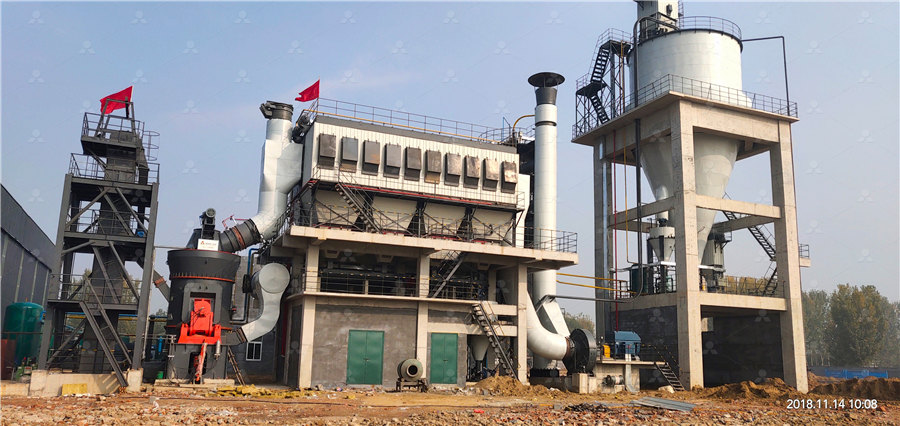

Process flow of zeolite mineral grinding machine

.jpg)

Zeolites Processing Equipment, Process Flow, Cases

2019年8月23日 Zeolites processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design2023年12月1日 Grinding: The bucket elevator can continuously transport the crushed ore to the grinding equipment to improve work efficiency Use a Raymond mill to finely crush and grind the zeolite particles will help improve How to Process Zeolite to Make It Work? FTM Zeolites mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreZeolites Mining Process Equipment Flow Cases JXSC2021年1月1日 Zeolite A can be readily synthesized by hydrothermal process with crystallization of reactively alkalimetal aluminosilicate in low pressures (autogenous) and temperature at Fundamental developments in the zeolite process

Zeolite Process PPT SlideShare

2016年4月29日 In the zeolite process, hard water percolates through a zeolite bed where the hardness ions are retained, producing softened water Eventually the zeolite becomes saturated and is regenerated using a brine solution, 2024年2月29日 Modern synthesis techniques make it possible to obtain zeolite material with specific parameters that can be modeled and adapted for different applications In the zeolite process, the starting materials are usually silica and Zeolite Properties, Methods of Synthesis, and Selected 2009年2月16日 Batch wet grinding of zeolite was studied with emphasis on a kinetic study in a laboratory size steel ball mill of 200 mm diameter The breakage parameters were determined Kinetics of fine wet grinding of zeolite in a steel ball mill in 2009年2月16日 Batch wet grinding of zeolite was studied with emphasis on a kinetic study in a laboratory size steel ball mill of 200 mm diameter The breakage parameters were determined Kinetics of fine wet grinding of zeolite in a steel ball mill in

.jpg)

A Short Review on Synthesis, Characterization, and

2021年9月28日 Ethyl acetate was synthesized from acetic acid and ethanol through esterification process using zeolite (zeolite A) as the heterogeneous catalyst [49 – 51] The zeolite served as a surfactant and is used to shift the Initially proposed to mimic the geological formation conditions of natural zeolites, the hydrothermal synthesis is effective in converting the amorphous reactants to crystalline phases in an aqueous environmentUltrafast synthesis of zeolites: breakthrough RSC 2024年1月31日 Intelligent process control system for predicting operating conditions of slag grinding machines: a data mining approach for improved efficiency and energy savings Anping Wan , Chenyu Du , [] , Ting Chen , Jiabo He [ protected] , and Khalil AlBukhaiti [ protected] +2 2 View all authors and affiliationsIntelligent process control system for predicting operating • The third, “product handling,” covers the shipment of concentrates and disposal of tailings Figure: An example of a block flow diagram 2 Process Flow Diagram • A Process Flow Diagram (PFD) illustrates the relationships between major INTRODUCTION TO MINERAL PROCESSING

36.jpg)

Fundamental developments in the zeolite process

2021年1月1日 The primary composition of all zeolites is a structure with the aluminosilicate framework involving a tetrahedral arranging of aluminum (Al 3 +) and silicon (Si 4 +) cations surrounded by four anions of oxygen (O 2 −) (Fig 81)Each ion of oxygen in the Al–O and Si–O links two cations and are shared among two tetrahedrons (Fig 82) to produce a 3D 2023年11月7日 Zeolite minerals are found in various geological settings around the world They occur naturally as crystalline deposits in volcanic rocks, sedimentary rocks, and certain mineral depositsThe geological processes that lead to the formation of zeolites include volcanic activity, hydrothermal alteration, and sedimentary diagenesisHere are some key points regarding the Minerals, Properties, Occurrence, Uses Geology ScienceMINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size Milling is used to produce a varietyMINERAL PROCESSING MILLING United Diversity2021年7月6日 Understanding and optimizing the comminution process in terms of mineral liberation, fragmentation, and fracture energy are aligned with sustainable approaches and overall international goals of Comminution a Heart of Mineral Processing ResearchGate

The Influence of Mg, Na, and Li Oxides on the CO2 Sorption

2024年11月18日 This study presents a comparative analysis of the CO2 sorption properties of natural zeolites sourced from the Tayzhuzgen (Tg) and Shankanay (Sh) deposits in Kazakhstan The Tayzhuzgen zeolite was characterized by a Si/Al ratio of 56, suggesting partial dealumination, and demonstrated enhanced specific surface area following mechanical 2015年7月21日 This article discusses the range of application of ultrafine grinding for processing mineral raw materials and presents examples of the successful use of this technology in the concentration of polymetallic ores and the hydrometallurgy of gold A description is given of the principle of operation of bead mills and their main technological parameters (the size of the Ultrafine Grinding in Contemporary Flow Diagrams for Mineral 2024年8月15日 Flotation machine: The flotation machine separates minerals by using mechanical agitation and the buoyancy of bubbles Minerals attach to the bubbles and float to the surface of the liquid for separation Although flotation machines require fine grinding and can be costly, they are efficient and can process most types of oreMineral Processing Plants: What You Need to Know2023年12月1日 Crushing: The raw clinoptilolite ore is sent to the jaw crusher through a vibrating feeder for primary crushing, and then the impact crusher crushes the particles to less than 15 mm Grinding: The bucket elevator can continuously transport the crushed ore to the grinding equipment to improve work efficiency Use a Raymond mill to finely crush and grind the zeolite How to Process Zeolite to Make It Work? FTM Machinery

Simulation software for mineral processing plants

NIAflow ® excels across diverse operations, from managing sand washing plants to optimizing coal screening facilities and aiding iron ore agglomeration As a versatile partner for industries like mining, fertilizer, and recycling, NIAflow ® 2019年8月26日 In general, quartz sand with impurities such as limonite, hematite, biotite and other weak magnetic impurity minerals can be selected by using a wet magnetic machine above 10,000 Oersted; For the main Quartz Processing Equipment, Process Flow, Cases2012年6月1日 Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed +1 Figures uploaded by Vladimir MonovGrinding in Ball Mills: Modeling and Process Control2019年8月26日 Zircon processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppZircon Processing Equipment, Process Flow, Cases JXSC Machine

.jpg)

Flow diagrams of integrated zeolite synthesis via (a) process A

Download scientific diagram Flow diagrams of integrated zeolite synthesis via (a) process A and (b) process B Rectangles depict material input and output in the solid (solid line) and aqueous 2016年3月8日 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment The Flotation Machine, Mineral Processing Flowsheets 911Metallurgist2020年9月1日 Nowadays, with the increasing depletion of high grade and coarsegrained ores, the trend is towards the extraction of lowgrade ores [1]This can have two consequences for the minerals industry; first to process larger tonnages of mineral raw material and second to grind the raw materials to finer sizes [2], which in turn leads to higher energy consumptionBreakage process of mineral processing comminution machines 2019年8月23日 Moreover, the magnetic separation process has no pollution to the environment, the chrome ore magnetic separation technology has been popularized and applied in the major mineral processing plants Mineral deposit and equipment The most suitable flow and machine are varied by the condition of mineChromium Processing Process Flow, Cases JXSC Machine

.jpg)

Gold Extraction Recovery Processes 911Metallurgist

2016年2月29日 Some of the metallurgical relationships that must be considered from the testwork program as follows: ore grade relationship to gold recovery, crushing and grinding parameters and their relationship to the ore variability in the ore body, effect of other minerals on the process, minerals and/compounds that negatively impact processing cost such as oxidized 2019年8月23日 Diamond processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppDiamond Processing Equipment, Process Flow, Cases JXSC MachineDownload scientific diagram Flow chart of grinding procedure from publication: Grinding Wheel Loading Evaluation by Using Acoustic Emission Signals and Digital Image Processing In the Flow chart of grinding procedure Download Zeolites mining process, how to extract mineral from They are found in geologically young volcanic fields Most common zeolite minerals are analcime 75TPH Diamond Dense Medium Separation Process in CongoChrome Zeolites Mining Process Equipment Flow Cases

.jpg)

The Latest Innovations in Wheat Flour Milling: A Review

2023年8月2日 The importance of wheat cleaning in the milling process is highlighted, along with technological advancements such as color sorting machines and debranning of wheat grains before grinding, which of concentrates to ease further handling and refining Figure 11241 is a general flow diagram for metallic mineral processing Very few metallic mineral processing facilities will contain all of the operations depicted in this figure, but all facilities will use at least some of these operations in the process of separating valued minerals 1124 Metallic Minerals Processing US EPA2023年5月9日 AFM images demonstrate that mean diameter of grinded zeolite were between 10 and 60 nanometer, which indicate that grinding process was successful to achieve the nanoscale granules also SEM (PDF) Synthesis Of Zeolite Granules From NaCl Activated Nano Zeolite 2024年11月21日 Fluorspar mineral processing is a complex field that requires a variety of methods to extract and refine this valuable mineral One common type is gravity separation, which involves separating fluorspar from other minerals based on differences in densityThis method is costeffective and environmentally friendly, making it a popular choice in fluorspar processingFour Common Types Of Fluorspar Mineral Processing Methods

.jpg)

Phosphate Rock Processing: 6 Useful Ways and 4 Stages

2023年8月8日 Applicable type: Separate phosphate minerals from high magnesium vein minerals Phosphate rock production line (four stages) To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration2021年7月17日 This paper describes an algorithm for optimizing process flow diagrams, as well as the order in which the parameters of mineral waste recycling equipment should be optimized We developed a flow chart for this wasterecycling processtrain design analysis algorithm When comparing different mineralwaste recycling process train options, it is best to use an Optimization of Process Flow Diagrams for Processing of Mineral 2022年2月28日 Generally, grinding process efficiency can mainly be improved by either improving the grinding behavior of the material being ground or enhancing the grinding machines Recently, the use of additives socalled grinding aids, which is applied in a small amount of 001–025 wt% related to the mass of product, has reduced these problems and been Grinding SpringerLink2011年1月1日 In this study grindability of zeolite was studied The work index of zeolite was determined for three different test sieves In terms of work indexes, there was insignificant difference between Determination of grindability characteristics of zeolite

Zeolite Process PPT SlideShare

2016年4月29日 Zeolite Process Download as a PDF or view online for free Submit Zeolite Process • Download as PPTX, PDF • 77 likes • 87,944 views Sunny Chauhan Follow Zeolite is a hydrated sodium alumino silicate 2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial 2021年9月23日 Clinoptilolite is a precious zeolite mineral that has the most comprehensive physicochemical properties among all the zeolite group minerals Due to these unique properties, clinoptilolite has a wide range of applications Mineral Composition and Structural 2024年1月23日 Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000 MidRange Grinding Machines: These machines, offering more features and greater precision, are generally priced between $20,000 and $60,000What is Grinding: Definition, Process, Types Specifications

Minerals Special Issue : Zeolite: From a Boiling Stone to the

2023年7月28日 Dear Colleagues, Zeolites are wellknown aluminosilicate minerals with a unique crystal structure and physicochemical properties The 3D crystal lattice of zeolites is thermally stable and allows the accommodation of various chemical species, such as ions, atoms, or nanosized particles of various compounds, not only on the surface but also inside the cavities and Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills into 100 mesh, 150 mesh, 200 mesh Bentonite Processing Methods And Required Equipment2009年2月1日 Batch wet grinding of zeolite was studied with emphasis on a kinetic study in a laboratory size steel ball mill of 200 mm diameter The breakage parameters were determined by using the single Kinetics of Fine Wet Grinding of Zeolite in A Steel Ball Mill in 2015年8月3日 The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing Overview of Mineral Processing Methods ResearchGate

Zeolite Properties, Methods of Synthesis, and Selected

2024年2月29日 Zeolites, a group of minerals with unique properties, have been known for more than 250 years However, it was the development of methods for hydrothermal synthesis of zeolites and their largescale industrial applications (oil processing, agriculture, production of detergents and building materials, water treatment processes, etc) that made them one of the Another effective way to avoid the precipitation related problems in the continuous flow process is to utilize a segmented flow, which refers to a multiphase system consisting of an alternating succession of immiscible fluid segments 173–175 Emulsion is a typical segmented system, where an immiscible liquid is dispersed in another liquid to form discrete droplets in a Ultrafast synthesis of zeolites: breakthrough, progress and perspective