Coal precrushing equipment

.jpg)

Coal Crushers, Shredders, Mills for Mining Power Industries

We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPH We also offer hammermills, impactors, double and Find your coal crusher easily amongst the 106 products from the leading brands (Fritsch GmbH, Fabo, Liming, ) on DirectIndustry, the industry specialist for your professional purchasesCoal crusher, Coal crushing plant All industrial Coal crusher, also known as double stage crusher, is a highly efficient crushing equipment It is a new type of equipment developed for the coal industry, and it mainly crushes high moisture Coal Crusher Types Impact Double Roller Crusher AIMIX GROUP2023年10月8日 To ensure that coal is not affected by overcrushing while achieving the required particle size and output requirements, FTM Machinery will help you choose the optimal coal crusher machine 1 Jaw crusher The jaw 6 Types of Coal Crusher: Which Is Best for Crushing My

Roll Crushers McLanahan

Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and We mainly provide equipment for coal mines crushing production lines The complete process includes washing coal of soil and rock, crushing and screening it into gradedsized chunks, dewatering, drying , stockpiling grades, and Coal Washing Process Plant JXSC MachineryROLLER SCREEN CRUSHER This equipment is specially designed for coalfired power plants, in order to remove impurities of commercial coal as well as to crush down existing coal lumps to SANDVIK SR ROLLER GRIZZLY, ROLLER SCREEN, ROLLER SCREEN Remove impurities from the coal for a more efficient and cleaner burning fuel with coal processing equipment from Multotec The first step of the coal preparation process involves feeding the ore through a size reduction machine which is Coal Processing Multotec

Crushing the competition – The Australian Mining

2019年8月9日 CRUSHING and screening material is a key component of any mining activity – and custom crushers to process your feed is what makes the difference in tonnage and productivity Finlay Screening and Crushing 2021年5月11日 The grizzly type fixed screens are chiefly utilized for primary screening applications in the coal preparation plants ROM coal is preclassified in a grizzly feeder to remove 13 shows a typical grizzly feeder installed at the minesite for heavyduty applications to protect the downstream crushing equipment from the oversized Mineral Beneficiation and Processing of Coal SpringerLinkIdeal for Primary secondary crushing of the ores/minerals like: Magnetite, Hematite, Limestone, Bauxite, Manganese ore, Quartz, Coal, Pet coke, Ferro Alloys and many more Jaw Blade gap adjustment mechanism makes it convenient to crush the material to different sizes by performing simple jaw blade gap adjustmentsJaw Crusher Sylab InstrumentsWhat equipment is used in the coal washing process November29,2022 Before coal preparation, it is necessary to crush raw coal Commonly used crushing equipment includes jaw crusher, hammer crusher, etc Commonly used coal washing equipment includes jig machine, spiral chute, highfrequency coal slime dewatering screen, flotation machine WaitWhat equipment is used in the coal washing process LZZG

.jpg)

coal screening equipment in mining project Sebocom

Pebble Semimobile Crushing Plant with Low Budget Pebble semimobile crushing and screening equipment is widely used in crushing coal, ore, rock and other bulk materials in mines (coal mines, noncoal mines), metallurgy, highway, expressway, railway, mineral processing, hydropower engineering, building materials, municipal solid waste, chemical, and other fieldsReversible Hammer Crusher is ideal for 1The crusher especially used in Coal Company, metallurgy, power, mining, building material, to crush the brittle material with high moisture content;PCK Reversible Hammer Crusher > Crushing Equipment > Coal is crushed to desired fineness between spheres or cylindrical rollers After that, air from the boiler is heated to around 330°C (650°F) The raw coal is then fed into the pulverizer where it is ground into fine coal particles What are the Advantages of Pulverized Coal? Pulverized coal produces a larger amount of heat than traditional coalCoal Crushers Coal Pulverizers Mills Williams CrusherThyssen Krupp apron feeder 18 m x 15 m, MMD Design primary sizer 25 m x 15 m, MMD Design secondary sizer 19 m x 1 m, Jig roller belt feeder 15 m x 1 m, Beumer Group bucket elevator 218 m, 2 x Hein Lehmann double deck sizing screens 6 m x 15 m, Schenck Process SPA4018 vibrating jig feeder, MBE Coal Materials Batac GK 4530 air pulsed jig, MBE Coal 2017 Gold Creek Engineering Coal PreTreatment Including Wash

Crushing Equipment For Sale IronPlanet

Buy used Crushing Equipment from Sandvik, Metso, Telsmith, Kleemann, Terex Pegson, KPIJCI and more Buy with confidence with our IronClad Assurance® Model Coal PreTreatment (1) Model Commander T443 (1) Model FT2650 (1) Model FT4250 (2) Model FT4250CC (3) Model GIP B 1490 FDR (1) Model GP170 FDR (1) Model GS6490 (1)Used Gold Creek Engineering Coal PreTreatment Coal Crusher in Dysart, Queensland, Australia for sale Thyssen Krupp apron feeder 18 m x 15 m, MMD Design primary sizer 25 m x 15 m, MMD Design secondary sizer 19 m x 1 m, Jig roller belt feeder 15 m x 1 m, Beumer Group bucket elevator 218 m, 2 x Hein Lehmann double deck sizing screens 6 m x 15 m, Schenck 2017 Gold Creek Engineering Coal PreTreatment Including2023年9月14日 Introduction: Crushing rocks is a common everyday activity for various uses, but achieving the desired size and achieving it with efficiency can be challenging That’s where Crushers come into play In this blog, we will CrushersIndia – LT Construction Mining Machinery2022年11月9日 1 Wet Coal Jaw crusher: (1) The jaw crusher is a driven extrusion type, which consists of two jaw plates, a movable jaw and a static jaw, forming a crushing cavity Simulate the movement of two jaws of an animal to Which Equipment Is Best For Crushing Wet Coal

Coal Crushing Machine MadeinChina

Sourcing Guide for Coal Crushing Machine: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: mining equipment, crushing machine, mining machine2023年11月29日 The grainsize composition of coal is governed by many mutually complimentary factors: petrography and mineralogy, distribution of organic and mineral components in coal, intensity of metamorphism, rate of oxidation, jointing and faulting of coal seams, as well as the method of coal mining (shearing, excavation, hydraulic mining, etc) and Change in GrainSize Composition of Coal in Toothed Screw Crushing Complete product series, through coarse crushing, medium crushing, fine crushing and ultrafine crushing operations AIMIX has jaw crusher, impact crusher, cone crusher and sand making machine as the core crushing equipment,with a full range of models to meet the customer’s tonnage and construction aggregate production needsAimix Group Stone Crushing Solutions2023年9月29日 In this paper, we propose an ultrasonically coupled mechanical rockbreaking technology, creatively design an ultrasonically coupled mechanical rockbreaking drum, concurrently develop an ultrasonic cracking simulation method based on test coordination, and study the cracking mechanism and characteristics of ultrasonically prebroken rock in order to Research on the Mechanism and Characteristics of Ultrasonically

Crusher; Crushing; and Classification Equipment PPT SlideShare

2020年11月8日 Crusher; Crushing; and Classification Equipment Download as a PDF or view online for free Sand and stone aggregate, metal mine, metallurgy, coal mine, mineral processing, building materials, chemical industry, abrasive, renewable resource utilization and other industries 90Coal washing plant investment and equipment selection in Indonesia A mediumsized coal washing plant is processing an annual capacity of 450,000 tons to 900,000 tons WhatsApp Chat The ground coal processing system consists of coal, sieving, crushing, coal preparation, storage and loadingCoal preparation plant process and equipment for coal washingThe PCH ring hammer crusher is used for crushing various fragile materials which are moderately hard and have weak corrosively, such as gangue, coal, salt, chalk, gypsum, tile, limestone, coke, red sandstone, slag, shale, etc Both dry crushing and wet crushing are availablePCH Ring Hammer Crusher > Crushing Equipment > Products > Longwall mining additionally requires large coal reserves to justify the capital cost of longwall equipment As surface mining in the Powder River and Rocky Mountain Basins proceeds, Crushing and breaking Runofmine coal must be crushed to an acceptable top size for treatment in the preparation plantCoal Mining and Processing Methods The National Academies

Coal gangue precrushing equipment Google Patents

The invention discloses coal gangue precrushing equipment which comprises a box body, a lifting mechanism, a lifting seat, a driving mechanism, a crushing mechanism and a material guide plate The advantages are that: 1 this gangue crushing equipment is provided with the screw rod through servo motor's bottom, and the screw rod is threaded connection with the sleeve, Find your coal crusher easily amongst the 106 products from the leading brands (Fritsch GmbH, Fabo precrusher The compact FRITSCH Jaw Crusher PULVERISETTE 1 classic line is the ideal instrument for fast and effective pre Coal crusher, Coal crushing plant All industrial 2024年2月22日 In South Africa, the company has expertise in coal crushing and screening solutions, including specialised mobile and modular crushers designed for the coal market, meeting strict product gradingsPioneering crushing and screening solutions for Coal is transported from Pit B to Run of Mine (ROM) stock or directly to Coal Crushing Plant (CCP) The capacity of our MIFA Coal Crushing Plant is 2500 tons per hour with 3 units of Fix Plant and 1 unit of Mobile Plant Crusher with Coal Sizing crushed from 400 mm to 100 mm (lumpy) and 50 mm (fines), The majority of ROM coal is low ash insitu, clean, and directly Coal Crushing Plant PT MIFA Bersaudara

.jpg)

Crushing Equipment Resansil

Crushing Equipment; Extremely powerful technology makes RM Compact Crushers suitable for a multitude of materials, including CD waste, natural stone, glass, coal, reinforced concrete and much, the 12 tonne model can also be combined with highperformance pre The crushing rolls consist of the roller bodies, complemented with crushing rings or crushing shells The rolls are secured either with anchor bolts and end disks, or bolted with screws In order to facilitate maintenance, the crushing roll shafts are arranged in heavyduty cast steel housings with lubricated, amply dimensioned spherical roller bearings2PG Roller Crusher > Crushing Equipment > Products > DSMACPilot Crushtec’s inhouse designed, fabricated and manufactured mobile doubleroll crusher, the DoppiaTrac DR400, has proven itself in South Africa’s coal market, having already crushed millions of tons of coal at coal mines as well as powerplants around the countryRoller Crusher For Sale Double Roller Crusher Coal CrushingOur ball mills are suitable for all different type of ores They can be used for softer ore like limestone to hard rock like copper and gold ore Ball mills can be utilized as a primary grinding stage (after precrushing) or as a secondary grinding operation following a SAG mill Additionally ball mills are also implemented for regrind Ball Mills – efficient grinding FLS

.jpg)

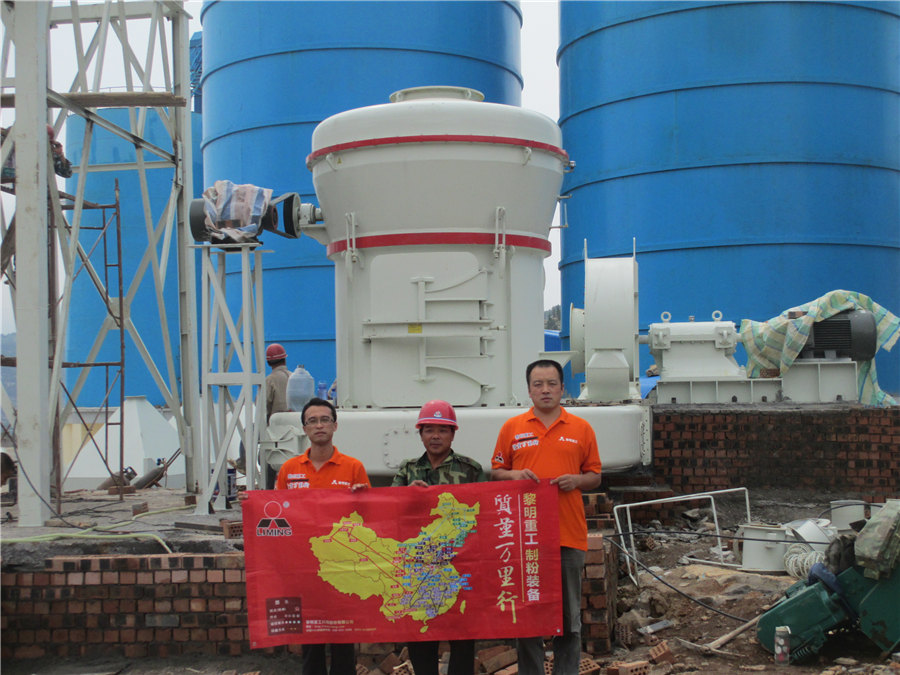

Coal crushing plant, Coal Crusher, Coal Crusher Manufacturer

Coal crushing plant is the production line of a largescale openpit mining era Equipped with roller crusher, to a large extent simplify the equipment configuration of the entire system, using prescreening design concepts for some conditions, In response to a series of problems restricting the production of the coal preparation plant,such as insufficient crushing capacity of the raw coal crusher, coal shutdown of the handselected belt, insufficient of the post, the high labor intensity and badly worn of the washing equipment, a technical reform of the large coal predischarge gangue process is researched and Optimization and upgrading of washing process in Tongxin coal McCloskey Equipment provide the Complete Crushing and Screening offer including complete of use, with a range of blow bar material options Features include an independently vibrating, doubledeck grizzly prescreen, it is The Complete Crushing and Screening Offer2019年11月12日 Two case studies were conducted in the Shennan mining area of Shaanxi Province, China to evaluate the surrounding rock deformation and stress evolution in predriven longwall recovery rooms These studies mainly monitored the surrounding rock deformation and coal pillar stress in the recovery rooms of the N1206 panel of 2−2 coal seam at Ningtiaota Surrounding rock deformation and stress evolution in pre

coal crushing and screening equipment

Coal Mobile Crushing And Screening Equipment For Sale Za coal mobile crushing and screening equipment for sale in south africa heavy industry is specialized in the design, manufacture and supply of crushing Chat Online In some industries to produce briquet or other coalproducts, the crushing and screening Chat Online2023年12月16日 Coal and gas outburst is a dynamic disaster that poses a significant threat to coal mines Energy analysis is an effective tool for understanding the mechanisms behind such outburst The energy sources and dissipation during outbursts were explored using a multifunctional test system, and the energy transformation relationship was analyzed based on Energy Evolution and Coal Crushing Mechanisms Involved in Coal Our lab coke coal testing equipment include crushers, grinders, splitters mixers are used for sample prepping, particle sizing or hardness determinations Log in; Favorites List; Shopping Cart You have no items in your shopping cart Gilson Chat; Materials Testing Equipment Contact Us Today! 8004441508 Menu Personal menuCoal Testing Equipment Gilson CoCoal crushing equipment, also known as coal crusher, can crush coal into 8100mm with uniform particle size Coal crushing purpose The crushed coal has a uniform particle size, generally 8100mm, which can fully burn coal and ensure emissions meet standards Related ProductsCoal crushing solution Xinxiang Gaofu Machinery Co, Ltd

Crushing Equipment, Conveyors POWERSCREEN MICHIANA

Our Powerscreen crushing equipment is ideal for mediumscale operators in aggregates, compost, topsoil, coal, construction and demolition waste, and iron ore 2019 ® 1000 Maxtrak is a small to medium sized cone crusher which has been designed for direct feed applications without prescreening on clean rock 2011 Powerscreen Screening is mainly used in the mining sector in primary and secondary crushing systems (Fig 3), coarse screening (scalping) in the preheap leaching process, fine screening and finegrain elutriation in various process stages, enrichment of valuable materials, eg of the iron content in iron ore, grinding and screening circuits (open and closed) and screens in DMS circuits (DMS Advances in screening technology in the mining sectorThe new PreStart Inspection tool by the world leading mining simulation technology provider, Equipment PreStart Inspection Training By: IMMERSIVE TECHNOLOGIES Views: Steep declines in the price of coal have placed an emphasis on existing operators improving their productivity by improving cut sequencesEquipment PreStart Inspection Training Resource CenterCoal Crushers, 16mm / 475mm Final Particle Size Gilson Co Units are mounted on four casters for easy relocation in the lab A special control box with NEMA 12 magnetic starter and overload protection is standard, and wiring is 230V/60Hz, 3phasecoal crushers for laboratory