Desulfurization limestone acceptance

Insights into the desulfurization mechanism of lowgrade

2021年12月1日 In this study, a promising approach of employing lowgrade limestone with different particle sizes as absorbent in wet flue gas desulfurization technique was investigated, 2005年12月7日 This work presents a practical result of experimental investigation of the limestone particle size effect on deSO x from a circulating fluidized bed combustion (CFBC) Desulfurization with a Modified Limestone Formulation in an 2015年10月30日 This study investigated that status of domestic and international furnace desulfurization and desulfurization characteristics of limestone for fluidized bed use depending on the technology(PDF) A Review of Desulfurization Technology using 2021年12月1日 Drybased limestone desulfurization, limestonegypsum wet desulfurization (Van Caneghem et al, 2016), lownitrogen combustion, selective catalytic (SCR), and noncatalytic Insights into the desulfurization mechanism of lowgrade

.jpg)

Modeling of SO2 Absorption into Limestone Suspensions

1997年1月6日 The wet limestone flue gas desulfurization process, and more specifically absorption of SO 2 limestone suspensions, was studied Experiments of SO 2 absorption were 2021年2月1日 In this paper, chemical precipitation process is used for the treatment of the desulfurization wastewater generated by the waste gas treatment system of the limestone LimestoneGypsum Wet Flue Gas Desulfurization Wastewater The desulfurization characteristics of limestone under O2/CO2 atmosphere were studied by a droptube furnace test rig The experimental results show that high CO2 concentration makes Mechanism of Highly Efficient InFurnace Desulfurization by 2015年10月30日 Abstract This study investigated that status of domestic and international furnace desulfurization and desulfurization characteristics oflimestone for fluidized bed use depending on the technology for CFBC one [PDF] A Review of Desulfurization Technology using

Research on red mudlimestone modified desulfurization mechanism and

2021年10月1日 With the increasingly stringent emission standards of flue gas, a demonstration project of desulfurizing by “red mudlimestone process” was established to make the flue gas meet the Emission Standards of Pollutants for Aluminum IndustryAs shown by the detection results, the emission concentration of Sulfur dioxide (SO 2) was less than 50 mg/m 3, and the 2022年12月1日 Download Citation Desulfurization characteristics of limestone slurry with added organic acid In this study, a desulfurization experiment was performed in a bubbling reactor to investigate the Desulfurization characteristics of limestone slurry withCurrently, desulfurization technologies can be categorized into three main types: wet flue gas desulfurization (FGD) [11], [12], [13], semidry desulfurization [14] and dry desulfurization [15]Wet flue gas desulfurization is widely employed in largescale desulfurization processes due to its high efficiency and low energy consumption [16]However, it poses a significant environmental Recent advances in process and materials for dry desulfurization 2010年5月11日 Request PDF Limestone dissolution in flue gas desulfurization Experimental and numerical study BACKGROUND: Wet FGD technologies account for around 87% of such systems worldwide, particularly Limestone dissolution in flue gas desulfurization ResearchGate

.jpg)

Desulfurization and Denitrification Technologies of Coalfired

Acceptance date: Online publication date: Publication date: Pol J Environ Our paper introduces mature and new flue gas denitration and desulfurization technologies along with their processing 2001年5月19日 A detailed process model of the wet limestone flue gas desulfurization system has been presented This model can be used to calculate indispensable parameters for estimating costs and next to minimize capital and operating costs The process model describes most important stage of SO2 removal running in an absorber and a holding tank It includes Model of the Wet Limestone Flue Gas Desulfurization Process 2015年11月30日 The flue gas desulfurization (FGD) process is one of the most effective methods to reduce the amount of SO₂ gas (up to 90%) generated by the use of fossil fuel Limestone is usually used as a desulfurizing agent in the wettype FGD process; however, the limestone reserves of domestic mines have become exhausted In this study, limestone sludge A Study on the Desulfurization Efficiency of Limestone Sludge Neither lime nor limestone dissolves well in water and therefore, both are pumped in slurry form to the scrubber tower Lime slurry is more alkaline, having a pH of 125 while limestone slurry is roughly neutral A lime based system will therefore add more lime when pH drops below 12 and a limestone based system will be controlled around 6 UnlessLime / Limestone Wet Scrubbing System for Flue Gas Desulfurization

Insights into the desulfurization mechanism of lowgrade limestone

2021年12月1日 From the analysis above, it can be deduced that the desulfurization process by using lowgrade limestone as SO 2 absorbent is divided into three stages: (1) SO 2 dissolves into LGL slurry firstly followed by the formation of SO 3 2−, HSO 3 − and H 2 SO 3 species [21]; (2) continuous dissolution of Cabased compound including CaCO 3 and CaMg 2024年2月12日 Scientific Reports Experimental study on integrated desulfurization and denitrification of lowtemperature flue gas by oxidation method Skip to main content Thank you for visiting natureExperimental study on integrated desulfurization and Nature2017年7月1日 The most common types of FGD system are based on the contact between the flue gases and an alkaline sorbent such as lime or limestone (Wang et al, 2005)Furthermore, the major types of largescale power plant FGD systems include (i) spray towers, (ii) spray dryers and (iii) dry sorbent injection systems (Song et al, 2012)These FGD systems can achieve about Enhancing the recovery of gypsum in limestonebased wet flue 2013年10月1日 Limestone slurries are widely utilized in wet flue gas desulfurization (WFGD) processes The evaluation of the reagent's reactivity is fundamental for process design and plant operationModeling Limestone Reactivity and Sizing the

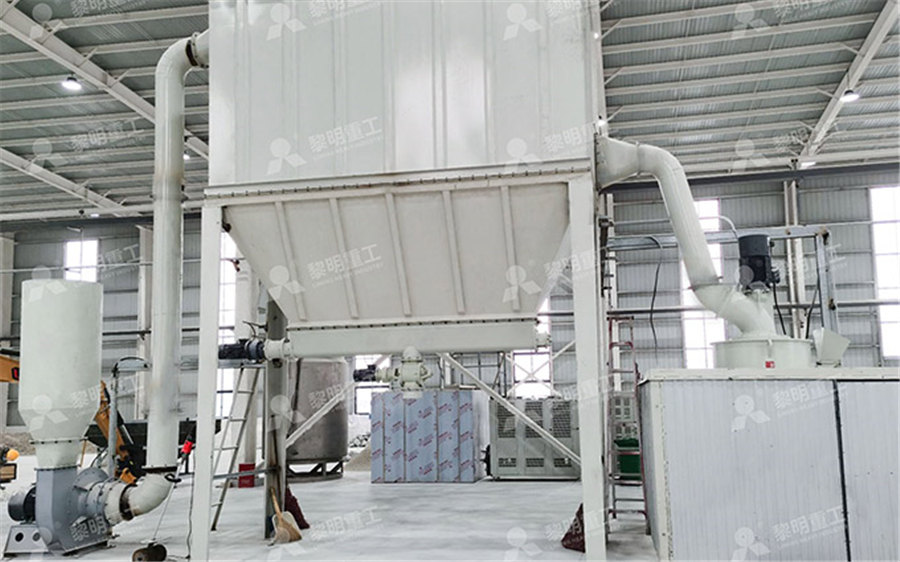

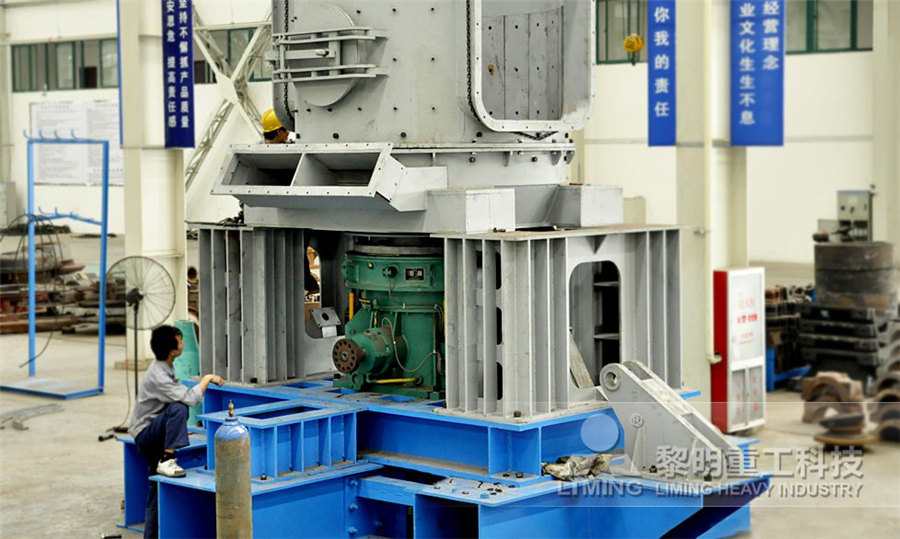

LimestoneGypsum FGD Wet Desulphurization

4 Limestone Limestone is a sedimentary rock Its major materials are the minerals calcite and aragonite, which are different crystal forms of calcium carbonate (CaCO3) In order to ensure good performance and high desulfurization absorption capacity, limestone powder as a desulfurization absorbent should have the following main qualities:2017年1月1日 Evaluation of Limestone Impurities in the Desulfurization Process of Coal Combustion Gas 271 Brazilian Journal of Chemical Engineering Vol 34, No 01, pp 263 272, January Evaluation of limestone impurities in the desulfurization process 2012年1月1日 The effect of red mud on limestone’s desulfurization activity is mainly due to superposition of improvement in solidstate ionic diffusion and surface chemical reaction 3 Conclusions The desulfurization performance of limestone has been observed to be significantly improved in the whole temperature range by red mud from alumina Experimental Study and Mechanism Analysis of Modified Limestone 2012年2月1日 Reactivity of various calcium carbonate samples for flue gas desulfurization was tested Two groups of CaCO 3 samples were considered; natural limestone containing calcite phase dominantly and Use of Carbonate Rocks for Flue Gas Desulfurization Reactive

Fine Particle Transformation during the Limestone Gypsum

Special attention is required on the fine particle control after desulfurization because a large quantity of fine particles are emitted into the atmosphere from the coalfired power plants In an attempt to figure out the transformation of fine particles during the limestone gypsum desulfurization, the physical properties of fine particles before and after the desulfurization EHDA has been demonstrated to reduce droplet diameter effectively, enhance droplet spatial dispersion, and modify liquidgas interface behavior [17], [18], [19]This technique is widely applied in inkjet printing [20], spray cooling [21], electrospinning [22], nanomaterials preparation [23], and bubble coalescence [24], [25]These characteristics are also expected to improve Atomization and desulfurization characteristics of limestone 2020年8月15日 Postcombustion flue gas desulfurization and denitrification technologies are essential in achieving the full compliance of fine particulate matter (PM25, aerodynamic diameter less than 25 μm) air quality standards by 2030 in China as sulfur dioxide (SO2) and nitrogen oxides (NOX) are the main precursors of PM25 Some studies have addressed the Comprehensive evaluation of flue gas desulfurization and 2024年3月20日 Desulfurization wastewater is industrial wastewater with a high salt content, high metal ions, and high hardness produced by flue gas desulfurization of the limestonegypsum method in coalfired power plants This paper summarizes the source of desulfurization wastewater, water quality characteristics, water quality impacts, and other factors, combined Current Status of Zero Liquid Discharge Technology for Desulfurization

Typical limestone wet FGD system (adapted from

Download scientific diagram Typical limestone wet FGD system (adapted from Miller and Miller 2010) from publication: Spray drying absorption for desulphurization: a review of recent developments 2024年1月10日 Flue gas desulfurization (FGD) is a critical process for reducing sulfur dioxide (SO2) emissions from industrial sources, particularly power plants This research uses calcium silicate absorbent Modeling based on machine learning to investigate flue gas 2024年8月13日 This blog post is the third in a threepart series that discusses flue gas desulfurization (FGD) The first post provides overviews of sulfur dioxide (SO 2) and emissions regulations, the FGD industry, and global FGD market trendsThe second post provides highlevel overviews of wet, semidry, and dry FGD technologies with respect to SO 2 capture Flue Gas Desulfurization: Detailed Process Overview2002年4月1日 In this article the method of cost optimization of the “Wet Limestone Flue Gas Desulfurization System” is presented The optimization calculations include process and cost modelsOptimum Values of Process Parameters of the “Wet Limestone

Sulfur dioxide removal: An overview of regenerative flue gas

2020年5月16日 Numerous mitigation techniques have been incorporated to capture or remove SO2 with flue gas desulfurization (FGD) being the most common method Regenerative FGD method is advantageous over other methods due to high desulfurization efficiency, sorbent regenerability, and reduction in waste handling The capital costs of regenerative methods are 2015年9月18日 But even the most widely used wet limestone flue gas desulfurization method has the disadvantage of huge power consumption (Carletti et al 2015; Liu et al 2008)Optimization of a Wet Flue Gas Desulfurization Scrubber through 2011年1月14日 Model of the wet limestone flue gas desulfurization process for cost optimization Ind Eng Chem Res, 40 (2001), pp 25972605 View in Scopus Google Scholar [18] YJ Zheng, S Kiil, JE Johnsson Experimental investigation of a pilotscale jet bubbling reactor for wet flue gas desulphurizationFlue gas desulphurization based on limestonegypsum with a prepared by first crushing the limestone into a fine powder using a ball mill and then mixing the powder with water in the slurry preparation tank Particle size of the limestone impacts the efficiency of SO2 removal In the typical wet limestone FGD system, the limestone is ground to an average size of 5 to 20 μm The sorbent slurryA review wet flue gas desulfurization by the use of limestone

.jpg)

A review wet flue gas desulfurization by the use of limestone

prepared by first crushing the limestone into a fine powder using a ball mill and then mixing the powder with water in the slurry preparation tank Particle size of the limestone impacts the efficiency of SO2 removal In the typical wet limestone FGD system, the limestone is ground to an average size of 5 to 20 μm The sorbent slurryFlue gas desulfurization gypsum (FGDG) is an industrial byproduct generated during the flue gas desulfurization process in coalfired power plants Song H A study on the desulfurization efficiency of limestone sludge with various admixtures J Korean Chem Soc, 52 (2015), pp 479–482 [Google Scholar]Recent advances in flue gas desulfurization gypsum processes Abstract: Wet flue gas desulfurization technology by using limestone gypsum has following advantages such as excellent adaptability for changes of coal and unit load, high desulfurizing efficiency, cheap absorbent, high reliability, and using less energy So it's widely used in our country This paper introduces the glue gas desulfurization process, network structure, main Application of wet flue gas desulfurization control system for 2 × 2021年12月1日 Limestone method has the advantages of high desulfurization efficiency and rich desulfurizer resources, which is the main technology of flue gas desulfurization in coalfired power plants [4], [5], [6]In the actual operation process, only large slurry circulation and high liquid gas ratio (L/g) can ensure the concentration of SO 2 in outlet to reach the standardAn investigation into the influence of dissolution rate on flue

A Review of Desulfurization Technology using Limestone in

청정석탄발전기술 중 하나인 순환유동층보일러(CFBC) 기술의 고도화에 따라 국내외 로내탈황 기술개발 현황과 국내외 유동층보일러용 석회석의 탈황특성 연구현황을 조사하였다 석회석계 탈황제는 고온탈황특성이 우수한 원소 중 하나로 $850950^{\circ}C$ 내외에서 최적의 탈황특성을 가지고 2021年10月13日 Wet flue gas desulfurization (WFGD), using limestone with forced oxidation (LSFO), is a common Flue gas desulfurization (FGD) process where limestone reacts with SO2 to produce gypsum (CaSO42H2O)A Technical and Economic Comparison of Ball Mill Limestone 2005年12月7日 This work presents a practical result of experimental investigation of the limestone particle size effect on deSOx from a circulating fluidized bed combustion (CFBC) boiler that burns domestic anthracite and is the first industrial scale in Korea Because of combustion problems such as clinker formation, fine limestone has not been used as a desulfurization Desulfurization with a Modified Limestone Formulation in an 2022年8月28日 Three types of limestone were tested, obtaining desulfurization efficiencies from 59 to 99% We show the importance of choosing an appropriate limestone in order to get a better performance from FACTORS EFFECTING EFFICIENCY PREDICTION OF LIMESTONE

.jpg)

Flue Gas Desulfurization: The State of the Art [J] ResearchGate

2002年1月1日 This paper presents a comprehensive review of the state of the art in flue gas desulfurization and specifically wet limestone FGD, have been predominantly selected over the FGD technologiesparticles formed during the desulfurization is CaSO 4 With the increase in SO 2 concentration, the fine particle emission has little difference The fine particles formed during desulfurization are mainly from the entrainment and evaporation of desulfurization slurry Keywords Limestone–gypsum desulfurization Fine particles Characteristic Fine Particle Characteristics from Limestone– Gypsum Desulfurization 2020年11月24日 Examples are illustrated here in relation to limestone dissolution taking place within the Wet Flue Gas Desulfurization process, where calcium carbonate is dissolving in an acidic environment The method is the most common used technology to abate SO2 released by fuel combustion Limestone dissolution plays a major role in the processModeling of Limestone Dissolution for Flue Gas Desulfurization It commonly includes Limestonegypsum desulfurization, NaOH desulfurization, MgO desulfurization, etcBecause of abundant raw materials and low cost, Limestone gypsum is most widely used MgO At the stage of project acceptance,the client will do a comprehensive inspection about equipment and complete a clear tproject acceptance list Power plant desulfurization