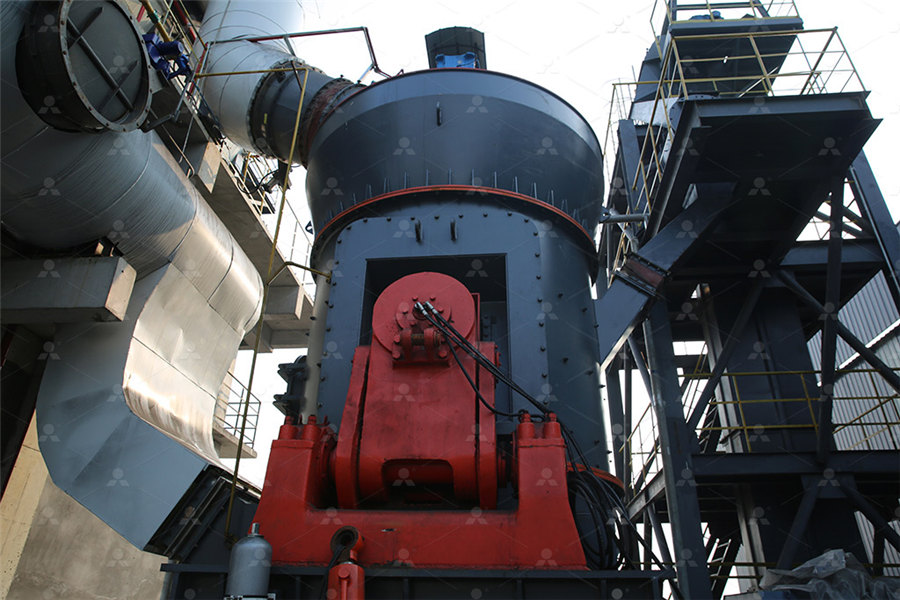

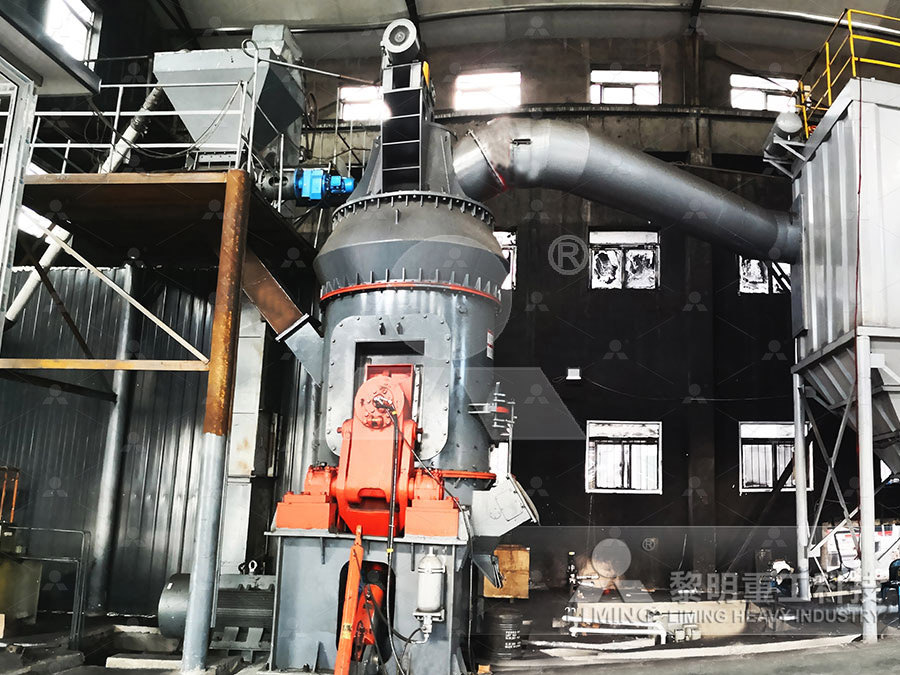

Corundum ore powder machine production line

Corundum Processing Equipment, Process Flow, Cases

2019年8月23日 Corundum processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designWeifang Jinghua Powder Engineering Equipment Co, Ltd specializes in the development and production of corundum pulverizers, designed to efficiently crush and grind corundum into fine China Corundum Pulverizer Manufacturer, Supplier JINGHUAWhite corundum is made from industrial alumina powder, which is smelted in an arc at a high temperature of more than 2000 degrees and then cooled It is suitable for the manufacture of Production method of white corundum micropowder LZZGChemists at the Max Planck Institute for Coal Research in Germany have found a way to produce corundum, a particularly stable variant of alumina, in the form of nanoparticles using simple Nanoceramics from the Ball Mill Interceram International

Corundum disc mill for wet grinding type KMT KAProcess

Corundum disc mill for wet grinding type KMT Mill for fine grinding of liquid and pasty products in the food industry Unlike fine cutting systems, the mill technology enables even the smallest 2013年7月18日 Phase composition, crystal size development in powder, and microstructure are studied, and data are summarized for specific surface and particle size distribution of Corundum powder preparation by SHSmethod Springer1999年11月1日 The new synthesis of nanocorundum can be used to give pure corundum filtration membranes with average pore sizes that can be adjusted in the range between about Nanocorundum—advanced synthesis and processing ScienceDirect2021年6月1日 Corundum abrasives with good chemical stability can be fabricated into various free abrasives and bonded abrasive tools that are widely used in the precision machining of Advances in fabrication of ceramic corundum abrasives based on

State of the art in production, properties and applications of the

Microcrystalline sintered corundum grains are produced in a chemical process in which microcrystalline alumina oxide, acquired using the expensive solgel technology, is sinteredFinally, the entire chrome ore powder briquette production line feeds smoothly and evenly The workload of the briquetting machine is stable and the production efficiency is high, which solves the problem of the low utilization rate of Iron Powder Briquetting Machine Fote MachineryPebble sandmaking machine is widely used and its performance has achieved the international advanced level, which is the most effective and reliable pebble sandmaking machine, particularly suitable for the production of abrasives, Pebble sand making production line LZZG2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, Study on the Basic Characteristics of Iron Ore Powder

Gold Ore Processing Production Line TAYMACHINERY

Reasonable and efficient process flow: The production line usually adopts the process flow of “crushinggrindingore dressingsmelting”, and each link is carefully designed to ensure that the ore can be fully processed and extracted Economical investment and large production capacity: The overall investment of the gold ore dressing production line is economical, with a small Here, we delve into the key components and technologies that make up the modern ore powder production process Key Components of Ore Powder Production Equipment: 1 Crushers The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly Advancements in ore powder production process equipment: Applications of Ore Powder Dryer Machine Ore powder dryer or mineral powder dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004Ore Powder Dryer Zoneding Machine2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to Powder

.jpg)

Quartz Industrial Powder Grinder Machine SBM Ultrafine Powder

2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 1503000 mesh The industrial grinding mills independently developed and produced by SBM have the advantages of stable operation, high efficiency, energysaving, and environmental protection, and long 2024年1月17日 Electronics Industry: Corundum powder finds application in the electronics industry, where its high dielectric strength and thermal conductivity are leveraged in the production of insulating Corundum Powder and Its Diverse Applications in IndustriesThus, iron ore materials in the vortex chamber by two more times’ impact, friction and grinding to got the final iron ore powder product Iron ore beneficiation equipment Deep Rotor VSI Crusher new sand making machine is easy to install, easy to operate, large capacity can up to 50640t/h; optimum material impact angle crushing chamber design Iron ore powder beneficiation production sand crusher plant2021年8月17日 The depositforming problem is one of the main bottlenecks restricting the yield and production benefit of iron ore pellets produced by coalfired rotary kilnsThe Deposit Formation Mechanism in CoalFired

Gypsum Powder Production Line Manufacturers Suppliers

gypsum powder production line manufacturers/supplier, Gypsum Board Production Line, Gypsum Powder Machine , Gypsum Powder Production Line RD Capacity: Own Brand, ODM, OEM Mgmt Certification: ISO9001:2015 Contact Now Talk to me! US$ / Set 1 Set (MOQ) US$ / Set 1 Set (MOQ) US$ 2021年10月26日 Graphite Production Line Equipment Intro – Crushing Grinding Link The equipment configuration of the complete graphite powder production line is complicated, and the equipment selection can be planned and adjusted according to the actual production needs of customers, and the production line has a high degree of automationGraphite Grinding Machine Powder Mill EquipmentFeatures of the cocoa powder production line This cocoa powder production line is suitable for large, medium, and small cocoa powder processing manufacturers All cocoa powder manufacturing machines adopt foodgrade machine materials, which cocoa powder production line,cocoa beans processing machineThese devices are connected in series to form a complete pellet production line High grade (>60%) iron concentrate powder is mixed with a binder, flux, and fly ash to prepare green pellets with the particle size of 8~16mm by the disc pelletizer, and then evenly distributed on the grate machine for subsequent processing [19] Figure1shows theThe Deposit Formation Mechanism in CoalFired Rotary Kiln for Iron Ore

.jpg)

White corundum micro powder Corundum Silicon Carbide

3、Screening of fine powder, through the wet sorting process, screening, microscope realtime monitoring, drying, production of white corundum micropowder 4、Packed with 25kg per bag, one tonne as a unit for tonnage packaging, weighing using floor scales, and selecting the economical mode of transport according to the customer’s demandSpare Part Single MachineOur main products: Gypsum board production line, Gypsum powder production line, Gypsum block machine etc At the same time, we can supply single machines, spare parts Raw Material Raw MaterialWe produce raw materials for the production lines, such as modified starch, foaming agent, glue, etcGypsum Board Making Machine Manufacturer,Gypsum Powder Production Line Ultrafine Glass Powder Making Machine Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 0545 T/HUltrafine Glass Powder Making Machine2024年7月29日 This rubber powder machine production line adopts fully automatic tire recycling machines, which has high machine efficiency and reduce the labor cost It is suitable for factories with relatively large output The final product can be Automatic rubber powder production line Plastic recycling machine

.jpg)

Cocoa powder processing machine production line

The cocoa powder production line is a complete production line that can process cocoa beans into cocoa powder Cocoa powder from the bean to the final powder consists of six steps The whole processing process highly automates, making Corundum is a crystalline form of aluminum oxide and a rockforming mineralIt is naturally clear but can have different colors when impurities are present It is superior in hardness and therefore useful as an abrasiveIn addition, Corundum New World EncyclopediaGelgoog can offer you whole solution for continuous or batch cocoa powder production Fully automatic cocoa powder production line consists of cocoa roasting, peeling machine, grinding, pressing, packaging machine and other Cocoa Powder Production Line GELGOOG2022年7月30日 Study on the Basic Characteristics of Iron Ore Powder with Different Particle Sizes Zezheng Li 1,2,3,4,5, Yifan Li 1,2,3,4,5, According to the particle size distribution of iron ore powder in sintering production, there are not only fine there was a special area outside the machine to display the temperature inside the Study on the Basic Characteristics of Iron Ore Powder with

Production method of white corundum micropowder LZZG

White corundum is made from industrial alumina powder, which is smelted in an arc at a high temperature of more than 2000 degrees and then cooled It is suitable for the manufacture of ceramics, resinbonded abrasive tools, grinding, polishing, sandblasting, precision casting (corundum for precision casting), etc2016年12月13日 If you are interested in this rubber powder machine production line, please contact us online or leave a message below And we will give you a reasonable quotation of rubber powder machine Please feel free to give your Rubber Powder Machine Rubber Powder Production LineIt includes onion peeling and head removing machine, onion washing machine, onion slicer, air dryer, onion dryer, onion grinder, onion powder packaging machine, and other equipment This onion powder processing line is divided into three parts: pretreatment part, drying part, and grinding part The pretreatment part is dedicated to onionsSmall Output Onion Powder Production Line Henan Baixin 2023年11月8日 The HGM125L highend calcium oxide ultrafine powder grinding production line equipped with SBM micro powder technology has The loader transports the crushed ore with a particle size of less than 500 mm to the first Gypsum Industrial Ultrafine Powder Mill Machine; China Shanxi annual production of 30,000 tons of anchoring Highend calcium oxide ultrafine powder making equipment

.jpg)

Automatic Cocoa Processing Machine Cocoa Powder Production Line

The total set of cocoa processing machine is energy saving and can do automatic working starting from cocoa roasting, cocoa peeling, grinding to final packaging Such cocoa powder production line can be also used for making cocoa butter, cocoa liquor, cocoa oil etcTalcum powder making machine is also called talc industrial ultrafine grinding mill, which can produce 1503000 mesh talcum powder and other nonmetallic ore +17 [ protected] language Process Flow of Talcum Powder Production LineTalcum Powder Making Machine2021年8月17日 The depositforming problem is one of the main bottlenecks restricting the yield and production benefit of iron ore pellets produced by coalfired rotary kilns In order to implement measures to ensure the efficient The Deposit Formation Mechanism in CoalFired 2021年10月13日 Fluorite fine powder grinding mill is an industrial ore grinding machine, which can grind nonmetallic ores into a fine powder (1503000mesh) +17 [ protected] The equipment configuration of the complete fluorite powder production line is Fluorite Fine Powder Grinding Mill SBM Ultrafine Powder

.jpg)

High Strength 25tph Iron Ore Powder Briquetting

2003年3月18日 High Strength 25tph Iron Ore Powder Briquetting Machine The iron ore powder briquetting machine Introduction: Briquetting Ratio:9095% Production Capacity:130TPH Processing Materials:Iron ore fines, cast iron Powder Production Line chinayongh T12:00:41+00:00 Powder Production Line Application: Feldspar, calcite, The whole powder making line includes the crushing process and grinding process based on different requirements Building Materials Machine; Ore Beneficiation Machine; Contact yonghanmachinery@126 +86 Powder Production Line – My Blog2024年1月20日 Main equipment Machines for high grade 997% lithium carbonate production plant 1: Lepidolite ore crusher 2: lepidolite ore ball mill (lepidolite ore grinding mill) 3:lepidolite rotary kiln I 4 Equipment Machines For Lithium Extraction From We offer turnkey milk powder production line Fresh milk after reception, pretreatment, evaporation and spray drying to make milk powderMilk Powder Production Line IBC MACHINE

Talc Powder Grinding Mill Stone Powder Making Machine for

Talc powder ultrafine grinding mill main bearing and each dial are driven by electricity of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger After being crushed by hammer crusher, the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by HGM Ultrafine Grinding Mill Is Applied To The CCM Powder Production Line CCM Powder Production Line: Raw material: custic calcined magnesia; Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 SBM Ultrafine Powder Technology Industrial Grinding Mill, Can Production Line Canrace builds and installs complete production lines for deepdrawn round, conical, rectangular or irregularly shaped canbodies It allows threepiece can production, milk powder tin production, beverage can and Thanks to their stateoftheart design, the machines are easy to operate and create very little noise Our Can Production Solution Canbody Making Machine CanraceOnion powder packing machine: automatic onion powder packing equipment Packaging weight and quantity can be adjusted automatically Advantages Of Onion Powder Processing Machine Made of highquality 304 stainless steel Hygienic and healthy Adopt advanced technology, simple design, easy to use, a high yield that onion can handleIndustrial Onion Powder Processing Machine Plant