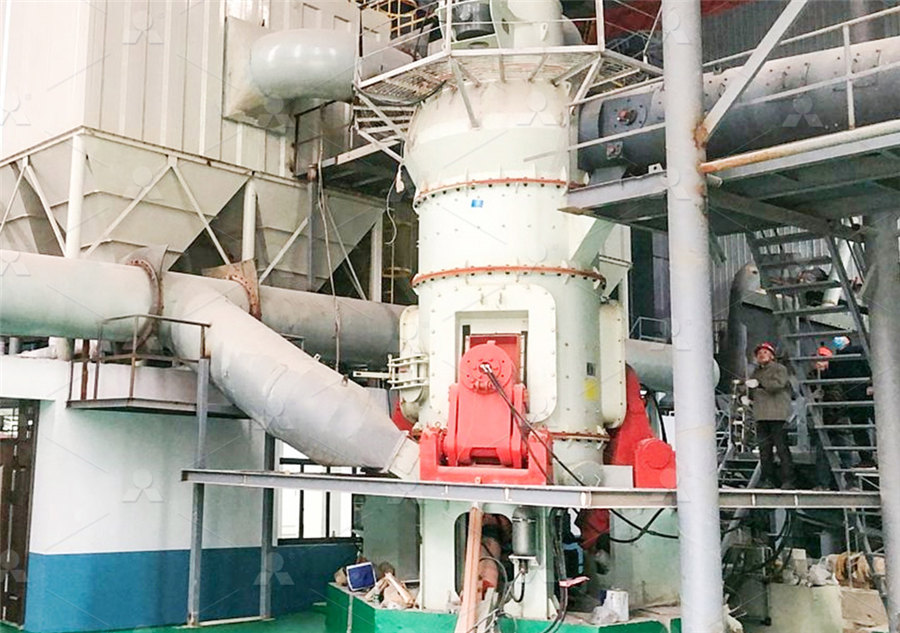

Pingshan slag vertical mill project site

.jpg)

Highrise vertical factory to be put into use

2023年5月17日 The project is China’s first smart prefabricated highrise vertical factory consisting of six buildings, with the highest RD building reaching 1516 meters and the PINGSHAN New Energy Vehicle Industry Park’s Phase 1 has passed the construction acceptance review, and a vast highquality industrial space will soon be put into use The Highrise vertical factory to be put into use英文报2023年11月13日 China's first prefabricated highrise vertical factory, the phase1 project of the Pingshan New Energy Vehicle Industry Park in Shenzhen, south China's Guangdong China sees bright prospects in green development2023年10月5日 Pingshan Phase II, a cuttingedge 135GWGW ultrasupercritical coalfired unit, achieves a remarkable net efficiency of 4937%—making it the world’s most efficient coalfired China’s Pingshan Phase II Sets New Bar as World’s Most ICSC

.jpg)

NGC Facilitates Connection of New UltraSupercritical Double

2020年12月25日 The national demonstration project “High and Low Level 1350 MW Unit for the Shenneng Anhui Pingshan Power Plant Phase II” has been successfully connected to the 2019年2月4日 Feng 5E vision becomes concrete reality at Pingshan Phase 2 site The double reheat ultrasupercritical Pingshan Phase 2 coal plant currently under construction in China will Feng 5E vision becomes concrete reality at Pingshan Phase 2 siteUpon commissioning by the end of August, 2020, the Pingshan Phase 2 will be the most efficient and cleanest plant in the world Until the 1950s, pulverised coal combustion (PCC) power Visiting the Pingshan Phase 2 power plant in Anhui, China2024年3月8日 Sitting on the boundary between Shenzhen and Huizhou in Guangdong province, the Pingshan New Energy Vehicle Industrial Park is a benchmark project demonstrating how Shenzhen goes above and under

.jpg)

Pingshan Thermal Power Plant Phase Two NS Energy

2020年11月5日 The Pingshan thermal power plant in Anhui province, China is undergoing phase two expansion to add a 1,350MW ultra supercritical coalfired unit to the existing 2023年5月10日 Pingshan New Energy Vehicle Industry Park Phase 1 has passed the construction acceptance review, and a vast highquality industrial space will soon be put into Highrise vertical factory to be put into useLocal NewsPeople's CHAENG steel slag vertical mill has complete models and strengthens the iron dressing process, with the feeding size of ≤ 5mm 【Product capacity】: 200,0001,500,000t/a 【Specific surface area】: 450~500 m²/kgSteel Slag Vertical Roller MillProcess introduction The GRMK cement vertical roller mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions It can save 30% of power per ton compared with traditional ball mill At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little Vertical Cement Mill

Vertical Roller Mills Cement Processing Equipment

2 vertical roller mills for slag (LGMS5727), annual output 1,400,000 ton Vietnam Hoa Phat Group Anhui Fengyang Zhongdu Clinker Project Vertical roller mill for raw material (LGM5426, 6000t/d) Why Choose CITIC HIC's Vertical Roller Project name: Great Wall machinery slag powder demonstration and training base with annual production of 600,000t Project address: Great Wall Road, Mengzhuang Town, GRMS 4641,GRMS3331 slag vertical roller mill Production capacity: Annual production of 900,000t slag powder Related Products Cement Vertical Roller Mill; Slag Ball Mill;GGBS Vertical Roller MillIndustrial Ally recently completed a study for the installation of a modular vertical roller mill (VRM) system to produce Type IP and Class N Pozzolan cement Follow Us 6366925595; Menu About Us Our Please complete the form below to be connected to one of our engineering experts for your upcoming project Full Name; Address Modular Vertical Roller Mill System Industrial Allya Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm Loesche

High Efficiency Slag Vertical Roller Mill in Ggbs Production Line

Company Introduction: Founded in 1958, Xinxiang Great Wall Machinery Co, Ltd is a wellknown national hightech enterprise specializing in the development, production and sales of largescale building materials making equipment including crushing and grinding equipment It covers an area of 700, 000 square meters and has a total asset value of RMB 500 millionFirst vertical mill for cement grinding Gebr Pfeiffer Granulated blastfurnace slag Raw material 15 MPS vertical mill Optimized free fl ow areas Executive Director – Sales and Project Engineering The very first onemill solution in the world MVR 6700 C6 with 11,500 kW drive power Biggest gypsum calciningPASSION FOR GRINDINGVertical roller mill (VRM) is a type of industrial equipment used to crush or grind materials into small particles PTIndoferro t/a nickel slag grinding plant EPC project; Great Wall Machinery GGBS Plant with 600,000 t/a Capacity; Hot Vertical Roller Mill CHAENG Great Wall MachineryProjects 1 Hebei aosen steel GRMSS3331 30,0000t/a Steel Slag Grinding Plant 2 the steel slag ≤5mm and the metal iron content ≤2% enters the GRMSS series steel slag vertical mill developed by Xinxiang Great Wall Company for final grinding Auxiliary Equipment Rod Mill Vertical Raw Mill Slag PotSteel Slag Grinding Plant CHAENG

Vertical Roller Mills

Projects More than 100 customer cases of vertical mill production lines CHAENG vertical roller mill is applied in many large production lines, playing an important rolls in slag, cement and other material production lines, such as: Shanghai Baosteel 1,500,000 tons /year composite powder (slag, steel slag) production line, Henan Meng Electric Group 1,000,000 tons/year GGBFS 2018年9月22日 Hebei Tangshan t a slag powder production line EPC project in July 2018 GRMS5341 slag vertical mill Production time: July 2018 Analysis Project introduction: the owner of this project built this line according Hebei Tangshan t/a slag powder production Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and Vertical roller mills FLSmidth CementIntroduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsVertical Raw Mill

.jpg)

Vertical roller mill Welding Alloys

During the height of the COVID19 pandemic, Welding Alloys undertook a project to repair a vertical roller mill (VRM) at Hanson Cement’s site in Purfleet, Essex The work involved the repair of a Loesche 46 2+2S VRM grinding table and rollers, which suffered extensive wear during the processing of 3 500 tonnes of granulated blast furnace slagvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSitems Amongst others these involve the mill drive and the roller/hydraulic system Figure 1: Loesche Mill type LM 696 with 6 rollers for cement raw material grinding Grinding track outer diameter Number of rollers Mean roller diameter Roller width Mill motor capacity kW m – m m 9600 70 4 S + 4 M ˜ 27 ˜ 075 Mill radial bearing Mill LATEST TECHNOLOGICAL INNOVATIONS IN GRINDING WITH THE VERTICAL ROLLER MILLSlag vertical mill is mainly applied in metallurgical and cement industries and is the highend equipment for treatment of slag and crushed coal 1,500,000 t/a slag vertical mill EPC project undertaken by DHHI 900,000t/a slag vertical mill developed and manufactured by DHHISlag vertical mill

.jpg)

Slag Grinding Vertical Roller Mill Ggbs Grinding Processing Plant

Type: Vertical Roller Mill Motor Type: AC Motor Motor Power: 135kw Rotationl Speed: 1315r/min Application: Mine Materials: Coal, Slag, Flyash, Cement, Calcium Carbonate• A Vertical Roller Mill for grinding the GBFS into a finished product Ground Slag (GGBFS) • A finished product silo and weighbridges • Upgrades to the existing facilities including: Wharf for unloading the GBFS Office and Amenities Truck and vehicle parking • The site will continue to operate 7 days a week, 24 hours per dayProposed Port Melbourne Slag Grinding Facility Cement AustraliaVertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production Vertical Coal Mill Great WallGrinding Rollers: Grinding roller is the main part for crushing and grinding materials The grinding roller is composed of cast steel roller sleeve, forging shaft and wearresistant surfacing bushing The grinding roller is installed on the rocker arm of the water slag vertical roller mill, under the action of external force, it is pressed tightly on the material of the grinding table, as the Water slag vertical roller mill

.jpg)

Highrise vertical factory to be put into useLocal NewsPeople's

2023年5月10日 Among them, there are eight vertical factory projects in Pingshan with a total construction area of 39 million square meters ICP Registration Number: 粤ICP备号1 Police Registration Number:124 Website 2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/gMPS vertical roller mills for slag and slag cementsThe company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, Vertical Lime Kiln CHAENGCreating this project on a vertical mill takes a day to complete Once done with it, you’ve got a professionallooking hammer Making a machinist hammer is one of the best ways to practice your shaping and sharpening techniques It’s also a great way to master your mill machine and what it can and can’t do15 Mill Projects That Are SUPER Easy for Beginners! Lathe Matters

Slag Vertical Roller Mill CHAENG

CHAENG GRMS slag vertical mill integrates fine crushing, grinding, drying, powder separation and conveying It has large drying capacity and low power consumption It can meet the annual output of 200,0001,500,000 tons of slag grinding plant projects The specific surface area of the finished slag powder can be up to 420~450 m²/kgMain equipment: GRMR2621 raw material vertical mill , φ32X50m cement rotary kiln, GRMK3331 cement vertical mill, GRMC1621 coal vertical mill Project in: Uzbekistan In the nearly 60 years of largescale grinding equipment manufacturing experience, CHAENG has manufactured many coal vertical grinding equipment which have been adopted by a number of Coal Vertical Roller MillVibration is avoided by a variable speed control table rotation by an inverter motor Especially its effect on fine products such as slag and slippery materials like oil cokes 2 2way System For making a stable grinding bed between the roller tire and table liner, UBE Slag Grinding Mill adopts a '2Way System'UBE Vertical Mill UBE Machinery Corporation, LtdE/SLAG – Enhanced slag reactivity 200 million t of slag from steel production are generated worldwide – 140 million t of converter slag (BOF, basic oxygen furnace) and 60 million t of EAF slag (electric arc furnace) In contrast to granulated blast furnace slag from pig iron production, untreated steel slag shows only a low hardening Greenkey Solutions: Loesche’s contribution to a sustainable ZKG

R)8OC`6F[ZIB.jpg)

Slag Mill

Overview Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, For slag vertical mills, targeted and planned maintenance should not omit hidden dangers in key wearresistant parts of the vertical mill, so as to achieve advance prediction and control, and eliminate hidden dangers in advance, which can prevent major accidents and improve the operation of the equipment efficiency and unithour output, providing guarantee for efficient How to properly maintain cement and slag vertical mills?The output of the GRMS nickel slag vertical mill produced by Great Wall Company can reach 160t/h, and the power consumption of the system is below 38kWh/t, which can meet the annual output of 200,000 to 15 million tons of Nickel Slag Vertical Mill CHAENGHLM series slag vertical roller mill produced by HCMilling(Guilin Hongcheng) can be widely used in slag grinding treatment The whole set of slag grinding treatment process includes crushing, drying, grinding, grading, transportation, collection, storage and other steps, which can realize the complete production and processing of slag from large particles to finished fine powderNews Application Of Slag Grinding Mill Introduction To

.jpg)

Steel slag vertical roller mill

Specifications of steel slag vertical roller mill Specification: Capacity: (t/day) Grinding table diameter(mm) Grinding roller diameter(mm) Feeding size(mm) Power: (kw) ZJTL800 3~5 800 300 ≤30 100~250 ZJTL1300 Steel slag powder can be used in land reclamation projects to improve soil quality and promote vegetation growth Surface 2021年4月14日 Completed in 2019 in Shenzhen, China Images by Shengliang Su, Chao Zhang Shenzhen Pingshan Art Museum is situated on the boundary of an urban spatial transitioning — to the west, a high Shenzhen Pingshan Art Museum / Vector Architects ArchDailyConsult Xinxiang Great Wall Machinery Co, Ltd's Slag Vertical Roller Mill brochure on DirectIndustry Page: 1/1Slag Vertical Roller Mill Xinxiang Great Wall Machinery Co, Ltd Project: Port Kembla/Australia ; Plant/product: cement grinding plant with MVR 6000 C6 vertical roller mill with MultiDrive ® Material to be ground: natural gypsum, FGD gypsum, clinker granulated blastfurnace slag ; Capacity: 215 t/h Portland cement (target: 208 t/h) Spec energy consumption of mill: 215 kWh/t (target: 228 kWh/t)Reference report MVR vertical roller mill with MultiDrive® for

.jpg)

ADVANCED TITANIUM SLAG VERTICAL MILL PRODUCTION LINE HCM Grinding Mill

2021年2月7日 PROJECTS; Solutions; Service; About; Blog; CONTACT US; ADVANCED TITANIUM SLAG VERTICAL MILL PRODUCTION LINE 17:05 The production line of a hightitanium slag vertical mill purchased by a steel mill started to formally produce titanium slag powder for customers and create profits The grinding table is one of the key parts of vertical roller mill It includes drag rings, segments (lining plate) and bases The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome the deficiencies in structure and make the grinding base bear force Grinding Table of Vertical Roller Mill Great Wall