Coal mill SM oil seal

天蚕土豆HP coal mill oil sealAnhui Xuyue Sealing Technology

Sealing requirements Vertical mill rollers rotate in a mill filled with ore powder or coal powder Its sealing is difficult, demanding, and extremely important It is necessary to prevent oil leakage Temperature resistant 70 DEG C to 300 C, oil resistance, acid and alkali resistance, corrosion resistance, aging resistance Application scope It is suitable for sealing all kinds of lubricating HP coal mill oil sealSHANGHAI POF SEALS SOLUTIONS CO, LTDSKF provides a large variety of customized seals for machines in the mining, mineral processing and cement industries, covering hydraulic seal kits with piston, rod and wiper seals, rotary Solutions for the mining, mineral processing and cement This catalog lists Koyo oil seals and Orings, including all items of the dimension series specified in ISO, JIS and JASO (Japanese Automobile Standards Organization) standardsOIL SEAL ORINGS 株式会社ジェイテクト

Coal mill oil sealCoal mill oil seal批发Coal mill oil seal价格

Coal mill oil sealNingbo STF Sealing Technology Co,Ltd为你详细介绍Coal mill oil seal的内容,包括Coal mill oil seal的用途、型号、范围、图片、评论等,在这里你可以得知所有Coal mill oil The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 LOESCHEMILLSSo there are quite a number of plant components that need to be sealed: rotating equipment, such as pumps, agitators, coal mills and compressors; valves, flanges and pipes and ducts Sealing competence for power plant technology EagleBurgmannOperation and Maintenance of Hydraulic Reversing Valve Seal Kit MG00111901 The hydraulic reversing valve MG00111901 is an important control component commonly used in coal mill news Operation and Maintenance of Hydraulic Reversing Valve

Coal Mill Oil Seal

Coal Mill Oil Seal , Find Complete Details about Coal Mill Oil Seal,Coal Mill Oil Seal,Seal from Supplier or ManufacturerXi 'an Minghe Fluid Control Co, Ltd MENU MENU Alibaba Sm Oil Seal Parts Center Sm Oil Seal Parts Center (Sealmatic) Sealants No Ratings Call Chat Call Chat Address 1044 G Masangkay Street, Barangay 294 Zone 28, City of Manila 1006 Metro Manila Landline +63 (2) 8 244 7804 +63 (2) 8 244 7792 +63 (2) 8 244 7793 +63 (2) 8 244 0190 See More MobileSm Oil Seal Parts Center Yellow Pages PHWelded Steel Mill; Combination; Conveyor Scraper Leaf Drop Forged Rivitless Motorcycle Tensioning Devices Tensioner Arms; Article SM 32527 METRIC OIL SEAL Brand: TTO Added to Your Shopping Cart R17,68 Each Excl VAT Details; Rotary shaft seals are also known as oil seals close spaces between stationary and moving components SM 32527 Rotary Shaft Oil Seals All Categories BMG OnlineThis type of coal mill framework oil seal is divided into three layers, two layers of lip facing the roller bearing side, one layer of lip facing the roller head(3)Lack of lubricating oil (4)Low sealing air pressure Fault treatment and improvement optimization:After stopping grinding, remove the grinding rollerSHPHGLXPVSHHGFRDOPLOO IOPscience

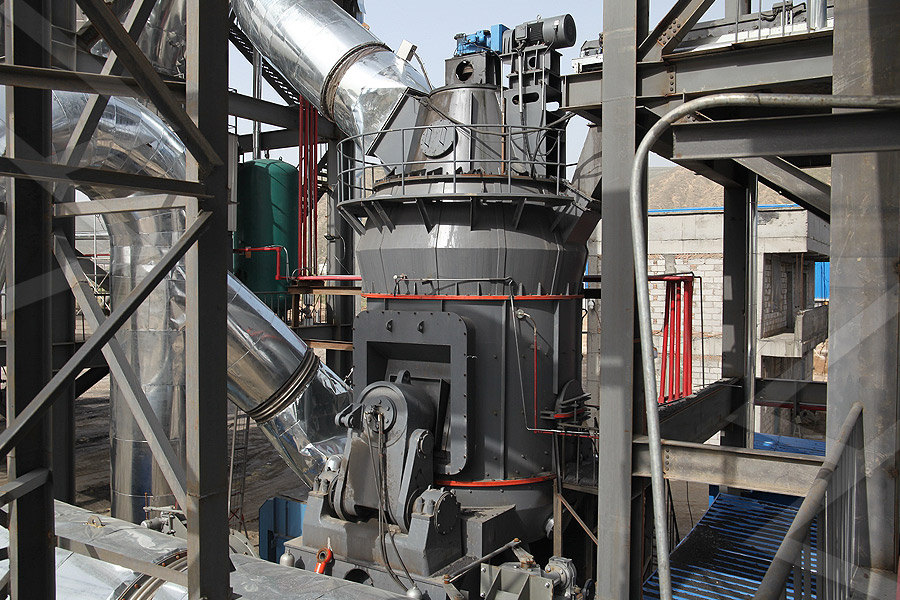

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

SM OIL SEAL Manila Facebook

SM OIL SEAL, Manila, Philippines 136 likes Importer of Oil Seal, Oring, and PackingSection of coal bowl mill Table 1 Guaranteed coal conditions for mill performance evaluation Coal Moisture % 20 Coal HGI 55 Mill Outlet Temperarure °C 80 Mill Air Flow T/hr 102 Coal Fineness (% passing trough 200 mesh) 70% passing through 200 mesh and 90% passing through 50 mesh Differental Pressure 300 mmwc Coal Output from Mill 609 t/hrA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Coal Sintering machine Blast furnace Converter Continuous casting machines Shapedsteel rolling mill Plate mills Rod / Wire Rod mills Hot Rolling Mill Backup Rolls Oil Seal (YS) Features Features Wider driving surface when assembling seal on the choke prevents seal distortion,Oil Seal For Steel Production Equipment 株式会社ジェイテクト2022年9月3日 need improvement to achieve milloptimal performance Coal feed to the mill is important, this was observed to be a limiting constraint on mill capacity when the coal required exceed nominal load requirement KEYWORDS: Air fuel ratio; pulverised fuel distribution; classifier; elutriation; heat balance; isokineticPerformance optimisation of vertical spindle coal pulverisers

Coal Mill PDF Combustion Chemistry

Coal Mill PPT Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document provides an overview of coal mill operation, protections, and interlocks It discusses coal combustion theory, coal properties, coal mill components and operation, and troubleshooting The coal mill grinds coal into fine particles for Add:Songjiang District, Shanghai Jing Jing Road, No 19, building 115 Zip code: Contacts:Miss Yang Tel:021| 021|HP coal mill oil sealSHANGHAI POF SEALS SOLUTIONS CO, LTDMill Training Manual Alstom Free download as PDF File (pdf), Text File (txt) or read online for freeMill Training Manual Alstom PDF Coal Mill (Grinding)2023年5月11日 As a result, it was confirmed that the seal air flowrate at each of the coal mill locations was normal value and that there were no problems with operationFlow measurement of five seal air pipes at a coal mill using the

(PDF) Fault analysis and optimization technology of HP

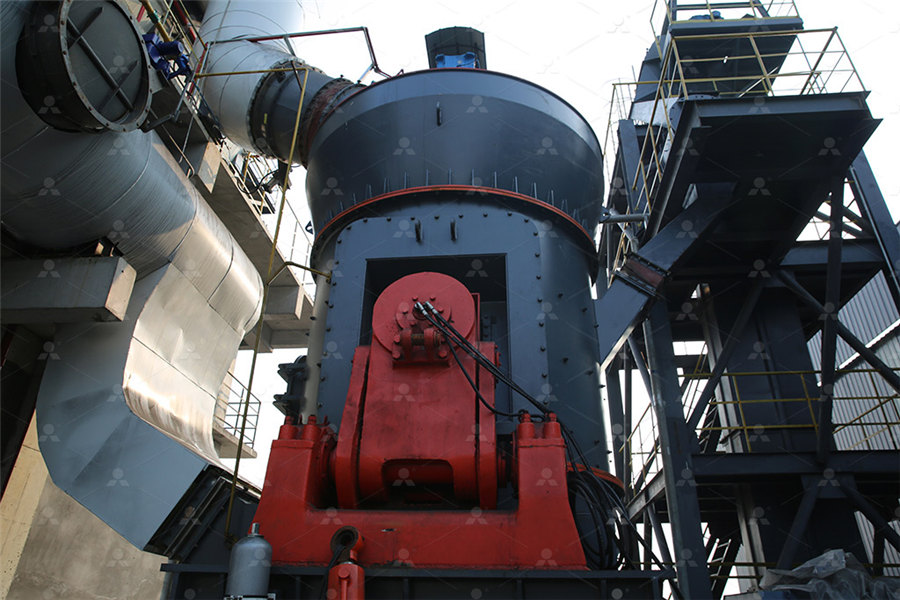

2021年8月1日 36 Serious oil leakage of bearing oil seal on vertical shaft of coal mill re ducer Cause analysis :( 1 ) The upper bearing oil seal is seriously worn ( 2 ) The wearresistant sleeve ofThis type of coal mill framework oil seal is divided into three layers, two layers of lip facing the roller bearing side, one layer of lip facing the roller head(3)Lack of lubricating oilSHPHGLXP VSHHGFRDOPLOO ResearchGateSeal air for the mill gear box is taken from each cold tempering air duct A separate seal air fan is not required for this mill The mill inlet pressure downstream of the rating damper is normally between 0 to 10" wc The exhauster is connected to the mill worm shaft through a Pulverizer Fineness and Capacity Enhancements at Danskammer HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

Labyrinth Seal for Coal MIll IndiaMART

Get Labyrinth Seal for Coal MIll in MIDC, Nagpur, Maharashtra at best price by HiTech Machinery Also find Labyrinth Seals price list from verified suppliers with contact number ID: IndiaMART All India Get Best Price Shopping Sell Help Messages Copied to Clipboard Get More Photos IndiaMART > Seals, Oil Seals Industrial Oil Seal Overview Oil seals, often called a rotary shaft seal or grease seal, closes the gap between stationary and moving components in mechanical equipment — most often rotating shafts — helping prevent lubricant escape and stopping harmful materials, such as dirt, from moving in through the clearanceOil Seals More Global ORing and SealOur ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelATOX® Coal Mill FLSmidth CementSudarsan Engineering Industries Offering Labyrinth Seal Coal Mill, लबीरिंथ सील at Rs 75000/unit in Chennai, Tamil Nadu Check best price of Labyrinth Seals in Chennai offered by verified suppliers with contact number ID: Labyrinth Seal Coal Mill at Rs 75000/unit IndiaMART

Oil Seals (Part 1): The structure, functions, and types of oil seals

2023年10月11日 Major oil seals are specified in ISO 61941 and JIS B 24021 Table 2 shows the common types of oil seals, while Table 3 shows the features of each type of oil seal Table 4 lists the JTEKT oil seal type codes and corresponding ISO and JIS standards Table 2 a): Common types of oil seals (with spring) With spring Rubber OD wall Metal OD wall1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSWelded Steel Mill; Combination; Conveyor Scraper Leaf Drop Forged Rivitless Motorcycle Tensioning Devices Tensioner Arms; Article SM 10197 VF METRIC OIL SEAL VITON Brand: TTO Added to Your Shopping Cart R52,62 Each Excl VAT Details; Rotary shaft seals are also known as oil seals close spaces between stationary and moving SM 10197 VF Rotary Shaft Oil Seals All Categories BMG OnlineKLOZURE® Model 87 Oil Seal MODEL87 Shipping Weight: 0 lbs Brand: KLOZURE® Style/Model: Model 87 View Details Add To Cart PSSEAL® Rotary Shaft Seal, Single Lip, Dust Lip, GYLON Black Lip Material, 14571/316Ti All Oil Seals Garlock

.jpg)

FSSS (Furnace Safeguard Supervisory System) POWER PLANT

For MILLA START PERMISSIVE: Elevation AB3/4 oil burner firing OR MILLB firing AND BOILER LOAD >30% BCMR FOR B, D, F MILLS At least 3 OIL BURNERS firing in the burner group above AND Adjacent COAL BURNER above in operation AND This elevation is highest in the burner group EXAMPLE For MILLB START PERMISSIVE Elevation AB3/4 OIL Coal Nozzle Castings Forgings Rings, Girth Gears and Flanges Shafts Manufacturing Process MILL BOTOM MECHANICAL FACE SEAL ASSLY; MILL BOTTOM; MILL BOTTOM INSULATION COVER SEGMENT; MOUNTING PLATE AND DOWL APLICATION; SPLIT OIL SEAL, ID A4318/A4699 , OD; SPLIT PIN A 6 X 25; SPRING AIR SEAL CAP; SPRING GUIDE;Pulverizer Spares Kappati Bowl MillsWelded Steel Mill; Combination; Conveyor Scraper Leaf Drop Forged Rivitless Motorcycle Tensioning Devices Seals; Oil; Rotary Shaft; SM HPVF; Article SM HPVF METRIC OIL SEAL VITON HIGH PRESSURE Brand: Excl VAT Details; Rotary shaft seals are also known as oil seals close spaces between stationary and moving SM HPVF Rotary Shaft Oil Seals All Categories BMG Vertical grinding mill ram cylinder units perform a vital role in the operation of the pulverizer They maintain a contact load and automatically compensate operational wear to ensure optimum performance As the seals on the cylinder degrade the performance of the cylinder, and therefore the pulverizer, degrades making it less effectiveRAM CYLINDERS CHASE International

TRM SERIES COAL VERTICAL ROLLER MILL

Triple fluoro rubber framework oil seal for grinding roller Adjustable gas ring area and dam ring height Auto liftup grinding roller and no load startup Simple and stable operation, less vibration TRM COAL GRINDING SYSTEM TYPE SPECTRUM of TRM COAL MILL 3 4 TRM 2023年9月19日 In mill stop condition you may crosscheck it by starting the seal air fan and throw the dust on top of sealing ring area If your seal ring gap is maintained properly, then the dust will be What is seal air fan for coal mills? AnswersThis oil from the bearing drains back to the sump throughthe oil cooler placed in the mill base A view port withsight glass is provided on the oil return line to monitorthe floe However, in963 1003Design and Modify of Mill Discharge Valve Using in2022年4月13日 The shaft oil seals supplied by XI’AN XINBEILANG IMPEXP CO,LTD for BPEG coal mills can guarantee good performance in coal mill pulverizers for thermal power plants The material used for making the oil seal What is the oil seal for BPEG coal mill pulverizers

.jpg)

15sop For Coal Mill and Feeder

This document provides standard operating procedures for coal mill and coal feeder operations at a 1x525 MW thermal power plant in Tuticorin, Tamil Nadu, India It outlines responsibilities for personnel, safety and environmental CHASE supplies coal mill parts and spares for grinding rings, motors, gear boxes, bellows and seals to customers around the worldCOAL MILL PARTS AND SPARES CHASE International2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important Review of control and fault diagnosis methods applied to coal 2024年7月4日 West Bengal Tender Supply of Oil Seal for Journal Assembly of Coal Mill (HP 1103), Dimensions OD 508mm, ID 4585mm, H 25mm, O Ring for Journal Roller Assembly of Coal mill HP 1103( OD 650mm, Thickness10mm, Material Viton, O Ring for Journal Roller Assembly of Coal mill HP 1103( OD650mm, Thickness08 mm, Material Vito at Dumdumi, Supply of Oil Seal for Journal Assembly of Coal Mill (HP 1103

JK Pioneer Industrial Oil Seals Prabhat Mill Store

Discover topquality JK Pioneer Industrial Oil Seals at Prabhat Mill Store, your official distributor Our wide selection of oil seals ensures superior sealing performance for various industrial applications Trust Prabhat Mill Store for genuine JK Pioneer products and reliable service35 years of experience in manufacturing of oil seals for every applications: Paper Mill, Metals, Wind Mill and Mining Industry FP PARIS ATS OIL SEALS SLIB ITALY FP MILANO Italiano; The •FP• and ATS production capacity for oil seals reaches out to a diameter of 2200 mm in one single piece, CEMENT AND COAL PULVERIZERSOil seals, jointvulcanized and antivibration seals Rubber gasket SealMaster Coal Tar ReadyMix A third coat of mixed Coal Tar ReadyMix may be applied to high traffic areas such as entrances, exits, and drive lanes Application Rate of Mixed Coal Tar ReadyMix: Apply properly mixed Coal Tar ReadyMix (Coal Tar ReadyMix, Sand, Additive) at a rate of 11 to 13 gallon per square yard (7082SealMaster Coal Tar ReadyMix Pavement Sealer2012年5月1日 Coal fired power plants are heavily used due to large and long lasting coal resources compared with oil or natural gas An important bottleneck in the operation of this particular kind of plants, however, is the coal pulverization process, which gives rise to slow takeup rates and frequent plant shutdowns (Rees Fan, 2003)In typical coal fired power plants, Derivation and validation of a coal mill model for control

.jpg)

Analysis of the Coal Milling Operations to the Boiler Parameters

5 Oil skid purposely to the mill journal hydraulics systemAuxiliary steam supply for inerting circuit From the coal yard, the coal is transfer to the mill bunkers through conveyor belt The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal Each mill bunker has one hopper, connected to the feeders