What equipment are needed for cement plants and mines

Cement Euipment Overview Cement Making Machines Cement

As we all know, the first step of the cement production line is raw material preparation Cement crusher is the main equipment of this step The raw materials are fed into cement crusher by vibratory feeder; the breaking material is transported by the belt conveyor to the impact crusher for further crusher There are 展开Cement manufacturing equipment needs to withstand the heat and the abrasive material from which cement is made Making cement involves combining raw materials including limestone, clay, and shale, which are milled into a very fine What Equipment is Used for Cement Manufacturing?2019年8月20日 Cement production is dependent on a wide range of sedimentary and metamorphic rocks, limestone being the essential one A limestone resource required for setting up a cement plant needs to be first Basics of mineral resources for cement productionThere are several kinds of large equipment used in cement plants that are designed for special utilization We take an indepth look Bearings are the mechanical elements that hold motion responsible for reducing the friction Different Kinds of Equipment Used in Cement Plant

Cement Manufacturing Machine Cement Making

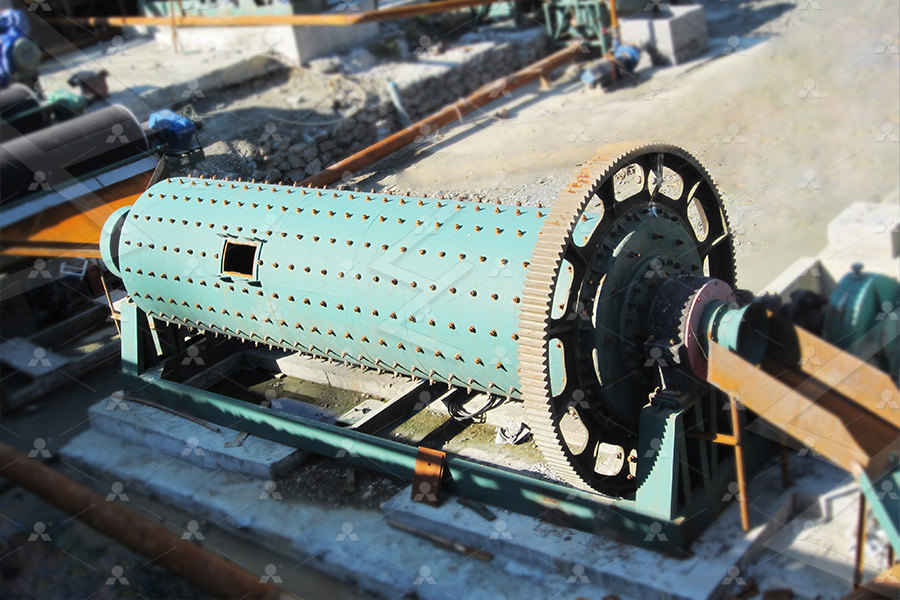

If you want to work in cement production, there are five crucial cement manufacturing machines you need to know, they are cement rotary kiln, shaft kiln, cement vertical mill, cement ball mill, and cement roller pressThere are many kinds of industrial equipment used in a cement plant, including thermal equipment, grinding equipment, dust removal system, transportation system, storage system, and so on When placing an order, we may need to How to Start a Cement Factory Design Construction The cement industry now prioritizes the efficient, energysaving, and ecofriendly cement machine A popular cement plant includes the cement crushers, raw material mill, cement kiln, cooler, cement mill, dust collector, cement Overview of Cement Making Machine (with Price and 2023年12月20日 How cement manufacturers can help ensure cement quality From the limestone mine, to crushing, blending, the raw mill, kiln and beyond, elemental analysis is a critical component to driving process control, The Cement Manufacturing Process Thermo Fisher

The Cement Plant Operations Handbook International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide Providing a Stationary crushing plants In the cement industry, which uses chiefly mediumhard to hard limestone as its principal raw materials, singlestage crushing plants equipped with hammer crushers are the commonly preferred type Feed Hoppers The feed hopper, feeding equipment, crusher and product removal conveyors are the main component units of Everything you need to know about Crushers in Cement industry2020年1月3日 Setting up a cement plant is both time and capital intensive; it could take anywhere between five to seven years from concept to commissioning and an investment of around to Rs 1,8002,000 crore for a typical integrated Key factors in setting up a cement plant Indian Everything you need to know about Cement Kiln Dust Generation In the early 1900s, cement plant employees began disposing of household waste at the company’s onsite landfill This practice continued until the mid Everything you need to know about Cement Kiln Dust

.jpg)

Everything you need to know about Stacker and reclaimer systems

Everything you need to know about Stacker and reclaimer systems TO buy the Most Important Books in Cement Industry + more than 30 excel sheets related to cement industry + Manuals and Notes click here now * Suitable for raw materials in the cement, coal, pulp and paper, mining and other industries as well as power plants ports IntroductionCement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 167t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand, ore, coal, Cement Conveyor Belt Conveyor In Cement Plant AGICO2019年9月27日 In the real application, as a professional EPC cement plant project provider, AGICO Cement always provides a solution according to clients ’ needs, such as mini cement plant, VSK cement plant, cement plant upgrading also provides single cement equipment with high quality and competitive price, welcome to contact!Cement Euipment Overview Cement Making Machines Cement PlantDeveloping a general plant layout for green cement plants Principles of developing general plant layouts for green cement plants are the same as those for conventional plants These have been dealt with in detail in Section 6 of the author’s book “Handbook for Designing Cement Plants”Cement Plant an overview ScienceDirect Topics

.jpg)

Everything you need to know about Automation and Optimization

Finally, the ability to observe where the measurements take place improves confidence in the measurements This type of new technology is expected to benefit the majority of cement plants OPTIMIZATION AND AUTOMATION Fuels Currently, the use of an increasingly varied mix of alternative fuel sources by cement plants have been growingFigure 614 Limestsone loading at a cement plant Raw Material Alkali/Sulfur Balance Another raw material substitution method that is potentially applicable to all kiln systems is to stoichiometrically balance the sulfur in the kiln system with Everything you need to know about Air Emissions and Control elements to have safe cement plant Major areas of concerns are the maintenance work in confined space, preheater cyclones and silos, work at height jobs, materials transportation systems, heavy mobile equipment and truck movement are major risks in a cement plant operation What are the key challenges in ensuring safety at a cement plant?Safety and Safety Equipment2024年10月14日 What machines are required for a stone crusher plant, and what is the function of each? Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine crushers and What Machines Do Stone Crushing Plants Need?

.jpg)

Everything you need to know about Cement Fuel

Figure 254 Crude oil distillation curve The commercial definition is more limited and focused on industrial applications of fuel oil According to this definition, fuel oil includes the heavier fractions – distilled between 500°K and 700°K – and A red spot located under or adjacent to a tire is cause for immediate action Often plant management will mandate an immediate kiln shut down 16 Loss of kiln feed A loss of feed is a situation where the kiln feed devices like feeders, Kiln Control and Operation INFINITY FOR CEMENT Cement manufacturing process The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater Cement Plant Cement Manufacturing Plant EPC ProjectHowever, some cement plants in the past have suffered fires or explosions in cement kiln air pollution control devices (APCDs) Dobson (1974), with Factory Mutual Research, stated that between 1971 and the date of the article (1974) damage had been reported to nine ESPs in cement plants insured by Factory MutualEverything you need to know about Kiln System Operations in Cement

.jpg)

8 Tips For Cement Plant Design

2023年11月1日 We give some tips for cement plant design, including cement site selection mines must make detailed geological explorations, and design a longterm mining plan and resource AGICO CEMENT supplies EPC projects for both cement plant and single cement plant equipment CONTACT INFO +86 s 2023年12月20日 Cement operators also use these analysis systems to analyze and adjust the coal mix instream, which enables the plant to reduce energy consumption by using exactly the amount of coal fuel required to meet the specific heating values required to process materials in the kiln and millThe Cement Manufacturing Process Thermo Fisher ScientificDuties of the plant safety professional include: 1) serving as a technically expert resource on issues pertaining to safety and health for the plant manager, line supervisors, engineers, purchasing personnel, hourly workers, and the joint safety and health committee, 2) coordinating, monitoring, keeping records, and producing reports regarding the plant safety process, 3) Everything you need to know about Safety Management and Organization2020年9月14日 Many young engineers consider cement plants pretty complicated because of their weird note that this article assumes that you are already familiar with the basic terms of cement plant equipment and process But, higher capacity is needed to be installed See Figure 8 For cement plants where most sections work in The essentials of electrical systems in cement plants EEP

Cement Plant For Sale Cement Equipment, Cement Plant Cost

Cement plant refers to the professional cement production line to manufacture cement What is your real need when you buy a cement plant? There are generally 5 aspects you may concern: cement equipment, cement manufacturing process, cement plant manufacturer, cement plant benefits, and related service2023年11月23日 It is crucial to prioritize safety at these facilities to prevent accidents and injuries Here, we will explore some safety tips that must be followed at cement manufacturing plant to create a secure and accidentfree workplace Safety tips that must be followed at cement manufacturing plantPersonal Protective Equipment (PPE):Safety Tips for Cement Manufacturing PlantMobile Equipment / Blind Spots – Injuries and fatalities from material handing and powered haulage is very common at surface mines Mobile mining equipment is often very large and very loud Drivers may operate the equipment within Common Types of Surface Mining Equipment – 2019年11月21日 Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant equipment to play own roles As we all Cement Plant Equipment Cement Crusher, Cement

.jpg)

Everything you need to know about Remote Access and Control in Cement

This is a useful feature when the plant is located Remote Access and Control in Cement Plants in a remote area, and a situation exists where program changes made over the telephone are much quicker than waiting for the appropriate personnel to travel to the plant2021年9月21日 Despite increasingly high use of alternative resources by way of blended cement making, limestone remains the mainstay for cement manufacturing This in focus series aims to feature prominent best practices followed by the Indian Cement Industry towards responsible mining of limestone mineral Surface Miners Equipment for Limestone MiningThe Indian Cement Industry: Responsible Mining Initiatives andThis comprehensive guide aims to provide a thorough understanding of the costs involved in setting up and running a cement plant, equipping you with the knowledge needed to make an informed decision TO Download this post and all the books and excel sheets and my personal notes and presentations I collected about cement industry in the last 30 years click the below The Comprehensive Guide to Cement Plant Costs: An InDepth Mining Limestone used in cement production is commonly found throughout the world and is sourced from calcium carbonate of marine origin Determining a suitable source of limestone for a new or existing cement plant requires consistent limestone grade (mineral content) and uniform quality in the limestone depositInfrastructure and Construction Materials Guide — Cement

A practical guide to improving cement manufacturing processes

for cement plants to meet regulatory requirements There are even provinces in China that are only allowing cement plants to operate 9 months out of the year to curb some of the unwanted emissions Continuous Emissions monitoring systems are critical for cement plants to monitor harmful emissions such as carbonSafety in Cement Plant IF YOU WORK IN A CEMENT PLANT AND YOU NEED COURSES AND MANUALS LIKE THIS MANUAL AND BOOKS AND EXCEL SHEETS AND NOTES I SPENT 23 YEARS COLLECTING THEM YOU SHOULD CLICK HERE TO DOWNLOAD THEM NOW Contents • Processes Involve • Hazards Involve in Operation • Safety Counter Measures Safety in Cement Plant INFINITY FOR CEMENT EQUIPMENT2020年2月18日 Based on overall impact of limestone mining in the area it is suggested that all stakeholders particularly the owners of mines and cement plants should give necessary attention to environmental (PDF) Environmental Hazards of Limestone Mining and2016年3月1日 Significant industry consolidation took place in 2013 2015 By the end of the period, China’s top 10 cement producers had 52% of the market share Several regions banned the construction of new cement plants, including Beijing in March 2014 and Tianjin in April 2014 Beijing also banned the expansion of existing cement plantsCoal for cement: Present and future trends

Cement Extraction, Processing, Manufacturing

2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the parallel, SAXUM is developing/defining all needed data sheets and specifications for purchasing the required equipment and construction/erection works GCC Rapid City Plant, South Dakota, USA CIVIL/STRUCTURAL ENGINEERING AND SITE SUPERVISION FOR UPGRADE OF GCC CEMENT PLANT PROJECTS LQIR#VD[XPLQJ QHWZZZ VD[XP XVZZZ VD[XPLQJ QHW PROCESS ENGINEERING FOR THE CEMENT LIME INDUSTRIES In cement plants, multiple kinds of conveying equipment are needed from the feeding, material transmission to the discharging and warehousingIt is conveying equipment that connects other equipment in the cement production line as a whole As a professional cement plant manufacturer, AGICO offers three types of conveying equipment for cement plant projects: Cement Conveyors Conveying Equipment System for Cement PlantRaw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials Cement Crusher – Crusher In Cement Plant AGICO Cement

Belt Conveyor Types for Cement Production Line

Case: The belt conveyor is mainly used for longdistance transportation of powder and small block materials High quality belt conveyor runs smoothly, no slip or run off, belt and roller have long service life, the upper belt type does not exceed the edge of drum or idler, and lower belt type does not grind the frameOlder plants with inefficient systems, combined with operational and maintenance failure, tend to have much higher energy consumption Based on the specific plant conditions and requirements, a general benchmarking is conducted to set goals Plant audits evaluate the performance of a cement plant against the appropriate benchmarkPERFORMING A CEMENT PLANT OPERATIONS AUDIT2023年8月22日 The highest share of cement plant impacts is observed with regard to modern cements plants in China due to the cement requirements for infrastructure buildup in recent years 9Global sitespecific health impacts of fossil energy, steel mills, oil Cement manufacturing begins with quarrying operations in which limestone in mines is quarried and brought to crusher for crushing Limestone quarries are opencast mines Often limestone appears as an outcrop right on the surface At other times it is under an overburden that can vary in depth but is generally less than 3 metres thickLimestone quarry, quarrying, cement raw materials

Clean Air Technologies for the Cement and Mining Industry

ANDRITZ has over 130 years of experience in designing and building clean air technologies equipment From single to multipollutants control equipment, adapted for heat recovery when needed, ANDRITZ solutions range from dedusting, desulphurization, denitrification, mercury control technologies to combined/multistage and multipollutants systems