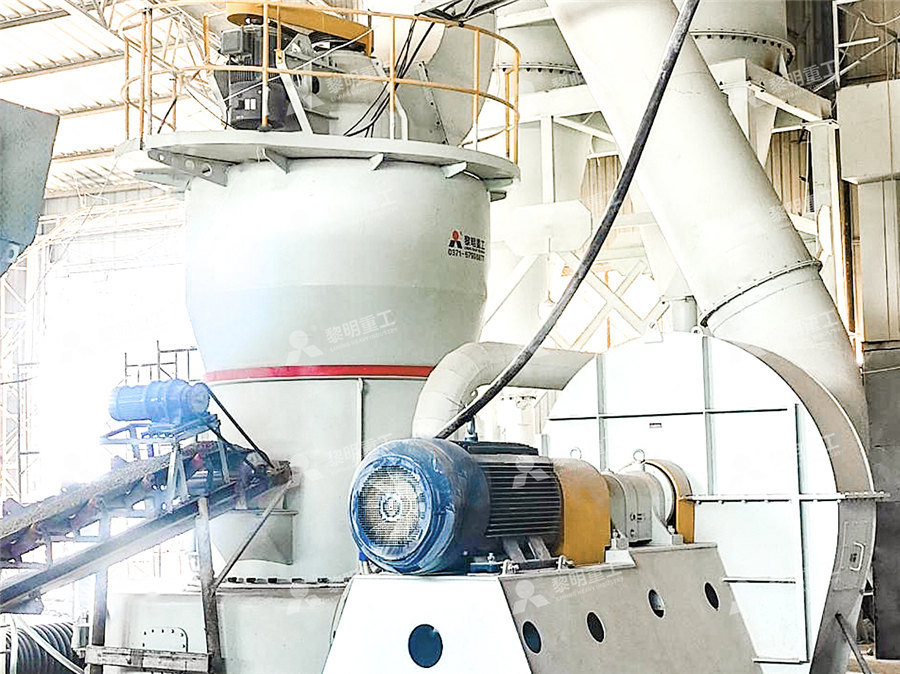

Suspension roller mill output 20TH

20High Mill Sendzimir

At Sendzimir, we’re renowned for our 20High Mills’ ability to roll rigid materials to very thin gauges without needing multiple anneals This unique capability produces highquality surfaces that are challenging to replicate with other 2019年3月11日 The 20roll mill is suitable for strip processing of stainless steel, silicon steel, carbon steel, nonferrous metals, etc The equipment has the characteristics of high speed, stability, good surface quality, and good shapeSendzimir 20 High Rolling Mill Hani Tech2020年1月23日 The Sendzimir mill arch is integrally cast and prestressed, and a circular arc track is provided in the arch to secure the backup roll All the intermediate rolls are fixed on the arch by the suspension hydraulic cylinders Sendzimir Mill Features 20Hi Cold Rolling Mill Hani The 20 high rolling mill from ANDRITZ Metals Germany is mainly used for cold rolling of metal strip to thinnest final gages and wide range of strip width The special feature in a 20 high mill is the relation between work roll diameter and Sundwig 20high cold rolling mill Andritz

.jpg)

Sendzimir’s 20High Mills

2024年3月20日 Sendzimir’s 20high mills are unique in that they have a small, chockless work roll and a cluster configuration for the backup rolls The cluster configuration transmits the roll 20 High Mills are used for highspeed production of cold rolled strip for both ferrous and nonferrous metals The system impressive accuracy tolerances deliver performance levels unmatched by traditional mills Roll Gap 20 Hi Cold Rolling Mill TenovaIn the main machine of highpressure suspension roller mill, a highpressure spring with a pressure of 10001500kg is fastened on the grinding roller hanger After working, the grinding YGM HighPressure Grinding Mill Shanky MachineryDMS 20Hi EcoMill for stainless steel features advanced strip cooling and flatness control systems to ensure increased rolling speed, maximum strip width and minimum thickness WORLD RECORDS: Minimum strip thickness: below 30 DMS 20Hi cold rolling mills for carbon, stainless and

.jpg)

Raymond Mill Models And Parameters

2021年8月27日 The trapezoidal mill draws on the advantages of the Raymond mill and the suspension roller mill, and connects the grinding roller assembly through a tie rod and a horizontally placed spring The radial force generated YGM series high pressure suspension grinding mill Breaking through the bottleneck of traditional pendulum mill production capacity, enjoy the advantages of large single production capacity at home and abroad, single processing YGM Series High Pressure Suspension Grinding Mill即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。DeepL翻译:全世界最准确的翻译 DeepL TranslateYGM High pressure suspension mill, With the same power, the output is improved by 1030%, the grinding force imposed on the material by the grinding device is improved by 8001500kgf, 4The grinding roller adopts the most YGM Series Suspension Mill LIMING (Shanghai)

.jpg)

Roller mill Wikipedia

An early 20thcentury oilseed rollermill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing 2022年10月21日 The ultrafine ring roll mill is more energysaving If the output and fineness are the same, compared with the Raymond mill, the system energy consumption of the ultrafine ring roll mill is one third of that of the Raymond mill Moreover, the grinding pressure of the ultrafine ring roll mill on the material is also 8001200kg higherHow to choose ring roll mill and Raymond mill SBM Ultrafine Fig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller MillsGrinding Process Optimization Featuring Case Studies and Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill

.jpg)

Detailed introduction of Raymond mill: Blade + grinding roller

2022年5月16日 Introduction to Raymond Mill: Raymond mill, also known as suspension roller mill or pendulum mill, is widely used in metallurgy, building materials, chemical industry, mining and other fields No more than 8% of the mineral material is ground and processed, and the fineness of the finished product is generally between 150 mesh and 800 meshR Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orRoller Mill Springer2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg it can not only reduce energy consumption but also increase output(PDF) Performance Evaluation of Vertical Roller Mill inRoller mills are now operated with throughput capacities of more than 500 tons per hour of cement raw mix (Loeschemill, Polysius double roller mill, Pfeif ferMPSmill, SKET/ZABroller mill) The working principle of roller mills is based Roller mills INFINITY FOR CEMENT EQUIPMENT

.jpg)

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM The conventional control system of VRMdidapatkan jumlah input sebesar ,24 Kcal/jam dan output sebesar ,11 Kcal/jam Nilai efisensi panas pada Vertical Roller Mill adalah 97,60% atau panas hilang sebesar 2,40% Hal ini menunjukkan bahwa kinerja alat Vertical Roller Mill Unit RKC masih berfungsi dengan baik Kata Kunci : Vertical Roller Mill, neraca panasTUGAS AKHIR MENGHITUNG NERACA MASSA, NERACA PANAS, 2021年8月27日 Raymond mill is a vertical mill It is widely used because of its small footprint, low investment cost, and simple operation Raymond mill is widely used in the industrial field, especially in the field of mine milling It can pulverize different raw materials Processing is divided into many different models according to the outputRaymond Mill Models And ParametersThe Horning Stationary Roller Mills are built to crack corn with the highest quality on the market Efficient and tough, featuring a 2belt drive with output volumes from 250 to 330 bushels per hour It is available with a 5HP singlephase or threephase motor and can be customized for a host of applicationsStationary Roller Mills and Corn Crackers Horning

Roller Mills vs Hammer Mills in Feed Mill Operations LinkedIn

2023年11月16日 Roller Mills: Tracing the history The late 19th and early 20th centuries saw roller mills powered by Uneven feeding can lead to fluctuations in the quality of the output Modern mills According to 30 years’ research and development experience, basing on design of LM Vertical Mill, adopting technology about superfine vertical mill’ s grinding roller made in Germany, LUM series superfine vertical roller grinding mill was produced as the fist choice for nonmetallic ore milling, the plant can be widely used in construction, mining machinery, chemical, concrete, LUM Series Superfine Vertical Roller Grinding Mill2024年8月7日 Multiphysics Simulation of a Vertical Roller Mill in Matlab®/Simulink®MultiphysikalischeSimulation einer Wälzmühle in Matlab®/Simulink® August 2024 BHM Berg und Hüttenmännische Monatshefte(PDF) Multiphysics Simulation of a Vertical Roller Mill in Matlab 2017年1月1日 For decades vertical roller mills have been in use in the cement industry for the grinding of cement raw material and coal Since the 1980's this mill type has also been used for combined or Case studies and operational results of modern MVR vertical roller mills

Vertical roller mill, Vertical roller grinding mill DirectIndustry

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchases Exhibit with us {{>currencyLabel}} Output: 4 t/h 300 t/hOur roller mills are efficient and easy to use! wellbuilt system to save you time and money by increasing the efficiency and output of your grain roller mill or feed mill operation To get the most out of your grain roller mill, call RMS at (605) Grain Roller Mills RMS RollerGrinder2017年7月17日 A threeroll mill is used mostly for dispersion, but does some grinding as well It uses three rollers of different speeds and directions to cause the sheer force between them to disperse and grind particles The threeroll Threeroll mill selection tips Processing Magazine2024年1月1日 The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the material held between them The grinding area is in a sealed crate, and the particles form a high output, easy maintenance, etc, and has been widely applied in cement, steel and power Roller Mill SpringerLink

.jpg)

Difference between Raymond Mill and HighPressure Suspension Roller

2022年10月17日 Compared with the Raymond mill, the highpressure suspension roller mill adds a highpressure spring above the grinding roller This unique design greatly increases the service life of the consumable parts of the mill, and the fineness of the finished product can be arbitrarily adjusted within the specified rangeWe offer two different types of rolls – steel or cast; multiple roll configurations ranging from 4 to 15 grooves per square inch depending on the particle size you require – and a variety of input and discharge options, including our Elevator Discharge or Crimper Mill, Blower Discharge Mill, Conveyor Discharge Mill, Electric Roller Mill, and Auger Discharge MillRENN Roller Mills High Performance Grain Processing Grain The output particle size of the YGM highpressure grinding mill ranges from 80 mesh to 425 mesh, surpassing the 30325 mesh range of the Raymond mill Due to the robust pressure exerted by the highpressure spring, the YGM mill exhibits YGM Raymond Roller Mill2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) The latest innovative technology for vertical roller mills

.jpg)

有道翻译文本、文档、、在线即时翻译

有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文翻译、翻译、文档翻译、pdf翻译、doc翻译、ppt翻译、人工翻译、同传等服务。SD threeroll mills For topquality requirements SD threeroll mills machine series Technical data Specification SDY200 SDX300 SDX600 SDW800 SDV1300 SDVE1300 Drive 22 kW 75 kW 135 / 175 kW 375 kW 55 / 75 kW 55 / 75 kW Rolls Open Open, VIVAC Open, VIVAS, VIVAC Open Open Open, VIVAS Roll diameter 150 mm 200 mm 200 mm 300 mm 400 mm SD threeroll mills For topquality requirements Bühler Group2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic The invention provides a material grading grinding production device applied to a suspension roller type ring roller mill, which comprises a mill body, an auxiliary grinding mechanism, a the driving motor 107 is fixedly installed at the bottom end inside the mill housing 101, an output shaft of the driving motor 107 is connected with a CNA Material grading grinding production Google

Roller mill IMD 800 series Modern Process

Find out all of the information about the Modern Process Equipment Corporation product: roller mill IMD 800 series Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale 2024年8月7日 The development of innovative products increasingly requires interdisciplinary collaboration among the fields of mechanical engineering, electrical/electronic engineering, and software The growing complexity of products, driven by increased automation, poses significant challenges Many equipment manufacturers optimise their development processes using Multiphysics Simulation of a Vertical Roller Mill in Sudenga’s Roller Mill is available in single, double, and triple pair high setups with capacities up to 36 TPH at 500 microns Available with roll gap automation and load compensating controls Specifications; Photos; Sudenga ROLLER GRINDER (RGS2020) Product DetailsRoller Mill Sudenga Industries Inc Request a QuoteThree roll mill manufacturerZili machinery uses the advanced technology to develop dependable and precise roll mills Each three roll mill is highly standard or customized for client's specific need With our enrich innovation and thirty years' experience of production, our triple roll mill machines have been all over the world: China, USA, Europe, Russia, India, Korea, Indonesia, Three roll mill manufacturer,China three roller mill for salezili

.jpg)

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tiresMVR vertical roller mill with planetary gearbox Gebr PfeifferThe highpressure suspension roller mill is the Raymond mill, which is an upgraded version of the Raymond millUnder the same power conditions, the output of the highpressure suspension roller mill is 10%20% higher than that of the ordinary Raymond mill, and the fineness of the ground material is finer and the dust is lessroller mills suspensionWe can design and manufacture vertical roller mills of diversified specifications and models for raw meal, cement, and slag comminuation systems in cement clinker production lines with capacity up to 10,000t/d To continuously meet the needs of grinding various materialsVertical Roller Mill (VRM)SinomaLiyang Heavy Machinery Co, Ltd

.jpg)

High Pressure Suspension Roller Mill China Ruida Machinery

The highpressure suspension roller mill is mainly composed of a main machine, a fineness analyzer, a blower, a finished product cyclone powder accumulator, a bag dust collector and a connecting air duct According to user needs, Compared with other mills, the output is increased by 1020% under the same power conditions,