Selection of conveyor model

.jpg)

An integrated multicriteria decisionmaking methodology for

2016年4月25日 This paper presents an integration of the analytic network process (ANP) with the benefits, opportunities, costs and risk (BOCR) model in order to select the best conveyor system The proposed model established a network with four merits, six strategies criteria, and 1996年10月1日 Following chapters examine each of five major categories of conveying systems, with practical details on their design, operation and applications The final chapter presents Mechanical Conveyors : Selection and Operation Google BooksWe define four belt wear rate metrics and develop a model to predict wear rates of new conveyor configurations using an industry dataset that includes ultrasonic thickness measurements, conveyor attributes, and conveyor throughputDeveloping and evaluating predictive conveyor belt The aim of this paper is to model and simulate the design parameters of a conveyor system that transport parts from one production stage to another The approach of modelbased design andMODELLING AND SIMULATION OF A CONVEYOR BELT SYSTEM

.jpg)

An integrated multicriteria decision making

2016年3月2日 This paper presents an integration of the analytic network process (ANP) with the benefits, opportunities, costs and risk (BOCR) model in order to select the best conveyor system2016年4月12日 This paper presents an integrated multicriteria decision making (MCDM) model of a fuzzy AHP (analytic hierarchy process) and fuzzy ARAS (additive ratio assessment) for conveyor evaluation and selection In this An Integrated MCDM Model for Conveyor Equipment 2021年8月28日 The present research article investigates three realtime MHE selection problems, ie, conveyor selection, automated guided vehicles (AGV) selection, and selection Solving Material Handling Equipment Selection Problems in an Conveyor systems are presently one popular type of MHE This paper presents an integration of the analytic network process (ANP) with the benefits, opportunities, costs and risk (BOCR) An integrated multicriteria decisionmaking methodology for

Application of multiattribute decisionmaking methods for the

2022年7月13日 Therefore, the present work aims to the selection process of the best option for conveyor by using four selected decisionmaking methods such as analytical hierarchy Now, let’s move to the selection criteria of conveyor belts Conveyor Belt Selection Guide Factors: 1) Material Compatibility: The conveyed material’s characteristics greatly influence conveyor belt selection Consider factors such Conveyor Belt Selection Guide: Factors For Optimal DOI: 1017531/EIN201615 Corpus ID: ; Selection of carry idlers spacing of belt conveyor taking into account random stream of transported bulk material @inproceedings{Gadysiewicz2016SelectionOC, title={Selection of carry idlers spacing of belt conveyor taking into account random stream of transported bulk material}, author={Lech Selection of carry idlers spacing of belt conveyor taking into 2016年4月12日 The conveyor system plays a vital role in improving the performance of flexible manufacturing cells (FMCs) The conveyor selection problem involves the evaluation of a set of potential alternatives based on An Integrated MCDM Model for Conveyor

.jpg)

Conveyor Systems Types, Specifications and Selection

Conveyor Systems Types Selection Considerations When deciding on which conveyor system best suits your needs, there are a number of key considerations these include 1: Material being transported Some important characteristics to consider are size, flowability, abrasiveness,2023年2月16日 Common Belt Conveyor Problems Even though belt conveyors have their benefits, they are complicated pieces of equipment that need to be watched and managed Among the things that need to be looked at are: Problem 1: Conveyor Runs to One Side Causes: Material buildup on idlers; Misaligned idlers; Tilted or uneven conveyor frame; Uneven belt Belt Conveyors Components, Types, Design, and Applications2019年7月10日 Was designed the mathematical model of the system "variable speed multiengine drive – conveyor – control system of conveyors", that takes into account the dynamic processes occurring in the The mathematical model of the belt conveyor ResearchGate2019年6月1日 The mathematical model of the belt conveyor I O Romanchev 1 Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering, Volume 560, International Conference on Mechanical Engineering, Automation and Control Systems 2018 12–14 December 2018, Novosibirsk, Russian Federation Citation I O The mathematical model of the belt conveyor IOPscience

Motor Selection Basics: Types of AC/DC Motors

2024年9月25日 Which type of electric motor do you size for your conveyor, XYZ table, or robot? Before you select one, Motor Selection Tip: Rule of Thumb: Use AC motors for constant speed, DC brushed and brushless motors for speed control, and 2023年9月8日 Roller Conveyor Selection Guide Roller Conveyors Our gravity roller conveyors can transport light, medium, and heavy duty loads that gave firm flat bottoms such as cartons, totes, cases, skids, drums, etc Ashland's line of roller conveyors includes models with the roller from 13/8" to 25/8" diameter and various frame stylesRoller Conveyor Selection Guide2024年5月2日 It aims to provide indepth insights into the design, installation, maintenance, and selection of conveyor belts, catering to engineers, technicians, and managers in various industriesIn the conveyor belt design manual, detailed information is provided on fire safety tests essential for ensuring the reliability and safety of conveyor beltsConveyor Belt Design Manual: Essential Techniques and Standards2016年1月1日 In conveyors commonly used in the domestic mining industry, the average distance of a set of rollers is used on the 125 m upper working route and 5 m in the lower belt, which means that there are Selection of carry idlers spacing of belt conveyor

.jpg)

Developing and evaluating predictive conveyor belt wear models

RESEARCH ARTICLE Developing and evaluating predictive conveyor belt wear models Callum Webb1, Joanna Sikorska2, Ramzan Nazim Khan3 and Melinda Hodkiewicz2 1WearHawk Pty Ltd, Western Australia, Australia 2Faculty of Engineering and Mathematical Sciences, University of Western Australia, Perth, Western Australia, Australia 3Department of Mathematics and 2024年3月15日 Abdullah Fadhil Mohammed (Selection and Evaluation of Robotic Armbased Conveyor Belts (RACBs) Motions: NARMA(L2)FO(ANFIS)PDI based Jaya Optimization Algorithm) 1 Introduction Recently, robotic arm has been taking a lot of interest in most countries and others worldwideSelection and Evaluation of Robotic Arm based Conveyor Belts 2024年4月15日 Roller Conveyor Selection Guide Roller Conveyors Our gravity roller conveyors can transport light, medium, and heavy duty loads that gave firm flat bottoms such as cartons, totes, cases, skids, drums, etc Ashland's line of roller conveyors includes models with the roller from 13/8" to 25/8" diameter and various frame stylesRoller Conveyors Selection Guide2024年5月13日 Examples of HeavyDuty Roller Models and Their Specifications Steel roller, 3inch diameter, 1,000 lbs load capacity Galvanized roller, 4inch diameter, Here is a stepbystep guide on how to make a basic conveyor roller: Material Selection: Choose the appropriate materials for the roller, such as steel, aluminum, Conveyor Roller Frame: Selection and Application

.jpg)

Essential Types of Conveyors You Need to Know

2024年3月26日 For example, a standard, nongravity conveyor model comes with a basic frame, an electrically powered motor, and a belt, rollers or chain that provides the platform for Key considerations in the conveyor selection process include: The system’s capacity to manage the anticipated volume of materials The surface that the product 2023年9月19日 Your conveyor system should match the transfer speed needed to achieve those targets Before deciding on any conveyor, determine the volume of dry powder or granules you anticipate moving in a given time — hourly, daily, or weekly units This helps in selecting a conveyor with the right capacity to avoid bottlenecks or underutilisationChoosing the right conveyor system Floveyor1996年10月1日 This book is a comprehensive, practical guide and reference to today's mechanical conveyor systems It covers all types of mechanical conveyors, providing indepth information on their design, function and applications More than 180 photographs and schematics illustrate details of design and system layout An introductory chapter provides an Mechanical Conveyors: Selection and Operation Google Books2024年6月5日 Compare gear motors with conveyor belt motors to understand their roles, advantages, and applications in conveyor systems : [ protected] Phone:+86 Torque is another vital factor in the selection of conveyor belt motors Torque, measured in Newtonmeters (Nm) or poundfeet (lbft), Best Types of Conveyor Belt Motors Explained

Conveyors Application, Selection, and Integration

Conveyors: Application, Selection, and Integration includes a pictorial of various installations of conveyors in detail that the reader can model after It presents common application mistakes made and discusses how the reader can avoid 2024年7月25日 Motor SelectionThe motor selection process is not as simple as you might think While selecting a motor, you will need to concentrate on many things eg Motor Speed, Motor Power Ratings, Motor load torques, Motor Motor Selection: Selecting a Motor on the basis of2024年5月17日 Therefore, the frame’s design and conveyor belt material selection are integral to an accurate power calculation FlexSim offers advanced simulation capabilities, allowing users to model conveyor systems Efficient Roller Conveyor Power Calculation: Methods 2024年1月4日 Factors Affecting Conveyor Selection Choosing the wrong conveyor system could result in a disaster for your business – it could lead to decreased productivity, increased safety risks, and ultimately cost you a fortune! Therefore, it is essential to consider various factors before selecting a conveyor prehensive Guide To Different Types Of Conveyor Systems

.jpg)

Variable Selection for ConveyorBelt Mean Wear Rate Prediction

2021年2月4日 Request PDF Variable Selection for ConveyorBelt Mean Wear Rate Prediction Rubber belt conveyors are an integral part of many mining and bulk haulage applications The belts are designed to 2020年7月7日 The KelvinVoigt viscoelastic mechanical model is widely used in constructing dynamic models of conveyor belts [14, 15] The conveyor belt is divided into many units, and the dynamic model of each Influence of the elastic modulus of a conveyor belt on the We trained linear regression and random forest models to learn a relationship between conveyor specifications and worstcase wear rate that generalizes to outofsample conveyors The random forest approach performed slightly better, with $ \overline{\mathrm{RMSE}}=0152 $ (463% better than an uninformative model with no explanatory variables), and a median $ {R}^2 $ value of Developing and evaluating predictive conveyor belt wear models2024年4月2日 Choosing Quality Rubber Spiral Conveyor Rollers Your Guide to Interroll Conveyor Parts Selection Scroll to top +86 Click here to contact us We are ready and happy to fulfill all your requirements for conveyor roller and conveyor belt needs Please contact us right away!Roller Conveyor Design Principles: Applications And Benenfits Guide

.jpg)

Application of multiattribute decisionmaking methods for the

appropriate conveyor utilizing a variety of decisionmaking methods Researchers have worked on strategies for finding the best optimum solution for various selection problems, but conveyor selection using selected methods is not reported Therefore, the present work aims to the selection process ofScroll through this replacement roller guide to learn about Ashland Conveyor's roller models and how to choose the right roller for your application Diameters Shaft Sizes Material Options Our Roller Models Ashland Conveyor's roller models are designated by an assortment of lettersRoller Selection Guide For Roller Conveyors Ashland Conveyor2024年5月2日 Six key conveyor belt design parameters to consider: Material properties such as size, shape, weight, and abrasiveness impact the selection of belt material, width, and strength Environmental conditions such as Conveyor Belt Design Parameters: to Be Considered2010年2月24日 The effects of idler spacing selection on belt conveyor power consumption have been discussed A mathematical model to analyze the relation between total life cycle cost and belt, idler sets and Analytical Model between Power and Idler Spacing of Belt Conveyor

.jpg)

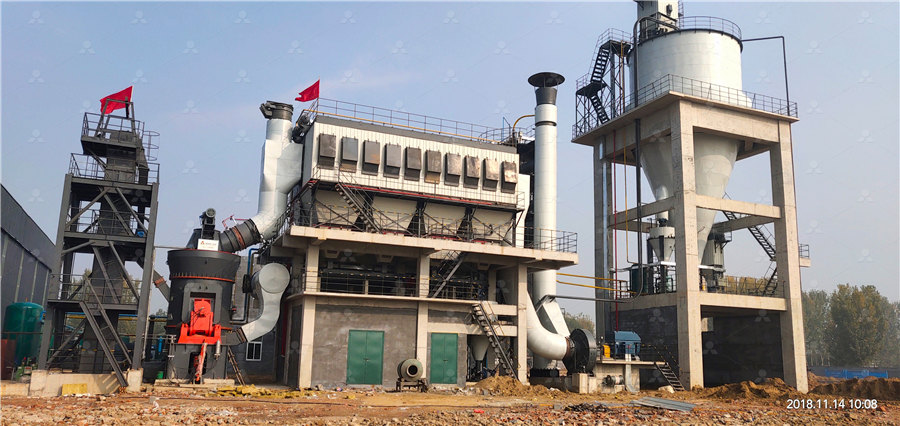

Selection, commissioning and operation of belt conveyors

First, the choice of belt conveyor model (1) The weight of the conveyed object (including the weight of the spreader), its external dimensions and its hanging method; (2) the length of the line and its complexity, that is, the number of horizontal turning sections and vertical bending sections;2021年1月1日 Request PDF A methodology for the selection of Material Handling Equipment in manufacturing systems Mastering the Material Handling System in manufacturing is a crucial issue According to A methodology for the selection of Material Handling Equipment 2024年3月20日 The enclosed belt conveyor with multidischarge are divided into two categories according to the different intermediate unloading devices: fixed trolleys (back throwing type) multidischarge belt conveyors (see Fig 181) and compound ploughtype multidischarge belt conveyor (see Fig 182)The structural characteristics of each model are shown in Table 181Enclosed Belt Conveyor with MultiDischarge SpringerLinkIn this study, four conveyor alternatives have been considered The results of the model implementation recommended slat conveyors as the best alternative for serving in the ceramic tile manufacturing environment, followed by belt and chain conveyors, while the last one in the ranking is the roller conveyorA MULTICRITERIA DECISION MAKING MODEL FOR CERAMIC TILES CONVEYOR SELECTION

.jpg)

Synthesis and Stabilization of Belt Conveyor Models with Intelligent

2021年7月16日 We consider the following conveyor transport models With a constant mass, the motion of loads is considered as a process of moving from a zero position along the axis x under the influence of the scalar value of the thrust developed by the conveyor belt In addition, during the motion of the conveyor, the angle changes dynamically in accordance with the specified 2021年8月28日 Kulak first solved this conveyor selection using FUzzy multiattribute MAterial Handling Equipment Selection (FUMAHES) model considering six conflicting criteria and four alternative conveyors Furthermore, Rao ( 2007a , b ) considered the same problem and applied Graph Theory and Matrix Approach (GTMA), SAW, WPM, TOPSIS, and modified TOPSIS Solving Material Handling Equipment Selection Problems in an Proper selection of components is very important in the design of conveyor system This section of the Engineering Catalogue explains the different designs of primary components, and their principle uses Also, there is a list of special influencing factors for Conveyor Component SelectionReceived: November 11, 2019 Revised: November 27, 2019 Accepted: November 27, 2019 For the economical construction of a tunnel by TBM, the selection of TBM optimized with the various project conditions is important, and also necessary to predict the performances of selected TBM in advance This study was conducted to comprehensively evaluate the performance of the EPB Evaluation of Screw Conveyor Model Performance depending on