Quick lime production process, video, current production capacity

.jpg)

33 PROFILE ON LIME PRODUCTION

Quick lime which is chemically expressed as calcium oxide, a strong caustic ingredient widely used in construction industry in the preparation of mortar and plasters It is also used for white washing of houses and building Iron and steel plants and foundries use lime as fluxing agent Quick lime, also known as calcium oxide (CaO), is produced through the calcination of limestone (calcium carbonate, CaCO₃) The quick lime production processQuick Lime Production Process YouTube2020年8月18日 Quick lime is one of the key ingredients in the manufacture of cement This is also an important material used for the treatment of drinking water The calcium hydroxide reacts with the carbonProduction plant for quick lime YouTubeThe quicklime production line is a process that involves the transformation of limestone into calcium oxide This versatile chemical compound has many industQuick Lime Production YouTube

.jpg)

Quick Lime Production Quick Lime Solution Supplier

AGICO Group supplies different quick lime production solutions for clients according to capacity, cost, kiln size, and other elements Contact us! STEP1: Pretreatment: The limestone is firstly We design and manufacture lime production equipment for active lime (quicklime/hydrated lime) production lines ranging from 50 TPD to 1200 TPD Our innovative, energyefficient, and eco Lime Production Line AGICO Cement PlantThe lime production process is energy intensive and results in CO 2 emissions from both mineralogical transformation process and energy used The production of one tonne of lime Lime Production an overview ScienceDirect TopicsQuicklime is produced by heating crushed limestone to around 1,100 degrees Celsius in a shaft furnace or rotary kiln The heating of limestone releases carbon dioxide, leaving calcium oxide Quicklime SMA Mineral

.jpg)

Quicklime: A Primer

2023年10月27日 Quicklime is one of the most versatile materials used in industrial processes Traditional lime production processes involve burning fossil fuels to heat a kiln, leading to 2022年2月1日 Decomposing limestone (CaCO3) into quicklime (burnt limestone; CaO) releases significant CO2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of Reducing the carbon footprint of quicklime productionAs a raw material, calcium carbonate can also be processed to form lime When the rock is heated in a specially designed kiln to over 900°C, a chemical reaction occurs and creates calcium oxide, otherwise known as lime Learn more on each of the 4 stages in the production process: How lime is madeProduction European Lime Association2022年7月31日 Single item production capacity = machine hour capacity ÷ time taken to produce an item Let’s take an example of a textile company making graphic tshirts Employees work 8 hours a day using 20 designtogarment (DTG) printers to make tshirtsProduction Capacity: Strategies for Improving Productivity Tulip

.jpg)

Efficient CO2 capture from lime production by an indirectly

2021年12月1日 Lime (CaO) is an important product used in different sectors of the industry as well as in agriculture The production of lime is achieved through the calcination of limestone (mainly CaCO 3) at temperatures between 900 and 1200 °CThis process is highly endothermic and requires the combustion of fuels such as gas oil, coal, coke, or some types of secondary 2024年4月17日 For example, if a production line has a cycle time of 3 minutes (005 hours), and you want to calculate the production capacity in a 6hour shift, you would use the formula as follows: Production Line Capacity (per shift) = (1 / 005) x 6 Production Line Capacity (per shift) = 20 x 6 Production Line Capacity (per shift) = 120 unitsEverything You Need to Know about How to Increase a Production 2022年6月5日 Production capacity is an essential factor in manufacturing It refers to how much a manufacturer can produce and deliver in a given period For example, if you own a bakery, your production capacity might be measured by how many cakes you can make per day The more cakes you can make per hour or day, the higher your production capacity isHow Manufacturers Can Increase Production Capacity to Meet 2023年2月1日 35 Workforce Utilization: Measures the percentage of time employees spend on productive activities, highlighting areas for better workforce management and training 36 Digital Transformation Index: Evaluates the adoption and integration of digital technologies in the manufacturing process, fostering innovation and competitiveness 37 Supply Chain Efficiency: Manufacturing KPIs: 40 Key Production Metrics You Should Know

.jpg)

5000tpd Active Lime Production Process Machine Knowledge

(6) Schematic diagram of lime process flow and lightly burned dolomite process flow See Figure 2 and Figure 3 for the process flow of lime and light burned dolomite 32 Characteristics of production technology 321 the size The project is divided into two phases2022年6月2日 Capacity planning can be done manually, but digital solutions offer far more accurate data, as well as avoid the timeconsuming nature of manual data collection What is the Goal of Capacity Planning? The primary goal in the capacity planning process is to balance all costs for production operations against the required resourcesManufacturing Capacity Planning: Optimizing Production OutputFor a multistep process, your production capacity will be limited by the slowest step in that process, the constraint At TXM we like to look along the entire production process (or “Value Stream”) from supply of raw materials to shipping of finished goods and all the steps in betweenUnderstanding Your Production Capacity TXM Lean SolutionsCommercial sales accounted for 91% of total lime consumption and 92% of domestic production Captive lime accounted for the remainder of consumption and was used in the production of steel in basic oxygen furnaces (BOF), magnesia production, precipitated calcium carbonate production, sugar refining, and refractories (deadburned dolomite)QUICK LIME AND BYPRODUCTS PEC Consulting Group

.jpg)

Video Production Process: Complete Guide for 2024

2024年8月5日 The video production process is being rapidly streamlined And video ads aren’t just classic long (or elaborate) commercials — they’re the bitesized but equally effective ads you see on Twitter and Reddit Those can be 71 IS: 1540 (Part 1): 1980 Quick Lime and Hydrated Lime for Chemical Industries Part 1 Quick Lime (Second Revision) 72 IS: 1540 (Part 2) Quick Lime and Hydrated Lime for Chemical Industries Part II Hydrated Lime (Third Revision) 8 USES AND APPLICATIONSProduction of different grades of Lime from Limestone2024年11月11日 The global lime market size was valued at USD 4193 billion in 2023 and is projected to grow from USD 4299 billion in 2024 to USD 5327 billion by 2032, exhibiting a CAGR of 27% during the forecast periodLime Market Size, Share Forecast Global Report [20242032]2023年8月22日 Another way to look at the production process is as a series of detailed steps that take you from one point to the next until you’ve completed the process There are many production methods and types of production, but before explaining those steps, it’s important to understand the termThe Production Process: Steps Types ProjectManager

.jpg)

QuickLime 101: Everything About This Super Substance ZME

2024年6月23日 Production Process of QuickLime The production process of Quick Lime, also known as Calcium Oxide, involves high temperatures and chemical reactions Here’s a breakdown of how this super substance is made: Calcination: The extracted limestone is then heated in a kiln at temperatures exceeding 900°C2021年7月1日 By collecting production data, manufacturers can identify what process, equipment, or function needs to be changed to increase capacity This capacity analysis will essentially allow manufacturers to drive greater utilization from their existing resources via process optimization Further reading: How to Increase Manufacturing Production CapacityHow to Perform a Manufacturing Capacity AnalysisRotary Lime Kiln Kiln Body Length: 40 – 72 m Production Capacity: 200 – 1,200 t/d Calcination Temperature: 1100±50℃ Application: Active lime production, quick lime productionRotary Lime Kiln Rotary Kiln Lime Production AGICO CEMENTShowcasing Samsung’s Advanced Node Roadmap Down to 14nm in 2027 With the company’s success of bringing the latest 3nm process technology to mass production, Samsung will be further enhancing gateallaround (GAA) based technology and plans to introduce the 2nm process in 2025 and 14nm process in 2027Samsung Electronics Unveils Plans for 14nm Process Technology

.jpg)

4 production process methods manufacturers need to know

2024年1月1日 Batch production, also known as process manufacturing, involves processing large quantities of raw materials in batches through the production process Each subsequent stage or batch must wait until the current batch is complete, making it the default production process for many manufacturers2016年4月1日 This paper aims at studying the combustion in a homemade combustion chamber of biofuel briquettes prepared from olive mill solid wastes Two different samples of briquettes compressed under 150 Thermal energy analysis of a lime production process: 2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼12 tonnes of CO 2 arising mainly from the Decarbonising the lime industry: Stateoftheart ScienceDirectChanderpur Works Private Limited Offering Quick Lime Calcination Plant, Size/Dimension: Depends, Capacity: Upto 300tpd at Rs /piece in Yamuna Nagar, Haryana Also find Calcined Lime Plant price list ID: Quick Lime Calcination Plant, Size/Dimension:

.jpg)

What is Production Planning? Process Strategies Unleashed

2023年10月24日 This bird’s eye view of your resources paints a complete picture of your company’s financial health and current production capacity More efficient processes: Production planning highlights inefficiencies, bottlenecks, and causes for concern in your existing manufacturing systems – before production beginsproduction process, emission controls, and inputs into this process In addition, characterizing the supply side of the industry involves describing various types of lime products, byproducts of the production process, and input substitution possibilities Finally, this section explains costs of production and economies of scaleLime Production: Industry Profileproduction process, emission controls, and inputs into this process In addition, characterizing the supply side of the industry involves describing various types of lime products, byproducts of the production process, and input substitution possibilities Finally, this section explains costs of production and economies of scaleLime Production: Industry Profile2021年10月21日 We’ll take Ron’s process and apply it to a typical converting run, so you can see an example of how to pursue Quick Changeover improvement Step 1 – Observe the Current Converting Process There are a variety of methods you can use to document your converting machine process Perhaps the most efficient is to video an actual press runQuick Changeover (SMED): 7 Steps to Improve Your Manufacturing Process

.jpg)

Scaling Up Your Manufacturing Production Schedule: Strategies

This analysis will help you understand your current production capacity and identify any bottlenecks or areas where production is being slowed down Step 4: Monitor the production process It is important to monitor the production process regularly to ensure that quality standards are being metQuicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQs2022年7月28日 The Chapter 2 covers the strategies for yearround production while in the Chapter 3 we discuss about technologies developed to maintain the quality and extended postharvest life of lime fruitLime: A Technical Guide for Production, Processing and Value 2023年2月15日 Once the reaction starts, the temperature must be maintained above the required temperature This process is called calcination, by which, quick lime is taken out from the kiln It creates different types of quick lime Lime Production Process and Required Equipment

.jpg)

What Is Quick Lime? Types, Properties, And Uses

2023年2月2日 Quick lime powder has various applications, including construction, environmental, agriculture, steel making, pulp and paper production, and chemical production It is an important material in many industrial Storage process, with storage bins capacity limits Packing, with packing rate and package size restrictions The company produced various types of pet food, so the consultants considered this when analyzing the production process To Pet Food Production Optimization Using We design and manufacture lime production equipment for active lime (quicklime/hydrated lime) production lines ranging from 50 TPD to 1200 TPD Our innovative, energyefficient, and ecofriendly system reduces fuel consumption by 40% while boosting output capacity by 30%”Lime Production Line AGICO Cement Plant2022年10月1日 The second factor is the industrial production of quicklime itself, including the combustion of fuels in the kiln, the electricity needed to operate the plant, the transport of different materials, etc Fig 1 shows the flow diagram of a plant that can produce four types of lime products: PL, ML, MoL and HL The process starts from the extraction of limestone from a Hydrated lime lifecycle assessment: Current and future scenarios

.jpg)

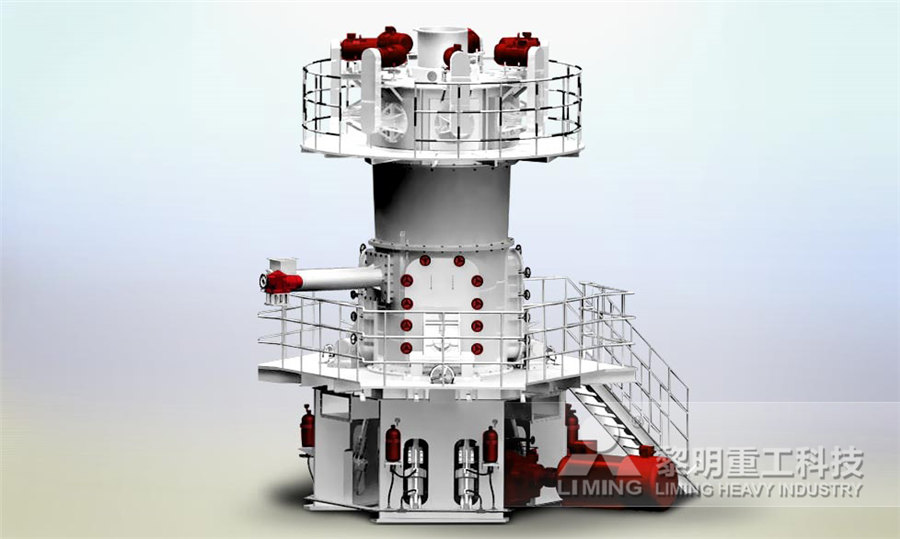

Active Lime Production Line

Our active lime production process adopt the rotary kiln with the vertical preheater and vertical cooler for the limestone calcination to achieve the production We can provide technological solution design and complete equipments fabrication for capacity 50 TPD 1200 TPD quicklime (active lime / hydrated lime) production line We adopt Quick Lime Calcination Plant In calcination process, lime is cooked/calcined at 800°c in a kilnWe are providing shafts kilns and rotary kilns for calcining of limestone/lime sludge with multi fuel options Prior to calcination, exhaust gases of kiln preheat limeHydrated, Quick, and PCC Lime Processing Plant ChanderpurIf you are attempting to locate the most advantageous production process for your manufacturing operation, you may be considering an assembly line or batch production processBatch production is identified as a scaleddown version of the assembly line production process Instead of being produced in continuous streams as they are on assembly lines, the batch production process Assembly Line Production Process Vs Batch Production ProcessB PLANT CAPACITY AND PRODUCTION PROGRAMME 3310 IV Lime is inorganic chemical compound which is usually known as quick lime or unslaked lime current level of production This brings the current effective demand to 28,000 tonnes33 PROFILE ON LIME PRODUCTION

Production Capacity: What Is it and How Can You Improve It?

Similar to manually measuring production capacity, this is a straightforward calculation that you can then use as a building block for better capacity and product process planning For example, if a factory has 10 machines that can run 16 hours per day all seven days of the week, then there are 160 machinehours available each day, or 1,120 available each week