Kaolin powder production process

.jpg)

An overview of kaolin and its potential application in

2023年8月1日 Kaolin is a natural clay mineral with potential applications as a filler in improving the performance of thermosetting polymers like mechanical properties, thermal stability, The use of kaolin for geopolymer formation produced a relatively weak structure due to its low surface area; which minimized the dissolution rate of Si and Al by alkali reactant and limited gelSimplified kaolin production and processing flow 2012年5月1日 In this paper work, a new processing route is introduced to produce cement powder by applying geopolymerization process Formerly, geopolymer mortars and concretes Processing and characterization of calcined kaolin cement powder2023年7月27日 Kaolin is a clay mineral commonly used in various industrial applications, such as paper manufacturing, ceramics, rubber, plastics, paint, and cosmetics The processing of kaolin involves several steps to extract and Exploring the Properties and Applications of Kaolin

.jpg)

Transforming Petrochemical Processes: CuttingEdge

2024年10月8日 Advanced catalytic approaches are crucial for efficient asphaltene removal and the conversion of heavy feedstocks into valuable light fractions Kaolin, an aluminosilicate mineral, has emerged as a key precursor In the calcination of kaolin for speciality applications, the aim is to generate a product in an intermediate stage between the amorphous and crystalline spinel phaseproduction of calcined kaolin ResearchGateAbout 15 % of the UK production is used in ceramics The kaolin extracted from the commercial deposits contains kaolinite as the major component together with ancilliary minerals The Kaolins: Their Properties and UsesIn this research, the effects of parameters such as sintering temperature, forming method, milling type and the content of alunite within kaolin were investigated for the production of porous The processing of kaolin powder compact Semantic Scholar

Kaolin Imerys

The calcination process increases whiteness and hardness, improves electrical properties, and alters the size and shape of the kaolin particles Imerys offers a wide range of innovative and sustainable engineered kaolinbased solutions to Kaolinite (/ ˈ k eɪ ə l ə ˌ n aɪ t,l ɪ/ KAYələnyte, lih; also called kaolin) [5] [6] [7] is a clay mineral, with the chemical composition Al 2 Si 2 O 5 4It is a layered silicate mineral, with one tetrahedral sheet of silica (SiO 4) linked through Kaolinite WikipediaPROCESS SYSTEMS FOR KAOLIN POWDER Hosokawa Micron offers excellent processing solutions for drying and mixing kaolin, for example for the production of fillers, pigments, ceramic products, concrete additives or pharmaceutical products Kaolin or china clay is a kind of rock that is rich in kaoliniteProcess Systems for Kaolin Powder Hosokawa MicronKaolin heavy, powder; CAS Number: ; EC Number: 3101941; The process of mechanical milling has been found to effectively stabilize heavy metals in municipal solid waste incinerator Research Development Production We are a leading supplier to the global Life Science industry with solutions and services for research, Kaolin heavy, powder MilliporeSigma

Sericite Supplier Malaysia Kaolin China Clay Mica Powder

Under our own brand name, we also supply hard clay, mica powder, sericite, calcium carbonate, wollastonite, talc and calcined kaolin KAOLIN CLAY Kaolin clay is chemically hydrated aluminium silicate and structurally unmodified1991年9月1日 This product may be subjected to further grinding to recover additional amounts of previously unliberated clay Wet process The wet processing of kaolin is more complex than the dry process tech nique The water wash process scheme for kaolin coating and filler produc tion is shown in Fig 7Kaolin: processing, properties and applications ScienceDirect2021年8月27日 As previously stated, kaolin slurry passes the ‘degritting‘ process through particular devices such as screens, hydrocyclones, and hydroclassifiersThese screens here can be the 100 mesh screen, 200 mesh screen, and 325 mesh screen Meanwhile, the classifiers consist of centrifuge hydroseparator and centrifugal seizuresAll Steps in Kaolin Production Mining and Processing Explained2020年4月14日 The first demonstration production line with suspension calcining technology has been completed in China The design, construction process and the first trial calcining kaolin clay production results show: (1) The suspension calcining technology can meet the processing requirements of raw materials with different moisture contents (2)Research and Design of Suspension Calcining Technology and

.jpg)

Kaolin – EICL Limited Best china clay manufacturers in india

Kaolin is a form of clay Clays are formed by the weathering of rocks Weathering of rocks can be classified as physical or chemical process In case of kaolin, the chemical reaction between water, carbon dioxide and feldspar (rock) gives rise to kaolin clay deposits Feldspar (Rock) + Water + Carbon Dioxide (Gas) > Kaolin (Clay)2021年8月25日 3 Kaolin Powder The finished product is kaolin powder, with a moisture content of about 2% to 3% It is a kaolin noodle that has passed the disc milling machine, crushed into the finest particles of all three It becomes critical to measure or determine the precise moisture level of kaolin deposits, regardless of the finished product formsKaolin: Its Moisture Content and Three Commercial Grade Products2024年4月17日 Quartz powder is often overlooked when discussing ceramic products Quartz’s inherent hardness and chemical inertness make it the ideal material to extend product longevity from industry leaders demonstrate the significant improvements in durability and strength in ceramics made with quartz powder The Manufacturing ProcessHow Quartz Powder Enhances the Strength and Durability of Download scientific diagram Metakaolin manufacturing process through kaolin calcination [247] from publication: Materials for Production of High and UltraHigh Performance Concrete: Review and Metakaolin manufacturing process through kaolin

Kaolin Palamatic Process

Discover all the characteristics of kaolin powder to optimise your industrial process Contact our experts Skip to Kaolin powder is prepared industrially by An installation at one of our customers sites on a product similar to kaolin has proven its effectiveness and allows the desired particle size to be achieved following a milling Kaolin grinding production process November14,2024 The following is a method for preparing kaolin powder Crushing The large pieces of kaolin powder are crushed by a crusher to a feed fineness that can enter the mill (15mm50mm)Kaolin grinding production process LZZG2019年11月16日 A process for producing reductive bleach insitu in kaolin slurries has been developed The bleach is formed by mixing an iron sponge powder (325M) with slurry treated with SO2 The process has been successfully demonstrated in production, and applied to Kaolin Bleaching Process 911MetallurgistUnderstanding Kaolin Grinding Production Line Equipment: The kaolin grinding production line is a comprehensive system designed to process raw kaolin into a fine powder that meets the specific requirements of different industrial applications This system typically includes crushers, mills, classifiers, separators, and other associated equipmentAdvanced kaolin grinding production line equipment: Elevating

Kaolin Palamatic Process

Kaolin, composed mainly of hydrated aluminum silicate (kaolinite), is a white clay, friable and refractoryOriginally from China, it is the raw material used in the manufacture of porcelain The varieties of kaolin come either from "primary" deposits resulting from the weathering of granite rocks, or from "secondary" deposits resulting from primary deposits and redeposition of kaolinThe results indicated that ceramic tile formulations containing up to 60% of waste could be used for the production of tiles with low water absorption and low sintering temperature (1150 °C), and Mullite formulations with more than 40% of kaolin waste could been used in theProduction of bodies with high strength, which can be used as refractory materialsThe processing of kaolin powder compact Semantic Scholar2005年1月21日 manufacturing process: from raw materials, processing, and forming, to the kinetic limitations and complexities of the mi crostructure and phase development(PDF) Porcelain—Raw Materials, Processing, Phase Evolution, and of the process by ensuring the adherence of the product to the quality specifications, reducing the necessity of offline analyses and providing reconciliation data for realtime monitoring and production of calcined kaolin ResearchGate

Mineral Planning Factsheet Kaolin

and exporter of kaolin after the USA and Brazil Hydraulic mining of kaolinised granite This factsheet provides an overview of kaolin supply in the UK It forms part of a series on economically important minerals that are extracted in Britain and is primarily intended to inform the land use planning process It is not a statement of planProduction Process All of our familyowned manufacturers operate stateoftheart plants that utilize the latest techniques and machinery (First Choice) label Kaolin is only importing First Choice Warehousing Our own brand Production Process kaolin2022年12月1日 However, to mitigate these drawbacks of using TiO 2, the use of mineral fillers as a substitute for TiO 2 in the paint production process can result in significant reductions in the environmental impacts and improve the inconsistency in paint finish [8, 9]Among mineral fillers, kaolin is the most valuable name for the mineral products composed of coarseto finegrained, A comprehensive review on kaolin as pigment for paint and The most important and the most valuable process developed by Dabster is the production of aluminum sulfate from various raw materials Dabster owns the technology and knowhow to produce aluminum sulphate from such raw materials like kaolin, bauxite and aluminum hydroxide The process occurs under conditions of elevated temperature and pressure and takes place in Aluminum sulfate production Dabster

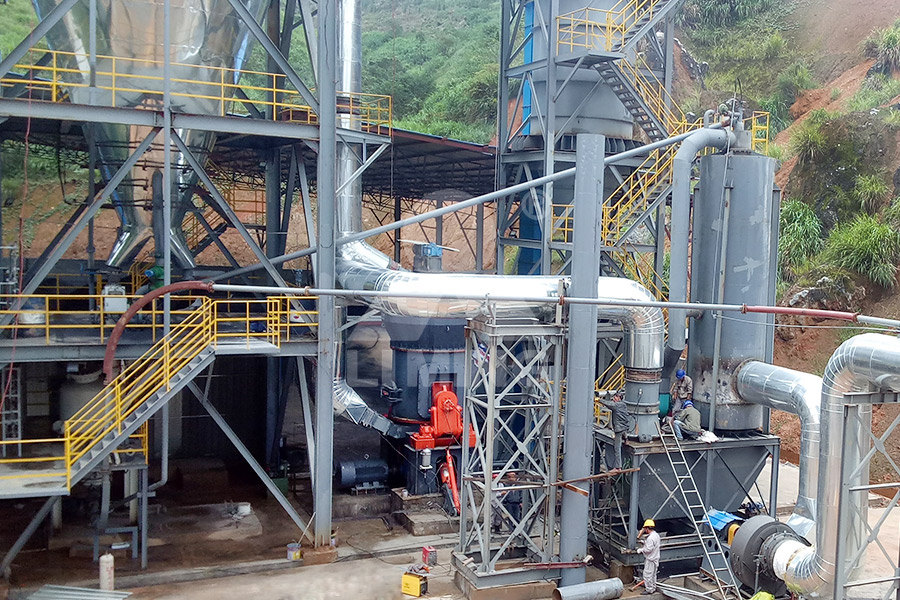

CFB石灰石脱硫剂制备64.jpg)

Kaolin Introduction, Production, Uses, Dirt, Mud Mask, and

About Kaolin Kaolin is a white, soft powder in its natural state, consists of mineral kaolinite principally, Production Nealy, 40% of the kaolin produced is used in the coating and filling of paper The Process of Drawing Out a Glass Jet Types, Effects, and PredictionsKaolin clay is chemically hydrated aluminium silicate and structurally unmodified improved physical electrical properties of the final product ar e realized Specific gravity is reduced from 258 to about 250 in the process, while hardness and porosity, and thus brightness, opacity and oil absorption, Kaolin Sericite Supplier Malaysia Kaolin China Clay Mica Powder2021年7月5日 How Kaolin Powder was Made The powder version of kaolin went through a pretty extensive process before it can be used in industrial processes Since kaolinite is a type of mineral found in the earth, people must mine it first, usually using water jet mining to Kaolin Powder: Everything You Need to Know and More PT KAOLIN PRODUCTION The UK is a leading world producer and exporter of china clay and ball clay This process is planned to continue with backfilling accounting for around 30% of future waste mineral disposal The industry in Cornwall was a partner of the Cornish Heathland Project having created some 750 hectares of heathlandWhat is Kaolin The Kaolin and Ball Clay Association

.jpg)

Asian Micron Levigated Kaolin Supplier and Mineral Product

Kaolin in the form of noodles has several possible applications Because it is versatile and adaptable, it may be used in a variety of sectorsWondering which industry employs kaolin noodles in its process2024年3月1日 Materials Kaolin (50 kg) was obtained from the Ceramic Atelier of the Faculty of Fine Arts, (Minia, Egypt) Kaolin (Al 2 O 3Fe 2 O 3 2H 2 O) was in the form of ultrafine, reddishbrown powder Production, characterization and performance of green 2023年8月15日 The calcination of kaolin in industry is commonly carried out using rotary kilns and multiple hearth furnaces (MHF) (JämsäJounela et al, 2018)While this process does not produce harmful gases that pollute the environment, it requires a significant amount of energy, often derived from the combustion of fossil fuels such as oil or coal (Tasiopoulou et al, 2023)Solarization of the zeolite production: Calcination of kaolin as After grinding, the kaolin powder may need to be dried to remove excess moisture Once dried, the powder is packaged in bags or loaded into bulk containers for transportation 4 Advantages of the Stone Grinding Process High Production Efficiency: The stone grinding process is highly efficient, capable of processing large quantities of kaolin Kaolin production equipment: Screening and stone grinding process

(PDF) Processing and Evaluation of Locally Sourced Kaolin for

2018年8月10日 Processing and Evaluation of Locally Sourced Kaolin for Pharmaceutical Production August 2018; DOI:1026538 This work sought to process, All the kaolin powder samples were used to make Kaolin Market Size Trends The global kaolin market size was valued at USD 398 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 40% from 2024 to 2030Increasing investment in construction and infrastructure industry is propelling demand for paints coatings, ceramicbased products, and cement, which is driving market growthKaolin Market Size, Share Trends Report, 2030 Grand View Production Process of Kaolin Powder The Property of Belesa kaolin was as shown in table below TABLE I: PHYSICAL PROPERTIES OF CEMENT AND BELESA KAOLIN POWDER Material OPC Kaolin Powder Specific gravity 315 259 Fineness (𝝁𝒎) 85 65 Specific surface (m2/kg) 20 17 The Effect of Partial Replacement of Cement with Kaolin Powder 2015年9月24日 Hi Friends, In present post, we will discuss the specifications, industrial applications and production process route for manufacture of Kaolin clay as described here underSpecifications, Industrial Applications and Production of Kaolin Clay

.jpg)

Kaolin Supplier in India, Kaolin Manufacturer in India ZSM

Ceramic Body grade Kaolin: This is most demanding kaolin product in ceramic body applications: Buy Now: 2: We have various grade washed kaolin powder such as Types of Kaolin 1 Levigated Kaolin 2 Calcined Kaolin 3 Hydrous Kaolin Please feel free to contact us if you are looking for process kaolin at a price that is as low as Kaolin appears as odorless white to yellowish or grayish powder Contains mainly the clay mineral kaolinite (Al2O3 a dry process or a wet process the dry process involves crushing, drying, pulverizing and classifying the wet processes involve formation of a kaolin slurry Kaolin's production and use in paper, domestic Kaolin Al2H4O9Si2 CID PubChemIndustrial kaolins, which encompass pure kaolin, refractory clays, and bauxitic kaolin, among others, are distinguished by their relatively high content of clay minerals from the kaolinite group Bentonite clay deposits, containing a high amount of clays from the smectite group (eg montmorillonite), are prized for their high cation exchange and volume expansion capabilitiesClay calcination technology: stateoftheart review by the 2022年8月10日 Kaolin Clay Milling Process Choose the main machine according to the output and powder fineness requirements: below 325 mesh, you can choose a Raymond mill; 1502500 mesh can choose an ultrafine grinding mill; 1503000 mesh largeoutput production line can choose a vertical roller millKaolin grinding production line and equipment selection