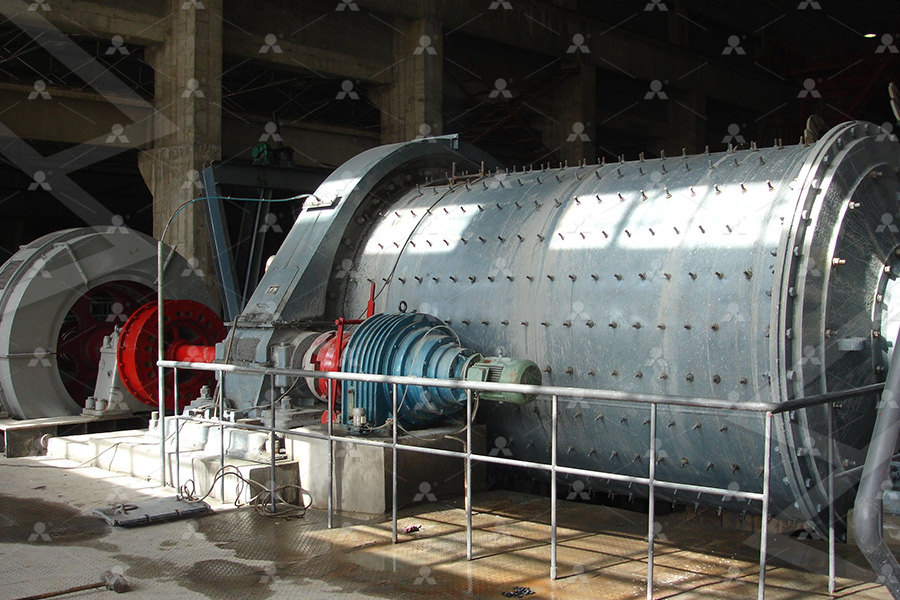

FMC200 mesh coal powder mill

Raymond® Bowl Mill Coperion

Raymond® Bowl Mills provide the following performance features: Wide range of capacities–base capacities from 8 to 150 tph Easily adjustable fineness–externally adjustable classifier permits selection of fineness from When selecting a vertical mill for a 200 mesh coal powder preparation system, several factors should be considered: Material Properties: The hardness and moisture content of the coal Choosing the right vertical mill for 200 mesh coal powder The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarA 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller 200 mesh coal powder mill/coal powder preparation production line

A Comparison of Three Types of Coal Pulverizers Babcock Power

The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in Coal pulverizers increase the crosssectional area and dryness fraction of coal prior to it entering a furnace Pulverized coal ignites more efficiently than raw lumps of coal, thus the overall efficiency of the furnace increases if it is fired Vertical Grinding Mill (Coal Pulverizer) Explained saVReeCage mills are mechanical impact machines that crush, grind, or pulverize a variety of materials to specified degrees of fineness They can be configured in two, four, and six row designs depending on the specific application needs, Cage Mill Crushers Pulverizers Stedman MachineThe Raymond® Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of products including limestone, clay, minerals and othersRaymond® Roller Mills Coperion

.jpg)

CPRI Online Coal Flow Balancing and Fineness Adjustment

ONLINE COAL FLOW MEASURING AND BALANCING (CONTROL) AND ONLINE COAL FINENESS MEASURING SYSTEM FOR COMBUSTION OPTIMISATION IN A THERMAL BOILER Suresh G Chandwani1, Dr Francesco Turoni2, Reinhardt Kock2, Dr Michael Haug2, Dr Michael Schreiber2 1NSGuzder Company Pty Ltd, Neville House, Currimbhoy Road, While all these are regarding the mill performance, the coal fineness and mill out let temperature also affect the boiler performance The coal fineness has an effect on the combustion performance like the bottom ash percentage combustibles when the plus 50 mesh percentage goes up It has been very well established that in the case of tangential firing system, the Boiler Performance and Mill Outlet Temperature Bright Hub Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, 25TPH LM1700 Coal Grinding Mill Capacity: 2025T/H Output size: 200 mesh Calcium carbonate ultrafine vertical mill Capacity: 8T/H Output size: 3253000 meshvertical roller mill, vertical coal mill, vertical slag mill, superfine Mill Speed Capacity Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D)A Comparison of Three Types of Coal Pulverizers Babcock Power

MESH and MICRON SIZES Industrial Spec

cinnamon (ground) 70 to 200 clay 01 to 2 coal dust 1 to 100 coffee (ground) 5 to 400 concrete dust 3 to 100 dust (household) 005 to 100 dust mites 100 to 300 eye of a needle 1230 flour (wheat milled) 25 to 212 gelatin powder 5 to 90 giardia cysts 8 to 14 ginger (ground) 25 to 40 200 No 200 200 Mesh 00500 00020 0 The whole grinding line is used for processing coal to 200 mesh, our technicians configure one set of LM150M in order to meet customer's demand for production MTW European Type Grinding Mill for limestone powder making Output size:200mesh MTW European Type Grinding Mill for limestone powder making Output size:200meshLM150M Coal mill , 200mesh D90 25tphLIMING HEAVY Raymond Mill for Coal Powder Making The Raymond mill is widely used for grinding coal into fine powder, [] 2024 1115 HGM Ring Roller Mill: Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, D90; Capacity: 4000 kg/hourSBM Ultrafine Powder Technology Industrial Grinding Mill, Find your powder mill easily amongst the 104 products from the leading brands (Fritsch GmbH, NETZSCH, BOHLE, 200 kg/h 1,200 kg/h Motor power: 30 kW metallurgy chemistry etc Suitable materials: Coal powder the air swept mill is suitable for coal grinding When the rotary kiln operates with coal powder as Powder mill, Powder grinding mill All industrial manufacturers

Grinding Characteristics of Coal and Petroleum Coke/Coal

2015年8月7日 Tests were carried out using a laboratory batch ball mill for optimal production of −200 mesh size product In general, addition of petcoke to the original coal powderTypically a mill will be controlled so that 70% of the coal powder it produces will pass through a 200 mesh, indicating a particle size of less than 75 microns Operation of coal mills is affected by both the moisture content and volatiles content of the coal and so will vary from coal to coal, therefore coal processing must normally be tuned to a particular type of coalCoal Mill an overview ScienceDirect TopicsThis Bentonite powder making plant using our HC1700 bentonite powder grinding mill, which has the output of 9 t/h, and fineness is 200 mesh D95For more details about bentonite mill, please contact: hcmkt@hcmilling Bentonite is a nonmetallic mineral with 85~90% montmorillonite, and a small amount of illite, kaolinite and halloysite, etcHC1700 Bentonite Powder Grinding Mill, 200 mesh D95, 9TPH2022年2月24日 Coal is an important energy source in my country and is widely used in metallurgy, 200 mesh, D8090, according to the needs of backend combustion Suitable coal types: bituminous coal, HGM superfine powder How is pulverized coal processed? SBM Ultrafine

200 MESH Armor Pharma

200 MESH ARMOR PHARMA™ lactose monohydrate 200M is a fine milled powder of αlactose monohydrate, combining good compaction and blending properties This lactose is mostly used for tablet manufacturing using wet and dry granulation technologies Key benefits : Steel plant blast furnace injection coal mill, 200 mesh D85 anthracite grinding powder In a steel plant, the blast furnace is a crucial component used in the smelting process to produce iron Coal is one of the primary fuels used to provide heat and reduce the raw materials in the furnaceSteel plant blast furnace injection coal mill, 200 mesh D85 2022年9月13日 Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill Coal gangue powder is widely used in the construction field +17 [ The particle size of the finished fine powder can be adjusted arbitrarily between 1503000 mesh, and the output can reach 0245 tons per hour CONTACT US Coal gangue ultrafine powder mill2011年8月1日 Adequate fineness for both western and eastern fuels (Powder River Basin or bituminous) is a minimum of 75% to 80% passing 200 mesh and zero to 01% remaining on a 50 mesh screen (Figure 10)Pulverizers 101: Part I POWER Magazine

.jpg)

Coal Mill Manufacturers Powder Making Machine Price

Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2021年10月13日 Fluorite Fine Powder Grinding Mill >> The application of fluorite powder in various fields has different fineness requirements Common ones are 100 mesh, 200 mesh, 325 mesh, 600 mesh, 800 mesh, 1250 mesh, and above According to different needs, the most suitable grinding mill machine can be configured to achieve the best benefitsFluorite Fine Powder Grinding Mill SBM Ultrafine Powder Fuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Pulverized Coal Boiler an overview ScienceDirect Topics

.jpg)

Online measurement of pulverized coal fineness on a 300

2021年6月1日 This was mainly due to the sparseness of coarse coal powder, leading to a low probability of coal powder larger than 200 μm to be captured by the measurement system Although the obvious difference of PCF for mill D and B can be revealed with SAD directly, R 90 results and distribution curves were still with deviations comparing to the sieving method2019年8月1日 Design and Modify of Mill Discharge Valve Using in pulverizing the coal to required fineness of about 70 microns coal powder are embedded with a stainlesssteel wire mesh Design and Modify of Mill Discharge Valve Using in2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 1503000 mesh The industrial grinding mills independently developed and produced by SBM have the advantages of stable operation, high efficiency, energysaving, and environmental protection, and long Quartz Industrial Powder Grinder Machine SBM Ultrafine Powder If your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been designing, manufacturing and creating innovative solutions for large and small customers all over the worldParticle Size Reduction Solutions Prater Industries

.jpg)

A unified thermomechanical model for coal mill operation

2015年11月1日 Samples are generally screened on 50, 100 and 200 mesh screens The amount retained on the 50 mesh and the amount passing the 200 mesh screens are reported Studies have shown that 70 75% of the pulverized coal passing a 200 mesh screen is optimal for the mill and combustion performance180200: 250280: 325355: The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine mill, vertical mill, Raymond mill, wet mill, etcVertical Roller Mill SBM Ultrafine Powder Technology2023年12月2日 YINDA YDWF series 200 Mesh Corn Starch Grinding Machine Air Classifier Mill (ACM Mill) comprises several essential components, each contributing to its efficient operation The grinding chamber, rotor, classifier, and fan work in harmony to 200 Mesh Corn Starch Grinding Machine YINDA YDWF series Air Classifier Mill3 天之前 Low Ash Coal Powder: 1400: MANGAL INDUSTRIES: INR: 989% Pure 223 G/Cm3 Density Carbon Coal Powder For Industry Fuel: 10: MEHTA MANUFACTURING AND TRADING CO INR: 95% Methane Content Hydrogen 5800 Kcal/Kg Industrial Fuel Black Coal Powder: 56: Purushottam Traders: INR: FragranceFree Black Coal Powder Used As A Cooking Fuel: 150: Coal Powder Manufacturers, Suppliers, Dealers Prices TradeIndia

Online measurement of pulverized coal fineness on a 300

2021年6月1日 Particle size distribution (PSD) of coal powder, socalled pulverized coal fineness (PCF) [2], is a crucial parameter in coalfired power plants, with a significant effect on combustion efficiency [3], wear of equipment, and emissions [4,5] Not only reliable and repeatable, but realtime measurement of PCF is required before any optimizations [6]China Powder 200 Mill wholesale Rock Gold Grinding Hammer Mill for Gold Crushing Plant Coal Stone Gold Ore Hammer Crusher Mill for Powder Making Output Size 13 mm US$ 850900 / Set 1 Set Mining Machine Grinding Machine High Capacity Raymond Mill for 80200 Mesh Powder Crushing Machine US$ 5000 / PiecePowder 200 Mill MadeinChinaRaymond Mill for Coal Powder Making The Raymond mill is widely used for grinding coal into fine powder, [] 2024 1115 HGM Ring Roller Mill: Equipment: HGM Series Ultrafine Grinding Mill; Feeding size: 200325 Mesh, D97; Output size: 800 mesh, D90; Capacity: 4000 kg/hourSBM Ultrafine Powder Technology Industrial Grinding Mill, Its adjustment range is between 30400 mesh Therefore, in order to improve the quality of charcoal products, Such as Raymond mill, and coal powder mixer Welcome to contact us for a business consultation charcoalraymondmillforsale coalpowdermillmachineplant Charcoal Powder Mixer Wheel Roller Mixing Machine Related ProductsCharcoal Raymond Mill Coal Powder Milling Machine

Powder Processing Equipment Production Line HongCheng

Grinding Coal Powder Grinding Phosphogypsum Powder Grinding Slag Powder Project case Provide you with reference cases 1200 Mesh Micro Silica Fume Powder Production, HLMX600 Superfine Mill HC1700 Bentonite Powder Grinding Mill, 200 mesh D95, 9TPH HC series Calcium hydroxide production line, 325mesh 15 tons per hourCoal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thBest Practices and Precautions Coal Mill Safety, Explosion and Our vertical coal mill is designed to enhance the process, maximizing energy efficiency Home; Products compact equipment, low dust emission, and efficient combustion of coal powder Working Principle Fineness of pulverized coal (200 mesh pass %) 80: Coal moisture content (%) ≤1: Main motor Power (kW) 55: 110: 132: 180: 250250: 315 HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization2009年1月1日 % 50 Mesh 99 % 100 Mesh 952 Pulveriser is employed to grind the lumped coal and transport the fine coal powder to furnace A newly developed coal mill model provides a valuable tool that CFD Modeling of MPS Coal Mill for Improved Performance and Safety