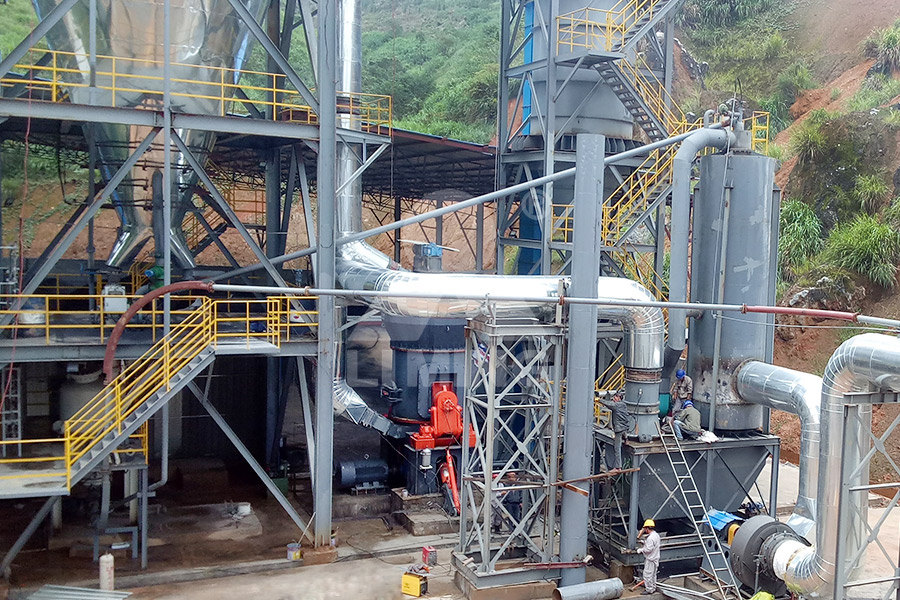

Cement rotary kiln pulverized coal preparation

.jpg)

Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

Combining the models of gassolid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were bining the models of gas−solid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were establishedModeling of Pulverized Coal Combustion in Cement Rotary Kiln2006年9月6日 In this paper, a comprehensive 3D mathematical model for rotary cement kiln including heavy fuel oil combustion, hot flow, zone heat flux model for clinker formation and Modeling of Pulverized Coal Combustion in Cement Rotary Kiln2006年9月6日 Combining the models of gas−solid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

(PDF) Modeling coal combustion in a rotary cement

1999年1月1日 A mathematical model is described for the numerical prediction of the distribution of velocity, temperature, species concentration and particle trajectories in an axisymmetric rotary cementIn the current study, based on the available plant data, first a base CFD model for 68 m long, 455 m ID rotary kiln along with multichannel coal burner (4500 t/d clinker production capacity) was CFD MODELING OF A CEMENT KILN WITH MULTI CHANNEL An industrial rotary kiln geometry was simulated; temperature and velocity fields along with mass fractions of released volatiles and combustion products were analyzed The model allows better insights in the cofiring process with the Improving Pulverized Coal and Biomass Co 2022年5月24日 In the present study, CFD were used to investigate the effect of a new type of rotary kiln on the velocity field, temperature field, material component distribution, and NOx Numerical simulation of pulverized coal combustion in rotary kilns

Numerical Simulation of Pulverized Coal Combustion Process in

Abstract: In order to study the variation laws of NOx concentrations and temperatures in cement rotary kilns,combustion processes of pulverized coals were simulated inside In this paper, we present the first part of the development of a cement rotary kiln model, comprising careful CFD setup and simulations of a cofiring of petroleum coke (petcoke) and An industrialscale cement rotary kiln CFD model to characterise We supply pulverized coal burners for rotary kilns; feel free to contact us! Skip to content +86 s about blog contact EN ES Menu Menu Home; 05mm Tolerance Cement Rotary Kiln useful Pulverized Coal Burner Pulverized Coal Burner For Cement production line with annual output of 12 million tons Pengfei EPC cement production line project includes process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and Cement Production Line,Cement Machine,Rotary

.jpg)

Air Swept Coal Mill Cement Plant Machinery

Air Swept Coal Mill Introduction The airswept coal mill produced by AGICO equipment has reasonable structure, high grinding efficiency, strong adaptation to raw materials, which is the ideal equipment for pulverized coal preparation FeediCombining the models of gassolid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were established In terms of commercial CFD code (FLUENT), the distributions of gas velocity, gas temperature, and gas components in a cement rotary kiln were obtained by numerical simulation of a 3000 t/d rotary Modeling of Pulverized Coal Combustion in Cement Rotary KilnDuring working of cement rotary kiln, pulverized coal (natural gas) is burned in the cement rotary kiln to generate heat The heat is used to heat the material by gas conduction or radiation At the same time, as the kiln body rotates according to the designed inclination and rotation speed, the raw materials rolling forward periodically in the kilnCement Rotary Kiln For Sale Rotary Kiln Manufacturer 180 2024年11月23日 Cement Extraction, Processing, but the dominant means of burning is the rotary kiln These kilns—up to 200 metres or firing, end The fuel for firing may be pulverized coal, oil, or natural gas injected through a pipe The temperature at the firing end ranges from about 1,350 to 1,550 °C Cement Extraction, Processing, Manufacturing Britannica

.jpg)

Thermal Analysis for Rotary Kiln in Cement Industry

Generally, the combustion of pulverized coal is carried out on the top of the cement rotary kiln The combustion of pulverized coal produces a large amount of smoke and dust, which is combined with the water vapor in the cement rotary kiln shell and forms a large amount of smoke on the top of the kilnPrevious Post Contents1 EVERYTHING YOU NEED TO KNOW ABOUT FUEL SYSTEMS IN ROTARY KILN11 FUEL HANDLING AND COAL GRINDING12 FUEL BURNERS AND FLAMES13 TESTING COAL BURNERS FOR TIP VELOCITY EVERYTHING YOU NEED TO KNOW ABOUT FUEL SYSTEMS IN ROTARY KILN FUEL HANDLING AND COAL EVERYTHING YOU NEED TO KNOW ABOUT FUEL SYSTEMS IN ROTARY KILNThe cost of a coal preparation department of a cement plant amounts to about 1520 % of the cost of the total plant machinery when burned as pulverized coal in a rotary kiln, generates a long flame The standard content of volatile matter for coals used in the combustion of pulverized coal is about 18 22 % However, Fuels in the cement industry INFINITY FOR CEMENT EQUIPMENTTypes of coal fuel rotary kiln for sale upon your needs The fineness of pulverized coal in the coalfired rotary kiln is best controlled at 88 μm, In order to ensure that the temperature in the cement rotary kiln is maintained at 1450℃, Coal Fuel Rotary Kiln with Various Output and Length for Sale

Everything you need to know about Kiln System

In a cement rotary kiln, The problem noted above with Western coals can also occur If the pulverized solid fuel undergoes spontaneous heating and the mill is restarted with hot embers present, Coal Preparation, 4th Edition, The 2023年12月26日 Pulverized coal preparation system Pulverized coal preparation is an important part of the active lime rotary kiln system using coal There are generally two systems One is a pulverized coal preparation system 6 Cement Equipment For Dryprocess Cement 2019年8月1日 Temperature Distribution in Rotary Kiln 422 Species concentration The fuller the pulverized coal combustion in rotary kiln, the smaller the volume fraction of CO in the kilnNumerical Simulation of OxygenEnriched Combustion of LowQuality Coal Note: parameters in the form are only for reference, and specific ones should refer to the contract As a professional manufacturer and supplier of cement rotary kiln in China, Jiangsu Pengfei Group Co, Ltd can also provide you with various other machines, such as lime rotary kiln, active lime production line, cement production line, cement grinding plant, industrial kiln and furnace Cement Rotary Kiln

NUMERICAL SIMULATION OF PULVERIZED COAL COMBUSTION IN A ROTARY KILN

5 Table 1 Parameters of cement rotary kiln The size of the rotary kiln used in this paper is ∅4×46 m Due to the thickness of the refractoryWorking Characters 1 The fuel distribution at the outlet of the pulverized coal burner is uniform and the air distribution is reasonable The mixing point of secondary air and primary air is appropriate, and the black flame head at the outlet of the burner is generally controlled between 200mm~350mm to ensure timely ignition and strong combustionFour Channel Pulverized Coal Burner Rotary Kiln and Pulverized Coal The activated carbon rotary kiln was developed by a professional rotary kiln manufacturer AGICO CEMENT has guaranteed quality and competitive Cement Screw Conveyor; Pulverized Coal Burner; Vibratory Feeder; Long Distance it is often used as a hydrophobic adsorbent The main preparation principle is to convert all carbonrich organic Rotary Kiln For Activated Carbon Production Cement PlantLiedman et al [7] started to study the influence of operating conditions in cement rotary kilns by cofiring different mixtures of RDF and pulverized coal Clinker formation process in a modern plant rotary kiln

-2.jpg)

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

The coal mill in a cement plant should be reliable and should be operated with great care, or it is easy to cause safety accidents In the process of grinding, storage, transportation, and burning of pulverized coal, resulting in casualties and equipment damagewholeMany cement manufacturers use dry process method for cement production by applying Low Pour Fuel Oil (LPFO) and natural gas to firing the kiln to generate heat energy required in the kiln for production of clinker from the kiln feed In modern cement plant, natural gas and fuel oil are preferred for firing the kiln over coalQuantitative Optimization of Cement Rotary Kiln for Heat Advantages of rotary kiln dryer High temperature resistance, use hightemperature and hot air to dry materials fast; Strong expandability of AGICO dryer, the design of dryer fully consider the allowance of production, even if a Rotary Kiln Dryer Cement PlantTailored Lime Calcination Solutions: Optimized Customized CAPACITY: 200~1500T/HFUEL: Coal Gas, Natural Gas, and Pulverized CoalEQUIPMENT: Jaw Crusher+Raymond mill+Rotary Kiln/Vertical Kiln+Cooler+Bucket Lime Calcination Plant AGICO Cement Plant

Analysis of installation and commissioning of

The kiln hood and the kiln tail chamber are static equipments that are connected with the front and rear equipment of the rotary kiln; the pulverized coal combustion device transfers the heat to the cement raw material by burning Pulverized Coal Kiln Feed Units 21 General 99 A Dry Process Kiln 06 Raw material preparation includes a variety of blending and sizing operations of the oxides in the burning zone of the rotary kiln, to form cement clinker at temperatures of approximately 1510°C (2750°F) Rotary kilns are long, cylindrical, 116 Portland Cement Manufacturing US Environmental different coal sources before and after beneficiation Sink Float ) through the use of ( heating microscope as a tool for the c haracterization of ash characteristics In the manufacture of Portland cement clinker with coal as fuel in a rotary kiln, the ash introduced as part of the fuel will become an integral part of the clinkerEFFECT OF COAL ASH CHARACTERISTICS ON KILN 2019年9月27日 AGICO offers cement making machines including cement mill, rotary kiln, cement crusher, cyclone preheater, cement dryer, clinker cooler etc any need? Skip to content +86 Cement Euipment Overview Cement Making Machines Cement

.jpg)

Numerical simulation of pulverized coal combustion in a rotary kiln

The cement industry is the second largest source of global manmade CO2emissions after the power industry, and the adoption of O2/CO2combustion technology for cement kilns is of great significance in reducing CO2emissions In this paper, the effects of pulverized coal mixed air combustion and pulverized coal mixed O2/CO2combustion on the velocity field, temperature 2023年1月1日 The utilization of coal in the cement and concrete industries takes three basic forms: (1) as a fuel in the production of cement clinker; (2) ash produced by burning coal in power stations is used as a component in cement rotary kiln feeds; (3) ash produced by burning coal in power stations is used as a mineral additive in concrete mixesCoal utilization in the cement and concrete industries1999年1月1日 Modeling coal combustion in a rotary cement kiln January 1999; species concentration and particle trajectories in an axisymmetric rotary cement kiln with turbulent combustion of pulverized coal(PDF) Modeling coal combustion in a rotary cement kilnThis paper deals with the detailed CFD modelling carried out for a full scale rotary cement kiln with multi channel coal burner The study includes developing and combining the models of gassolid flow, modelling of pulverized coal combustion and heat transfer from flue gas to the reacting mass and surroundings RNG ke model for turbulence, eddy dissipation model for coal CFD MODELING OF A CEMENT KILN WITH MULTI CHANNEL

Cement Kiln Cement Rotary Kiln AGICO Cement

Cement rotary kiln A cement rotary kiln is a laterally set cement kiln that is inclined to a certain angle with the ground Raw meals in the kiln body will be calcinated in a lowspeed rotation In present cement plants, the new dry AGICO Cement supplies cement equipment for cement raw material production as you need, such as cement mill, cement crusher, onestop turnkey project, welcome to contact! Skip to content +86 Preparation Of Cement Raw Material Cement Mill, 2014年6月24日 The use of waste wood biomass as fuel is increasingly gaining significance in the cement industry The combustion of biomass and particularly cofiring of biomass and coal in existing pulverized Numerical study of cofiring pulverized coal and 2020年4月20日 In this paper, a comprehensive 3D mathematical model for rotary cement kiln including heavy fuel oil combustion, hot flow, zone heat flux model for clinker formation and rotating wall was developedHEAVY FUEL OIL COMBUSTION IN A CEMENT ROTARY KILN

.jpg)

Cement Rotary Kiln Thermal Equilibrium Analysis

AGICO shows you the knowledge about cement rotary kiln thermal equilibrium analysis and the Rotary Kiln for Liion Battery Material Preparation; Roller Hearth Kiln; Pusher Kiln; 05mm kiln head), kiln tail into the kiln raw materials, kiln head into the kiln and kiln tail smoke chamber into calciner pulverized coal, quality of dust 2016年4月1日 In this paper, a comprehensive computational fluid dynamics (CFD) methodology was adopted to investigate the characteristics of oxycoal combustion in a cement kiln with a specially designed burnerNumerical Simulation of Oxycoal Combustion in a Rotary Cement KilnOne way to cope with high pollutant emissions is to cocombust biomass with pulverized coal A mathematical model was developed, which is detailed enough to consider the complex physical and chemical behavior of the cocombustion process but simple enough to perform simulations with a real geometry of cement rotary kiln within reasonable timeImproving Pulverized Coal and Biomass CoCombustion in a Cement Rotary 2014年5月1日 feed preparation process is about 54 kg CO 2 and leaving the rotary kiln in cement industry and the heat losses C Pulverized coal is bu rnt in the rotary kiln to reac hAnalysis of the parameters affecting energy consumption of a rotary

.jpg)

Energy Saving Pulverized Coal Burner , Cement Kiln Burner High

Pulverized Coal Burner Manufacturer / Cement Kiln Burner / Coal Dust Burner for Sale Pulverized Coal Burner Introduction: Pulverized coal burner can make pulverized coal fully burn at a short time and produce high temperature vortex It can be divided into three types according to the usage: 1 pulverized coal burner for rotary kiln; 2 2009 This paper deals with the detailed CFD modelling carried out for a full scale rotary cement kiln with multi channel coal burner The study includes developing and combining the models of gassolid flow, modelling of pulverized coal combustion and heat transfer from flue gas to the reacting mass and surroundingsCFD Modeling of a Cement Kiln with Multi Channel Burner for