kaolin roller crusher output

Kaolin Processing Plant MachinerySBM Industrial Technology Group

2023年1月3日 Compared with the combined grinding system of traditional Raymond mill and ball mill, vertical roller mill has the advantages of large output, wide adaptability, simple operation, rapid adjustment, low use and maintenance cost, energy saving, etc, and is the preferred The kaolin bulk material is crushed into a fineness of the mill (15mm50mm) by crusher Crushed kaolin small pieces of material by the hoist to the silo, and then by the vibration feeder to its kaolinite processing line Kefid Shanghai MachineryRoll crushers by Loibl are the ideal solution for the reliable homogenization of mediumhard, lumpy and caking bulk materials in the bulk solids industry Our innovative technologies Roll Crusher Crusher Loibl Förderanlagen GmbH2022年8月10日 The kaolin bulk material is crushed by the crusher to the fineness (15mm30mm) that can enter the mill The crushed small pieces of kaolin are sent to the storage hopper Kaolin grinding production line and equipment selection

.jpg)

Advanced kaolin grinding production line equipment: Elevating

The kaolin grinding production line is a comprehensive system designed to process raw kaolin into a fine powder that meets the specific requirements of different industrial applications This It is ideal for grinding nonflammable and explosive nonmetallic minerals with a Mohs hardness below 7 and a humidity below 6%, such as gypsum, limestone, kaolin, and coal The output of Highefficient Raymond Mill Fote MachineryHeavyDuty Double Roll Crushers are ideal for the primary, secondary and tertiary crushing of limestone, gypsum, ROM coal, etc where higher compressive strength material is anticipated Double Roll Crushers McLanahanPure kaolin is white, delicate and soft, and has good plasticity and fire resistance Kaolin has become a necessary mineral raw material for dozens of industries such as paper making, Kaolin Grinding Zenith Crusher

.jpg)

Design, Fabrication and Testing of a Double Roll Crusher

The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80% Keywords: Double roll, crushing, Particle size, design analysis, solid 2013年3月20日 Double roll crusher cocok digunakan untuk menghancurkan material menengah kekerasannya seperti batubara, batu kapur, dan kaolin Dokumen ini juga menjelaskan prinsip Tugas pengolahan bahan galian double roll crusher PDFThe output of FTM Machinery Raymond mill can reach 8 – 176 t/shift (1–22 t/h), and the finished product fineness is 0173 mm–0044 mm (80–325 mesh) Model 4525Highefficient Raymond Mill Fote MachineryDouble Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, Double Roll Crushers McLanahan

.jpg)

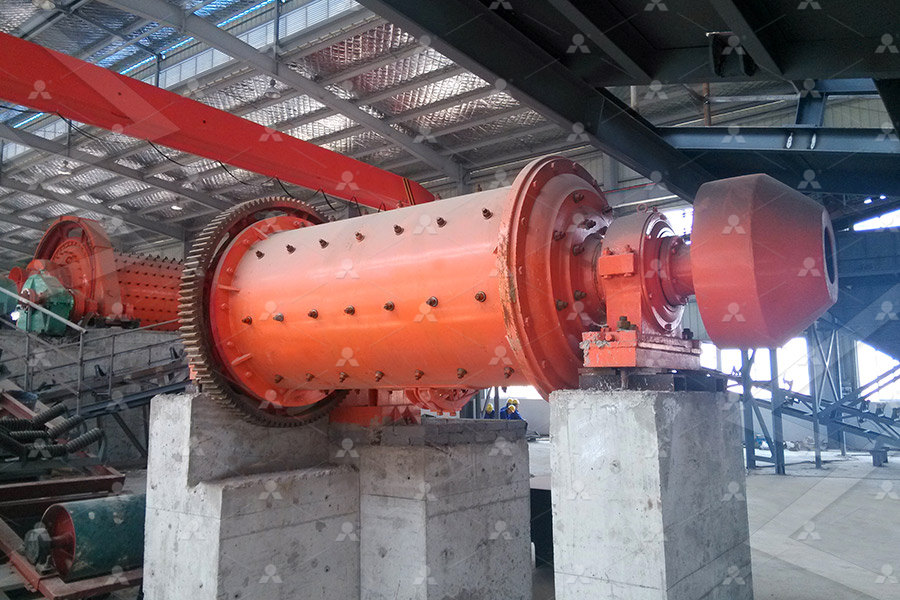

Smooth Roller Crusher huashengming

The Smooth Roller Crusher is the most suitable machine for the sand making industry The first choice for crushing is roller crusher home; products 1 2PGT400×250, 2PGT400×400, 2PGT610×400, with an hourly output of about 220 tons, are small spring roller crushers, The equipment has stable performance, high output per hour, and can Low consumption and good environmental protection can ensure the smooth development of kaolin fine processing projects At the same time, HCM’s aftersales team is large and professional, so there is no need to worry about the followup of the project1000 Mesh Kaolin Ultrafine Mill Kaolin Fine Powder Processing The toothed roller crusher is very useful for crushing clay, cohesive materials, or rocks mixed with soil with water content up to 30%, such as kaolin, bentonite, montmorillonite, etc Because equipped with a scraper and adjustable discharge size, it Reliable Toothed Roll Crusher Fote MachineryRoll crusher Roll crusher Roll crusher Applicable materials: medium hard ores and rocks such as river gravel, iron ore, limestone, basalt, quartz, granite in metallurgical industry, cement industry, power sector, construction, phosphate, refractory industry, etc Feed size:≤25≤100 mm Abilities:5110 tons/hourHydraulic Roll Crusher Zhengzhou Chunlei Machinery

.jpg)

Design, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%Special material for grinding roller and ring, long service life and convenient maintenance 5:More environmentally friendly The whole vertical roller mill has low noise, small vibration, full negative pressure operation, less dust emission and good environmental protectionThe Best Kaolin Superfine Vertical Grinding Mill Made By HCM1Fixed roller and movable roller There are spines for connecting the two roller guards on the shafts of fixed and movable rollers The tires are installed in the roller guards, and the shaft is equipped on the one end of the chain wheel There are singlerow tapered roller bearings on both sides of roll millingOnestop Turnkey ROLL CRUSHER FTM MachineryJun 24, 2021 At present, vertical roller mill has been widely used in the production and processing of white nonmetallic mineral industry abroad, and has been successfully used in crushing processing of heavy calcium, barite, limestone, gypsum, pyrophyllite, kaolin, cement raw materials and clinker in Chinavertical roller mill for mixing kaolinHXJQ Crusher Machine

Types of Crushers: Choosing the Right One for Each

2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses ideal for applications requiring highquality particle shapes They handle feed sizes up to 800 mm and output capacities from 30 to 2,000 t/h typically Output, kg/hour* 25300: Technical parameters: Hopper loading door dimensions, mm: 160х200: Crusher loading door dimensions, mm: 25х100: Discharge slot adjustment range, mm: 012: 50 Hz supply voltage, V: 380: Electric motor power, kW: Advantages of VIBROTECHNIK Doubleroller Crusher DRC 200х125:Doubleroller Crusher VIBROTECHNIK2024年4月19日 Roller crushers are usually applied for soft materials, for example, coal, clay or soft rocks They can give a finer end product as defines the size and type of crusher If the output is higher, then the crusher may need Types of Crushers Explained: Everything You Need to 2024年1月1日 As to cone crushers, Evertsson (2000) developed an analytical model for estimating the performance of cone crushers Huang et al (2007) established a multiobjective model for the crushing chamber, output, and particle size reduction based on a new production calculation method Bengtsson (2009) proposed two models to predict the shape of crushed Study on productivity of eccentric roll crusher based on theory

Roller Crusher – Nesans Mining and Automation Private Limited

• Cubical shape of the output product • Easy roll liner replacement and better dismantling mechanisms for repair Back To Top Technical Data Models CI456 CAPACITY : 25 TPH CI7550 CAPACITY : 50 TPH CI1200 CAPACITY : 100 TPH CI456 Can bigger feed sizes be fed into roller crusher ?1 The complete set is strong; from the rough processing of raw materials to the packaging of finished products, it forms a milling production system independently, and the onetime investment is small 2 The dry continuous milling has a high capacity, the fineness of the finished product can be adjusted, and the powder is fine and uniformRaymond Mill JXSC Machinery2021年6月18日 Ultrafine powder kaolin clay mill equipmentHGM ultrafine ring roller mill model parameters are as follows: Name: HGM ultrafine ring roller mill/HGM micro powder grinding mill Models: HGM80, HGM90, HGM100, HGM125, HGM1680, etc Input Size: ≤20mm Power: 144680KW Weight: 17570 t Capacity: 0545t/h Output Size: 010005mm / 303000 mesh What is the hourly output of 800 mesh kaolin clay processed 2023年2月15日 France has an annual output of about 85 million tons and a stockpile of The second is to recover beneficial mineral products such as kaolin; the third is the production of silicon, aluminum, sulfur and other inorganic chemical 8 The roller crusher is equipped with a replaceable wearresistant lining plate which adopts How a Roller Crusher Crush Coal Gangue Fote Machinery

.jpg)

Design, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%2023年12月28日 For ball mills of the exact specifications, the output of the closedcircuit process is 15 to 20% higher than that of the opencircuit process During closedcircuit operation, choosing the appropriate powder selection efficiency and cycle Factors Affect The Output and Quality of Ball Mills And How to Introduction of Hammer Kaolin Crusher: Hammer small kaolin crusher is a kind of equipment that breaks material by impact energy The machine can be divided into two forms: single rotor crusher and double rotors crusher It is a crushing machine that can break the material about 6001800 millimeters into 25 or 25 millimetersKaolin Crusher Turns Kaolin Into Industrial Raw Material2022年12月1日 SBM Factory SBM Micropowder Technology Co, Ltd is an excellent manufacturer of ore grinding equipment in China, and has made great achievements in the field of ultrafine powder grinding SBM is recognized by Rock grinder machine

Introduction To 7 Types Of Stone Crushers

2024年10月31日 Choosing the right rock crusher can not only improve production efficiency, The particle size of the input and output materials can be adjusted to meet the different needs of users 07 Wheel Sand Washing Machine Wheel sand washing machine, Clirik Roller Mill Achieves Ultrafine Grinding of Marble in India;Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%Design, Fabrication and Testing of a Double Roll CrusherRoller crusher is widely used in solid and block material pulverizing Roll gap between the rollers is usually adjusted to satisfy the particle size of output materialMechanical structure of roller crusher ResearchGateRoll Crushers In Mineral Processing Design and Operations (Second Edition), 2016 61 Introduction Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions Single roll crushers are also available which rotate a single roll against a fixed breaker plate Mineral or rock particles placed between the rolls are nipped and Roll Crusher an overview ScienceDirect Topics

.jpg)

Crusher rotor, Hammer Mill Rotor and Impact Crusher Rotor

The crusher rotor is a wearing part, therefore, the crusher rotor of the crusher needs regular maintenance or replacement due to various reasons Firstly, the highspeed rotating hammers and the constant impact they make against the material being crushed can cause wear and tear on the crusher rotorFor the equipment with an annual output of 100,000 tons of calcined kaolin, the calcined kaolin ultrafine vertical roller mill has higher efficiency and ideal production capacity (440t/h), and the particle size of the powder is excellent (545μm If it is equipped with a secondary classification system, the fineness is as high as 3μm)News How To Configure The Calcined Kaolin Grinding Mill In the main body of the Bentonite Grinding Equipment, the grinding roller assembly is suspended on the grinding roller hanger through the cross arm shaft The grinding roller hanger is fixedly connected with the main shaft and the blade holder The pressure spring is on the outer end of the cantilever of the grinding roller bearing chamberNews Bentonite HighPressure Suspension Roller MillApplication: mainly used for medium and fine crushing of medium hardness stone such as coal and limestone (compressive strength below 100MPa)Roller crusher is not used in road crushing Advantages: simple, compact structure, low investment, convenient adjustment, can be used for crushing viscous materials Disadvantages: low production efficiency, unable to break hard Different Crushing Types Among 7 Crushers MC

.jpg)

SMTR series roller screening crusher

Details of pebble sand production line with output of 150200 tons per hour; 500 the SMTR series intensive roller screening crusher mainly adopts special wearresistant rollers to rotate the coke, clay, limestone, granite, copper, gold, nickel, iron, etc; gypsum, talc, wollastonite, kaolin, rubber and other minerals Application coal 2015年4月24日 4 ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing Roll crushers have a Roll crushers PPT Free Download SlideShare2023年6月29日 This is because the components of a jaw crusher are simpler and easier to access than those of a roller crusher However, roller crushers are often more durable and can handle more wear and tear than jaw crushers, Jaw Crusher VS Roller Crusher BaichyIn the kaolin sintering process, the temperature of the rotary kiln used needs to reach 950℃ or higher Kaolin clay rotary kiln is also called kaolin calciner, and can also be used for the calcination of clay, kaolin clay, bauxite, magnesium oxide, zinc oxide, and other materials Application of Kaolin Rotary KilnKaolin Rotary Kiln Kaolin Calciner for Sale

.jpg)

Kaolin Magnetic Separator And Equipment Repair JXSC Mineral

2024年4月17日 Among the development of many mining machinery industries, the kaolin magnetic separator exists as a special example, and it has maintained a good momentum of development in such a fierce market environment Its role cannot be replaced by any equipment In the mining, energy, transportation construction, and industrial raw materials industries, it 2017年3月10日 I believe his crusher, with the improved eccentric, is the best thing on the market today” A jawcrusher constructed upon certain lines, having a jawopening 10 in by 20 in, and weighing not over 15,000 lb, will take a steady stream of 10in runofmine and reduce it without sliming to 1in sizeRoll Crushers 911 Metallurgist2023年2月15日 Heart of beauty in everyone Among many skincare products, kaolin clay has prominent benefits in skin beauty New uses are constantly discovered, ensuring the longterm demand for kaolin powder This blog will introduce you to what is kaolin, the best way and equipment for grinding kaolin, to meet the market needs for ultrafine kaolin powderGrinding Kaolin Clay? Now Is the Time to Know the Best WayWhat is Roller Crusher Roll crushers crush the material use two opposite rotation of the rollers The crushing is made up of electromotor, holder, fixed roller, movable roller and safety spring The surface of the roller is mostly smooth According to the number of rolls, there are singleroll, doubleroll or multiroll crushersRoller Crusher Mineral Crushing Aggregate Processing JXSC

Kaolin Raymond Mill SBM Ultrafine Powder Technology

Kaolin processing technology 1 Crushing and grinding The large piece of kaolin mined is crushed into small pieces of 1540 mm in size by a crusher, and then sent to different grinding equipment through a feeder to be processed into coarse powder, fine powder, ultrafine powder, and micro powder of different fineness wait