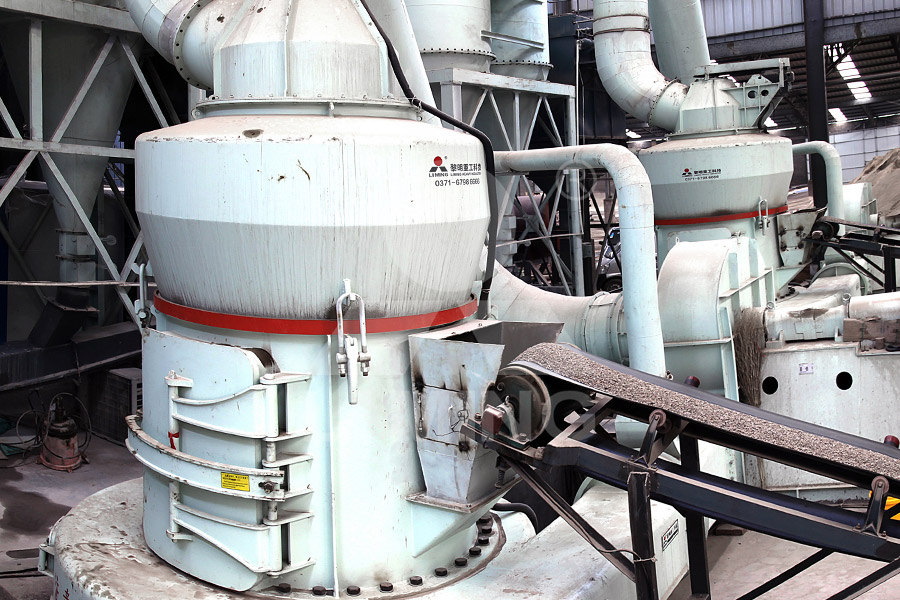

Manufacturing process of calcium carbonate crushing station

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk occurs as a microcrystalline material and has 展开2024年8月21日 Calcium carbonate manufacturing process involves extracting natural calcium carbonate deposits and purifying them to create different forms of the compound for specific The Ultimate Guide Calcium Carbonate Manufacturing ProcessLight calcium: Light calcium carbonate, also known as precipitated calcium carbonate, or light calcium for short, is produced by chemical processing A complete calcium carbonate processing plant mainly consist the following 4 4 Steps to Build a Calcium Carbonate Processing Plant2023年12月7日 For natural calcium carbonate, the process typically involves crushing the ore, followed by screening and grinding The ground ore is then washed to remove impurities For synthetic calcium carbonate, the process What is the steps in the Calcium Carbonate

Production of precipitated calcium carbonate from calcium

2005年11月1日 Integrated pulp and paper mills use carbon dioxide (CO 2) from the lime kiln stack gas to manufacture precipitated calcium carbonate (PCC), which is synthetic calcium Calcium carbonate is divided into two industrial categories: Ground Calcium Carbonate (GCC) and precipitated calcium carbonate (PCC) The two categories use different manufacturing methods GCC is manufactured by physically How Calcium Carbonate is dioxide to form calcium carbonate There are three common processes for the production of synthetic PCC (Sezer, 2013; and Bilen, 2010): 1) lime soda process (Kraft pulping method, Eq PRECIPITATED CALCIUM CARBONATE PRODUCTION, SYNTHESIS Here is a general overview of the process: Extraction: Calcium carbonate is typically extracted from limestone, which is a sedimentary rock composed of calcium carbonate The limestone is Calcium Carbonate Manufacturing Process and Grinding Mills

Cradletogate life cycle assessment of precipitated calcium

2014年12月1日 The main PCC production method is the socalled carbonation process, in which limestone (CaCO 3) is first calcined in a lime kiln to calcium oxide, slaked with water to In the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, annual output (uncoated and coated GCC), dry or Calcium Carbonate (GCC) Hosokawa AlpineCalcium carbonate manufacturing process At first, the raw materials, such as limestone, calcite and marble are mined from the quarry Daswell supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, Customize Suitable Calcium Carbonate Plant DASWELLThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY

.jpg)

Cement Manufacturing Process INFINITY FOR

Cement Manufacturing Process by TIZITA MOGES , Crushing; Crusher is a device Limestone consist of predominately of calcium carbonate (CaCO 3), in generally its most stable modification known as calcite, in addition, they often Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process2023年3月7日 Calcium carbonate powder is a common mineral that is widely used in a variety of industries, including construction, agriculture, pharmaceuticals, and more The manufacturing process for calcium calcium carbonate powder manufacturing process LinkedInDownload Table Manufacturing Process of Decorative Paint Using Local Calcium Carbonate from publication: Evaluation of Samalout and Beni Khalid “Minia” Limestone for Producing Paint Extender Manufacturing Process of Decorative Paint Using Local Calcium Carbonate

.jpg)

Calcium carbonate manufacturing plant surface modification process

2020年1月13日 Calcium carbonate manufacturing plant surface modification process Posted: Calcium carbonate is currently the largest amount of inorganic filler in organic polymerbased materials However, calcium carbonate without surface treatment has poor compatibility with the polymer, which can easily cause uneven dispersion in the polymer base Therefore, it makes the manufacturing process more efficient by reducing the melting point of silica sand to 1,562 °F Limestone (calcium carbonate) Limestone, also called calcium carbonate (CaCO3), is another compound added to glass Pure limestone is a white powder that is poorly soluble in waterFlat Glass Manufacturing Process AGC Inc AGC株式会社2023年7月10日 Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector However, the process of cement production is associated with various environmental Cement Manufacturing Process and Its Environmental Impact2023年9月28日 Calcium carbonate manufacturing process Calcium carbonate can be processed using various methods depending on the desired particle size, purity, The crushing process reduces the size of the raw material to a more Exploring Different Grinding Mills for Calcium Carbonate Processing

.jpg)

4 Steps to Build a Calcium Carbonate Processing Plant

And to apply calcium carbonate, we need to process calcium carbonate into suitable fineness In the following part, area for storage, fed into the storage hopper above the belt conveyor, into the raw material bin of the batching 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Guide to Calcium Carbonate Grinding: Mills, Tips, and In the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, annual output (uncoated and coated GCC), dry or Calcium Carbonate (GCC) Hosokawa Alpine2017年3月3日 The phenomena of desalination processes of the waters containing a considerable amount of calcium are occurs both in cases of the pressuredriven membrane and electro membrane processes, and is Beneficiation and Mineral Processing of Calcium Carbonate and Calcium

.jpg)

Process flowchart of low and highpurity calcium carbonates

Download scientific diagram Process flowchart of low and highpurity calcium carbonates obtained from eggshells and four calcium phosphate products from publication: Simple recycling of This blog will share with you calcium carbonate manufacturing process and how to choose best calcium carbonate grinding machine Calcium Carbonate Manufacturing Process The manufacturing process of calcium carbonate involves several steps, including extraction, crushing, grinding, classification, purification, and packagingCalcium Carbonate Manufacturing Process and Grinding Mills27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM 2019年8月28日 process and evaluation of its Physical and chemical properties 1 Calcium Carbonate 1250 mg 2 Vitamin D3 200 mg Hardness test was done to measure the tablet crushing strength(PDF) Formulation of Vitamin D3 + Calcium tablets and evaluation

.jpg)

Effects of sodium silicate, calcium carbonate, and silicic acid on

2014年10月28日 nitrate degradation in the diluti on process with the addition of calcium carbonate (Tab le 1) than with both sodium silicate and calcium carbonate (Tab le 2) Thus, better results wereThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2023年12月7日 Calcium carbonate is a common mineral found in nature It is often used in a variety of applications, including construction, agriculture, and manufacturing Crushing and screening is a process used to break down calcium carbonate into smaller particles This can be done using a variety of methods, including jaw crushers,Crushing and Screening Calcium Carbonate CM Mining Learn about the detailed manufacturing process of calcium carbonate, including quarrying, crushing and grinding, classification, carbonation, drying and packaging, quality control, and its various applications in different industriesCalcium Carbonate Manufacturing IndexBox

Calcium Carbonate Powder Manufacturing Process

This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatAgain, noncarbonate magnesium compounds (for example, phlogopite) react thus: KMg 3 AlSi 3 O 10 (OH) 2 + 05 SO 2 + 025 O 2 → 05 K 2 SO 4 + 3 MgO + 05 Al 2 O 3 + 3 SiO 2 + H 2 O (vapor) Lowtemperature calcite decomposition Calcium carbonate, present in the rawmix as calcite, produces carbon dioxide, the amount of which exceeds half the Cement Clinker Manufacturing Process with ReactionsThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2022年5月5日 Calcium carbonate crushing and grinding process According to different production methods, Most of the production process of calcium carbonate is inseparable from the milling process Common calcium carbonate powders include 300 mesh, 400 mesh, 600 mesh, 800 mesh, 1200 mesh, 1500 mesh, and 2000 meshCalcium Carbonate Grinding Mill Powder Modify SBM

CALCIUM CARBONATE POWDER

equipment to process calcium carbonate minerals into various powders that can meet the requirements of industrial applications Because different industrial applications have different requirements on the particle size, shape, whiteness and particle size distribution of ground calci um carbonate powder, the processing technology of ground 2024年5月23日 How is calcite used in cement production? (Calcium carbonate processing plant) The cement production process is commonly referred to as "two grinding and one calcination" Here is an overview of cement manufacturing: 1 Raw materials like limestone and clay are crushed, mixed, and finely ground to obtain raw lime 2Calcite: A Key Ingredient in Efficient Cement Manufacturingand purity The calcium carbonate used in industries can be classified according to the manufacturing methods as ground calcium carbonate (GCC) produced by crushing limestone physically and PCC chemically formed through the calcination, hydration and carbonation of limestone GCC production is cost effective and simple process,Formation Characteristics of Precipitated Calcium Carbonate by 2017年1月1日 PDF Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Find, read and cite all the research you need on Precipitated Calcium carbonate production, synthesis and properties

.jpg)

Manaseer Carbonate

Manaseer Carbonate is one of the major Calcium Carbonate producers in the region We were established in 2016 to produce all grades of calcium carbonate, from superfine to coarse grades, with the highest standards of quality and manufacturing best practiceCaCO3 can be packaged, transferred and stored using various dedicated equipment The FlowMatic® 07 mobile bulk bag filling station can be used for connection to existing truck or silo loading zones This bulk bag conditioning equipment is available for industrial companies handling calcium carbonate and looking for a versatile, accurate and confined solutionCalcium Carbonate Palamatic Processnesium carbonate which comprises crushing dolomitic limestone, heating the crushed stone to a temperature such that a portion of its, magnesium carbonate is dissociated but substantially all of its calcium carbonate remains undissociated, grinding the soheated stone, dissolving out the magnesium carbonate fromthe heated and ground stone by treating said stone with carbon Process of manufacturing magnesium carbonate Google Patents2023年6月13日 Calcium carbonate is a widely used chemical compound with the formula CaCO3 It is an essential substance found in nature and has various industrial applications In this blog, as a responsible, reputed and trusted Calcium Carbonate Powder Manufacturer we will explore to you the stepbystep manufacturing process of calcium carbonateHow is calcium carbonate manufactured? Sudarshan Group

(PDF) Calcium Carbonate ResearchGate

2016年12月31日 Calcium carbonate is a chemical compound with the formula CaCO3 formed by three main elements: carbon, oxygen, and calcium It is a common substance found in rocks in all parts of the world (most 2019年7月10日 Ground Calcium Carbonate (GCC) Manufacturing Business Production of Ground Calcium Carbonate with 90% Brightness and Whiteness and > 90% CaCO3 Calcium carbonate is one of the most abundantly occurring minerals on earth and composes nearly four percent of earth’s crustGround Calcium Carbonate (GCC) Manufacturing BusinessPart 4 RSmC Manufacturing sodium carbonate by the Solvay process An overview of the process for post16 students Manufacturing sodium carbonate by the Solvay process Sodium carbonate is used by many different industries as a raw material and about one million tonnes is produced each year in the UK all of it by the Brunner Mond Company in Northwich, CheshirePart 4 Manufacturing Sodium Carbonate by the Solvay ProcessA large range of fillers and coating pigments for best whiteness, printability and costeffective fiber substitution We offer a wide range of carbonate products that differ in particle size, particle size distribution and brightness to suit all paper and board application needs Ground Calcium Carbonate (GCC) is composed of the crystalline mineral calcite, which occurs naturally in the Calcium carbonate for paper and board Imerys

Cement Manufacturing Process: Know Extraction, Processing

2024年9月10日 Steps of Cement Manufacturing The steps involved in cement manufacturing are as follows: Quarrying: Raw materials such as limestone and clay are extracted from quarries or mines; Crushing and Grinding: The extracted raw materials are crushed and ground into a fine powder; Blending: The crushed and ground raw materials are blended in specific proportions 2024年8月3日 Microbialinduced calcium carbonate precipitation (MICP) can enhance the physical properties of recycled aggregates Compared to traditional technologies, MICP offers environmental benefits and produces no pollution However, its mineralization efficacy is significantly influenced by the process parameters To investigate this, an MICP mineralization Factors Affecting the Physical Properties of Microbial Induced Calcium