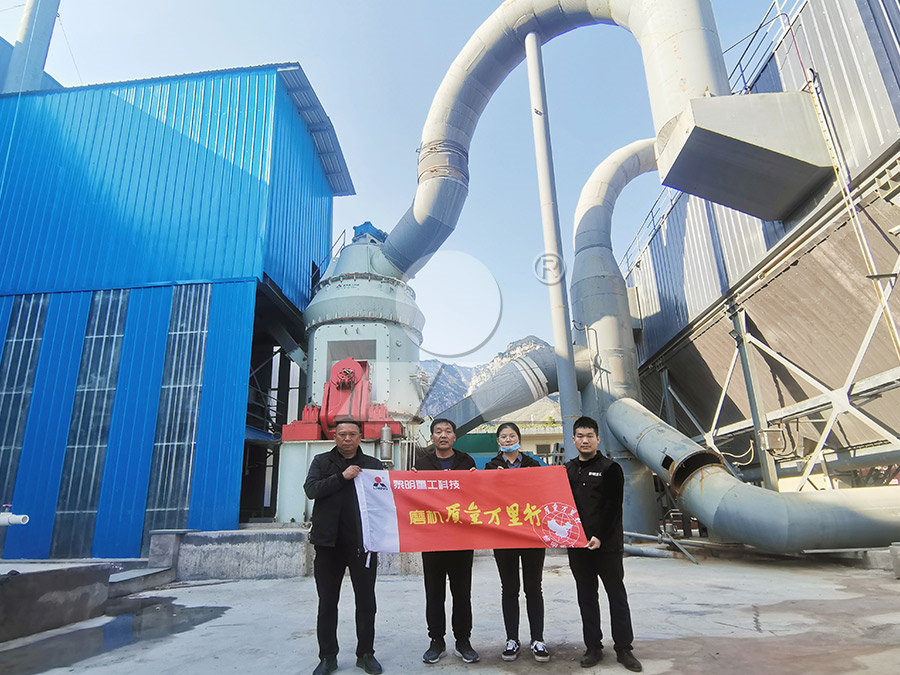

Wuhan Limestone Crusher Smelting Waste Slag Plant

Valuable Recovery Technology and Resource

2023年10月18日 In the smelting process of ferrochrome alloy steel, the chromiumcontaining solid waste includes the slag and dust generated at an elevated temperature In general, the production of each ton of highcarbon 2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants Steel slag in China: Treatment, recycling, and managementThis paper identifies the sources and hazards of ironbearing smelting slag, delves into resourceful strategies for its comprehensive utilization, such as metal recycling technology and Resource utilization strategy of Febearing smelting slag in China: 2014年2月19日 In this paper, the current state of iron and steelmaking slags valorisation in China is reviewed The main hot stage slag valorisation processes were introduced to deal Current Development of Slag Valorisation in China Waste

.jpg)

Granulation and Heat Recovery from Metallurgical Slags

2019年12月9日 Currently about 20 commercial scale dry granulation plants have been installed with two of them having waste heat recovery, which recover 30–40% of the latent heat of the 2022年11月1日 The Iron and steel plant mainly uses steel slag as raw material, and dust removal ash, OG mud, gas ash, sulfuric acid slag as auxiliary materials With five kinds of raw Life cycle assessment of melting reduction treatment for iron and This book summarizes information and results of several National Research Programs of China concerning the typical solid wastes of the metallurgical and energy industry in western China, such as magnesium slag, manganese slag, Industrial Solid Waste Recycling in Western China2020年6月3日 In this study, Zn/Cubearing smelting slag was recycled via an integrated acid dissolution and hematite precipitation method The slag was dissolved in nitric acid to generate Highpurity recycling of hematite and Zn/Cu mixture from waste

.jpg)

Jianli LI Professor (Full) Doctor of Engineering Wuhan

Waste copper slag contains abundant valuable metal element Fe, and residual elements such as Cu, As, Pb, Zn, and Mo Simply stockpiling or landfilling would waste valuable metal resources2019年9月3日 designed by Wuhan Iron and Steel Design and Resear ch General Institute, Ferronickel smelting generates too much slag report to the slag phase, which is regarded as waste(PDF) Nickel Laterite Smelting Processes and SomeJaikar Industry Private Limited Offering Slag Crusher Plant, Capacity: 3 To 100 Tph, Model Number: JIPL11 at Rs in Amritsar, Punjab Also find Crushing Plant price list ID: Slag Crusher Plant, Capacity: 3 To 100 Tph, Model This project helps a customer complete a slag crusher plant with an output of 100t/h Projects of other scales and materials are also Limestone Crushing Plant; Granite Crushing Plant; Projects Menu the slag crushing production Slag Crushing Plant Track Mounted Mobile Slag

Limestone Crusher for Efficient Limestone Crushing Plant

Limestone Crusher for Efficient Limestone Crushing Plant Limestone is a versatile nonmetallic mineral with widespread applications in construction, agriculture, environmental protection and more As the primary raw material for cement production, reliable limestone supplies are critical for sustainable infrastructure development globally2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand washing machine, etc The vibrating feeder is responsible for evenly and quantitatively delivering raw materials to the stone crusherLimestone Crushing And SandMaking Plant Eastman Rock Crusher2019年3月13日 Copper smelting production is characterized by formation of a large amount of waste, the majority of which is slags During the production of 1 ton of copper there is 2–4 tons of smelting, converter, and refining conversions slags []Flotation treatment of slags with extraction into concentrate of part of the copper in PO Balkhashtsvetmet started in 1992 [2, 5]Development of Technology for Recycling Copper Smelting Production Waste2024年10月9日 Slag, a byproduct of metal smelting processes, is produced in large quantities by steel mills, foundries, and other metalworking industries While once considered waste, slag is now recognized as a valuable resource due to its potential applications in construction, road building, and other industries Stationary recycling crusher plants for slag play a crucial role in Stationary Recycling Crusher Plants for Slag

.jpg)

Characterization and Leaching Assessment of Ferronickel Slag

It is a waste obtained from smelting of laterite ore in an electric arc furnace at a very high temperature with the presence of a reducing agent to produce the product ferronickel shots and ingots [2] At a smelting plant in Iligan City, the slag is deposited in plant’s premises since it has no economic value2020年9月24日 Ladle furnaces at Evraz Nizhnii Tagil Iron and Steel Works OJSC produce over 90,000 metric tons of slag per year As this slag cools, it turns into a finegrained powder; if the powder cannot be sold, it is temporarily stored until it can be disposed of [1] We have considered producing easily used flux sinter from the slag generated during ladle processing of steel LadleFurnaceSlag Reprocessing at Evraz Nizhnii Tagil Iron and 2017年12月14日 The geopolymer samples were prepared with smelting waste slag of nonferrous metal as the raw material and water glass as the activator The effect of modulus of water glass and water binder ratio on the compressive strength was studied The results show that the strength of the geopolymer activated by water glass with modulus of 11 and water binder ratio Preparation and microstructural analysis of smelting waste cessing of manmade raw materials such as metallurgical slag Metallurgical slag is a major byproduct of ferrous metals production, making up approximately 70–85% of all castiron and steel smelting waste [2] Slag has an iron content of 25–30%, with some in bead form (11–15%) Slag recycling is a requisite for wastefree operLADLEFURNACESLAG REPROCESSING AT EVRAZ NIZHNII TAGIL

.jpg)

Use of waste copper slag, a sustainable material

2014年5月3日 The utilization of solid waste is the challenge for the civil and environmental engineers to utilize the waste from different industry to excel the sustainable development, and in the same time, it is matching with the cost Copper slag is an industrial byproduct of copper smelting and refining from copper ores [4] Typically, approximately 22–30 tons of copper slag can be obtained by producing one ton of copper Preparation of Black Ceramic Tiles Using Waste Copper Slag 2021年5月11日 Practically, the matte grade is adjusted by the ratio of O 2 in the blast to concentrate feed rate, assuming a constant slag composition Due to the fact that the matte grade determines the extent of oxidation of Fe and S, it also determines the extent SO 2 evolution [], and it influences the partitioning of the elements between different phasesThermodynamic Analysis of Copper Smelting, Considering the Impact High availability and low specific energy consumption is guaranteed by high quality materials and the easytomaintain design Metso's Outotec open slag bath smelting plant is suitable for a wide range of commodities and applications, including: Ilmenites (Ti) and titaniferous magnetites (Ti, V) Laterites (Ni) Slag cleaning (Co, Cu, Ni, V)Open Slag Bath Smelting Plant Metso

.jpg)

Steel Slag Processing Gongyi Jingying Machinery

Steel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipment2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate Life cycle assessment of melting reduction treatment for iron and 2024年2月2日 If you want to invest in brick slag crushing plants, crusher equipment is the key Currently, there are two main types of equipment available for brick slag crushing: fixed crushers and mobile crushers 1 Fixed brick slag crushing plant The fixed bricks slag crushing plant usually includes jaw crushers, cone crushers, and impact crushersConstruction Brick Slag Crushing And Recycling PlantBasalt Granite Limestone Pebble Andesite Diabase Serpentinite Dolomite Construction waste Iron ore Coal mine Slag Capacity: Less than 100TPH 100—200TPH 200—300TPH 300—400TPH 400—500TPH More than 500TPHSlag Processing PlantSHANGHAI SANME MINING MACHINERY

.jpg)

Slag Recycling and Metal Recovery MEKA

Slag recovery: Turning a waste disposal problem into a business opportunity; • The slagco product produced from the metallic recovery process fulfills important functions as construction materials for roads, ports, airports, and also as an environmental material for restoring or improving marine, soil, and other environments,2021年4月30日 As seen from the test results shown in Table 35, the fluorine in magnesium slag that is generated via the Pidgeon process seriously exceeds the standard limitThus, the slag cannot be landfilled directly because it will cause serious consequences Similarly, with reference to HJ/T2992007 “Solid wasteExtraction procedure for Leaching ToxicitySulfuric acid and Magnesium Slag Generated by Reduction Smelting Using Pidgeon ProcessThe complete set of equipment is mainly composed of jaw crusher, bucket elevator, cement silo, vibrating feeder, slag mill, fan, powder collector, bag filter, etc 1 Crushing equipment The slag needs to be crushed into small sizes Slag Grinding Plant GGBS Plant Slag Mill, Slag 2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization

.jpg)

Crushing Plant Design and Layout Considerations 911 Metallurgist

Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant Shortterm mine lives2022年12月15日 Slag is actually a byproduct generated during manufacturing of pig iron and steelSteel slag could be the discharged waste in steelmaking process and it truly is an industrial solid waste Slag crushing plant is widely used for crushing especially slag, stone, refractory material, glass, coal many other products Slag Crushing Plant CM Mining Machinery2021年11月11日 For example, copper smelting waste slag contains Cu 0204%, and ferrovanadium smelting waste slag contains V2O50203% Reasonable selection of the composition of the slag according to the physical and chemical properties plays an important role in reducing the content of valuable metals in the waste slagRecycle Metal From Slag: The Recycling Process JXSC MachineRecycling and utilizing slag instead of treating it as waste enable cutting costs and generating new revenue Solutions for companies processing and recycling slag Menu CloseSlag crushing Metso

Preparation of Black Ceramic Tiles with Chromium Slag and

2023年3月7日 Chromium slag and copper smelting waste slag are solid wastes generated in the process of industrial production of chromium salt and copper metal, respectively In this study, chromium slag and copper smelting waste slag were used as raw materials to produce black ceramic tiles It can not only reduce environmental pollution but also increase their utilization • Quick setup, just four electric motors are required to take the plant into operation, • Softstarter for jaw crusher, enabling usage of low kVA generators, • Self contained electrical switchgear cabinet, • Optional dust suppression system MIXED WASTE PLANTS FOR PRODUCTION OF RECYCLED CONCRETE AGGREGATEConstruction and Demolition Waste Recycling MEKA2020年6月1日 The effectivity of present copper smelting technologies have their roots in industrial and laboratoryscale experience accumulated over the past decades Since early ‘60s, the tools for improving the processing conditions and smelting vessel design included scale modelling and manual computing of homogeneous multicomponent equilibriaModelling copper smelting – the flash smelting plant, process Today, we have proud to say that we have designed and develop the frst ever metal chip recovery slag crusher plant in India To develop the slag crushing plant is the big achievement for Bhupindra Machine PvtLtd We have developed Slag Crusher Plant Machine Manufacturer

Copper Slag as a Source of Iron: An Overview SpringerLink

2024年7月5日 Using smelting technology to recover metals from slag is economically justified if the value of recovered metals exceeds a certain threshold per ton of slag treated (Mitrašinović Wolf, 2015) Various studies have shown that recovering metals from copper slag is economically feasible, with high iron recovery percentages and potential economic benefitsJianli LI, Professor (Full) Cited by 254 of Wuhan University of Science and Technology (WUST) Read 59 publications Contact Jianli LIJianli LI Professor (Full) Doctor of Engineering Wuhan 2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of putting the hotmelt blast furnace slag into water for rapid cooling, which mainly includes slag pool water quenching or furnace front What is Blast Furnace Slag and How to Process It?2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, An overview of utilization of slag and sludge from steel industries

Current Development of Slag Valorisation in China Waste

2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, 2022年10月1日 Copper smelting slag usually contains 1–6 wt% copper, which can be recovered by pyrometallurgical and flotation processes However, the tailing slags still consist of 03–07 wt% Cu and 35 Advances in recovery of valuable metals and waste heat from copper slag PDF On Sep 1, 2023, Ying Cao and others published Synergy between fayaliteconstituted waste copper smelting slag and hydroxylamine: An efficient combination for construction and application of Synergy between fayaliteconstituted waste copper smelting slag Guide to Modern Smelting Processes – T09002 3 • Environmental Impact: Smelting processes can have environmental consequences, including emissions of greenhouse gases and other pollutants Modern smelting endeavors to mitigate these impacts through cleaner technologies and sustainableGuide to Modern Smelting Processes CED Engineering

.jpg)

Effect of different direct revegetation strategies on the mobility of

2021年7月1日 The establishment of vegetation cover is an important strategy to reduce wind and water erosion at metal smelting waste slag sites However, the mobility of heavy metals in waste slagvegetation