The cost performance of hollow clay bricks and hollow coal gangue bricks

.jpg)

Building hollow clay bricks embedding phase change material:

2022年5月1日 Integrating PCM in bricks allowed increasing the time lag and reducing fluctuations amplitude Volumes of HCBs and clay were reduced up to 30% and 35% for improving the thermal capabilities of the brick that results is more cost effective solutions of masonry is analyzed In terms of the mechanical behavior of hollow clay masonry distinct The design and performance of highperformance perforated2018年6月19日 In this paper, mechanical properties of a new structural and ecoefficient hollow clay bricks are investigated The principal goal was to recycle residual sludge from aluminium anodizingMechanical performance of ecoefficient hollow clay 2024年4月10日 Considering the current scenario, by replacing 1–2% of brunt clay bricks with agroforestry waste, CD waste based fly ash bricks can potentially reduce 05–15 million Large CO2 reduction and enhanced thermal performance of agro

Monitoring Thermal Performance of Hollow Bricks with Different

2014年10月7日 In this paper, a steadystate technique utilizing a system of two climatic chambers separated by a connecting tunnel for sample positioning is used for the 2007年5月15日 This research compares the strength, load deformation characteristics and the applications of English and Rattrap bond patterns in masonry construction The findings are based on burnt clay(PDF) Comparative Performance of Burnt Clay Bricks 2024年2月9日 This research shows that the thermal performance of unit bricks and the whole masonry wall is significantly improved by varying the thermal properties of the clay and cement Improvement of the thermal performance of hollow clay bricks for 2023年3月1日 In order to minimize the cost and time needed to build an insulated wall as well as to decrease greenhouse gas emissions, this manuscript proposes to incorporate a biobased Thermal performance assessment of double hollow brick walls

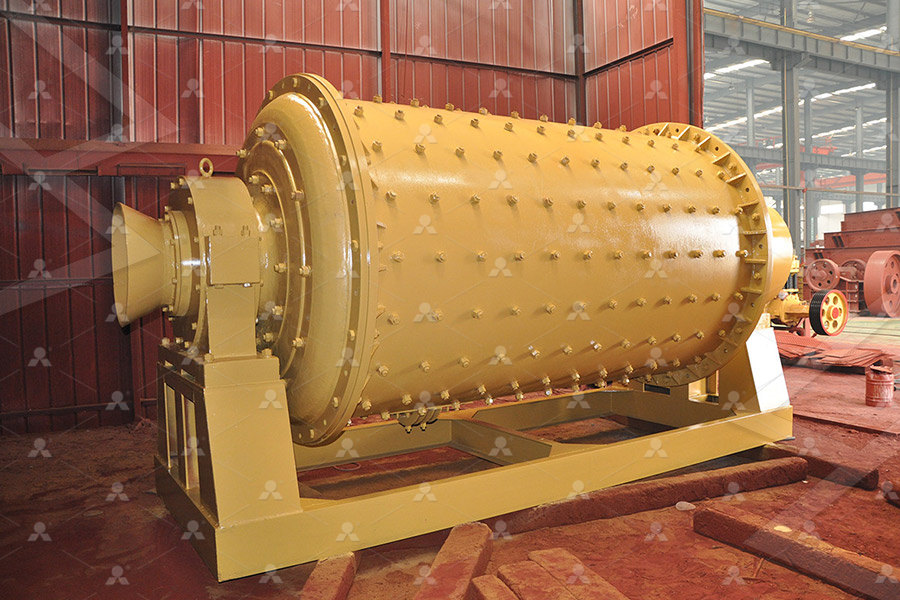

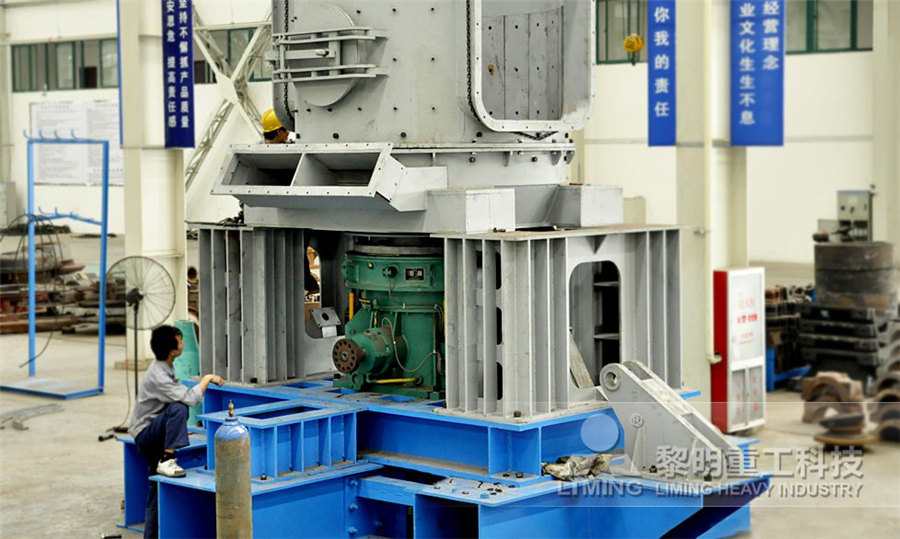

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

[PDF] Thermal Performance of Hollow Clay Bricks for Ceiling Under

Airconditioning applications consume over half of the energy used in residential 10 buildings Thus, the present paper aims to investigate the potential of using three passive measures Find here Hollow Clay Bricks, Hollow Bricks manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Hollow Clay Bricks, Hollow Bricks, Hollow Clay Blocks across IndiaHollow Clay Bricks Hollow Bricks Latest Price, Article Mechanical Properties of CementClay Interlocking (CCI) Hollow Bricks Panuwat Joyklad1,a,*, Qudeer Hussain2,b, and Nazam Ali3,4,c 1 Department of Civil and Environmental Engineering Mechanical Properties of CementClay Interlocking (CCI) Hollow Bricks2019年6月6日 • To compare conventional brick ie clay brick and nonconventional brick ie fly ash papercrete b rick • To determine the suitable brick according to its compressive stren gth(PDF) Comparative Study of Normal Clay Bricks, Fly

.jpg)

Improvement of the thermal performance of hollow clay bricks

2024年2月9日 Although structural masonry walls are widely used in construction, achieving lower Uvalue is crucial to minimize energy losses and greenhouse gas emissionsThe effect on the Uvalue of hollow clay masonry walls is evaluated by modifying the clay and mortar thermal conductivities, as well as the brick grid and thicknessHeat transfer through bricks and walls 2021年10月22日 As such, you may find yourself caught up in the big cement bricks vs clay bricks debate In fact, Of course, the cost of bricks varies based on the type, as well as the application The average homeowner usually spends between $340 and $850 for 1,000 bricksCement Bricks Vs Clay Bricks: What Are The Major Differences?2007年5月15日 The objective of this research is to analyze and compare the performance of fired clay and quarry dust concrete bricks, produced locally, because, building's cost has risen which necessitate the (PDF) Comparative Performance of Burnt Clay Bricks and 2015年4月1日 At present, some wall experts and brickmaking enterprises which produce clay bricks, sandlime bricks and fly ash bricks have made some achievements in research on how to use the fly ash in manufacturing building wall, but utilization rate of fly ash was only 5–20 %, and the use of additives was increased, production costs for manufacturing enterprises were barely New technology and application of brick making with coal fly ash

.jpg)

[PDF] Comparative Performance of Burnt Clay Bricks and

2007年4月23日 DOI: 104038/ENGINEERV40I27137 Corpus ID: ; Comparative Performance of Burnt Clay Bricks and Compressed Stabilized Earth Bricks and Blocks @article{Jayasinghe2007ComparativePO, title={Comparative Performance of Burnt Clay Bricks and Compressed Stabilized Earth Bricks and Blocks}, author={Chana Jayasinghe}, 2024年4月10日 Production of 1burnt clay brick and 1ton of cement results in approximately 041 kg and 085 ton of CO 2 emission 1,2,3Utilisation of farm soil in burnt clay bricks reduces the fertility of Large CO2 reduction and enhanced thermal performance of agro CCI hollow bricks [25] Namboonruang et al [26], Yoosathaporn et al [27], Namboonruang et al [28], Joyklad [29] and Shakir and Mohammed [30] investigated the mechanical properties of these CCI hollow brick The CCI hollow brick masonry walls are main load carrying elements whichPERFORMANCE OF CEMENT CLAY INTERLOCKING HOLLOW BRICK 41 Burnt clay bricks The bricks of standard size of 215 mm x 105 mm x 65 mm were used for one of the testing series Only few manufacturers are currently manufacturing these standard bricks in Sri Lanka They are identified as burnt clay Type 1 for further discussion A sample was physically Table 1: Average wall strengthsComparative Performance of Burnt Clay Bricks and Compressed

Building Bricks, Hollow Construction Brick

Thermal performance; Decreased building costs; As the name suggests, Reinforced Hollow Clay Masonry is designed with hollow bricks, much like CMU, to allow for placement of reinforcing steel and can be fully grouted to achieve What are Clay Hollow Bricks? Clay hollow bricks are perforated( horizontally) bricks and have the property quite similar to Hollow bricks It is made up of natural materials like clay or natural additives like coal ash, sawdust, and fly ash It is Hollow Bricks Its Properties, Sizes, Manufacturing, 2023年2月18日 While hollow bricks can be a costeffective building material, Hollow clay bricks have a thermal conductivity of 028031W/wk 4 Dry Density The dry density of hollow bricks is 694788Kg/m 3 coal ash, and fly ash Q Disadvantages of clay hollow bricks?Hollow Bricks – Properties Sizes Advantages Disadvantages2009年5月1日 Understanding the behavior of masonry structures when exposed to fire and predicting their fireresistance is a major need that has been expressed by brick manufacturers Whereas clay brick masonry is widely used because of its thermal and sound insulation performance; fireresistance is certainly its weakness if improper design methods are usedThe behaviour of masonry walls subjected to fire: Modelling and

.jpg)

Brick Types and Properties: Everything You Need to Know

The perforation area should be under 45% of the brick face Cavity or hollow bricks: These are approximately onethird of the weight of a typical brick and are quicker to work with (hollow and cavity bricks can be laid four times faster) Plinth, splay or cant bricks: made with a missing edge, these are used for door and window jambs2023年2月4日 Plastic bottles have compression properties that are 20 times greater than those of traditional clay bricks a Kenyan company, produces up to 1,500 paving bricks Furthermore, her lowcost bricks reduce the need for environmentallyhazardous The hollow design of the bricks not only provides good heat and noise insulation Exploring The Cost And Potential Benefits Of Recycled Plastic Bricks 2021年8月23日 The environmental concern of plastic waste (PW) generation has escalated to an alarming level due to the versatility and high demand in various applications(PDF) Reusing plastic waste in the production of bricks and paving Findings of this study serve as a reference to discuss improvements in clay hollow brick geometry regarding [24][25][26][27][28] For a more costeffective performance of hollow bricks as The improvement in the Uvalues of 5row hollow bricks

Prediction of the sound reduction index of clay hollow brick

2020年2月10日 This study aims at improving the prediction of the sound transmission loss performance of fired clay hollow brick walls, with or without a thermal lining, using a finitesize transfer matrix A study from Leeds Metropolitan University found that clay bricks have a potential of 650 years of performance in solid walls Even when a building is no longer needed, the clay bricks in its walls can often be recycled and used again The Ultimate Clay Bricks Guide BuildingMaterialscoukMaterial: Hollow Clay Bricks are primarily made from natural clay, which is fired at high temperatures to achieve strength and durability Size: Common sizes of Hollow Clay Bricks include standard dimensions of 8 inches long, 4 inches wide, and 2 ¼ inches thickHollow Clay Brick A Versatile and Efficient Building Material51 The size of burnt clay hollow bricks when 4 TYPES measured according to 52 shall be as follows: 41 The bricks shall be of the following types: a) Type A Bricks with both faces keyed for plastering or rendering, b) Type B Bricks with both faces smooth Length mm 190 290 Width mm 190 90 Height mm 90 90 c) IS 3952 (1988): burnt clay hollow bricks for walls and partitions

.jpg)

The behaviour of masonry walls subjected to fire: Modelling and

2009年5月1日 The behaviour of masonry walls subjected to fire: Modelling and parametrical studies in the case of hollow burntclay bricks May 2009 Fire Safety Journal 44(4):629年11月1日 Most research works have focused on perceptions on barriers to the use of burnt clay bricks (Baiden et al, 2014), cement stabilised clay bricks and sandcrete block (Ogunbiyi et al, 2014 (PDF) A Comparative Study on Conventional Clay Bricks and 2024年3月25日 This paper evaluates the thermal performance of building walls in Morocco’s hot and dry climatic zones Two types of hollow brick walls, namely, single wall (Type A) and double wall (Type B), are examined The objective is to identify the configuration that offers optimal thermal performance Numerical simulations are conducted to analyze key thermal Thermal performance analysis of hollow brick walls in hot and the environmental sustainability of clay bricks by reducing the quantity of clay but also at improving the thermal capabilities of the brick that results is more cost effective solutions The mechanical performance of hollow bricks and it its influence on the mechanical behavior of masonry is analyzedThe design and performance of highperformance perforated

(PDF) Optimizing Building Thermal Insulation: The Impact of Brick

2023年5月11日 The thermal performance of clay bricks can be modeled directly using computational fluid dynamics (CFD) simulations or using a si mplified method ba sed on EN 1745, EN ISO 10211:2007 and EN ISO 2023年9月28日 Hollow bricks: An overview There are two types of clay bricks – solid and hollow Solid bricks contain a maximum of 25 percent holes or cores On the other hand, hollow bricks have more than 25 percent but less than 60 percent holes, also known as cellsHollow Bricks: Price, Size, Features, Advantages Disadvantages8in (203mm) hollow brick masonry, units at least 71% solid, combustible members framed in ; 1 : 5in (127mm) hollow brick masonry, solid grouted ; 2 : 6in (152mm) hollow brick masonry, solid grouted ; 3 : 8in (203mm) hollow brick masonry, units at least 71% solid, with noncombustible members or no members framed in ; 3Hollow Brick Masonry2021年8月1日 After comparing the three materials like burnt clay brick, AAC block and fly ash bricks it has been concluded that the AAC blocks will cost 155% lesser than burnt clay brick and 98% lesser (PDF) Comparison of Fly Ash Based (AAC) Block and Clay Bricks

Specifications for and Classification of Brick Brick Industry

Facing Brick ; C 216 : A82 : Hollow Brick : C 652 ; A82 : Thin Veneer Brick Units Made from Clay or Shale ; C 1088 — Pedestrian and Light Traffic Paving Brick : C 902 — Heavy Vehicular Paving Brick ; C 1272 — Ceramic Glazed Structural Clay Facing Tile, Facing Brick, and Solid Masonry Units : C 126 — Glazed Brick, Single Fired ; C 1405 —2014年10月7日 Hollow brick blocks have found widespread use in the building industry during the last decades The increasing requirements to the thermal insulation properties of building envelopes given by the national standards in Europe led the brick producers to reduce the production of common solid bricks Brick blocks with more or less complex systems of internal Monitoring Thermal Performance of Hollow Bricks with Different 2018年6月19日 Mechanical performance of ecoefficient hollow clay bricks incorporating industrial nanocrystalline aluminium sludge June 2018 European Journal of Environmental and Civil engineering 24(1)Mechanical performance of ecoefficient hollow clay bricks Advantages and Disadvantages of Clay Bricks and Hollow Clay ricksSolid Clay Bricks VS Hollow Clay Bricks Which is Best? (Full Comparison) Advantages and Disadvantages of Clay Bricks and Hollow Clay Bricks

What Are Hollow Bricks? Advantage Disadvantage of Hollow Bricks

2021年8月20日 Hollow brick is used in construction as an excellent quality fireresistant material Excellent fireresistant materials can be made using fire clay for hollow brick 2 Sound Resistance Hollow bricks have better sound insulation than conventional bricks2020年6月22日 Clay bricks are commonly used for building wall One of the functions of a wall is to create a habitable internal environment, such as enabling internal temperature to be controlled at a human Steadystate heat flow through hollow clay bricks ResearchGateHollow bricks are horizontally perforated bricks having hollow spaces or holes through them which total at least 25%60% of their bed area It gives more carpet area available compared to clay brickwork 11 Costeffective and low maintenance Easy to handle, reduces the labor cost coal ash, granite slurry, rice husk, etcHollow Bricks Advantages, Disadvantages, Sizes Daily CivilCheaperWhen compared to brick masonry, Hollow Blocks are far less expensive They are known to cost Rs 1,500 less per cubic meter than brick masonry This is not an insignificant distinction According to reports, the cost of constructing a wall out of AAC blocks is 1765% less than the cost of constructing a wall out of traditional bricksHollow Blocks or Bricks: Which one is cheaper and better?

.jpg)

A Comprehensive Guide to Hollow Brick Construction Jindal Mechno Bricks

2023年9月22日 Residential Buildings: Ideal for constructing walls in homes, hollow bricks provide thermal comfort and energy efficiency; Commercial Structures: Hollow bricks are used in offices, shopping malls, and other commercial buildings due to their costeffectiveness and durability; Industrial Facilities: Hollow bricks are appropriate for industrial projects due to their