Investment cost of steel slag powder machine

.jpg)

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in 2018年8月1日 China’s steel enterprises follow two investment models of steel slag treatment: (1) selfinvestment or selfemployed, and (2) invested and operated by specialized companiesSteel slag in China: Treatment, recycling, and management2019年5月23日 The process of making steel slag cement is a simple manufacturing technique with less investment and low cost Meanwhile, steel slag cement has excellent performances Comprehensive Utilization Technology of Steel SlagNippon Steel Sumitomo Metal Corporation has eight integrated iron and steel works with blast furnace in the whole country of Japan, and each manufacturing process is different based on Overview of Slag Usage Technology Development at Various Works

.jpg)

A Review on Environmental Concerns and

2023年11月20日 In this context, we have reviewed the global steel slag generation, processing, characteristics, and potential application with suggestions for futuristic possibilities to address the technical, economic, and structure in the steel slag market is changing and Nippon Steel Corporation is developing the technologies to create new features of steel slag and to utilize them, especially in the field of Processing and Reusing Technologies for Steelmaking Slag2023年8月15日 This study evaluated lowenergy basic oxygen furnace slag (BOFS) powders as supplementary cementitious materials (SCMs) The powders were produced from residual Performance of lowenergy steel slag powders as supplementary 2019年10月29日 In this article, the potential application of iron and steelmaking slag has been reviewed, which included the slag utilization in construction as cement and sand, in water, soil, and gas treatment, as well as in value The potential utilization of slag generated from iron

.jpg)

Application of Steel Slag as an Aggregate in Concrete

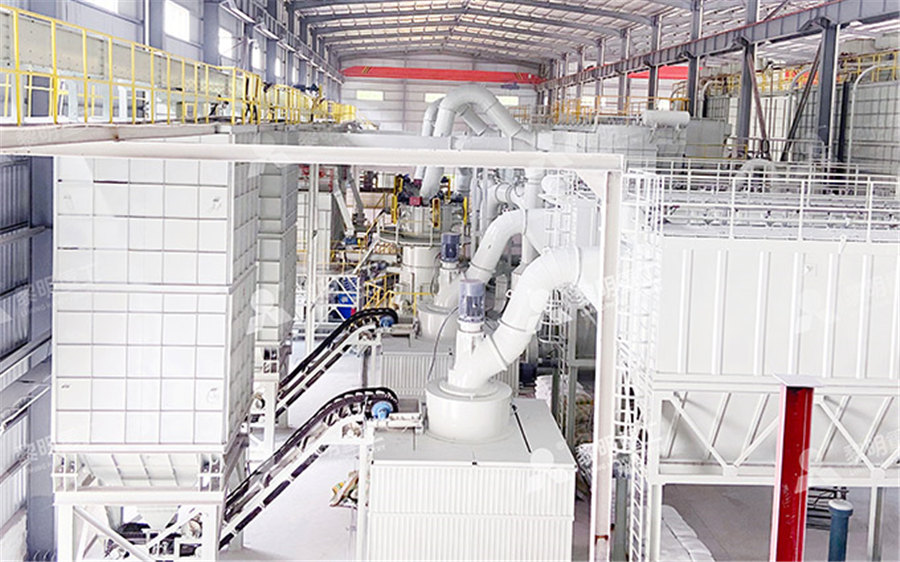

2023年8月25日 The grinding energy consumption of steel slag is 367 kWh/ton, and the laboratory accelerated carbonation cost of steel slag powder is 421 $ /ton Therefore, cost control will be a key issue after this method is applied to Mill Machine of Powder Grinding, /Coating for Iron Phosphate, Slag, and squeezing to get the best fineness of 300nanometer particles of powder Low investment, costeffective operation, stable process, The material of the Mill Machine of Powder Grinding, /Coating for Iron 2022年11月1日 This paper presents a design method for green ultrahigh performance concrete (UHPC) through machine learning (ML) models and steel slag (SS) powderUltrahigh performance concrete design method based on machine 2018年8月1日 In recent years, common applications of steel slag have been road construction, concrete aggregate, cement production, and landfill materials [2, 3,5,6] 80,000 tons of steel slag was used in the Steel slag in China: Treatment, recycling, and management

Steel Slag Market By Type By Application Report [2030]

2024年11月11日 The global steel slag market size is projected to grow from $2683 billion in 2023 to $3828 billion by 2030, In construction projects, road construction, railroads, and concrete, it can replace natural aggregate at a lower cost and with greater sustainability LATEST TRENDS Major Manufacturer of Precision Machine Parts in 2022年4月29日 The effects of various replacement ratios of steel slag powder (SSP) to Portland cement (ie, 10%, 20%, 30%, 40%, and 50%) on the workability, mechanical properties, and durability of SCRAC were Mechanical properties of selfcompacting concrete using steel slag The unit weight of slag varies within a range of 1600 kg/m 3 to 1920 kg/m 3 with a specific gravity between as high as 36 (Hainin et al, 2014)Typical physical and chemical properties of steel slag [1316]2024年10月1日 Xu Lu et al [16] steel slag micro powder as absorbent, Investigation of the effect of 12 parameters of steel slag carbonization by machine learning Future research should focus on enhancing the reactivation processes of steel slag, developing costeffective methods for air pollutant treatment and CO 2 sequestration, Utilization of steel slag in air pollution and greenhouse gas

.jpg)

Experimental study on influencing mechanism of the multiple

2024年1月19日 The gradation of aggregate and the hydration reaction of cementitious materials are important factors affecting the performance of backfill materials Steel slag powder (SSP) can be used as both aggregate and cementitious material according to different particle size SSP has multiple influencing effects on coarse tailings cemented backfill (CTCB) Experiment with 2024年9月11日 Using steel slag (SS) as cementitious material and fine aggregate in concrete is an effective and environmental method for SS consumption and cost reduction In this paper, SS was recycled in large volumes in concrete as partial cementitious material and fine aggregate The compressive strength and reaction mechanism of cementitious material with different SS Recycle of steel slag as cementitious material and fine aggregate 2019年2月1日 Cement is the most important ingredient in concrete, which acts as a binding material It is evaluated that cement is the second largest industrial source of CO2 on earth(PDF) Evaluation of Steel Industrial Slag as Partial Replacement 2023年8月25日 It has been proved that replacing cement with 10–20% steel slag powder The grinding energy consumption of steel slag is 367 kWh/ton, and the laboratory accelerated carbonation cost of steel slag powder Application of Steel Slag as an Aggregate in Concrete

.jpg)

(PDF) Application of Steel Slag as an Aggregate in

2023年8月25日 slag, electric arc furnace (EAF) steel slag, and ladle furnace (LF) steel slag The typical morphologies of different types of steel slag are shown in Figure 3 Steel Slag Powder Steel slag powder is a byproduct of the steelmaking process It can replace a portion of Portland cement, reducing CO2 emissions and lowering the overall cost of concrete production Soil Stabilization Slag Slag Powder: A Sustainable and Valuable Resource2023年3月2日 By using Slag Crusher Machines, companies can not only reduce their carbon footprint but also save money on disposal costs Applications of Slag Crusher Machines Steel Industry Slag Crusher Machines are widely used in the steel industry for the processing of slag generated from the iron and steelmaking processWhat is a Slag Crusher Machine and How Does it Work?2020年9月24日 With the rapid development of China’s steel industry, rising rates of steel production have led to the increase of steel slag emissions Steel slag is a kind of industrial solid waste produced in the process of iron and steel smelting, and its emission is about 15 wt%–20 wt% of crude steel output []According to the data released by the World Iron and Steel Sustainable Utilization of Steel Slag from Traditional Industry and

.jpg)

Steel slag and zeolite as sustainable pozzolans for UHPC: an

2024年6月24日 Steel slag and zeolite also enhanced the durability characteristics of UHPC mixtures significantly Abrasion loss was reduced by 918%–2202% with steel slag and by 1285%–1927% with zeolite Pulloff test results demonstrated the positive effect of both pozzolans on enhancing resistance, but zeolite yielded better outcomes than steel slag2024年6月12日 1 INTRODUCTION Blast furnace slag (BFS) and steel slag (SS), as industrial solid wastes produced in the process of steelmaking, account for 80%–90% of the total smelting slag [] BFS accounts for about 30% of pig iron output, [] while SS accounts for 10%–15% of the crude steel output [] SS comprises various slags, including basic oxygen furnace slag (BOFS) Recycling of iron and steel slag for carbon reduction and low 2023年11月15日 Moreover, in the view of the problems that highbasicity refining slag is usually needed for desulfurization of molten steel and lowbasicity refining slag is usually needed for plasticization of inclusions, Wang et al developed a ‘twostage basicity control’ refining method of Sikilled spring steel, which can realize the comprehensive control of desulfurization and oxide Modeling of LF refining process: a review Journal of Iron and Steel 2023年8月3日 Measurement layout and specimen in the RMT301 compression test machine steel slag powder in cement concrete as a supplementary cementitious costeffective production of highAutoclaved steel slag coarse aggregate: A potential solution for

.jpg)

Effect of steel slag powder and stone powder byproduct from

2024年5月1日 Recently, the effect of using steel slag alone is not satisfactory and the performance of blended cementitious materials is expected to improve after compounding with other admixtures In this study, steel slag powder (SSP) and SP byproducts from manufactured sand were employed with a total dose of less than 30% as a replacement for cement2024年4月28日 Ultrahigh performance concrete incorporating carbonated steel slag powder: Steel slag powder 145 (28 d) — A Review on the Carbonation of Steel Slag: Properties, Low investment: The total cost of spiral steel silo is 30 to 50 percent lower than that of reinforced concrete silo, the steel column and the connecting machine Set the molding machine, bending machine and support frame horizontally Slag steel ilo, necessary to store slag2023年10月25日 The authors acknowledge the financial support of the Fundamental Research Funds for the Central University (Grant No 2020kfyXJJS123), the Open Fund of National Engineering Research Center of Highway Maintenance Technology (Changsha University of Science and Technology) (Grant No kfj), and the Opening Foundation of Research Snow and Ice Melting Performance Evaluation and Economic

Interpretation and Prediction of the CO2 Sequestration of Steel Slag

2023年8月25日 The utilization of steel slag for CO2 sequestration is an effective way to reduce carbon emissions The reactivity of steel slag in CO2 sequestration depends mainly on material and process parameters2018年8月1日 The Code for the Design of Environmental Protection of the Iron and Steel Industry (GB 504062007), Steel Slag Treatment Technology Standard (GB/T 295142013), and Standard for Pollution on the Storage and Disposal Site for General Industrial Solid Wastes (GB 185992001) stipulate the rules for the treatment, storage, and disposal of steel slag, as well Steel slag in China: Treatment, recycling, and managementand 10 demonstration projects which produce cement and composite powder by BFS and steel slag will be built These projects will cost 12 billion yuan and consume 5475 million tons of steel slag annuallyThe Present Situation and Development of Iron and Steel Slag2022年12月1日 Ultrahigh performance concrete (UHPC) is a new type of construction material made by combining the matrix of high performance concrete with fibers [1], [2], [3]Compared with conventional concrete, UHPC has excellent mechanical properties and durability performance [4], [5], [6]However, high cost, high energy consumption and large greenhouse gas emissions Ultrahigh performance concrete design method based on machine

.jpg)

Physical Properties of Steel Slag Download Table ResearchGate

Download Table Physical Properties of Steel Slag from publication: Steel slag to improve the high strength of concrete Steel slag is an industrial byproduct of steel industry It possesses 2023年5月5日 Every ton of cement produced emits half a ton of carbon dioxide, so there is an immediate need to limit cement use Cementitious materials such as fly ash, silica fume, and steel slag can be Assessment of the Combined Effect of Silica Fume, Fly Ash, and Steel Typical morphology of steel slag [](a) BOF steel slag(b) EAF steel slag(c) LF steel slagBOF steel slag is the solid waste produced in the converter steelmaking process, and its discharge is approximately 100–150 kg per ton of BOF steel [20,21,22,23]BOF steel slag commonly has a grayishwhite appearance and a vesicular nature, with many noninterconnected pores []Application of Steel Slag as an Aggregate in Concrete Production: One of poineers of Slag Crushing Machines in India They have their own inhouse RD Excellent products and production line palwinder kaur Good Sukhdeep Singh Best Quality Products Services Slag Crusher Plant Machine Manufacturer

.jpg)

Waste to wealth: Recovery of valueadded products from steel slag

2021年5月1日 BOF slag is a main byproduct of the steelmaking process and its annual production has exceeded 100 million tons in China, but the utilization rate is less than 30 %2015年12月2日 The utilisation of steelmaking slag as recycled aggregate for concretes is a widely investigated solution for mitigating the expenditure and environmental impacts of its storageEvaluation of the economic feasibility of a processing plant for 2024年4月22日 Sun et al used steel slag to fix carbon, fully mixed steel slag powder with water at a mass ratio of 1:2, and introduced CO 2 with purity of 995% into mortar for 6 h to obtain carbonized steel slag, Without calculating operating costs or investment costs, Research progress of hydrogen production and CO2021年6月10日 For four weight fractions of steel slag powder (10%, 20%, 30%, activity of steel slag at a later age Also, the cost of the chemical activator is much higher The machine wasExperimental Study on the Effect of Compound Activator on the

.jpg)

Steel Slag an overview ScienceDirect Topics

Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine 2007年2月1日 In the secondary phase, around 6080 kg of a coproduct, Ladle Furnace Slag (LFS), is recovered per ton of refined steel In some cases, the LFS is reintroduced into the steel production process (PDF) Recycling of ladle slag in the EAF: A way to improve 2021年11月1日 Also, Fan et al [27] designed a green UHPC with steel slag using DOD model, which achieved high usage of steel slag (200 kg/m 3 ) and multiobjective optimization (ie, maximized steel slag A new development of ecofriendly UltraHigh performance concrete mixer, granite aggregate was first dry mixed with steel slag powder for two minutes and then A commercial block machine shown in Figure 4 was used to make masonry block It has the capacity of making 800 standard size blocks (400x200x200 mm) every day Fresh mixture was cast into the block maker molds with a shovelPilot production of steel slag masonry blocks University of

Recent trends in slag management utilization in the steel

2019年1月1日 In an integrated steel plant, wastes (including solid, liquid and gas) are generated for every ton of steel produced In India, almost 100 million tonnes of steel is produced every year, and along