Open circuit crushing process

.jpg)

Open or Closed Circuit Crushing 911Metallurgist

Thus far we have considered opencircuit crushing through the several reductions in a multistage crushing plant Very rarely are we able to turn out a finished product without closing the flowline circuit somewhere along the line Without going into any argument for or against closedcircuit crushing in any of the various 展开There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 MetallurgistDifferent crushing circuits such as “closed circuit crushing” and “open circuit crushing”, may be utilized Closed circuit crushing involves circulating back oversize material to a crusher for re Crushing Circuit an overview ScienceDirect Topics2016年10月12日 Compare open circuit grinding and closed circuit grinding Open circuit grinding consists of one or more grinding mills, either parallel or in series, that discharges a final ground product without classification equipment Closed Circuit Grinding VS Open Circuit Grinding

.jpg)

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日 Process simulation for crushing plants can be classified as either steadystate simulation or dynamic simulation The steadystate simulation models are based on instantaneous mass balancingOpencircuits may include scalping ahead of the crushers with undersize material from the screen being combined with the crusher product, which is then routed to the next operation If the Crushing Plant an overview ScienceDirect Topics2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of Ore Crushing SpringerLink2023年7月21日 The threestage crushingscreening flowsheet of concentrator with single closed circuit is commonly used in the large and mediumsized mineral processing plant, which can CrushingScreening Flowsheet of Concentrator SpringerLink

.jpg)

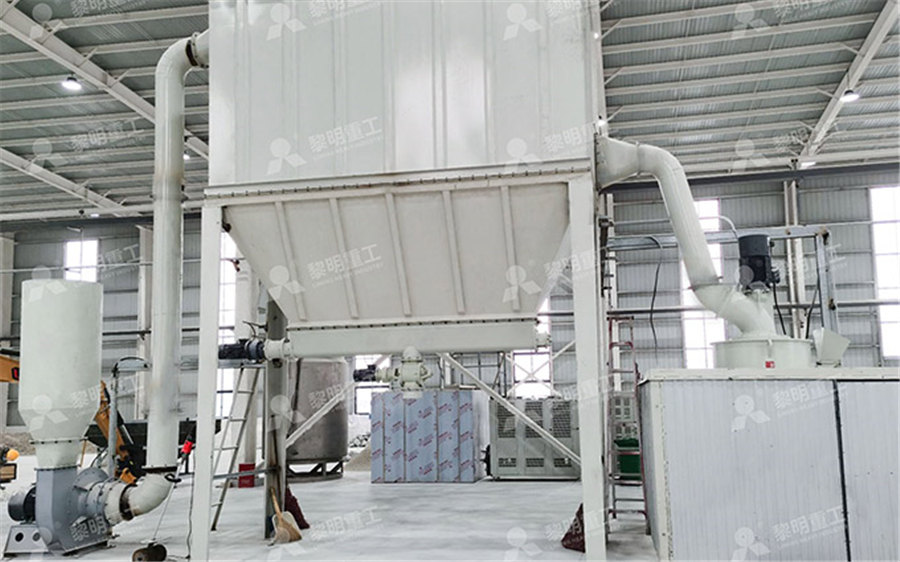

process flow (threestage opencircuit crushing

process flow (threestage opencircuit crushing process adopted; Grinding includes coarse) Different techniques have been used to study the reduction process of iron ore In this paper, theCrushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 Crushing Circuit an overview ScienceDirect TopicsCompare different equipment components and different methods to control the crushing process; Reading Lecture The Art of Crushing Crushing Gravel Rock Limited size reduction; Cubical shape; Over and Gyratory crushers AMIT 135: Lesson 5 Crushing – Mining Mill Operator Unveiling the Power of Cone Crushers: Open vs Closed Circuit Crushing is an essential process in many industries, and cone crushers have become a goto solution for efficiently breaking down materials into smaller sizes But did you know that there are open and closed circuit in cone crushers – stone cruxder

Common Iron Ore Crushing and Screening Process GeologyHere

If the granularity of the crushed product is not strict, the open circuit process can be used Otherwise, a closedcircuit process should be used However, when the closedcircuit process is adopted, the configuration of the equipment will become more complicated due to the addition of inspection and screening 2 Threestage Crushing ProcessIn many machines, the feed material is reduced to a satisfactory size by passing it once through the machine If the material is passed only once through the machine (crushing or grinding), and no attempt is made to return the oversized material to it for further reduction, the process is known as opencircuit grindingIf the partially ground material from the machine is sent to a size The Open Circuit and Closed Circuit Grinding Process2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, while the opencircuit crushed product (as shown in Fig 2 for coarse crushing in the first stage and medium crushing in the second stage) often contains Ore Crushing SpringerLink2023年7月21日 Its basic forms include the threestage crushingscreening flowsheet of concentrator with open circuit and threestage crushingscreening flowsheet of concentrator with single closed circuit (Fig 2)Preliminary screening is generally provided in front of each crushing operation to improve the production capacity of the crusherCrushingScreening Flowsheet of Concentrator SpringerLink

Selection oof Comminution Circuits for Improved Efficiency

Principal Process Engineer, GRD Minproc Limited John Fleay Principal Process Engineer, GRD Minproc Limited Kevin Reynolds Principal Process Engineer, GRD Minproc Limited Steve La Brooy Consultant, Global Renewables Limited Abstract This paper examines the design of comminution circuits and the issues that impact on comminution circuit efficiency2020年11月13日 Ball mill is not suitable for opencircuit process Because ball mill itself does not have the ability to control grinding particle size, In this way, the firststage rod mill has a smaller crushing ratio and higher production capacity, and opencircuit grinding process is simpleOpenCircuit Grinding VS Closed Circuit Grinding: What Are the 2020年12月3日 Crushing and grinding processes are typically used by crushers and mills to the grinding process in opencircuit mill produces about 700% of the fine product with particle size smaller A process mineralogy approach to study the efficiency of ing stages into separate crushing circuits Process control of a crushing circuit focuses two fundamental tasks: size reduction control and mass balance control (It¨avuo et al, 2017) The objective of mass balance control is to ensure maximum circuit throughput (and availability), whereas size reMass balance control of crushing circuits Tampereen

GrindingClassification Circuit SpringerLink

2023年7月27日 The single grinding circuit composed of mill and grading operation is suitable for grinding products with the required particle size of P 80 ≥ 106 microns (equivalent to particle mass passing 0074 mm sieve less than 65%) There are four types of onestage grindingclassification circuits (Fig 1): onestage closed circuit grinding circuit with integrated preclassification and %PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resourcesSize reduction by crushing has a size limitation for the final products If further reduction is required, below 5 20mm, grinding processes should be used Grinding is a powdering or pulverizing process using the rock mechanical forces of impaction and attrition The two main objectives for a grinding process are:AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator 2018年12月26日 Crushing Circuit Process Control As indicated in the introduction to this paper, it is a sequel to that which i gave to the last annual meeting in Atlanta in march, this paper goes further into aspects of crushing and screening, primarily from the standpoint of circuit controlCrushing Circuit Process Control 911Metallurgist

.jpg)

Comminution a Heart of Mineral Processing ResearchGate

2021年7月6日 undersize from the crushing process is the feed (Inoue, T 2009) In this study, a magnetiterich ore was comminuted using laboratoryscale SFC and HPGR in opencircuit operationsThe invention discloses a crushing process, and particularly relates to a limestone crushing process The crushing process is the twostage open circuit crushing and comprises the following steps that: raw ores are subjected to firststage crushing in a firststage screeningcrushing machine, the crushed materials are subjected to firststage screening, the oversize materials CNA Limestone crushing process Google Patents2022年1月23日 Additionally, when the downstream process involved grinding mills, the fines created from highspeed crushing circuit were a benefit to the comminution process In general, if the feed material, application parameters, and downstream process match with the capabilities of a highspeed impact style crusher, this is the crusher type to usePhysical Bauxite Processing: Crushing and Grinding of Bauxite2022年4月26日 In conclusion, optimization capabilities are essential for the modernization of the decisionmaking process in crushing plant operations crushing (closed circuit or open circuit)(PDF) Optimization Capabilities for Crushing Plants ResearchGate

What Is Primary, Secondary, and Tertiary Crushing?

2024年9月6日 In addition to the second crushing, an open circuit portable crushing plant can often be used, where the processed material is screened and transferred from one crusher to another Utilizing more crushers after the primary crusher can make a crushing screening process much more efficientThis practice makes crushing processes vulnerable to process variation and exposes them to inefficient production and capacity underutilization The aim of this thesis is to address this deficiency by bridging the gap between theoretically possible and realized crushing circuit performance, by means of automatic process controlProcess Control of Crushing Circuits — Tampere University 1 Crushing and screening: Due to the different nature of fluorite mines in different regions, some processing plants use a threestage oneclosed crushing process, and some processing plants use a threestage opencircuit crushing process Fluorite Flotation Process, Equipment JXSC Machinery2018年8月22日 There are a couple of steps to optimizing a crushing circuit– firstly to optimize machine performance, and secondly to optimize the overall performance of your circuit Optimizing a machine involves verifying all Three ways to improve your crushing circuit for

.jpg)

Working Principle of Crushers 911Metallurgist

2016年2月18日 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and 2012年6月1日 process control in industrial ball mills remains an open problem motivating future research activities and comprehensive studies [2, 19, 26, 27, 48] We shall conclude this section by mentioning Grinding in Ball Mills: Modeling and Process Control2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of Crushing Screening Plant Design Factors 911Metallurgist2015年7月18日 Coarse crushing includes crushing operations discharging at sizes 4 to 6in or coarser; intermediate crushing comprises operations taking feeds 6 or 8in maximum and making products down to 1/2″ or 3/8″ Fine crushing is reduction by crushing to 1/4″ or finer; the distinctions are not sharpRock Crushing Process in Mining 911Metallurgist

CrushingScreening Flowsheet of Concentrator SpringerLink

Its basic forms include the threestage crushingscreening flowsheet of concentrator with open circuit and threestage crushingscreening flowsheet of concentrator with single closed circuit (Fig 2)Preliminary screening is generally provided in front of each crushing operation to improve the production capacity of the crusherCase Study: Optimizing a Crushing and Screening Process Agenda The crushers are the last size reduction stage in the value chain Over crushing is common The connection between Open Circuit Processes All or parts of the material will pass the crusher at least one time Screens placed in order to return overOptimizing the Crunch process 911 MetallurgistIn addition to this closed circuit crushing process, the 1213S can also be utilized in an open circuit process to make two different end product sizes the 1213S is ideally used to make 20mm or 40mm road base product Contact Us for More Information Technical SpecificationsMETSO 1213S CCS Complete Crushing ServicesCrushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 Crushing Plant an overview ScienceDirect Topics

.jpg)

Characteristics of open and closedcircuit grinding systems

2004年4月15日 The characteristic differences between open and closedcircuit grinding systems were examined via the use of a continuous vibration ball mill and a blade type classifier For the same median diameter of the product, the rate of powder production in the closedcircuit is about 5% higher than that of the opencircuitBoth open and closed circuit crushing are employed For close circuit the product is screened with a mesh size much less than the set Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) Crusher an overview ScienceDirect Topics2016年10月21日 It may operate in either open circuit or closed circuit Two stage or multiple stage grinding may be defined as grinding in two or more units with each unit making a step in size reduction Each mill may operate either as open circuit or closed circuit Advantages of open circuit grinding 1 Simplicity of mill layout minution Theory Process Equipment 911MetallurgistFig 152 Closed circuit grinding continuously However, an important distinction must be made between open circuit and closed circuit milling In open circuit crushing the material passes through the mill once, with no rework of any oversize material, and results in Crop Process Engineering: Lesson 16 Size Reduction Equipments

SAG Mill Grinding Circuit Design 911Metallurgist

2016年6月6日 A number of operations have implemented a secondary crushing circuit prior to the SAG circuit for further comminution of primary crusher product Such a circuit can counteract the effects of harder ore coarser ore decrease the size of SAG mill required, or rectify poor throughput due to an undersized SAG circuit23 Electrochemical process for recovery of copper layer from WMPCBs Figure 2(a) shows the sketch of an electrochemical cell that is used for the recovery of the copper layer from the WMPCBs Figure 2(b) shows the experimental setup of the electrochemical cell, where a sufficient amount of the copper sulfate (CuSO 4 ⋅5H 2 O, 98%, origin Merck, India) electrolyte solution is Recovery of Copper Layer from Waste Mobile Phone Printed Circuit 2016年5月16日 CRUSHING AND GRINDING CIRCUIT Twostage, open circuit crushing is shown on the flowsheet since a rod mill is incorporated in the grinding circuit The resulting sponge product is ground to —35 mesh for use in the precipitation circuit of the LPF processCopper LPF Leach Precipitation and Flotation ProcessWhen crushing a bed of material weaker particles will break first Optimization of a Final Crushing Stage Who is control of your process performance? capacity, especially in a closed circuit • Production of 4 valuable products – 008016’’ (24 mm)Crushing Principles of Mechanical Crushing 911 Metallurgist

.jpg)

Simplifying the crushing process Pit Quarry

2019年5月10日 The type of rock you need to process will dictate the types of crushers needed in the crushing circuit The more you know about the aggregate you wish to crush – along with its end use – the easier it will be to select the best equipment