Cracking carbon black grinding equipment

.jpg)

hecaicarbonblack

Since its inception, Deqing Hecai Pigment Co, Ltd has been committed to the production and development of thermal cracking granular carbon black, thermal cracking powder carbonBlack, The Cracking Carbon Black Grinder by Weifang Jinghua Powder Engineering Equipment Co, Ltd is a highperformance grinding device designed specifically for the processing of carbon black China Cracking Carbon Black Grinder Manufacturer, Supplier1 Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding ash is CAMC Horizontal Cracking Carbon Black Deep Processing Special 2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill Tire pyrolysis carbon black deep processing grinding

制粉项目-2023.11.17.jpg)

Carbon Black Processing Equipment FEECO

Whether looking to produce carbon black from biomass, transform it into biochar or activated carbon, or recover it from waste tires, FEECO custom rotary kilns provide an ideal thermal processing environment2024年6月14日 This article will delve into its processing, covering grinding, granulation, drying, and the necessary equipment What is carbon black? Carbon black is typically produced from coal tar, petroleum, or natural gas, heated at Carbon Black Processing: Turning Soot into Industrial At Pulva Corporation, our range of PulvaSizer ™ carbon black pulverizers allows you to grind materials to your desired level of fineness You can process the material in batches, use a conveyor for continuous acceptance and choose Efficient Carbon Black Milling Equipment PulvaCarbon Black Grinding Systems: We provide advanced grinding systems specifically designed micro pulveriser air classifying mills for carbon black These systems utilize specialized grinding mills and equipment to break down Best Carbon Black Processing Plant Rieco Enquire Now

Recovered Carbon Black NETZSCH Grinding

Especially the rCB can be used to replace the virgin Carbon Black in various applications Most important is the fineness of the rCB, which determines the final use To reach the fineness required, NETZSCH offers machines which meet Specially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black processing machine, tyre pyrolysis carbon black The company's pyrolysis carbon black production process is fine grinding and wet process, which can partially or completely replace the original carbon black N330, N550, N660 and N772 in the production of more rubber and plastic productsGranulation, rapid drying and precise packaging, the finished product of pyrolysis carbon black granulation uniformity, high finish, granulation hecaicarbonblackThe recovered carbon black accounts for 60% of the return on investment, so advanced nano carbon refining equipment is the key to a profitable business model The Klean Team has been involved in building and operating commercial tire pyrolysis plants since the 1980s and are experts in the field of carbon black upgrading and manufacturingKlean Industries: Clearing up the Tire Pyrolysis Carbon Black

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Best Carbon Black Processing Plant Rieco Enquire

Carbon Black Grinding Systems: We provide advanced grinding systems specifically designed micro pulveriser air classifying mills for carbon black These systems utilize specialized grinding mills and equipment to break down 2023年9月19日 Refined carbon black after cracking of waste tires 1 Refined carbon black is reused to make car tires, fan belts and printer toner 2 Regenerated carbon black can be refined to nanolevel quality, replacing expensive virgin carbon black, allowing manufacturers to provide cheaper alternatives and alternative productsHGM80 Ultra Fine Grinding Mill Used in Waste Tire Powder Carbon black grinding machine is for process crude carbon black produced from tire/plastic pyrolysis process to fine powder used for carbon black required products This grinding machine is mainly used to pulverize various nonflammable and unexplosive materials less than 93scale Moh’s hardness and 6% humidity, in the industries of glass, rubber, pesticide, ceramic, paint, Carbon black grinding machineAuxiliary EquipmentDue to the adjustable configuration of the carbon black ultrafine vertical mill with a large powder range, it is suitable for the needs of multiple medium powder fineness and is a very powerful powder making equipment HLM series carbon black vertical grinding mill machine, an ultrafine grinding equipment for rubber powder and carbon black What Are the Uses of Carbon Black In Rubber Rubber Powder And Carbon

制粉-10.25公众号.jpg)

Carbon Black SP Global

e 0 Report No 90 CARBON BLACK by HAROLD C RIES May 1974 a a A private report by the PROCESS ECONOMICS PROGRAM STANFORD RESEARCH INSTITUTE MENLO PARK, CALIFORNIAWaste tyres after pyrolysis, we can get metal parts, heavy crude oil, gas and carbon black Metal and gas can be recycled Crude oil can be distilled into fuel oil Carbon black can be further processed into different sizes, and broadly used in rubber and painting industry The specific usages are as followed: carbon black; carbon black; carbon Waste Tyre Pyrolysis Carbon Black Processing SystemNETZSCH Trockenmahltechnik GmbH GD recovered Carbon Black EN 04/2019 Technical specifications are subject to change Rodenbacher Chaussee 1 63457 Hanau Germany Tel: +49 6181 50601 Fax: +49 6181 571 270 infontt@netzsch Business Unit Grinding Dispersing – The World’s Leading Grinding TechnologyProcess Technology for recovered Carbon Black (rCB) Grinding Carbon Black Powder Grinding Mill Processing carbon black We generally use a mill, in industrial applications, carbon black usually needs to be processed to more than 425 mesh Between 4252500 mesh belongs to fine powder, micropowder category It is usually necessary to use a Raymond mill or a superfine mill Raymond MillCarbon black production process and equipment selection

.jpg)

Recovered Carbon Black Hosokawa Alpine

After pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine grinding, Hosokawa Alpine primarily uses 2021年6月10日 The constructed continuousoperation plant consisted of the following sections: Tire grinding (preprocessor, conveyor, cutter machine, fine crusher, etc), Tire pyrolysis (screw conveyor, cracking furnace, cross cleaning part, magnetic separator, cooling pump, etc) and carbon black grinding (discharge screw conveyor, grinder, dust extractor, returning charge fan, Recovery of carbon black from waste tire in continuous The comprehensive utilization of waste rubber tires includes the cracking of giant old tires and the application of waste rubber pyrolysis regenerated carbon blackIn response to these difficulties, CLIRIK company based on many years of experience, developed a new process of refurbishing used tires and producing rubber oil and carbon black through pyrolysis process, making tyre Tyre pyrolysis carbon black grinding technology breakthrough1Carbon Black Classfication 11 Furnace Black 12 Channel Black 13 Thermal Black 2The Difference in Application 21 Rubber Carbon Black 22 Color Black 3Mill Recommendation 31 Crusher 32 MillClassfication and Application of Carbon Black

News What Are The Uses Of Carbon Black From Tire Refining

In addition to tire oil, that is, fuel oil, the products of waste tire refining include steel wire, carbon black, and combustible gas The black face of the tire is due to the addition of carbon black to the rubber Carbon black has excellent reinforcement to rubber and can give tires excellent wear resistance By processing carbon black through a pulverizer, the byproducts of waste tires can 2024年6月17日 Reinforcing building materials: Many manufacturers use carbon black, a reinforcing agent, for applications like making rubber, asphalt and concrete Using this component reinforces material wear resistance, strength and robustness Providing UV protection: Carbon black is a UV absorber, making it a powerful component for protecting building componentsCarbon Black Uses and Applications Pulva2022年3月29日 Petroleum coke can be used in ceramics, glass, carbon products, steelmaking and other industries after being processed and ground into powder by industrial grinding mill +17 [ protected]What grinding equipment is needed for petroleum coke Schematic representation of ELT pyrolysis and ensuing products 31 Gaseous Product The pyrolysis gas product is mainly composed of lowmolecularweight hydrocarbons, namely, C 1 –C 5 paraffins and olefins [24,25], with traces of sulfur and nitrogencontaining volatile compounds []A typical composition comprises H 2 and CH 4 as main components, with each of these Production and Upgrading of Recovered Carbon Black from the

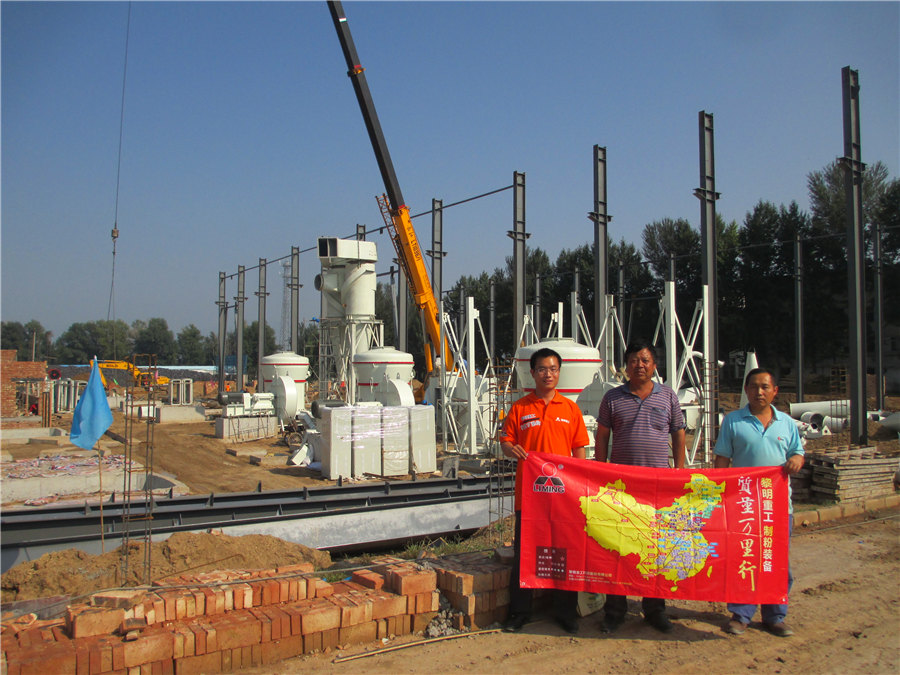

China Metal Grinding Manufacturer, Supplier JINGHUA

As one of the cracking products, cracked carbon black accounts for about 30%35% of the entire cracking product, but it Graphite production process for lithium battery negative electrode materials People often think that the manufacture of negative electrode materials only requires throwing the raw materials into the sintering furnace and raising the temperature for sinteringAt present, lamp smoke carbon black is mainly used as paint colorant, drum method and mixed gas method carbon black is mainly used for pigment carbon black for paint and ink, acetylene carbon black is mainly used for dry battery production, and other production processes are in the production of rubber Use carbon black in the application5 kinds of carbon black production processesCarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine grinding mill is also called (threering fourring) medium Carbon Black Ultrafine Grinding MillThe equipment has both modification and disintegration functions, suitable for materials of various fineness, and has unique modification and activation effects on materials with low pseudospecific gravity and large bulk density ratio such as white carbon black, mica powder, talcum powder, etcGXJ Series Continuous Powder Shaping and Modifying Machine

.jpg)

Recovered Carbon Black NETZSCH Grinding

NETZSCH offers machines which meet the specific requirements of recovered Carbon Black to achieve the highest performance with the finest cuts Grinding Dispersing About Us Business Unit Protein Shifting and Enrichment with 2023年12月14日 Five application scenarios of carbon black powder At present, the refined cracked carbon black industry is in the development stage The high added value brought by ultrafine milling has made its industrial use increasingly widespread: mainly used as a key material for solar cells; highly adsorbent and used as a pollutant adsorbent, etcTürkiye Pyrolysis Carbon Black Grinding Line Project ReviewISO 6964: Polyolefin pipes and fittings Determination of carbon black content by calcination and pyrolysis Test method and basic specification IEC 6: INSULATING AND SHEATHING MATERIALS OF ELECTRIC AND OPTICAL CABLES COMMON TEST METHODS PART 41: METHODS SPECIFIC TO POLYETHYLENEAND POLYPROPYLENE COMPOUNDS ISO 6964, ISO 1408 Carbon Black Test Equipment UT3500AIn this way carbon black processing machine is a kind of environmental equipment for getting carbon black from tyre pyrolysis The carbon black can be used for construction bricks with clay, also can be used as fuel BMF10 Carbon Black Processing Machine Get Free Quote in 24 HoursCarbon Black Processing Machine Carbon Refinery Kingtiger

carbon black processing machine, tyre pyrolysis carbon black grinding

Specially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etc2024年7月17日 Waste Tire Cracking Carbon Black Equipment; Solutions Superfine Grinding; ClassifyingSeparating; ShapingModifying; Powder Mixing; Project Case Environmentfriendly Desulphurization Material(Baking Soda) Waste Tire Pyrolysis Carbon Black; Other Industry Material; About Us Company profile; RD; Service; Development History Tire pyrolysis carbon black deep processing JINGHUAAfter deep processing of the waste tire refined carbon black, it can replace some of the commercial carbon blacks such as N330, N550, N660, N754, N774 as rubber filling, and use it as a plastic masterbatch in the plastic industry for EVA foaming, PE blown film, and plastic molds Components, etc,Carbon Black Grinding Mill, carbon back mill, carbon back mill Introduction of the carbon black grinding machine The carbon black powder grinder machine produced by Beston Group is suitable for the grinding process of metallurgy, building materials, chemicals, mining and other minerals materials It can be used for powder processing various materials with Mohs hardness below 8 and humidity less than 6%, such as red mud, kaolin, Carbon Black Grinding Machine Beston Pyrolysis Plant

.jpg)

Grinding mill for carbon black powder production

Carbon black microgrinding equipment consists of: The complete set includes crusher, bucket elevator, storage bin, belt feeder, microgrinding main machine, frequency conversion classifier, cyclone dust collector, pulse dust removal, high pressure fan, air The recovered carbon black produced by the pyrolysis reaction must be processed through a series of processes to make it into recovered carbon black The environmental protection carbon black processing system includes magnetic separation, grinding, granulation and drying procedures, etc Carbon Black Equipment Supplies Environmental XPRTAmong them, rubber carbon black, pigment carbon black and conductive carbon black are the most commonly used Carbon black grinding mill CLIRIK's HGM ultrafine grinding mill is suitable for processing carbon black powder The processing fineness ranges What is carbon black? What is the use of N220 N330 carbon black 1About Conductive Carbon Black 2Development of Conductive Carbon Black 21 Particle Size of Carbon Black 22 Structure of Carbon Black 23 Roughness of Carbon Black 24 Surface Volatiles of Carbon Black the distribution level of carbon black is significantly influenced by mixing equipment Carbon Black Grinding MillWhat is The Role of Carbon Black in Lithium Batteries?

.jpg)

Pyrolytic preparation and modification of carbon black recovered

2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of 2021年8月31日 To produce ultrafine carbon black powder, you can use SBM carbon black ultrafine powder mills to grind carbon black raw materials The carbon black raw material is crushed and then enters the ultrafine grinder to be squeezed and ground by the grinding roller, with a fineness of up to 3000 meshCarbon Black Ultrafine Powder Mill2022年11月9日 Three roll mill is the main equipment for grinding colored carbon black, as it is used extensively in rubber, plastics, paints, and inks, and some carbon black is added 09 November Guidelines For Three Roll Mill Laboratory Three Roll Mill|PLC Control System Three Roll Mill For Carbon Black|High Grinding Dispersion2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis

Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis

2024年3月6日 Carbon Black Produced by Tire Pyrolysis Appl Sci 2024, 14, 2192 The secondary cracking of larger primary pyrolysis products into smaller molecules occurs Fine grinding, achieved through a disintegrator or cavitation vortex mill, is essential for rCB Postprocessing, the material can potentiallyAnd the carbon black also be widely used in various industrial fields such as rubber, plastics, inks, coatings, etcThe carbon balck grinding mill also is an energy conservation and environmental protection equipment , with the advancement of technology, modern carbon black grinding machines have also made significant improvements in energy conservation and environmental Carbon Black Grinding Mill Equipment