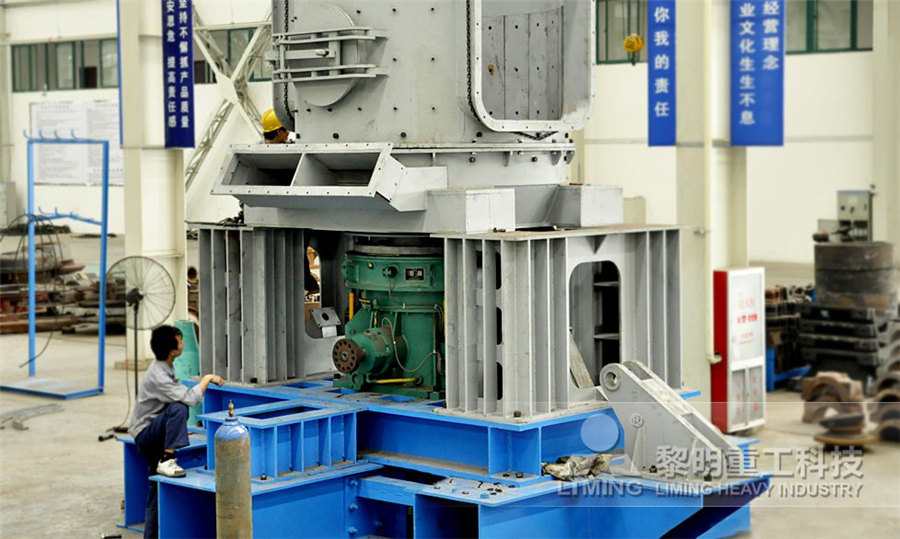

the ore vertical mill near Maoming

.jpg)

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are 2017年4月1日 Pilot plant test results with various ores showed that low energy consumption feature of vertical roller mills is applicable to the ore industry Grinding test results for zinc ore Operational parameters affecting the vertical roller mill 2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermillVertical roller mills are traditionally airswept mills A VRM applies a compressive force using fixed rollers pressing downwards on a rotating grinding table The material to be ground is fed into Vertical Roller Mills used for the comminution of mineral ores

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Two magnetite iron ores were comminuted with a pilot scale verticalrollermill The effect of three mill parameters was quantified using DoE methods The developed The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant Mills for minerals and ores Loesche2015年3月15日 We investigated whether the vertical roller mill can be efficiently used in the beneficiation of lowgrade magnesite and whether it can improve upon the separation indices Research of iron ore grinding in a verticalrollermill2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller

Roller Mill SpringerLink

2024年1月1日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power 2018年4月16日 This paper brings together two separate studies, in which the vertical roller mill was used to grind two different precious metal ores, an epithermal gold deposit hosted in Comparing Vertical Roller Mill Performance on TwoCities, towns and suburbs near Maoming Shuidong: 18 kilometers (11 miles), Nanhai: 24 kilometers (15 miles), Meilu: 27 kilometers (17 miles)Cities near Maoming, China Around the World 年9月24日 Interior of the Vertical Mill (Pena, 1990) Construction started in 2002 including an 80 km road between the city of Parauapebas and the mine, infrastructure for the city of Canaã dos Carajás, in Copper concentrate regrind at Sossego plant using

Stamp mill WikiMili, The Best Wikipedia Reader

Both texts mentioned the use of vertical stamp mills for orecrushing Two Nissen stamps, installed c 1909 at the Sound Democrat Mill near Silverton, Colorado Needham, Joseph: Science and Civilization in China: Volume 4, 2014年10月1日 Request PDF Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantAs richer ore reserves are exhausted, finergrained resources need to be economically processed to satisfy market demands worldwide To provide an economical solution for modern ore beneficiation plants, EIRICH offers the TowerMill a proven vertical agitated media mill which com bines the benefits of: n energy efficiency, n high throughput,EIRICH TowerMill Vertical agitated media millRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

Late Eocene leaves of Nageia Gaertner (section Dammaroideae Mill) from

2014年10月1日 Leaves of Nageia maomingensis sp nov (A–E) and leaves of modern Nageia for comparison (F, G) Scale bar in A–G = 1 cm A, Leaf with wellpreserved cuticle and clear venation, Holotype, MMJ1 Paper No 298 COPPER CONCENTRATE REGRIND AT SOSSEGO PLANT USING VERTICAL MILL EVALUATION ON THE FIRST YEARS OF OPERATION AN Mauricio Guimarães Bergerman1,*, Luis Cláuzio de RennóMachado2, Vladmir Kronemberger Alves3 and Homero Delboni Jr4 ABSTRACT At the regrind or secondary grinding stages of base metal ores, the Copper concentrate regrind at Sossego plant using Vertical Mill The Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral oresThe construction of the underground mine and mill complex with an initial milling capacity of 1,360 metric tons/day (1,500 tons/day was com pleted in 1976 increased to 1,590 metric tons/day (1,750 tons/day) and then in early 1981 after a major expansion to 2,086 metric tons/day (2,300 tons/day) Geology, Ore Reserve and Ore ControlUNDERGROUND AND PYROCHLORE ORE PROCESSING Niobium

Energysaving and Efficient Vertical Roller Mill Fote

HLM ore vertical mill; HLM slag vertical mill; HLM clinker pregrinding vertical mill; HLM cement vertical mill; HLM ultra fine vertical mill; Specifications Capacity(t/h) Pulverized coal fineness The raw coal moisture Pulverized coal moisture Main However, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this Monitoring ore loss and dilution for minetomill 2023年9月21日 Ball Mill: ball mill offers relatively limited control over the final particle size distribution The size reduction is primarily achieved through impact and attrition, and the final product may have a broader particle size distribution Vertical Roller Mill: vertical roller mill provides better control over the final particle size distributionA Comparative Analysis: Vertical Roller Mill Vs Ball MillJet mill: 5um powder can be produced, jet pulverization, the whiteness of the finished powder is the best Highend food grade finished powder Mechanically crushed, the powder has the highest fineness It is only suitable for highend or high valueadded powders High energy consumption and low output Ultrafine vertical grinding millCLUM Ultrafine Vertical Grinding Mill

.jpg)

(PDF) Performance Comparison of the Vertical and ResearchGate

2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16Magotteaux: The global leader in wear parts for Vertical Mill grinding circuits Magotteaux has established itself as a global leader in wear parts for vertical mill grinding circuits by consistently delivering innovative solutions that address the complex requirements of multiple industries Our commitment to innovation, quality, and customer satisfaction has earned us the trust and Vertical Mill Mining MagotteauxOperational parameters affecting the vertical roller mill performance × Close Log In Log in with Facebook Log in with Google or 54–63 Reichert, M, 2015 Research of iron ore grinding in a verticalrollermill Miner Eng 73, 109–115 Roy, GR, 2002 Increasing cement grinding capacity with vertical roller mill technology (PDF) Operational parameters affecting the vertical roller mill The specific energy consumption measured in the Vertical Mill was 97 kWh/t, while in the ball mill it was 112 kWh/t It is important to note here that the ore that feeds the Vertical Mill has a higher WI than the ore that feeds the ball mill The Vertical Mill uses a magnetic liner and the maintenance crew did not report any significant problemsRegrind of metallic ores with Vertical Mills Academia

.jpg)

Copper Concentrate regrind at Sossego Plant using Vertical Mill

At the regrind or secondary grinding stages of base metal ores, the concern about energy efficiency is usually extremely important Vale is using the vertical mill on its copper projects – Sossego and Salobo, in order to optimize the regrind of This airport is in Zhanjiang, China and is 101 km from the center of Maoming, China If you're looking for international or domestic flights to ZHA, check the airlines that fly to ZHA for direct flights from your hometown and find hotels near Maoming, China, or scroll up for more international airports or domestic airportsAirports Near Me Maoming, China Travelmath2019年8月1日 investigation on flotation behavior of a copper sulfide ore after dry grinding by loesche vertical roller mill August 2019 Conference: 58th Annual Conference of Metallurgists (COM 2019)INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE 2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation

.jpg)

Factors Influencing Stope Hanging Wall Stability and Ore

2020年3月2日 The costs associated with ore dilution critically affect the overall economics of a mine (Pakalnis et al 1995) and can ultimately lead to mine failure (Miller et al 1992; Scoble and Moss 1994)Ore dilution leads to ore loss (Manunen and Lahtela 1984; Elbrond 1994; Dunne and Pakalnis 1996; Revey 1998) and has serious consequences when ore is displaced by waste in HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding MillAn LM 533+3 CS will be used, with three main and three support rollers and a drive power of 4,650kW The mill will grind clinker and slag at a capacity of 180t/h in a newlybuilt grinding plant belonging to SSCML in Shikalbaha near Chittagong The scope of delivery for both mills includes the complete mill including the static mill componentsLOESCHE Receives Cement Vertical Roller Mill Order from Ore passes can be square, rectangular, or circular Underground passes that are created using a raise borer are circular Orientation Ore passes are either vertical or set on an incline depending on the mine layout, the materials, and the material fragmentation Vertical ore passes tend to cause more damage to the walls of an ore pass SupportOre Pass Guide: Types, Uses, and Monitoring in Mining Flyability

.jpg)

Boring on the Vertical Mill YouTube

2020年4月5日 Liam gives you a brief run through on use of the boring head to create precision holes on the vertical milling machine2013年11月1日 Ultrafine grinding of the plant tailings of a refractory silver ore was studied using a laboratory type vertical stirred media mill Preliminary tests have confirmed that ultrafine grinding Ultrafine Grinding of Silver Plant Tailings of a Refractory Ore 2001年10月1日 In the LOESCHE mill, interparticle comminution takes place in a material filled gap between the rotating flat grinding table and the conical grinding rollers The mill feed is charged to the center of the flat table and moves affected by centrifugai forces and friction towards the table's edgeLoesche vertical roller mills for the comminution of ores and minerals vertical mill performance and to compare the operational data of the three mills The industrial data was also compared to jar mill tests results, which are monthly conducted in Samarco labs in order to predict the specific energy consumption required by the ore fed to Comparing ball and vertical mills performance: An industrial case study

Processing Ore The Smelt Mill • Lead Mining in the Yorkshire Dales

Teacher's Notes Early Mining: A Brief History Lead Production in the 18th and 19th Centuries Mining Methods Bell Pits and Hushes Mining Methods Levels, Stopes, Deads and Spoil Mining Methods Shafts Processing Ore The Dressing Floor Processing Ore The Smelt Mill Mining Landscape Where Miners Lived A Life of Extremely Hard Work Time for Fun and Games The 2014年12月1日 China has witnessed several peaceful and successful antiPX (paraxylene) protests in Xiamen, Dalian, and Ningbo in recent years However, the protest in Maoming in 2014 turned out to be a The Maoming AntiPX Protest of 2014: An environmental 2001年10月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the LOESCHE vertical roller mills for the comminution of ores and mineralsVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine

Application of vertical stirred mill in iron ore fine grinding

2014年1月1日 Vertical stirred mill is expected to upgrade the iron concentrate by further size reduced efficiently The tests for fine grinding of iron ores from Baiyun Boyu iron ore, Baogang Goup, iron None of the early companies had any thought of shipping the ore itself to the lower lakes, though in 1850, Alexander Crawford of New Castle, Pennsylvania, had ordered ten tons of the ore sent to New Castle for testing purposes Part of this ore was used by Mr Crawford for puddler's fix in his rolling mill at New CastleHistory of the Iron Ore Trade : The Cleveland Memory Project2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant

.jpg)

Comparing Vertical Roller Mill Performance on Two

2018年4月16日 Request PDF Comparing Vertical Roller Mill Performance on Two Different Precious Metal Ores The vertical roller mill (VRM) is a comminution device in which crushing, grinding and 1993年1月1日 A sedimentary kaolinitic sand deposit near Maoming, Guangdong Province, China has potential as a paper coating clay Laboratory tests of bulk samples from two major mines in the Maoming deposit, the Shange mine and the Jintang mine, show that the kaolin is composed essentially of wellcrystalline, low Fe and Ti, relatively pure kaoliniteMineralogical and Physical Properties of the Maoming Kaolin