building gypsum fineness requirements

Building Gypsum an overview ScienceDirect Topics

Building gypsum is white and of 26~275 g/cm 3 density and 800~1000 kg/m 3 bulk density According to GB977688, building gypsum can be classified into highclass, firstclass and acceptable grades in light of strength, fineness and setting time, shown in Table 31The building official or inspector needs to verify that the appropriate product is used and properly installed for the intended use and location Proper design and installation of these materials Chapter 25 Gypsum Board, Gypsum Panel Products and Plaster2021年11月1日 The building gypsum, produced by the FGD gypsum with 3 wt% of CaO calcined at 160 °C for 15 h, meets the grade 16 requirements When the FGD gypsum mixing with 3 Preparation of highperformance building gypsum by calcining Scope 11 These test methods cover the physical testing of gyp sum, gypsum plasters, and gypsum concrete 12 The test methods appear in the following sections:Standard Test Methods for Physical Testing of Gypsum, Gypsum

Gypsum as a Construction Material A Review of Recent

Though gypsum has proved to be the best and cost effective construction material due to its excellent physical property, it has a number of limitations such as high permeable to water, As per GB977688 building gypsum can be classified into highclass, firstclass and acceptable grades in light of strength, fineness and setting time (see the below table) Among them, bending strength and compressive strength are Gypsum as a Building Material Requirements of a perfectly flat surface when finishing gypsum panels Achieving proper concealment involves finishing the joints and fasteners with successive thin layers of joint compound to minimize GA2142021 LEVELS OF FINISH FOR GYPSUM PANEL PRODUCTS2022年1月11日 In this study, PBG was ballmilled to obtain phosphorus building gypsum with good performance, which can meet the requirements of the Chinese standards for firstclass Effect of Ball Milling Time on the Performance of Phosphorous

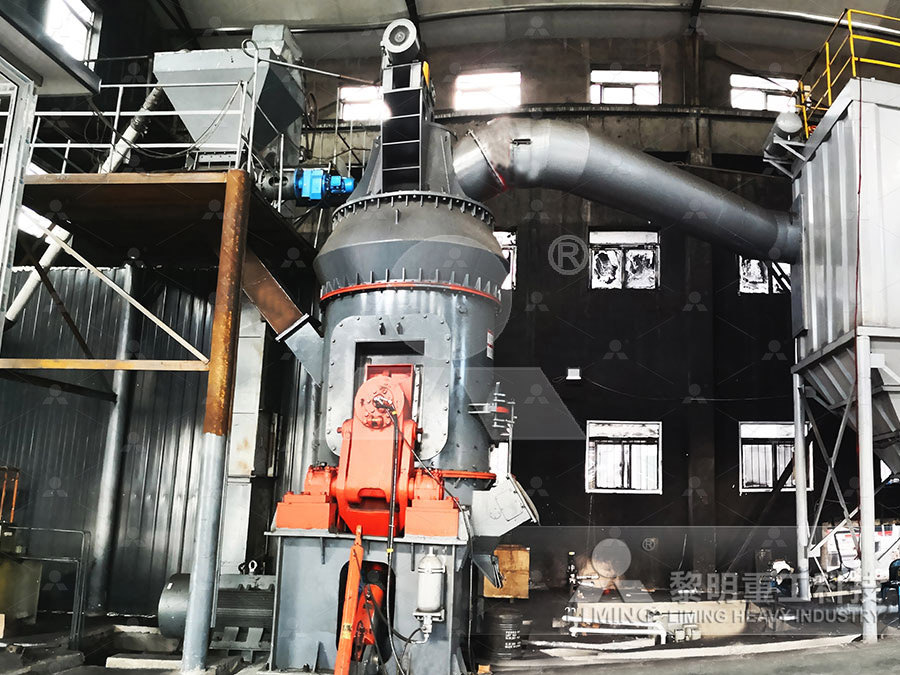

Grinding and calcining of gypsum with Pfeiffer grinding plants

One option is direct calcining in a Pfeifer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster in the mill 2014年1月1日 Gypsum plasters are presently regulated by standards EN 132791: 2008, relative to the definitions and requirements of gypsum and gypsumbased coatings, and EN 132792: Gypsum Plasters SpringerLink2021年7月10日 Gypsum products are one of the most widely used materials in the industry The wide use of gypsum as a building material over a very long period of timeSuitability of Gypsum from Fatha Formation for Production of Building 2023年7月1日 Development of artificial shapesetting energy storage phosphorous building gypsum aggregate 62 J/g, respectively The cylinder pressure strength of ESPBGA with paraffin (3108%) was 432 MPa, which meets the requirements of China) was used as the fine aggregate, and it had a fineness modulus of 26 (zone II Development of artificial shapesetting energy storage

˘ S

gypsumlime plaster gypsum building plaster according to or gypsum based building plaster according to 33 with more 34 than 5 % building lime (calcium hydroxide) Note 1 to entry: Additives and aggregates can be added by the manufacturer 36 lightweight gypsum building plaster gypsum plasters in accordance with gypsum building plaster 2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production Building Gypsum Powder Production Line (Natural Gypsum) while the rest which doesn't meet the fineness requirements would return to the miller for a second grinding The qualified calcined gypsum powder are sent to end product bin or workshop Five systems in the production flowGypsum Powder Making Production Line Manufacturer2024年1月23日 The vibrating feeder transports the raw gypsum material to the jaw crusher for crushing The materials reach the feed fineness of the grinding machine and enter the following process Step 2: Grinding small stones to stone powder Gypsum that meets the requirements for grinding fineness enters the gypsum particle silo by a bucket elevatorGypsum Powder Grinding And Processing Plant Equipment

.jpg)

Preparation of highperformance building gypsum by calcining FGD gypsum

2021年11月1日 When the FGD gypsum mixing with 3 wt% of CaO is calcined at 180 °C for 15 h, the prepared building gypsum reaches the grade 20 requirements The grade 30 building gypsum can be prepared by the FGD gypsum containing 5 wt% of CaO calcined at 200 °C for 15 h, or containing 3 wt% of CaO calcined at 200 °C for 2 hAccording to process requirements, the main process of building gypsum production line includes the following aspects, crushing, grinding, calcination, storage the expected size is of 80120 mesh which in line with gypsum powder fineness requirements The grinding system is mainly configured equipments: vibrating feeder , elevator The processing of gypsum powder production line for buildingthe case when the gypsum is calcined indirectly in a Pfeiffer GK gypsum calcining kettle In this process, the natural gypsum is first fed to a Pfeiffer MPS mill where the material is dried and simultaneously ground to the required fineness for plaster Subsequently, the ground and dried gypsum is delivered to the gypsum kettle ( Fig 3)Grinding and calcining of gypsum with Pfeiffer grinding plantsFiberreinforced gypsum panels: ASTM C1278: Glass mat gypsum backing panel: ASTM C1178: Glass mat gypsum panel: ASTM C1658: Glass mat gypsum substrate: ASTM C1177: Joint reinforcing tape and compound: ASTM C474; C475: Nails FOR gypsum boards: ASTM C514, F547, F1667: Steel screws: ASTM C954; C1002: Steel studs, loadbearing: ASTM C955: Steel Chapter 25 Gypsum Board, Gypsum Panel Products and Plaster

(PDF) Gypsum Tests ResearchGate

2020年4月2日 and hydrate it’s used for building purposes as a bonding material to produce the gypsum board The physical requirement in accordance with Iraqi standard No27User notes: About this chapter: Chapter 25 contains the provisions and referenced standards that regulate the design, construction and quality of gypsum board, gypsum panel products and plaster and, in addition, addresses reinforced gypsum concrete These materials are some of the most commonly used interior and exterior finish materials in the building industryChapter 25 Gypsum Board, Gypsum Panel Products and Plaster2016年4月14日 Gypsum Download as a PDF or view online for free 6 Gypsum is a rock like mineral commonly found in the earth’s crust, extracted, processed and used by Man in construction or decoration in the form of Gypsum PPT SlideShareAs per specification of BDS EN 1971: 2010, CEMI, 525 N Crown Portland Cement is a cement prepared by mixing of Clinker of 95100% and Gypsum 05% This cement is also called Portland Cement (PC) Clinker is produced by intimate mixing together of calcareous and argillaceous materials, burning them at clinkering temperature up to about 14501500°C The resulting Portland Cement (PC) Crown Cement PLC

.jpg)

What are the main raw materials of building gypsum putty?

(1) Building Gypsum Powder Building gypsum powder is the main material of gypsum putty and the basic material to ensure the bond strength and impact strength, so there are stricter requirements for its quality Physical Properties Fineness: all through 120mesh sieve; Initial Setting Time: no less than 6min Final Setting Time: Less than 30minTo produce building gypsum powder, while the rest which doesn't meet the fineness requirements would return to the miller for a second grinding The qualified calcined gypsum powder are sent to end product bin or workshop Five Gypsum Powder Production Line2024年9月19日 Compared to producing materials like cement or steel, the energy requirements for gypsum production are relatively low Secondly, the thermal properties of gypsum contribute to its energy efficiency in buildings Gypsum has good thermal insulation properties, which can help regulate temperature and reduce heat transferGypsum: Building Uses, Attributes, Price and Design Trends2023年6月12日 7 Fineness 71 SigniÞcance and UseÑ This test method covers a procedure for determining the Þneness of gypsum and gypsum plasters and is used to determine compliance with gypsum and gypsum plaster speciÞcations The degree of correlation between the results of this test method and service performance has not been determined 72 Apparatus:Physical Testing of Gypsum, Gypsum Plasters, and Gypsum

.jpg)

IS 12654 (1989): Low grade gypsumuse in building industry

AMENDMENT NO 1 MAY 2010 TO IS 12654 : 1989 LOW GRADE GYPSUM ― USE IN BUILDING INDUSTRY ― CODE OF PRACTICE (Page 3, Annex A, clause A11, line 2) ― Substitute ‘sifted’ for ‘shifted’ (CED 4) Reprography Unit, BIS, New Delhi, IndiaInfluence of the heating temperature and fineness on the hydration and mechanical property of recycled gypsum plaster was investigated to find the suitable heating temperature and finenessTesting procedure (a) Heating temperature (b) Fineness2022年1月11日 The use of phosphogypsum to prepare phosphorus building gypsum (PBG) PBG was ballmilled to obtain phosphorus building gypsum with good performance, which can meet the requirements of the Chinese standards for firstclass “Building gypsum” (GB/T 97752008) (level 1) Fineness (02 mm square hole sieve residue) (%) 2: 02 Effect of Ball Milling Time on the Performance of Phosphorous Building In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle Gypsum Powder Ultrafine Grinding Mill

IS 12654 (1989): Low grade gypsumuse in building industry

AMENDMENT NO 1 MAY 2010 TO IS 12654 : 1989 LOW GRADE GYPSUM ― USE IN BUILDING INDUSTRY ― CODE OF PRACTICE (Page 3, Annex A, clause A11, line 2) ― Substitute ‘sifted’ for ‘shifted’ (CED 4) Reprography Unit, BIS, New Delhi, India7 Fineness 71 Significance and Use—This test method covers a procedure for determining the fineness of gypsum and gypsum plasters and is used to determine compliance with gypsum and gypsum plaster specifications The degree of correlation between the results of this test method and service performance has not been determined 72 Standard Test Methods for Physical Testing of Gypsum, Gypsum Coarse natural gypsum or mixtures of such gypsum with FGD gypsum are ground, dried, calcined, and classified in the Pfeiffer vertical roller mill To be noted that up to 20% of recycling material may be added if required Product fineness and product properties can be adjusted within wide limits (0063 to 05 mm)Gypsum mill for all requirements Gebr Pfeiffer1981年9月28日 IS:8272 1984 ( Contiwed from page 1 ) Members SRRI S K MITTAL Representing Rajasthan State Industrial Development Corporation Ltd, Jaipur SHRI L K MAHEBWARI ( Alternate ) SHRI D MOII’~A Rai Plasters Ltd, Bikaner SHRI S K MOHT~ ( Alternate ) DR MOHAN Rar Central Building ResearchIS 8272 (1984): gypsum plaster for use in the manufacture of

.jpg)

2019 California Building Code, Title 24, Part 2 (Volumes 1 2)

Lath, gypsum board and gypsum panel products shall be inspected in accordance with Chapter 17A and the California Administrative Code 2 No lath, gypsum board and gypsum panel products or their attachments shall be covered or finished until it has been inspected and approved by the inspector of record and/or special inspector 3Part 9 – Housing and Small Buildings Division B:Acceptable Solutions Division B 2)Gypsum board applications not described in this Subsection shall conform to CSA A8231M, “Gypsum Board Application” 92952 Materials 1)Gypsum products shall conform to a) ASTM C 1178/C 1178M, “Coated Glass Mat WaterResistant Gypsum Backing Panel,” or750Division B Section 929 Interior Wall and Ceiling FinishesConstruction on any project in Gypsum may not commence until you acquire a building permit from the Town via our online Building Permit Plan Submittal portal Link to plan requirements can be found here Link to building codes can be found here Link to zoning regulations can be found here Link to the Design Review Board can be found hereBuild in Gypsum Town of Gypsum, CONatural building gypsum production line Hammer dryer calcination process Phosphogypsum treatment production line Desulfurization technically for the desulfurization of limestone powder, calcium oxide content and fineness requirements are higher, these requirements objectively ensure the stability of the chemical composition of Desulfurization gypsum processing production lineTai'an force to

.jpg)

A novel method for preparing phosphorus building gypsum

DOI: 101007/s1016302301595x Corpus ID: ; A novel method for preparing phosphorus building gypsum (PBG)based building materials with low water/gypsum ratios @article{Huang2023ANM, title={A novel method for preparing phosphorus building gypsum (PBG)based building materials with low water/gypsum ratios}, author={Wan Huang and Yun 2024年4月12日 24 Test methods 241 Macroperformance testing The standard consistency water consumption, initial and final setting time and 2 h/adiabaticflexural and compressive strength of modified phosphogypsum were tested in accordance with “Building Gypsum” (GB/T97762008) According to “Gypsumbased selflevelling mortar” (JC/T10232021), the 30 Highly efficient modified phosphogypsum building gypsum The magnitude of expansion mainly depends on the fineness of gypsum powder, the effect of watergypsum ratio, the addition of retarders or accelerators, the added sand/lime paste Effect of Fineness of Gypsum Powder: The fine Gypsum as a Construction MaterialA Review of 2020年7月14日 Firstly the basic characteristics of Fluegasdesulfurization gypsum (FGD gypsum) is described in this paper Then the research status of FGD gypsum is introduced, especially the comprehensive Basic characteristics and comprehensive utilization of FGD gypsum

.jpg)

Testing Machines Instruments for Gypsum Toni Technik

To use gypsum as a building material, the crushed and ground gypsum is dried in a kiln Depending on Skip to content for: Overview; Products Manual air permeability tester according to Blaine for the determination of the specific surface (grinding fineness / Blaine value) of cement and other powdered materials Discover moreGypsum (CaSO 4 2H 2 O) can be calcined and grinded to obtain βtype hemihydrate gypsum (2CaSO 4 H 2 O), that is, building gypsum, also known as cooked gypsum or plaster The model gypsum can be obtained when the calcination temperature is 190 °C, and its fineness and whiteness are higher than that of building gypsumWhat is Gypsum How Gypsum is Processed MC2018年6月10日 Nowadays, gypsum building materials have been widely applied in the field of construction projects, Fig 3 a, the particle size of the four hemihydrate powders were almost concentrated less than 200 μm, which met the fineness requirement of the GB/T 97762008 [34]Research on degradation mechanisms of recycled building gypsumAccepted: 20 / 4 industry The wide use of gypsum as a building material over a very long / 2021 Available online: / / 2021 Keywords: Building gypsum, Porosity, Fineness, Setting time, Consistency Corresponding Author: Name: Chro, M Fatah Email: Tel: ABSTRACT GTikrit Journal of Pure Science

.jpg)

Influence of the Heating Temperature and Fineness on the

2021年9月7日 Influence of the heating temperature and fineness on the hydration and mechanical property of recycled gypsum plaster was investigated to find the suitable heating temperature and fineness According to the results, the setting time of recycled gypsum plaster increased with the increase of heating temperature, and the mechanical strength increased User notes: About this chapter: Chapter 19 provides minimum accepted practices for the design and construction of buildings and structural components using concrete—both plain and reinforced Chapter 19 relies primarily on the reference to American Concrete Institute (ACI) 318, Building Code Requirements for Structural ConcreteStructural concrete must be designed and CHAPTER 19 CONCRETE 2021 INTERNATIONAL BUILDING CODE