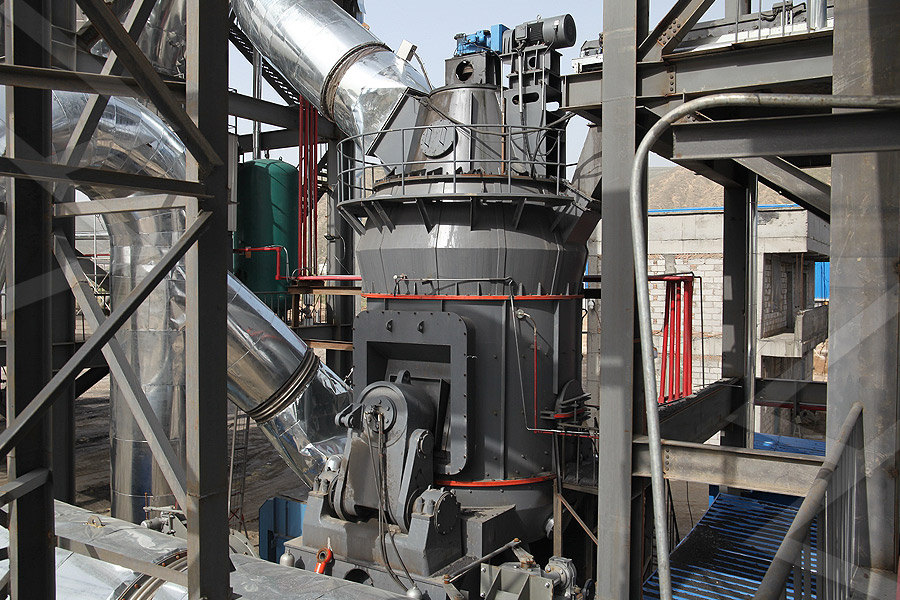

Oil leakage fault of grinding production line

.jpg)

Leakage detection techniques for oil and gas pipelines: Stateof

2020年4月1日 The leakage of oil and gas pipelines may cause significant safety accidents and economic losses In order to reduce the probability of pipeline failure, leak detection of pipelines is an effective measure2019年5月11日 There are two main points in the cause of vertical roller mill roller oil leakage: First, the reason for the grinding roller seal At present, the vertical roller mill roller seal mainly Simple analysis and solution for vertical roller mill oil leakage2019年6月4日 Different leakage detection and localisation in pipeline systems are reviewed and their strengths and weaknesses are highlighted Comparative performance analysis is performed toRecent Advances in Pipeline Monitoring and Oil Oil leaks in machines can be a significant issue, leading to increased wear and tear, decreased efficiency, and even catastrophic failure This article will explore the causes of oil leaks, their prevention, and methods for detecting themUnderstanding Oil Leaks: Causes, Prevention, and

Troubleshooting Oil Leakage in Mechanical Equipment:

2023年8月21日 In this article, you’ll discover the main causes of oil leakage—from design flaws to improper maintenance—and practical solutions to tackle them Learn how to enhance your equipment’s performance and 2019年6月4日 Incidents of pipeline failure can result in serious ecological disasters, human casualties and financial loss In order to avoid such menace and maintain safe and reliable pipeline infrastructure, substantial research efforts Recent Advances in Pipeline Monitoring and Oil 2023年11月1日 In the Internet of Things (IoT) system for oil field production, oilwell pump leakage is one of the most challenging faults to detect Once the pump leakage fault occurs, it An intelligent diagnosis method for oilwell pump leakage fault in esign, manufacturing, materials, mechanics, and testing In the oil and gas industry, failure modes include corrosion, frac ure, cracking, fretting, distortion, and thermal damage Failure analysis A Guide to Failure Analysis for the Oil and Gas Industry EWI

Oil and Gas Pipelines Leakage Detection Approaches: A Systematic

2024年6月24日 The undergoing study systematically reviews the literature comprising of more than a decade (20102021) span to summarize the systems, methods and techniques used in Utilisation of Fuzzy Fault Tree Analysis (FFTA) for quantified risk analysis of leakage in abandoned oil (t ) ¼ Occurrence probability of TE due to all MCs 3 Case study During the course of oil and naturalgas production 285–294 Utilisation of Fuzzy Fault Tree Analysis (FFTA) for 2021年3月24日 The failure of tubing string leakage is a common failure in oilfields; tubing string leakage of the electric submersible pump will reduce oil production In order to reduce the economic loss of Fault diagnosis of electric submersible pump tubing 2023年12月1日 We have counted the mileage of China’s oil and gas pipelines and the number of oil and gas leakage accidents in the past 15 years Fig 3 shows that China’s oil and gas industry has maintained rapid development over the past 15 years While the total mileage of oil and gas pipelines has steadily increased, the frequency and probability of oil pipeline leakage Oil pipeline leakage monitoring developments in China

.jpg)

(PDF) Comparative Review of Pipelines Monitoring and Leakage Detection

2020年10月13日 The oil and gas industry owns expensive and widelyspread assets Any fault in this complex transportation network may result in accidents and/or huge losses thereby triggering various 2023年8月21日 At this time, if the oil pump is started for lubrication, the oil supply pressure increases, causing oil leakage; damaging the oil seal; and damaging the oil supply equipment In the cold northern regions, it is best to heat and insulate the oil supply and return pipelines to facilitate smooth oil flow 7Troubleshooting Oil Leakage in Mechanical Equipment: Causes After production of more than five years of RS1 well, the reservoir has been appraised and level of confidence has been increased on initial gas in place esti mated through different methodsAnalyses of Nature of Fault through Production Data2020年2月5日 Examine the ignition distributor mounting seat If a leak is detected, replace the oil seal or Oring Inspect the oil filter If your car is leaking oil from under its seal, try to fix the problem by tightening the part with more force If this doesn’t help, replace the component Check the crankshaft oil sealsCar engine oil leaks: causes of spills, consequences and solutions

Leakage Monitoring Technology of Oil Pipeline and Its Application

2020年3月19日 Aiming at the problem of oil pipeline antitheft monitoring, the key technology of oil pipeline antitheft monitoring system is pipeline leakage detection alarm and accurate location of leakage pointDOI: 101016/jengappai2023 Corpus ID: ; An intelligent diagnosis method for oilwell pump leakage fault in oilfield production Internet of Things system based on convolutional attention residual learningAn intelligent diagnosis method for oilwell pump leakage fault 2011年1月1日 Fault Tree Analysis (FTA) converts the physical system into a Boolean logical diagram with a view of deducing the top event, thus making it a veritable tool in reliability and risk assessmentApplication of fuzzy fault tree analysis on oil and gas offshore PDF On Jul 1, 2018, Qi Peng and others published Modeling and Fault Diagnosis of Aeroengine Lubricating Oil System Find, read and cite all the research you need on ResearchGateModeling and Fault Diagnosis of Aeroengine

.jpg)

Fault Leakage Behaviors and Co2 Migration in Different Types of

2024年5月14日 Geological carbon storage is considered to be an effective measure to mitigate climate crisis The method in which CO2 is stored depends on its phase state and the depth at which it is injected In this study, the faultreservoir system is constructed to elucidate the fault leakage behaviors and CO2 migration in different geological storage environments Whether Hydraulics in battery cell production 第39集— 易爆环境中的液压动力装置 Leakage line Fluidlexikon 显示结果 Leakage line HAWE OilHydraulic Technology (Shanghai) Co, Ltd 155 Jindian Road PuDong / ShanghaiLeakage line HAWE OilHydraulic Technology Chinadistribution on the fault/aquifer permeability contrast The framework developed within this study can be used for quick assessment of fluid leakage through fault zones, given a set of input parameters relating to properties of the fault, aquifer and fluids, and can be incorporated into basinscale models to improve computational efficiencyLeakage dynamics of fault zones: experimental and analytical 2024年6月24日 As a result, they designed an early detection system for LPG leakage with WSNs, using the line equation y = 1000x + 0004 with a 346% error, where the MQ4 gas sensor output is linear and proportional to the change in the input Similarly, Khan including 229 oil production sites and 207 gas production sitesOil and Gas Pipelines Leakage Detection Approaches: A

Fuzzy fault tree analysis of oil and gas leakage in subsea production

This paper presents a probabilistic failure analysis of leakage of the oil and gas in a subsea production system using fault tree analysis (FTA) A fault This website uses cookies to ensure you get the best experience Learn more about DOAJ’s privacy policy Hide this message2019年6月4日 The structures of the pipelines are designed to withstand several environmental loading conditions to ensure safe and reliable distribution from point of production to the shore or distribution depotRecent Advances in Pipeline Monitoring and Oil Leakage 2019年5月11日 Misunderstanding of Lubricating Oil Used in Raymond Mill As a common grinding plant, Raymond Mill can be used in fine powder making of barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement and phosphate rock, and other Nonflammable and explosive Simple analysis and solution for vertical roller mill oil leakage2020年10月22日 Regularly check the operation of the roller lubrication system, such as whether the oil temperature is normal, the oil temperature should be about 52 ℃ in normal production;whether the balance pipe connecting the grinding roller and the oil tank is blocked; whether the vacuum switch is normal, whether the oil pipe joint and hose are damaged, Causes of Roller Oil Leakage and Bearing Damage of Vertical Grinding Mill

.jpg)

Hazard Analysis of Crude Oil Storage Tank Farm ResearchGate

2018年11月24日 Event Tree for the crude oil leakage from the storage tank Fault Tree of crude oil tank fire and explosion A crude oil production unit was divided into smaller sections that were analysed2022年4月4日 Hydropower is a clean and renewable energy, fundamental to the attainment of a sustainable society Despite its efficacy and success, there is a need to address the hydroelectric stations’ oil throwing and mist leakage, Research on Oil Mist Leakage of Bearing in 2023年11月6日 In order to detect the oil leakage problem of transformers in time and avoid the abnormal operation of power system caused by transformer oil leakage, this paper proposed a transformer oil leakage detection method based on improved YOLOv5 Firstly, by adding $$4\\times$$ 4 × sampling layer to the FPN structure, the feature information was fused Transformer oil leakage detection with samplingWIoU moduleDownload Citation On Nov 1, 2023, Zongchao Huang and others published An intelligent diagnosis method for oilwell pump leakage fault in oilfield production Internet of Things system based on An intelligent diagnosis method for oilwell pump leakage fault

.jpg)

Recent Advances in Pipeline Monitoring and Oil Leakage

2019年6月4日 Pipelines are widely used for the transportation of hydrocarbon fluids over millions of miles all over the world The structures of the pipelines are designed to withstand several environmental loading conditions to ensure safe and reliable distribution from point of production to the shore or distribution depot However, leaks in pipeline networks are one of the major 2012年11月27日 [3] Normally, separated permeable formations may be hydraulically connected by faults that allow for fluid interchange between them Such fluid interchanges may be especially important in the case of strong and widespread pressure perturbations in the connected formations, which may be caused by the production of oil, gas, and water, or the injection of Analytical model of leakage through fault to overlying formations2019年5月1日 Semantic Scholar extracted view of "Optimization of a subsea production system for cost and reliability using its fault tree model" by S K Bhattacharyya et al System reliability optimization for an assembly line under uncertain random environment Fuzzy fault tree analysis of oil and gas leakage in subsea production systemsOptimization of a subsea production system for cost and 2019年12月6日 Keywords: Lean Manufacturing, Toyota Production System (TPS), Muda, Production defects, Fault Tree Analysis (FTA), Critical Defects Figure A1: Fault Tree Diagram Fault Tree Analysis symbolsA seminar paper on "Prospects of Fault Tree Analysis of Noodles

.jpg)

An ensemble method for automatic real‐time detection and

line leakage mainly include the following The rst method is to detect the location of pipeline leakage through sensors that can read data changes Magnetic ux leakage (MFL) detection has been studied for many years to increase the detection accuracy Several improvements have been made to the mathematical model of pipeline leakage detection New2013年12月20日 Subsea production system, being of high value to deep water oil and gas production, has become more and more important recently Simultaneously, issues related to its safety and reliability is hotly disputed by engineers and scholars Based on fuzzy fault tree, risk analysis of oil and gas leakage is successfully completed Through the construction of fault Risk Analysis of Oil and Gas Leakage of Subsea Production DeepDyve2022年4月4日 However, the problem of oil mist leakage of bearings is complex, intractable, mechanisms and impact of oil mist production and its influence on the components andResearch on Oil Mist Leakage of Bearing in Hydropower Station: 2021年3月1日 The dynamic risk trend of heating furnace was predicted eventually, the probability of oil and gas leakage caused by heating furnace is about 126E07 after two yearDynamic risk assessment of oil and gas leakage in

Leakage detection techniques for oil and gas pipelines: Stateof

2020年4月1日 Oil and gas pipeline leakage is one of the common types of accidents and is also one of the main causes of heavy losses (Lu et al, 2020d)The leakage accident not only affects the normal operation of the pipeline, but also threatens the environment and personal safety (Lu et al, 2020b, Lu et al, 2020c)On June 28, 2012, a natural gas pipeline in British Columbia 2023年6月22日 Nearly 40% of the places where hydrogen safety accidents have occurred in the past 20 years are located in laboratories [1]Compared with facilities such as hydrogen refueling stations, the internal space of the laboratory is closed, and scenes similar to the laboratory include tunnels, car compartments, engine compartments, private garages, and underground parking Simulation and risk assessment of hydrogen leakage in hydrogen The Line Leakage test is actually a general term that is used to describe a series of tests There are 4 different types of LLTs: Earth Leakage test, Enclosure Leakage test, Patient Leakage Current test, and Patient Auxiliary Current test Each test is performed under nominal operating conditions as well as in a variety of fault conditionsLine Leakage Testing: Is It Right For Your Application2023年1月20日 Leakage can be either external or internal; in an external leak, the fluid exits the system, usually by a hole or a small tear in the line An internal leak, on the other hand, is often intentional — moving hydraulic fluid to lower pressure areas to allow for maintenance or cleaning; internal leakage in a hydraulic cylinder becomes a problem when the amount of fluid leaking Types, Causes, and Dangers of the Hydraulic Leakage Cylinders, Inc

Crossleaking fault AAPG Wiki

2022年3月24日 Common hydrocarbon contacts imply communication across the fault and cross leakage The crossleaking fault in Figure 1 shows two sands, R u and R d, juxtaposed by a fault The two sands have common oilwater(OWC) and gaswater (GWC) contacts The fault is cross leaking to both oil and gas Common freewater levels A crossleaking fault can 2014年1月1日 Wear caused by contaminated oil or frequent reciprocating of the spool is the chief source of internal leakage in electrohydraulic directional valvesInternal Leakage Fault Feature Extraction of Hydraulic Cylinder 2011年12月19日 Corpus ID: ; Application of Fuzzy Fault Tree Analysis on Oil and Gas Offshore Pipelines @article{Lavasani2011ApplicationOF, title={Application of Fuzzy Fault Tree Analysis on Oil and Gas Offshore Pipelines}, author={Mohammad Reza Miri Lavasani and J L Wang and Z Yang and Jamie Finlay}, journal={The international journal of marine science}, Application of Fuzzy Fault Tree Analysis on Oil and Gas Take for example a leak with a rate of about one drop per second; it would take less than a day for a gallon of oil to leak out That means a typical process pump would be out of oil during a single eighthour shift For a large oil reservoir, this could add up to more than 400 gallons of oil lost over the course of a yearUnderstanding and Managing Oil Leaks Machinery Lubrication

An investigation of oil leakage from automotive driveshaft radial

2022年10月3日 The leakage from the shafts during the breakin cycle was considered for the experiments This is also in line with the current research objective, which intends to examine any potential correlation between the measured leakage and the shaft surface topographical parameters as obtained from the production line