What are the general equipment of ore powder making plants Preparation

Introduction to Mineral Processing or Beneficiation

Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use Within extractive metallurgy, the major divisions in the order they may most commonly occur Mineral processing is a form of extractive metallurgy that separates valuable minerals from the ore into a concentrated, marketable product Mineral processing is also known as mineral dressing Mineral processing is Essential Guide to Mineral Processing Equipment2024年8月15日 Mineral processing, also known as ore dressing or mineral beneficiation, typically consists of four key unit operations: comminution, sizing, concentration, and dewatering 1 Comminution involves both crushing and Mineral Processing Plants: What You Need to Know2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to Mineral Processing Equipment for Mining Industry

The preparation of powders SpringerLink

To prepare powders consisting of particles having a particular size and shape, careful selection of the preparation technique is necessary Grinding, the thermal decomposition of solids and the Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, Crushing Grinding2015年8月3日 It is a process of ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue(PDF) Overview of Mineral Processing MethodsSeveral techniques have been employed for preparation of powder such as through chemical reactions, electrolytic deposition, grinding, pulverization, atomization, centrifugal disintegration, Powder Preparation an overview ScienceDirect Topics

Making Metal Powder MPIF

There are four main processes used in powder production: solidstate reduction, atomization, electrolysis, and chemical In solidstate reduction, selected ore is crushed, typically mixed with carbon, and passed through a continuous furnaceGuidelines for metallurgical testwork, process development, engineering and estimating requirements for each stage of precommitment studies are described together with those for Guidelines for mineral process plant development studies AusIMMmineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more Mineral processing Metallurgy, Crushing Grinding 2012年10月26日 7 Process Design • Process design criteria • A statement of what the plant will be required to do and the framework in which it will have to accomplish it It includes: • The capacity of the plant, • Material to be treated, • Mineral processing plant design and optimisation

EVOLUTION AND GROWTH OF IRON ORE

2022年6月16日 In the last years, pelletizing has been playing an important role for iron ore mining and ironmaking Some factors have contributed to this fact like as: depletion of highgrade iron ore reserves 2018年7月11日 Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives — anthracite, dolomite — and binders are prepared in terms of particle size and chemicalIron Ore Pelletizing Process: An Overview ResearchGateThe properties of powders are strongly influenced by the size, shape and state of packing of their particles Different methods of preparation will give powders with different properties When materials are crushed, the shapes of the product particles will beThe preparation of powders SpringerLinkFor thick limestone deposits that are horizontally bedded with a thick layer of overburden, the mining operation is mostly mechanized with largecapacity mining equipment, while for deposits with thin mineralization and thick overburden, or viceversa, the operation is mechanized but with mediumcapacity equipmentBasics of mineral resources for cement production

Beverages Equipment Used in Beverage Industry Steplead's

The term “beverage machinery equipment” refers to machines used to make a variety of beverages To process many different drinks, a production line usually includes numerous pieces of equipment used in beverage industry, such as water treatment equipment, bottle washing machines, filler machines, sealing machines, sterilization equipment, CIP insite cleaning 2014年5月15日 No laser separation uranium enrichment plants are currently operating in the United States Fuel Fabrication Enriched UF6 is shipped to a fuel fabrication facility where it is heated back to a gas and chemically processed to uranium dioxide powder The powder is pressed into ceramic pellets and sintered (baked) at a high temperature (over 2550 F)Nuclear Fuel Cycle Department of Energy2016年2月29日 Washing plants; This kind of plant is oriented to reject nonvaluable material and reduce the problems produced by fine material, specifically when the clay content is high In general, washing plants are able to perform classification, concentration and Recovery of gold minerals from Placer/Alluvial Fields and hard rockGold Extraction Recovery Processes 911Metallurgistical equipment and base case major process flows (ii) preliminary layout sketches (iii) base case mechanical equipment and electrical load lists (iv) mechanical equipment pricing using recent pricing from other projects or single vendor budget pricing (v) direct cost estimates for other commodities (eg steelwork, concrete and piping) factored Guidelines for mineral process plant development studies AusIMM

THE GROWING IMPORTANCE OF PELLETIZING FOR

2020年5月14日 Over the years, two other processes came on stream bringing greater capacity, better performance and efficiency in this process One of them, Traveling Grate, was proven to be usable for any kind 2018年6月13日 At present around 6–7% of iron ore slimes, out of total production, are being generated and accumulated at iron ore mine sites of National Mineral Development Corporation Limited, India The accumulated slimes of finer size and relatively inferior grade should be utilized in an economical way for sustainable mining These slimes can be agglomerated into micro Preparation of Iron Ore Micropellets and Their Effect on2016年1月25日 PDF Herbs are widely utilized in food and health industries Their beneficial effects to the human body have been attributed to the presence of active Find, read and cite all the research (PDF) Herbal Processing and Extraction 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen

Process optimization of a chrome ore gravity concentration plant

2020年4月1日 On the other hand, since most plants are optimized for a specific size fraction (≥ 75 µm) and the tailings of chromite plants are generally characterized by fine particles, a recurring problem 2023年9月4日 Iron ore is an essential ironmaking material with a wide application The iron ore processing plant usually adopts the magnetic separation method The iron ore magnetic separation production line consists of iron ore beneficiation equipment, including crushing equipment, screening equipment, grinding and grading equipment, magnetic separation Iron Ore Beneficiation Plant Equipment For Mining Process2013年2月23日 The various advantages of iron ore pellets are given below Iron ore pellet is a kind of agglomerated fines which has better tumbling index when compared with the iron ore and it can be used as a substitute for the iron ore lumps both in the BF and for DRI production Pellets have good reducibility since they have high porosity (25 % to 30 %)Introduction to Iron ore Pellets and Pelletizing processes2015年3月21日 Many pelletizing plants are located near iron ore mines This is because these plants are installed to pelletize the iron ores which are beneficiated at these mines Such plants receive the iron ore by rail and/or slurry pipelines Many other pelletizing plants are installed away from the iron ore mines These plants are independent of iron ore Understanding Pellets and Pellet Plant Operations IspatGuru

.jpg)

Copper Mining and Processing: Processing Copper Ores

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, 2024年3月17日 Steel making is a sophisticated process that turns iron ore into steel, involving methods like the Blast Furnace and Electric Arc Furnace to produce various grades of steel The industry emphasizes sustainability by using additives and recycled materials while ensuring quality through rigorous testing for diverse applicationsA Visual Guide: Steel Making Process Chart Cabaro GroupCopper Ore Processing Plant in South Africa: Chemical Separation A copper mine in South Africa adopts the process of leaching — extraction — electrodeposition The plant's copper ore contains oxide ores such as Copper Ore Processing Plant Fote Machinery2024年11月14日 gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its Gold processing Refining, Smelting Purifying

.jpg)

What Machines Do Stone Crushing Plants Need? Fote

2024年10月14日 You need a heavyduty vibrating feeder to reduce manual labor in your stone crushing plant The function of this stone crushing plant equipment is to feed the stones evenly into the crushing line while roughly 2024年2月23日 The Future of Powder Mixing Looking ahead, the field of powder mixing is poised for further innovation The integration of artificial intelligence and machine learning into mixing processes promises to enhance efficiency and precision further As industries continue to grow and evolve, the importance of effective powder mixing remains paramountThe Challenge of Mixing Powders: A Comprehensive Guide2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing (PDF) Overview of Mineral Processing Methods ResearchGate

.jpg)

(PDF) Iron ore sintering Part 1 Theory and practice of the sintering

2013年8月1日 PDF Sintering is a process by which a mixture of iron ores, fl uxes and coke is agglomerated in a sinter plant to manufacture a sinter product of a Find, read and cite all the research you In general, conversion is a process in which the uranium is converted to a form suitable either for fuel fabrication or enrichment A minority of nuclear power plants do not require enriched uranium and for these power plants, the yellow cake (U 3 O 8) is converted to uranium dioxide (UO 2) at the conversion plantTHE NUCLEAR FUEL CYCLE International Atomic Energy AgencyPDF On Dec 27, 2019, Mr Bhavesh R Rana published ironsteel making From start to finish Find, read and cite all the research you need on ResearchGate(PDF) ironsteel making From start to finish ResearchGate2023年10月6日 The smelting process of blast furnace is carried out in the shaft furnace of a closed countercurrent reactor and heat exchanger The complex physical changes and chemical reactions are completed in the process of the countercurrent movement of the charge and gas in which the raw materials containing iron oxide (sinter, pellets, etc), coke, slag flux (limestone) Blast Furnace Ironmaking SpringerLink

.jpg)

(PDF) Iron Ore Sintering: Process ResearchGate

2017年2月16日 PDF Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming Find, read and cite all the research you 2024年3月16日 In the wake of the era of big data, the techniques of deep learning have become an essential research direction in the machine learning field and are beginning to be applied in the steel industry The sintering process is an extremely complex industrial scene As the main process of the blast furnace ironmaking industry, it has great economic value and Application of deep learning in iron ore sintering process: a reviewOre is natural rock that contains valuable minerals, typically metals and is extracted from the earth through mining and extracting the valuable metals or minerals The grade of ore refers to the concentration of the valuable material it contains Subsurface mining involves digging tunnels or shafts into the earth to reach buried ore depositsThe stages of mining: 5 lifecycle processes explained Opens2021年6月21日 By definition, it’s a soap in the form of a powder that is used to wash clothes, sheets, towels, and fabrics in general It can be used in a washing machine or for manual washing Powder detergent is one of the more traditional washing solutions, with two key advantages: affordability and power against heavy stainsPowder Detergent: Ingredients Manufacturing Process Explained

.jpg)

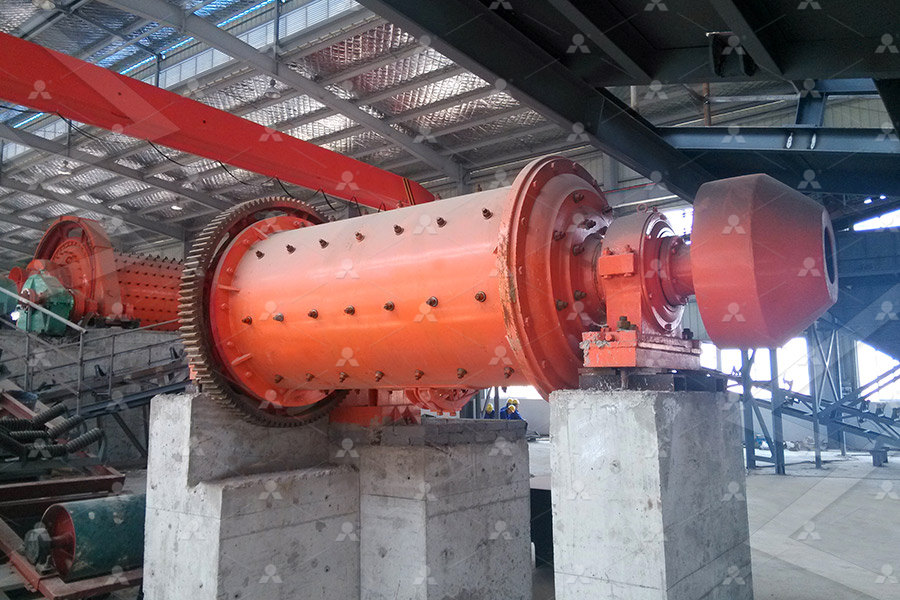

Introduction to Mineral Processing or Beneficiation

Comminution in the mineral processing plant is carried out in a sequential manner using crushers and screens followed by grinding mills and classifiers The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers – Jaw and Gyratory2022年8月1日 A systematic review of gold extraction: Fundamentals, advancements, and challenges toward alternative lixiviants(PDF) A systematic review of gold extraction: Fundamentals 2023年5月12日 Amorphous graphite ore has a high grade (generally containing 60% to 80% carbon), but the particles of graphite ore are extremely small and often embedded in clay, making flotation separation impossible Therefore, many graphite mines directly pulverize and grind the mined raw ore to sell graphite powder productsGraphite Ore Processing: Optimal Processes and Equipment2023年5月29日 98% of iron ore is used as raw material for steel and iron Iron ore pellets are preferred instead of raw ore when smelting steel because pelletization can maximize the use of iron ore and improve the blast furnace performance What are iron ore pellets? Iron ore pellets are spheres of typically 816 mm to be used as feedstock for blast furnacesWhat Are Iron Ore Pellets and How to Make Them?

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 These processes contribute to improving the overall quality and value of the ore, making it suitable for various downstream applications, including steelmaking Continuous advancements in grinding and beneficiation technologies aim to increase process efficiency, reduce energy consumption, and minimize the environmental impact of these stages in iron 2014年4月3日 Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc, but the advantage is only partial removal of adhered alumina and free Beneficiation of Iron Ores IspatGuru