Advantages of increasing cement bulk rate in cement industry

.jpg)

Trends in the global cement industry and opportunities for long

2019年4月20日 Cement production is associated with high levels of CO 2 emissions, with an average of 866 kg of CO 2 emitted per ton of cement produced2015年12月1日 We believe that large multiregional cement companies can turn the performance picture around and create sustainable value by making The cement industry at a turning point: A path toward improving its carbon footprint (emissions per unit of output) by improving energy efficiency, increasing the use of alternative fuels, and deploying renewable energy sources With a IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT 2023年3月1日 In locations where the use of bagged cement and hand mixing is commonplace, a shift to bulk cement offers the opportunity for improved material efficiency as well as the use of A forward looking perspective on the cement and concrete

The cement industry at a turning point McKinsey Company

Valued at approximately $450 billion,1 the cement industry has shown a mixed financial performance over the past 30 years Exhibit 1 looks at the industry through three different 2023年10月13日 The IEA tracks energy consumption and production data for the cement industry globally, while the DOE provides data on energy usage and costs for cement Global database of cement production assets and upstream The good news is that the cement industry is poised to sustain its gross margin expansion especially in Europe, primarily driven by higher cement prices and significantly reduced fuel World Cement Industry Status, Trends Outlook for 2024 2022年6月19日 Cement demand is increasing every year as a result of industrialization, urbanization, and population growth Such noticeable consumption growth has changed the Advances in statistical quality control chart techniques and their

.jpg)

How cement companies create value: The five elements of a

The bestperforming cement companies succeed by blending structural moves, such as changes in asset footprints or supply chains, with effective commercial practices based on a deep Ultratech Cement predicts an 8% rise in cement demand, driven by increased construction activities, government spending on infrastructure, and ongoing residential projects across Indian Cement Industry Analysis IBEF2022年7月1日 Adopting CBE in the cement sector requires changing existing business models Currently, cement industry business models are predominantly aligned toward increasing supply of cement to increase the business and economic performance of cement plants In contrast, CBE advocates resource sufficiency and efficiency through cascading use of biomassSustainable transition towards biomassbased cement industry: A 2022年4月27日 But the question arises, is it ecofriendly? That brings us to the pros and cons of cement Advantages of cement By combining cement with plaster and water, we can apply it to masonry surfaces to create a smooth 8 Upsides and Downsides of Cement Use Tech Quintal

15 Types of Cement Uses, Advantages

Introduction 15 Types of Cement – Uses, Advantages Disadvantages [Complete Details]: – Cement is a finegray powder that is blended in with water and different substances to make mortar or concreteCement is a critical part 12 “Global Cement Demand Stagnates” According to On Field® Research recently made global cement market demand is expected to be flat in the period 20242030 except for increases in the Middle East, India, and Africa Weakest cement markets are anticipated to be Turkey, China, andWorld Cement Industry Status, Trends Outlook for 2024 2021年11月1日 For the year 2019 alone, the growth in EFOS was only about 01 % with fossil emissions increasing to 99 ± 05 GtC yr1 excluding the cement carbonation sink (97 ± 05 GtC yr1 when cement An Overview of EcoFriendly Alternatives as the Replacement of Cement 2016年8月31日 Ever since its foray into coastal transport, Ambuja has greatly enabled swifter transportation of bulk cement and brought many coastal markets within easy reach Ambuja Cements has the distinction of exploiting the advantages of sea route transport in the Indian cement market Rama Murthy Nety, Head – Ports Shipping, speaks on the success storyDelivery of bulk cement via sea transport ensures safe and timely

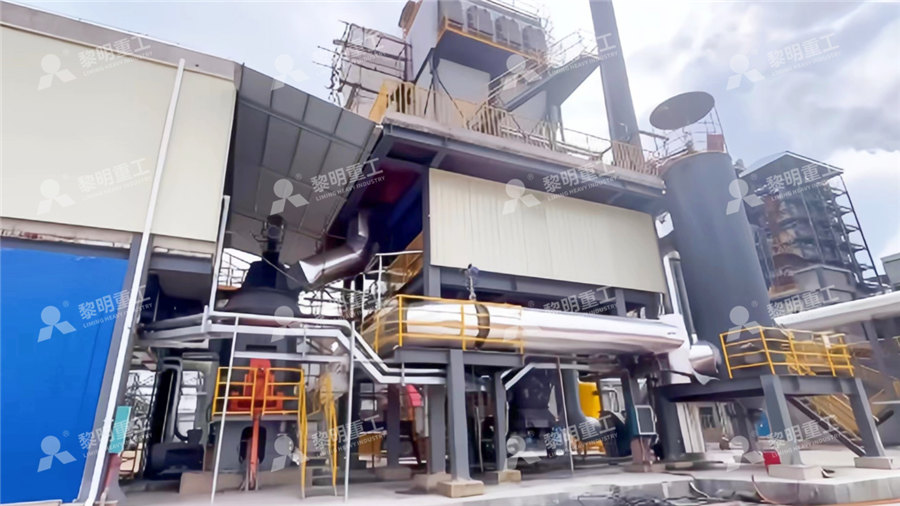

Clinker grinding technology in cement manufacturing

2019年1月3日 Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits significantly, India Cement Industry Report Statistics for the 2023 India Cement market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports India Cement analysis includes a market forecast outlook to 2030 and historical overview Get a sample of this industry analysis as a free report PDF downloadIndia Cement Market Size Share Analysis Industry Research 2010年1月1日 The international cement market –while constituting a small share of world industry output—has been growing at an increasing rate relative to local production in recent yearsGlobal Cement Industry: Competitive and Institutional DimensionsGrowth of Cement Industry in India Infographic Oligopoly market, where large players have partial pricing control * Low threat from substitutes * Indian cement companies are amongst the world’s greenest cement manufacturers * India's top four cement companies—UltraTech, ACCAmbuja, Shree Cement, and Dalmia Cement—are set to add over 42 million tonnes of Growth of Cement Industry in India Infographic IBEF

Alternative Fuels in Cement Manufacturing IntechOpen

2011年8月9日 The cement manufacturing industry is also under increasing pressure to reduce emissions Cement manufacturing releases a lot of emissions such as carbon dioxide (CO 2) and nitrogen oxide (NO x) It is estimated that 2015年4月1日 The cement manufacturing industry is under increasing pressure from the environmental protection agencies to reduce the emissions The usage of alternative fuels in cement manufacturing not only helps to reduce the emission but also has significant ecological benefits of conserving nonrenewable resources [23] Recent development on the uses of alternative fuels in cement Cement industry is the second most important primary and basic production during 200203 was 11635 million tonnes with a growth rate of 884% All restrictions on cement prices and distribution have been cement powder is then taken to packing plant or discharged from silo to a bulk loader directly Types of cementImportance of Cement Industry in India IJMRA2020年7月14日 At 2014 the production of China’s cement is 248 billion tons, equivalently 177 ton per capita and 1374 gram per USD of GDP, the driving forces of China’s cement industry include A perspective on environmental sustainability in the cement industry

.jpg)

Utilisation of Alternative Fuels and Raw Materials in Indian Cement

2022年1月15日 With the net zero target confirmed for India, the Indian cement sector needs to optimise its efforts in utilising alternative fuels and raw materials, as these two factors are instrumental in determining the industry’s contribution in the nation’s carbon neutral future Climate Change, fast depleting natural resources like limestone, increased cost of conventional fuels 2019年4月20日 The cement industry produces the second most consumed product by weight in the world after steel, utilising roughly 19% of the global electricity generation ([IEA] – International Energy Agency, 2018; [IEA] – International Energy Agency, 2017)Thereby releasing globally from 5% to 8% of anthropogenic CO 2 emissions (Richards and Agranovski, 2017; Summerbell et Trends in the global cement industry and opportunities for Impact of GST on Cement Industry These pointers explain how GST rate on cement impacts this industry – Transportation cost; Usually, cement manufacturers locate their operational bases near limestone quarries The fact cement has a high demand across India often makes the cost of transporting the product highGST Rate on Cement Impact of GST on Cement Industry Groww2014年5月15日 This study aims to produce an ecofriendly white cement clinker by incorporation of celestobarite mine waste Samples of synthesized pure MonoclinicC 3 S, CubicC 3 A and rawmix were dried AN OVERVIEW OF INDUSTRIAL WASTES AS FUEL AND MINERALIZER IN THE CEMENT

MARKETING TACTICS OF THE CEMENT INDUSTRY INSPIRA

cement industry The sac must be lightweight as the cement merely heavy Price In the cement industry, price depicts the difference between its competitors' companies The cement industry doesn’t show a great difference, it just displays 36 rupees in the type of bags used But,The market size of the India's cement industry was 3,6445 million tonnes in 2022 The industry hopes to reach 4,8326 million tonnes by 2028 at a compound annual growth rate (CAGR) of 494 per cent during 202320283 India’s cement industry has strong linkages with other sectors, such as, infrastructure, construction, housing,Microsoft Word Cement Industry Report March 2023 MSdocx2020年1月1日 Soil bricks were produced by increasing the cement compositions upto 5%, 10%, 15%, 20% of the total volume, and compacted to 3333% and 4444%, while applying 5kN force, and allowed for curing for (PDF) Cement Industry in Sri Lanka ResearchGate2018年8月17日 According to an Ethiopian Ministry of Industry report, the country has a high expected cement consumption due to a rapid urbanization (43%), high rate of population growth (26%), a substantial (PDF) The Cement Industry in Ethiopia ResearchGate

.jpg)

Cement Industry in Malaysia: Challenges and Potential

2024年1月3日 The recent upsurge in bulk cement prices, witnessing a notable 247% yearonyear increase in August 2023, highlights the industry's strength This surge contrasts with the threeyear average price, standing at 2019年2月14日 Cement industry is a very emissionsintensive In mid1980s, tires became very popular to the cement manufacturer as alternative fuel to cope with the increasing fossil fuel costs The advantages of using tires and rubber waste are high carbon The feeding rates of MBM Min cement kilns vary from country to country For Alternative Fuels from Waste Products in Cement Industry2023年9月25日 The cement industry is one of the most important industries in the development of a country utilization rate of fly ash is only 1012%, increase the ability of land to support plant growthUtilization of Fly Ash Waste in the Cement Industry and its 2021年6月1日 The study uses survey responses from four hundred operations' managers of cement industry in order to know about the advantages and benefits that cement industry have experienced by Just in time Implementation of Lean Manufacturing in a Cement Industry

Cement Industry in Sri Lanka JRTE

2020年1月2日 equivalent from cement industry rate, before and after the adoption of waste reuse [10] Process modification in the cement industry can be done according to two parts which can reduce the environmental impact of cement production • Process plant optimization • Production process optimizationIncreasing cement growth in developing countries significantly contributed to the increased CO2 volumes [5] 19 JRTE2020 pollution indicator and values for CO2 equivalent from cement industry rate, although some are also sold for beneficial reuse 612 Fly Ash The use of fly ash in Portland cement concrete has many advantages(PDF) Cement Industry in Sri Lanka Academia2020年7月3日 As the cement production industry grows and adapts to new technologies and innovations, qualified methods of using alternative fuels will play an important role in ensuring the profitable (PDF) SELECTION AND USE OF ALTERNATIVE FUELS IN THE CEMENT Indonesian cement industry is in a crisis It started from 2014 till present, where Indonesian cement industry has been experiencing an oversupply capacity (Indocement Public Exposure Report, 2020Q1, p: 816), on the contrary capacity kept on increasingSurvival From Crisis of Cement Industry in Indonesia

FYEFEPS2HDZ49G5Z0[B.jpg)

Assessment on Cement Production Practice and

2020年1月1日 The demand for cement, which is one of the key components of concrete, is high in Ethiopia, but it is the most expensive and environmentally unfriendly construction materialmajority of cement is shipped in large quantities to clients via trucks, railways, and bags, typically weighting 50 kg each Most cement is used in concrete as an essential material in the construction industry [38, 40] There are two types of processes used in cement production: the dry process and the wet process [38]Impacts of Cement Production on the Environment with Practical 2023年9月15日 SO 2 emissions first grew continuously with an annual increasing rate of 10 % from 1990 to 2003 the thermal substitution rate in the cement industry in the EU reached up to 50 % (Gao, 2021 which could provide potential environmental and economic advantages In China, the clinker to cement ratio experienced a downward Historical trend and decarbonization pathway of China's cement industry 2021年3月1日 Environmental sustainability in cement industry: An integrated approach for green and economical cement production(PDF) Environmental sustainability in cement industry: An

.jpg)

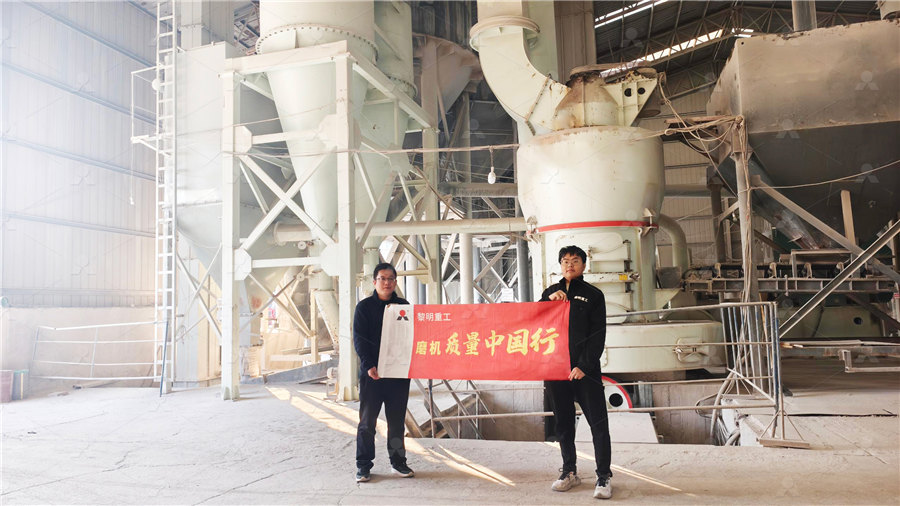

The Economics of Bulk Indian Cement Review

2022年5月15日 Also, the cement industry is keen on promoting bulk loading of cement for more efficient handling leading to faster loading as well as evacuation, thus improving turnaround time It offers advantages such as reduction in loss of cement, no seepage due to 2015年4月4日 The study uses survey responses from four hundred operations' managers of cement industry in order to know about the advantages and benefits that cement industry have experienced by Just in time Improvement of Logistics and Supply Chain Management in the Cement As per DGCIS, India’s export of Portland cement, aluminous cement, slag cement, super sulphate cement and similar hydraulic cement stood at US$ 11815 million in FY21 In 2021, working remotely is being adopted at a fast pace and demand for affordable houses with ticket sizes below Rs 4050 lakh (US$ 53,69467,118) is expected to rise in Tier 2 and 3 cities, leading to an Indian Cement Industry, Top Cement Companies in India IBEF2014年12月11日 The rate of development in the Mozambican cement industry has certaintly been rapid in recent years, with clinker and cement sales increasing by 137% in 2010 and Cimentos de Moçambique's sales rising by 98% in 2013The cement industries of southern Africa

.jpg)

(PDF) Competitive Strategies and Performance of Selected Cement

2023年2月10日 In an organization, performance is affected by various factors The performance of the cement industry in Kenya has been adversely affected by the challenge of inadequate employee training 2015年12月1日 With the exception of the crisis years of 2008 and 2009, the cement industry has shown strong cumulative returns, as expressed in TRS Sector performance has been partly cyclical, with the 5year TRS compound annual growth rate (CAGR) oscillating between 4 and 33 percent at the extremesThe cement industry at a turning point: A path toward value creation