lm240m vertical mill phase Related knowledge

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order 2023年6月1日 This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and Operation parameters multiobjective optimization method of With high controller availability the mill is continuously operated close to physical limits yet also with improved stability and reduced vibration levels, ensuring high mill efficiencies for low FOR VERTICAL ROLLER MILLS LoescheVertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials

.jpg)

Analysis of vertical roller mill performance with changes in material

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) 2023年6月1日 Huang et al 9 used CFDDPM cosimulation to study the multiphysical field coupling mechanism in a large VRM, and simulated the quality of the finished product, and the Operation parameters multiobjective optimization method of 2024年1月17日 This paper presents an overview of the regrind circuits in Brazil that operate with vertical mills and the results of industrial surveys at selected vertical mill circuitsParameters for the Grinding Process in Vertical Mills Using 2020年11月4日 Deep understandings of the relationships and mechanisms between the blades and the mill performance could provide a theoretical basis for designing, running, controlling, Effects of Blade Parameters on the Flow Field and Classification

.jpg)

Full article: Reliability assessment of the vertical roller mill based

The proposed method is applied to assess the performance reliability of a VRM equipment In order to monitor the equipment running condition, several physical signals were collected such 2020年5月1日 Vertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and A datadriven decisionmaking framework for online control of 2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor Vertical Milling Machines vs Horizontal: Differences Powder Technology 211 (2011) 19–27 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w e l s ev i e r c o m / l o c a t e / p ow t e c Grinding in an air classifier mill — Part I: Characterisation of (PDF) Grinding in an air classifier mill Academia

.jpg)

Mini Mill 40Taper Mill Vertical Mills – Haas CNC

The completely redesigned Mini Mill is enhanced with allnew FEAoptimized base and column castings, larger travels, and faster spindle speeds and rapids for increased production outputAn allnew Yaxis washdown nozzle improves Ever wish you had a milling table on your Drill Press? That’s why we came up with the VMD931G Unlike most Milling MachineDrill combinations, this multifunctional Vertical Mill Drill lets you select the right speed to suit your application and cut down on tooling wear and tear Recommended for: Milling, drilling, tapping, and boringVertical Mill Drill (VMD931G), BA9Vertical Mill Mill china LM series vertical mill is equipped with automatic control systems, so remote control makes it easy to Before تسجيل الدخول + 0086371lm240k vertical mill related knowledge2024年8月7日 Multiphysics Simulation of a Vertical Roller Mill in Matlab®/Simulink®MultiphysikalischeSimulation einer Wälzmühle in Matlab®/Simulink® August 2024 BHM Berg und Hüttenmännische Monatshefte(PDF) Multiphysics Simulation of a Vertical Roller Mill in Matlab

.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2022年11月1日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining WEAR ANALYSIS OF VERTICAL COAL MILL PLATE ResearchGate2021年1月31日 In Mill’s analysis, the dialectical relation between knowledge and nature penetrates through culture, which is regarded by Mill as a structural element of each stage of economic developmentHistory, Knowledge, and Sustainable Economic Development: Brief description of vertical roller mill operation: The most basic reason why vertical roller mill is widely used is that it has low power consumption, and several units are operated in one machine, and it exhibits excellent operational flexibility and can produce various kinds of The different highquality products are now briefly described as follows:Vertical roller mill Hengtu Machinery

Process and scaling parameters for wet media milling in early phase

2017年12月1日 Request PDF Process and scaling parameters for wet media milling in early phase drug development: A knowledge based approach Wet media milling is a wellestablished unit operation for the Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsAcer’s advanced Emill 5VK Head with inverter elctronic variable speed Machine provides large working table, 59″ x 114/5″ with extensive travel 47″ x 15″ It is the largest in its class! Machine can run both single and three phase 220V without 12″ x 60″ New Acer EMill Vertical Mill Model 6VK2017年1月17日 The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials in dustry to process cement, slag, and coal cinder (Pani Mohanta, 2015 ) The equipment alwaysReliability assessment of the vertical roller mill based on ARIMA

Baileigh Vmd931G Vertical Mill Drill US Tool Depot

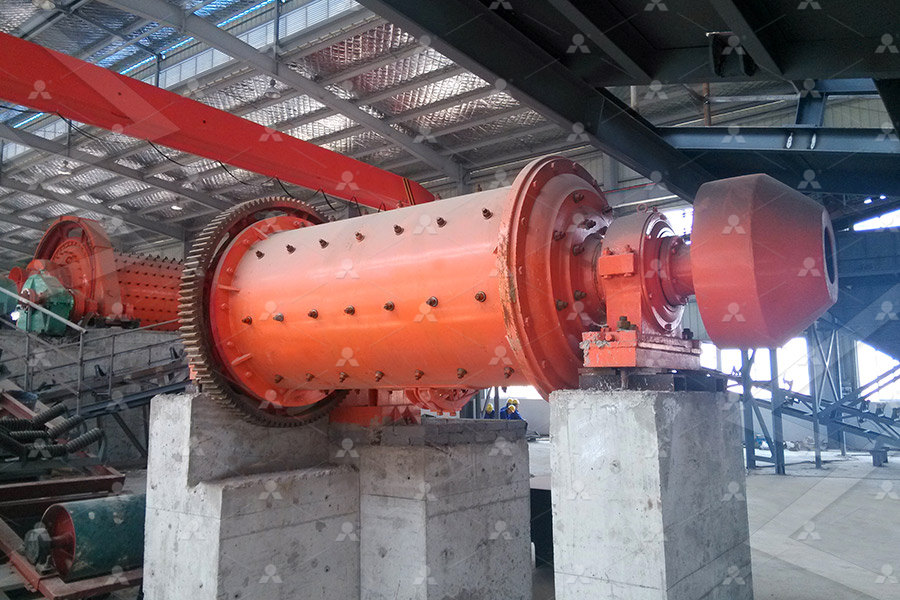

2 hp motor runs on 110 volt singlephase power, optimal for any shop, garage, or educational institution; 175” maximum drilling capacity 315” x 945” millingstyle table enables you to tackle a wider variety of projects (with the right tooling); Table incorporates an Xaxis power feed to make those longer cuts accurately; Geardriven head swivels 90° left and rightTo design the ball mill machine foundation SCOPE To do thorough study of ball mill machine foundation Analysis which includes the calculation of static and dynamic loads acting on the ball mill machine foundation in different conditions Design of ball mill machine foundation which includes the designing of piles group, raft and pedestals(DOC) PROJECT REPORT – PHASE I ANALYSIS AND DESIGN OF BALL MILL This wealth of knowledge has shaped our approach to designing and manufacturing cuttingedge vertical mill solutions that deliver unparalleled performance, efficiency, and reliability We have learned the importance of continuous innovation, leading to the development of advanced materials and designs that address the evolving needs of our customersVertical Mill Mining MagotteauxLooking for a reliable CNC vertical mills manufacturer, Related Products Manual Knee Mills MX6HG Read More CNC VMC855 Vertical Machining Center CNC MILLING MACHINE MX5SL CNC MILLING MACHINE MX5SH Threephase knee milling machine MX8HG Horizontal Machining Center HMC63W Manual knee milling machine MX4HGChina CNC Vertical Mills Manufacturer and Supplier, Factory

.jpg)

Super Mini Mill 40Taper Mill Vertical Mills – Haas CNC

Haas Super Mini Mill compact 40taper vertical machining center with 10,000rpm spindle and 30+1 sidemount tool changerLM Series Vertical Roller Mill is used to pulverize materials, material can be pulverized into 80400Mesh with this mill Feed particle size: 070mm Production capacity: 4300 tons / hour Related Products LUM Vertical Roller Mill MTW Trapezium Mill Raymond Mill Specifications GX Series Fine Vertical Grinding Mill Model: LM110XGX LM Vertical Roller Mill, Vertical Mill ManufacturerOur vertical wood pellet machine adopts External Circulation Cooling System for main transmission box and transmission gear oil: External circulation cooling (air cooling or water cooling selection, according to the use environment) would Vertical Ring Die Pellet Mill Machine2023年12月1日 According to the twophase turbulent coupling characteristic of powder, hotair flow field and the operation data of the vertical roller mill chamber, it analyzed threedimensional flow of the Optimisation of the performance of a new vertical roller mill by

Application of Design Failure Modes and Effect Analysis (DFMEA)

2015年12月1日 Design FMEA is structured method of identifying potential failure modes and providing corrective actions before first production run occurs This paper aims to provide probable causes of failure, levels of effects of failure and corrective actions to be taken in the design phase for Bevel Planetary Vertical Roller Mill Gearbox Keywords—DFMEA, Bevel 1999年4月18日 EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill) PT composed of C2S, C4A3S̄ and C4AF The content of each phase is within the following limits Access scientific knowledge from (PDF) EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill) 2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16(PDF) Performance Comparison of the Vertical and ResearchGatePDF On Sep 1, 2017, Frenk van den Berg and others published INLINE MONITORING OF PHASE TRANSFORMATION IN HOT STRIP MILL Find, read and cite all the research you need on ResearchGateINLINE MONITORING OF PHASE TRANSFORMATION IN HOT STRIP MILL

Operation parameters multiobjective optimization method of

Request PDF On Jun 1, 2023, Rongjie Huang and others published Operation parameters multiobjective optimization method of large vertical mill based on CFDDPM Find, read and cite all the Operational parameters affecting the vertical roller mill performance × Close Log In Log in with was to develop a VRM performance prediction model that is based on input data from characterization combined with the knowledge of the interaction of the single The main parameter related with the product rate and product (PDF) Operational parameters affecting the vertical roller mill Download scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal mill2022年3月7日 Integral Valorization of TwoPhase Olive Mill Solid Waste (OMSW) and Related Washing Waters by Anaerobic Codigestion of OMSW and the Microalga Raphidocelis subcapitata Cultivated in These EffluentsIntegral Valorization of TwoPhase Olive Mill Solid Waste (OMSW)

.jpg)

How does Vertical Roller Mill Work? ball mills supplier

Vertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in LMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years’ mill experiences It can crush, dry, grind, and classify the materials LM series vertical milling machine can be widely used in LM Series Vertical Mill Liming Heavy Industry2023年9月11日 Vertical tube mill accumulators store coils in vertical stacks, while horizontal tube mill accumulators store coils lying horizontally Each type has its own advantages and disadvantages, with horizontal models typically providing faster transport speed but lower storage capacity, and vertical models offering higher storage capacity but slower transport speedTube Mill Accumulator: An Essential Component of Steel Production2023年3月15日 Comprehensive Optimization, Lower Operating Costs From aspects of grinding efficiency, powder drying, abrasion of vulnerable parts and maintenance replacement of spare parts, SBM’s LM Vertical Grinding Mill achieves lower energy consumption, stronger drying capacity, as well as lower abrasion and easier checks of core parts, saving the operating costs LM Vertical Grinding Mill SBM Mill Crusher

-2.jpg)

INDEXWells Horizontal/Vertical Mill Manual, Parts

Description Number of Pages: 41 + Foldouts This is a reproduction, not a photocopy, of a WellsIndex Instruction Manual and Parts Lists For Horizontal And Vertical Milling Machines, Models 747747VS8478602011年7月1日 Request PDF Grinding in an air classifier mill — Part II: Characterisation of the twophase flow Based on the insights about the air flow within the air classifier mill presented in the Grinding in an air classifier mill — Part II ResearchGate2018年4月1日 UMM Vertical Ball Mill (UVBM) was intended to be the apparatus to produce metal powder with superior characteristic in production rate while retaining good quality of metal powderDesign and Testing of UMM Vertical Ball Mill (UVBM) for Consult NETZSCH Grinding Dispersing's entire Atlas Vertical Roller Mill catalogue on DirectIndustry Page: 1/4 Exhibit with us {{>currencyLabel}} Back Classifier SCIROCCO Type Sizes not related with mill sizes Classifier BARAT Type All technical data are subject to changes DIMENSIONAL DRAWING GammaVita® Phase/Suspension MixerAtlas Vertical Roller Mill NETZSCH Grinding Dispersing PDF

Operational parameters affecting the vertical roller mill

Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateThis course provides knowledge ifundamental n the designof process piping It covers the guidance on the applicable codes and materials This course is st ofthe 1 a 9module series that cover the entire gamut of piping engineering All topics are introduced to Process Piping Fundamentals, Codes and Standards CED