable and greener development The literature shows the potential use of iron ore tailings as a Tailings facilities must be constructed in such a manner as to protect people, downstream property and the environment Tailings are generally contained in some type of impoundment, which is buttressed by a tailings dam This paper What are Tailings Society for Mining, Metallurgy2016年12月31日 All content in this area was uploaded by Harley Lacy on May 03, 2020Closure and Rehabilitation of Tailings Storage 2024年5月16日 Many people use limestone and lime interchangeably when referring to aglime Lime also helps manage mine waste products like slurry, tailings, and acid drainage Manufacturers use lime in numerous products: Lime vs Limestone Rock: Types and Uses of Each

.jpg)

Iron Ore Tailings: Characterization and Applications

2021年1月1日 tailings generally comprise particles average size of 100 µm but with some particles up to 1000 µ m 48 Figure 4 presents information about the size of IOT particles from different2023年10月21日 Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO3) in the form of mineral calcite or aragoniteIt is one of the most common and widely distributed rocks on Earth, with a wide range of uses in various industries and natural settings Limestone forms through the accumulation and compaction of marine organisms, primarily the Limestone Types, Properties, Composition, Formation, Uses2022年1月17日 Wang et al [9] combined limestone tailing sand with optimized limestone tailingbased cementitious material as karst backfill material to improve the performance of the backfill material by optimizing the pore structure This karst backfill material effectively utilized limestone tailings with utilization rates ranging from 875% to 9375%Highefficiency utilization of limestone tailings: Used as 3 Tailings facilities must be constructed in such a manner as to protect people, downstream property and the environment Tailings are generally contained in some type of impoundment, which is buttressed by a tailings dam This paper is a brief introduction to methods used in storing tailings in engineered containment systems AWhat are Tailings?

(PDF) Tailings From Mining Activities, Impact on Groundwater,

2001年12月1日 Many tailings problems arise from the low strength of tailings deposit, their ongoing consolidation, erosion by wind and water, spillage and tailings water seepage (Bell, 1997)2007年7月1日 Although the initial dyke is commonly made of locallyderived soil (ÁlvarezValero et al, 2009;Chakraborty and Choudhury, 2009), waste rock and the tailings themselves are often used in Methods for the disposal and storage of mine tailingsHowever, there is one material that should NEVER be used with hardscapes yet we still see it being stocked by suppliers and used by some contractors Even when we search online, we see some information recommending this material to be used This material is stone dust, limestone screenings, crusher dust, or whatever it is that you may call itStop Using Limestone Screenings / Crusher Dust / Stone Dust 2016年2月25日 Tailings ponds are massive earth structures used to store coarse and fine solids contained in the oil sands deposit and recover water back to the main processing plant These ponds are temporary storage facilities Tailings Ponds 101 Oil Sands Magazine

.jpg)

Recycling and Reuse of Mine Tailings: A Review of

2022年8月12日 Mining is an important industry, accounting for 69% of global GDP However, global development promotes accelerated demand, resulting in the accumulation of hazardous waste in land, sea, and air Learn more about our proven wet processing solutions for limestone processing 682 350 0300 Language English English (US) French German Portuguese SpanishLimestone Processing Limestone Wash Plant CDE CDEGyratory crushers are generally used for primary crushing, and cone crushers are b Tailings basin 30302340 b Other, not classified 30302399 coarser than about No 10 mesh to be acceptable as blast furnace feed without further treatment Finer1123 Taconite Ore Processing2021年12月1日 Lime is the generic term used to describe various formats of the reagent (National Lime Association, 1995; du Plessis et al, 2021)Formats include: quicklime – a dry reagent with calcium oxide (CaO) as the main component, produced from the calcination of limestone containing calcium carbonate (CaCO 3); hydrate or hydrated lime – a dry reagent Lime use in gold processing – A review ScienceDirect

Highefficiency utilization of limestone tailings: Used as

2022年1月17日 Highefficiency utilization of limestone tailings: Used as cementitious materials and fine aggregate to prepare karst structure filling while the early and late strengths are generally low; 2023年2月15日 The flake rocks cannot be used as ballast, while limestone and basalt are suitable to be used as ballast Used as the ballast of railway 4 Raw materials of cement The basic raw materials of cement are limestone and clay Limestone, claystone, shale, and other stones are common waste rocks that remained in the mining process13 Applications of Tailings and Waste Rocks Fote MachineryLimestone is a carbonate sedimentary rock that consists predominantly of calcite [CaCO 3]Limestones are the commonest rocks that contain nonsilicate minerals as primary components and, even if they represent only a fraction of all sedimentary rocks (about 20 – 25%), their study is fundamental to understand past environments, climate, and the evolution of lifeLimestone Geology is the WayWhen the tailings contain minerals enriched in sulphides, it triggers the formation of acid mine drainage with the subsequent acidification of the nearby soils Nevertheless, some tailings can be very alkaline (pH > 9) due to the extensive use of beneficiation agents Mine Tailing an overview ScienceDirect Topics

.jpg)

An Overview on Methodologies for Tailings Dam Breach Study

(2020, p 161) Due to the physical characteristics of filtered tailings and the constructive operations of tailings stacks, these structures are generally associated with high volumetric 2023年7月22日 Heavy metals in mine tailings lead to serious environmental problems Cemented paste backfill (CPB) is widely used for treating the mine tailing The high cost of ordinary Portland cement (OPC) reduces the profit of mine production The work investigates the treatment of Cr(VI)containing tailings by using slagbased cementitious materials for CPB Immobilization of Cr(VI)containing tailings by using slag Furthermore, CiteSpace 57R2 was used to visually analyze the keywords of relevant studies on biological leaching of tailings to intuitively establish the current research hotspots(PDF) Progress, Challenges, and Perspectives of For the use of mine waste rock and tailings, many people know that they can be used to produce recycled sand and gravel aggregate, but they don’t know much about other uses Today, Fodamon engineer will share 13 uses of mine waste 12 uses of mine waste rock and tailings Fodamon

.jpg)

Strength and liquefaction assessment of tailings

the CPTu and sample the tailings using the Mostap or similar sampling technique, which is similar in nature to a fixedpiston sampler 23 The combined approach The combined approach utilises both drilling/sampling and CPTu methods As tailings dams are generally2019年4月22日 Stress strain curve and peak strength of fiberreinforced tailings clay (ρ d = 152 gcm −3 ) (a) Stressstrain curve, (b) peak strength increment of BFRT(PDF) Use of Basalt FiberReinforced Tailings for Improving the 2017年8月2日 Calcium phosphates for use in animal and poultry feeds are made from both furnace and wet process phosphoric acids Dicalcium phosphate, CaHPO 4, containing 185% P, and monocalcium phosphate, Ca(H 2 PO 4) 2 ∙H 2 O, containing 210% P, are made in large tonnages Both grades are prepared by reacting phosphoric acid with pulverized limestone Phosphorus and Phosphates SpringerLink2015年7月15日 The limestone tailings are detectable in the sediment as fine As can be seen in Fig 3, the proportion of fine tailings at SB12 generally increases, but temporarily decreases between the years 2000 and 2002 Download: Download highres image (54KB) Download: Download fullsize image;Biological effects of long term fine limestone tailings discharge

A Critical Review on Potential Use of Iron Ore Tailings as

2022年12月1日 The two prominent methods for mine wastes management or storage are dams and dumps, according to Blight []Mine tailing impoundments and dam failures are very common, and many literatures have reported this [13, 14] as a cause due to the geotechnical behaviour of tailingsThe Fundao dam failure in 2015 [], Brumadinho dam disaster at Corrego do Feijao iron ties in mining and metal space India has world‟s 7th largest reserves of iron ore (Indian Chamber of Commerce, May 2015) The production of iron ore in 201415 was 12910Sustainable use of mine waste and tailings with suitable sExperimental study of reasonable mesh size of geogrid reinforced tailings2019年10月18日 It was shown in previous research that while tailings had been used as a replacement for both fine aggregate and cement, the workability of mortar or concrete reducedUtilization of tailings in cement and concrete: A review

Recycling Mine Tailings for a Sustainable Future

2021年4月1日 tailings are generally disposed, either by direct disposal of tailings in rivers, seas or disposal in form of slurry (25–30% solid) into a cell, confinement or dam [ 5 ] MineREPROCESSING GOLD TAILINGS IN SOUTH AFRICA CHRISTOPHER A FLEMING, JAMES A BROWN SGS AND MARIUS BOTHA to ~pH 3 with limestone and processed with a strong base resin in a second resin in pulp (RIP) the most stable and generally the most desired iron product Oxidation Reactions 2FeS 2 + 7O 2 + 2H 2 O = 2FeSO 4 + 2H 2 SO 4 (1) 4FeSO 4 ReProcessing Gold Tailings in South AfricaOre mills generate large amounts of waste, called tailings For example, 99 tons of waste are generated per ton of copper, with even higher ratios in gold mining These tailings can be toxic Tailings, which are usually produced as a slurry, are most commonly dumped into ponds made from naturally existing valleys129: Mining Geosciences LibreTexts2016年5月7日 Flotation has been developed as the principal separating process for the potash salts which generally are coarsely crystalline and free from the sodium salts at about 10 to 14 mesh In most cases the potash is floated in the froth Potash Flotation Process 911Metallurgist

.jpg)

Current situation and prospects for the clean utilization of gold tailings

2024年5月15日 Firstly, the gold tailings are classified using a hydraulic cyclone, resulting in coarse gold tailings of + 325 mesh and fine gold tailings of − 325 mesh, respectively (2) A wet magnetic separator is used to perform the wet magnetic separation of coarse gold tailings2021年10月1日 Iron tailings were used in the preparation of iron oxidehydroxide (αFeOOH) and used as a support for gold nanoparticles for CO oxidation reactions The used iron ore has low iron content (40%), 42% of SiO 2 , and about 1% of Al 2 O 3 Iron Ore Tailings: Characterization and Applications2019年1月30日 Phosphate ore is an important raw material for manufacturing fertilizers and phosphorous chemical products While most of the phosphate resources cannot be directly treated as feed stock due to the low grade of P2O5 and high content of impurities In order to obtain a qualified phosphate concentrate, the beneficiation of the lowgrade phosphate ore is, Review on Beneficiation Techniques and Reagents Used for2021年7月30日 Static liquefaction has been associated with numerous recent failures of tailings storage facilities (TSFs) around the world (eg, the 2019 Brumadinho failure) These failures lead to devastating consequences for the environment and civil infrastructure as well as the loss of human lives In this study, we present trends for the mechanical response of mine tailings Properties of mine tailings for static liquefaction assessment

.jpg)

Tailingsfo What Are Tailings? Their nature and production

When considering the design of a tailings storage facility there are many parameters which impact on the optimum site selected and the storage and tailings discharge methods used (Ritcey 1989) The environment and ground conditions are the most crucial parameters that control tailings storage methodology which ultimately affects the way a facility is designed, built, operated and