What process does civil coal processing include

.jpg)

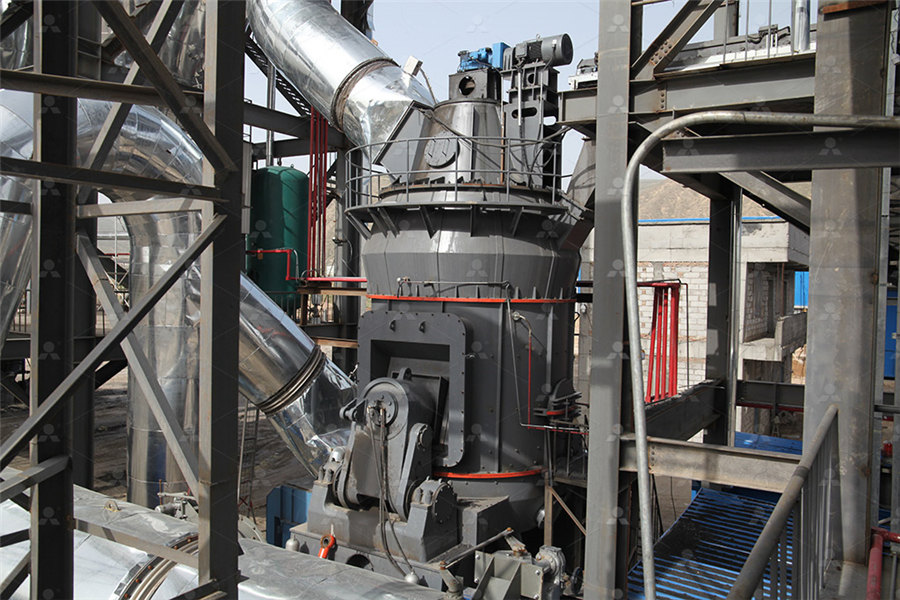

Coal Processing Coal Preparation Coal Handling

Coal processing involves crushing, screening and beneficiation Processing is where coal is converted from runofmine (ROM) coal to a product that meets the customer’s requirements Mined coal can include lumps Crushing to a 1982年8月9日 Coal processing refers to the practice of converting coal into various products such as coal tar, coke, and tarbased chemicals through methods like coal carbonization, coal Coal Processing an overview ScienceDirect TopicsCoal preparation, also called washing, cleaning, processing, and beneficiation of coal, is a physical process where coal is upgraded by the reduction of ash, sulfur, and moisture content Coal Preparation an overview ScienceDirect Topics2021年5月11日 Coalification refers to the series of processes involved during the transformation of this organic vegetation into coal The first step in transforming vegetation into coal is the Mineral Beneficiation and Processing of Coal SpringerLink

.jpg)

Coal Preparation SpringerLink

Coal preparation, which may also be called washing, cleaning or processing, is the methodology by which coal feedstocks are upgraded in order to reduce freight costs, improve utilization Coal beneficiation, or coal preparation as it is also termed, refers to the processes through which inorganic impurities are separated from raw mined coal, thereby providing improved Coal Beneficiation an overview ScienceDirect TopicsThe EHS Guidelines for Coal Processing cover the processing of coal into gaseous or liquid chemicals, including fuels They apply to the production of Synthetic Gas (SynGas) through Environmental, Health and Safety Guidelines for Coal ProcessingCoal Production and Processing Technology provides uniquely comprehensive coverage of the latest coal technologies used in everything from mining to greenhouse gas mitigation Featuring contributions from experts in industry Coal Production and Processing Technology MR

G[R.jpg)

South African Coal Mining Techniques

2023年6月12日 Coal mining can have significant environmental consequences The extraction, processing, and transportation of coal can contribute to various forms of pollution and land degradation It is essential to mitigate these 2014年6月27日 Coal is broadly separated into brown and black which have different thermal properties and uses Brown coal (lignite) has a low energy and high ash content Brown coal is unsuitable for export and is used to generate electricity in power stations located at or near the mine Black coal is harder than brown coal and has a higher energy contentCoal Geology Geoscience AustraliaDry coal processing benefits downstream utilizations through possible cost and energy savings along with a reduction in water pollution As a result, Prevost, 2018) Some of the major coal importers include Japan, Korea, China, G ermany, UK, Russia, India, USA, Netherlands and Spain (WA, 2009)Dry processing for coal preparation: aPotential environmental issues associated with coal processing projects include: • Air emissions • Wastewater • Hazardous materials • Wastes • Noise Air and are a significant source of air emissions during coal processing The gasification process may also generate pollutants such as hydrogen sulfide (H 2S), Environmental, Health and Safety Guidelines for Coal Processing

Coal Mining and Processing The National Academies Press

Although the United States has the vast coal resource described in the previous chapter, perhaps as much as 4 trillion tons, the key issue for policy makers is the amount of coal that is economically recoverableThis is not a fixed quantity, but depends on the geological resource, the market price, and the cost of mining The particular characteristics of the coal mining industry generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 11101 In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed,1110 Coal Cleaning US EPA2020年2月5日 The total coal consumption in China is on the rise The characteristics of CO2 and SO2 emissions in the whole process of coal processing and utilization in China are worthy of study Based on the five links of the whole process of coal production and utilization, including coal production, raw coal processing, logistics and transportation, conversion and utilization CO2 and SO2 emission characteristics of the whole process Engineering at Coal Mines Queensland has a rich and vast deposit of highquality coal resources with over 34 billion tonnes of raw coal having been identifiedIt boasts a combination of thermal coal for power generation and over 8 billion tonnes of coking coal suitable for high quality steel milling (from Dept of Natural Resources and Mines)Coal Mine Engineering, Processing, Surface and Underground

.jpg)

Coal Mining and Processing How Does It Work? Energy

2022年9月20日 Some underground mines are 1,000 feet deep To remove coal in these underground mines, miners ride elevators down deep mine shafts where they run machines that dig out the coal Processing the Coal Source: bloomberg After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining 2007年6月1日 Coal gasification is presented in terms of the chemistry of coal conversion and the product gas characteristics, the historical development of coal gasifiers, variations in the types and (PDF) Coal Gasification (chapter only) ResearchGate2024年1月11日 The 5step process to pulverize coal efficiently The coal pulverization process involves a precise sequence of steps Each is systematically designed to convert raw coal into a fine, efficient powder But How to Process Coal into Pulverized Coal in 5 Steps?Coal stockpile Coal stacker Coal reclaimer Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in Coal preparation plant Wikipedia

.jpg)

coal process engineer jobs Indeed

Discover 42 Coal Process Engineer jobs on Indeed View all our Coal Process Engineer vacancies with new positions you will manage small to medium Civil projects, This team includes various backgrounds and skill sets, allowing for a diverse environmentThe successful applicant will be based at an open cut metallurgical coal mine, in 2024年11月15日 Coal is a black or brownishblack sedimentary rock that can be burned for fuel and used to generate electricityIt is composed mostly of carbon and hydrocarbons, which contain energy that can be released through combustion (burning) Coal is the largest source of energy for generating electricity in the world, and the most abundant fossil fuel in the United StatesCoal EducationPotential environmental issues associated with coal processing projects include: • Air emissions • Wastewater • Hazardous materials • Wastes • Noise Air and are a significant source of air emissions during coal processing The gasification process may also generate pollutants such as hydrogen sulfide (H 2S), Environmental, Health and Safety Guidelines for Coal ProcessingFGX technology is an innovative, efficient, coal preparation process using air Typically coal processing is completed with water, which is a very costly and scarce resource requiring stricter permits to operate The FGX dry coal washing process is proven successful, cost effective, environmentally friendly, and requires only an air quality permitDry Coal Processing Coal Washing Process FGX SepTech

Advances in Coal Processing, Utilization, and Process Safety

Simulation and predictive modeling of coal seam gas outbursts and rock bursts; New technologies in coal processing and their implications for process safety; Research on coal utilization and its safety impacts; Environmental and safety considerations in coal–gas extraction and utilization; The coal spontaneous combustion mechanism Dr Feng Du2019年12月31日 This chapter describes the process of coalification, which gradually turns plant debris into coal, involving heat, pressure and the effects of time(PDF) The Origin and Classification of Coal ResearchGateA sophisticated machine called a continuous miner extracts the coal or more conventionally, coal can be blasted from the working face Underground mining operations leave tailings Tailings are the residue left over from the process of separating coal from economically unimportant minerals during the coal processing step at plantsThe coal mining life cycle Mining for schoolsEnviroplus Design has 30 years experience in the coal processing industry Our involvement ranges from designing a number of coal plants to examination Home; A highlevel process design review; In this way the critical path for the project does not include the time to construct the washing plant Project Management PhilosophyCoal Processing Enviroplus Design Engineering for a Cleaner

.jpg)

Coal Uses, Types, Pollution, Facts Britannica

5 天之前 Conversion In general, coal can be considered a hydrogendeficient hydrocarbon with a hydrogentocarbon ratio near 08, as compared with a liquid hydrocarbons ratio near 2 (for propane, ethane, butane, and other forms of 2006年4月1日 A coal preparation plant typically operates with multiple cleaning circuits to clean individual size fractions of runofmine coal Coal preparation plants are traditionally optimized using the (PDF) Coal preparation plant optimization: A critical FGX technology is an innovative, efficient, coal preparation process using air Typically coal processing is completed with water, which is a very costly and scarce resource requiring stricter permits to operate The FGX dry coal Dry Coal Processing Coal Washing Process FGX Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process Civil

.jpg)

Process design of the Phola coal J preparation plant o SAIMM

Process design of the Phola coal preparation plant by GM Cresswell* Synopsis The 2 360 t/h two module Phola coal preparation plant represents a new era of large plant in the Witbank coalfield designed to extend its life to 2020 and beyond The plant uses the optimum processing model for Witbank coals, receiving a feed coal size of 50 mm, wet2021年6月24日 Coal in the seam is then excavated Surveyors are present to ensure the coal is mined optimally The coal is blasted into smaller layers, which are dug up and transported by trucks to a processing plant Throughout the coal mining process, we minimise the impacts on the environment including the air and water quality, noise and heritage sitesHow Is Coal Mined? Bravus Mining Resources2016年4月12日 Fine coal is dewatered with a Disc Filter, as the Flotation Machine can usually be regulated to produce a product low in ash and with proper density for direct filtration Typical operating results are as follows: Coarse Coal Flotation Circuit It is highly desirable to extend the range of coal flotation to include the coarser SizesCoal Beneficiation Process Diagram 911MetallurgistPhD 2019 Dry processing for coal preparation: a review N Hughes i NWU in association with CoalTech Dry processing for coal preparation: a review (a) N Hughes (b) Prof M Le Roux (c) Prof QP Campbell NorthWest University Private Bag X6001, Potchefstroom 2520, South AfricaDry processing for coal preparation: a review

Technique to Investigate Pulverizing and Abrasive Performance of Coals

2021年11月4日 Technique to Investigate Pulverizing and Abrasive Performance of Coals in Mineral Processing SystemsThe challenge to the coal processing industry is to process lowyielding coals to produce goodquality products and at the same time ensure that coal mining remains economically viable This Some of the technologies recently implemented in South Africa include the 3product dense medium cyclone and dry beneficiationProcessing lowgrade coal to produce highgrade productsspecification, most suppliers process the raw coal using dense medium processing Although dense medium is the most efficient process available, it is expensive and it produces a wet product which requires dewatering by centrifuging and/or drainage on product stockpiles South Africa is a waterscarce country and water for coal processing (and Dry Processing Versus Dense Medium Processing For Preparing Thermal Coal2017年7月5日 Pyrolysis remains key to all coal utilisation processes such as combustion, gasification and liquefaction Understanding the thermochemical changes accompanying these processes through pyrolysis would help in Pyrolysis: Pathway to Coal Clean Technologies

.jpg)

FGX DRY COAL PROCESSING FGX SepTech

The FGX technology provides an innovative and costeffective dry coal processing process that integrates the separation principles of an autogenous medium separator and a conventional table Horse power does not include auxiliary equipment such as conveyor belts, etc 5 Specifications subject to change without notice NOTES: P3 MODEL 2018年12月26日 The normal yield of coal tar during the coal carbonizing process is around 4 % Coal tar has a specific gravity normally in the range of 112 to 120, but exceptionally it can go upto 125 These include (in order of the distillation fraction) (i) benzene, toluene and the xylene isomers, tri and tetramethylbenzenes, indene Coal Tar and its Distillation Processes IspatGuruCoal Combustion and the Environment Paul Breeze, in CoalFired Generation, 2015 Coal combustion is a dirty process, releasing a range of pollutants including sulphur dioxide, nitrogen oxides, carbon dioxide, volatile organic compounds, ash and a range of heavy metals If these are not controlled they can enter the atmosphere, causing damage to the environment and to Coal Combustion an overview ScienceDirect TopicsProcessing covers a wide range of operations performed on personal data, including by manual or automated means It includes the collection, recording, organisation, structuring, storage, adaptation or alteration, retrieval, consultation, use, disclosure by transmission, dissemination or otherwise making available, alignment or combination, restriction, erasure or destruction of What constitutes data processing? European Commission

.jpg)

Coal Preparation SpringerLink

According to the annual census of coal preparation plants conducted by Coal Age [], the USA operates 286 coal preparation plants in 12 statesThis number is relatively small by comparison to the worldwide fleet which is estimated to be 2,283 plants []The capacity of the plants can range from less than 200 t/h for small operations to 6,000 t/h or more for large industrial plantsCoalfired power generation plants are most commonly based on pulverised coal combustion (PCC) systems, in which heat from combustion of the coal is used to raise high pressure superheated steam that drives a steam turbine generator Steam turbine plants have been in use for over a hundred years, and have reached supercritical conditions withUnderstanding coalfired power plant cycles ICSC2016年2月1日 This paper presents an extensive review of the coal agglomeration process, including oil agglomeration theory, characterization methods of coal hydrophobicity, and the main factors affecting the (PDF) Coal Agglomeration Processes: A Review ResearchGate2024年5月22日 Samples of coal waste from one of the coal slurry ponds located in the Upper Silesian Coal Basin were collected following the applicable standards with a weight of about 50 kg (see Fig 4a) A sample was acquired from W2 and W3 well at a distance of 30 m from the embankment of the slurry pond, and sample B was acquired between W2 and W3 well at a Coal Recovery from Processing Waste and Coal Combustion