HOME→Gangue hollow spodumene ore powder grinding and powder making process equipment, complete supporting facilities

Gangue hollow spodumene ore powder grinding and powder making process equipment, complete supporting facilities

.jpg)

Lithium Processing Plant, Equipment JXSC Machinery

2023年1月6日 Lithium beneficiation processing plant includes crushing, grinding, gravity separation, flotation, magnetic separation and combined process According to the nature of lithium ore (spodumene, lepidolite, lithium feldspar), 2023年11月7日 Spodumene processing and production equipment are used in various stages of extracting and refining lithium from spodumene ore The equipment and machinery required Spodumene Processing And Production Equipment2022年10月31日 This work investigates the energy efficiency of different grinding circuits used for upgrading the lithium content in the finer fraction of the calcined spodumene oreLithium deportment by size of a calcined spodumene ore2023年12月27日 Two process pathways to achieve batterygrade chemical production from spodumene are summarized herein, with a focus on improving process yields and costs in the saline water circuit Lithium (Li) is essential to Hard Rock Spodumene Lithium Processing Saltworks

.jpg)

Powder Technology ScienceDirect

2023年2月1日 The beneficiation of spodumene using Dense Media Separation (DMS) and froth flotation, the most widely adopted techniques, have been appraised The application of 2023年1月1日 This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination Lithium extraction from hard rock lithium ores (spodumene, 2019年5月29日 This process starts with the crushing of spodumene ore The cause behind the grinding of the spodumene is an acceleration of the heat transfer between the surrounding atmosphere and the mineral The crushed Spodumene: The Lithium Market, Resources and 2022年3月30日 Thus, a combined process of dry–wet twostage desliming, gravity separation, and flotation for spodumene raw ore is proposed, which decreases the amount of raw ore Dry deep screening of spodumene and its mineral processing

.jpg)

Revisiting the Traditional Process of Spodumene Conversion and

2018年8月19日 Since 1950, the traditional process has been dominating the production of lithium compounds from spodumene ores to sustain the lithium market because of its Flotation is used to generate a high grade spodumene concentrate (7585% spodumene) suitable for lithium extraction Minimize the cost of roasting Lithium can be extracted from spodumene Hard Rock Lithium Processing SGS2021年6月18日 Summary of mineral abundance in the composite head sample; specific gravity; and concentration criterion (CC) in water and heavy liquid The Recovery and Concentration of Spodumene Using 2023年12月27日 In step 1, to convert spodumene into lithium sulfate (Li 2 SO 4), the raw ore is crushed and separated both mechanically and via floatationNext, the concentrate undergoes energy and chemically intensive Hard Rock Spodumene Lithium Processing Saltworks

The Recovery and Concentration of Spodumene Using

2021年6月18日 In coming years, global lithium production is expected to increase as the result of widespread electric vehicle adoption To meet the expected increase in demand, lithium must be sourced from both brine and Would you be a confirmed Engineer, a new graduate looking for information on the process he has 1st to work on, or a student, please access below articles on unit operations and equipment that, we hope, will be useful for you PowderProcess also hosts Process Engineer's Tools, a new online ressource for Process Engineers, not limited to Powder Processing This powderprocess Engineering resources for powder 2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car market, it is crucial to improve lithium recovery from its rich mineral deposits using the most effective extraction technique In recent years, both Aspects of Spodumene Lithium Extraction Techniques MDPIDOI: 101016/jconbuildmat2019 Corpus ID: ; Preparation, characteristics and mechanisms of the composite sintered bricks produced from shale, sewage sludge, coal gangue powder and iron ore tailingsPreparation, characteristics and mechanisms of the composite

.jpg)

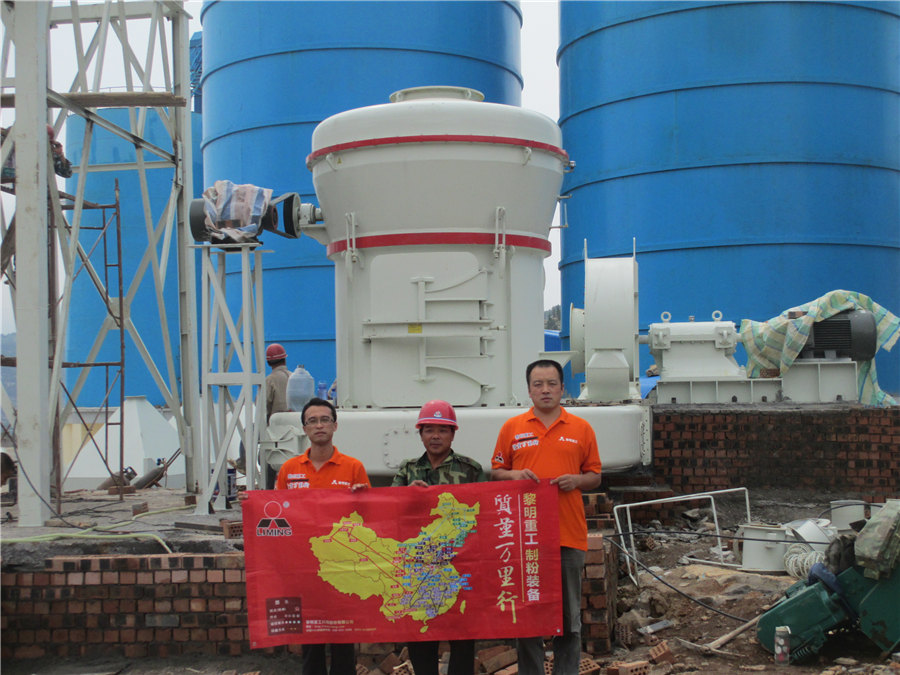

Coal gangue ultrafine powder mill

2022年9月13日 1 Brick making with coal gangue powder Coal gangue powder is the raw material for making solid gangue bricks, porous loadbearing gangue bricks, hollow gangue bricks and other bricklaying materials 2 Coal gangue powder replaces clay to produce cement The price of cement has skyrocketed Coal gangue powder replaces clay to produce cement for 2020年1月30日 It can be concluded that both iron ore tailings and coal gangue powder can be used as the materials for brick making To ensure the strength requirement of brick, binder is the necessary component due to its strong ability of bonding the raw materials together [18]Preparation, characteristics and mechanisms of the composite 2017年10月1日 In this paper, a complete scheme aimed at improving the flotation performance of spodumene and comprehensively recycling mica and feldspar from lithium tailings in an economical and A novel approach for flotation recovery of spodumene, mica and 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?

.jpg)

Literature Review and Thermodynamic Modelling of

2020年9月30日 Literature Review and Thermodynamic Modelling of Roasting Processes for Lithium Extraction from Spodumene2020年1月30日 Iron ore is one of the most common resource widely used in industry while the tailings discarded during the beneficiation and smelting process of iron ore become an important hazardous waste worldwide [1], [2]In China and Brazil, more than 10 billion tons of iron ore tailings have been discharged as waste and normally deposit in tailings dam while less than Preparation, characteristics and mechanisms of the composite 2020年4月2日 Powder Grinding Crystal Hollows not only included a new type of powder, it also introduced a new powder grinding strategy This guide includes everything you need to know about grinding powder, and it prioritizes powder The Ultimate Guide to Powder Grinding Hypixel 2018年10月17日 The influence of gangue compositions (mainly composed of SiO2, CaO, MgO and Al2O3) on the reduction kinetics of carbonbearing iron ore pellets was estimated at 1373–1473 K in N2 atmosphere(PDF) Effects of gangue compositions on reduction process of

Grinding Milling Powder ProcessSolutions

Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a whole range of requirements from deagglomeration and coarse grinding through to fine grinding and classifying3 Lithium Heavy Media Beneficiation Applicable minerals: Spodumene with relatively coarse crystal grain size The difference in specific gravity between lithium ore and gangue minerals is not greater than 0205g/m3 Main process: Mix the lithium ore after washing and desliming with heavy medium (heavy medium includes heavy liquid and heavy suspension, here mainly Lithium Ore Mining Process JXSC Mineral2016年5月9日 The selective separation of gangue minerals requires acidproof mining equipment, which is described more fully in Flowsheet Study on Feldspar The Lithium Ore Flowsheet Fatty acid or soap flotation of spodumene is one well established recovery method, but pulverized or ground particle surface conditions generally necessitate preflotation Processing Spodumene by Froth Flotation for Lithium Extraction2023年8月31日 Two types of gangue are mainly used in brick making: kaolinite mudstone (kaolinite content 60%) and illite mudstone (illite content 50%) Compared with the clay brick making process, its process adds a crushing process A jaw crusherand a roller crusher are used for coarse crushing and medium crushingHow to Recycle and Process Coal Gangue: 7 Effective Ways

.jpg)

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 Recently, there has been a steady increase in demand for lithium (Li) and its compounds, accounting for 10% over the past decade The level of production and industrial use of lithium currently 2023年9月5日 Powder metallurgy is a manufacturing process that involves using metal powder, or a mixture of metal powder and nonmetal powder, as a raw material The powder is then formed and sintered to produce a range of metal materials, composite materials, and various types of articlesPowder Metallurgy: A Comprehensive Guide for Beginners2021年5月31日 Indian iron ores are suffering from high amounts of alumina and loss on ignition (LOI), which are deleterious constituents in both the pelletizing as well as iron making processes Iron ore fines Effects of Iron Ore Type and Gangue MineralComponents on 2017年2月16日 PDF Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming Find, read and cite all the research you (PDF) Iron Ore Sintering: Process ResearchGate

.jpg)

Powder Technology ScienceDirect

2023年2月1日 The present scenario has urged the necessity to beneficiate and extract lithium from the available resources judiciously Pegmatites constitute the second major economic resource of lithium, after brines, accounting for about 25% of global production [14]The lithiumbearing minerals, hosted by the pegmatite rocks, include spodumene, lepidolite, petalite, Moreover, coal gangue was a byproduct of the coal mining and washing processes, accounting for approximately 10 %–25 % of the total raw coal production [[9], [10], [11]]Its carbon content was relatively low and its hardness was higher than that of coal [12]According to the data of China Resources Comprehensive Utilization, the production amount of coal gangue in 2021 Synergistic action and effect mechanism of coal gangue powder 2013年4月24日 1 Talcum Powder Manufacturing Process Within the talcum powder manufacturing process, crusher, grinding mill are utilized as talc powder making machine for powder production Most talc deposits are open pit mine Talc rock is found by giant spades Different ore types are sorted because they are removed in the seamTalcum powder manufacturing process PDF Free DownloadFood powder mixing Explore this informative page to gain insights into the world of food powder mixing Whether you're a smallscale business owner looking for practical mixing solutions or part of a largescale production facility aiming to maintain highquality standards, this resource offers valuable guidancePowder Mixing: The Ultimate Engineering Guide for Bulk Solids

Roasting and leaching behavior of spodumene in sulphuric acid process

2011年1月1日 The roasting and leaching behavior of spodumene in sulphuric acid process was investigated Thermal analysis results of ore sample showed that the peak temperature of crystal conversion was 1006°CSpodumene ore is one of the principal sources of lithium It occurs in muscovite type and lepidolite type granitic pegmatite It is a mineral of metasomatic origin in the process of pegmatite, which is often associated with lepidolite, beryl, niobium tantalite, tourmaline, muscovite, etc, and belongs to silicate minerals with these gangue mineralsLaboratory Spodumene Beneficiation Test To Get Purified Lithium2022年4月21日 Lithium is a key component in green energy storage technologies and is rapidly becoming a metal of crucial importance to the European Union The different industrial uses of lithium are discussed Lithium deportment by size of a calcined spodumene ore2023年3月15日 However, a relatively the high grinding media filling rate and high powder filling rate reduce the selective liberation of heterogeneous ore during the grinding process Therefore, for the heterogeneous grinding nature of ore, unequalprobability comminution can be strengthened by choosing an appropriate grinding time and optimizing the operational conditionStudy on the unequalprobability comminution of spodumene

Banana Powder Making Process Complete

Banana Powder Making Process Complete Production Line Banana powder has gained immense popularity in recent years as a versatile ingredient used in various food and beverage applications Its rich nutritional profile, long shelf 2023年1月1日 Lithium resources in nature are mainly stored in lithium deposits of brine, pegmatite, and sedimentary rocks (Talens PL et al, 2013; Liu LJ et al, 2017)Among them, brine mainly includes underground and salt lake brine, and pegmatitetype lithium ore is stored in spodumene, lepidolite, petalite, and zinnwaldite (Xi WW et al, 2022; Yu F et al, 2019), while Lithium extraction from hard rock lithium ores (spodumene, 2012年6月1日 The feed material is typically composed of the BFRs and the catalyst, both in powder form As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed Grinding in Ball Mills: Modeling and Process Control5 天之前 A single sulfide ore is usually treated by flotation process, using crushinggrindingclassificationflotationconcentration process to select a single copper sulfide ore as copper concentrate Copper ore beneficiation process The principle of priority flotation process is: crushing and screening→grinding and classification→priority flotation of copper Copper Ore Processing Plants, Flow And Equipment

.jpg)

Preparation, characteristics and mechanisms of the composite

Iron ore tailings and coal gangue powder are the main sources of industrial solid wastes, the dispose of which has become severe and urgent with the increasing demand of environmental harmony The present study firstly proposed a reasonable way to deal with the large amount of iron ore tailings and coal gangue powder by making them as the sintered bricks with sewage 2023年9月8日 Ljiagou pegmatite spodumene deposit is part of the Ke’eryin orefield in the central SongpanGarze Fold Belt of Sichuan, China After recent exploration and assessment, it has been established as a new superlarge spodumene deposit In order to determine the processing characteristics of the ore and assess its industrial value, based on detailed Process Mineralogy Characteristics of Lijiagou Pegmatite Spodumene 2023年3月1日 Traditional finegrinding mills in mineral processing rely on the use of steel medium for particle size reduction The IsaMill (a horizontal stirred mill with a 3,000L net chamber volume and a Study on the unequalprobability comminution of spodumene 2022年10月31日 Processing of spodumene ores requires calcination as a compulsory pretreatment to convert αspodumene to a more reactive βspodumene phaseLithium deportment by size of a calcined spodumene ore

Effect of Gangue Distribution on Compressive Strength of Iron Ore

2023年7月21日 A novel ambient condition production of superior strength, nonabrasive, nonsticky iron ore pellets devoid of undesirable fines under the compression stress of 4 kN is presented2022年7月28日 Calcination of spodumene is a pretreatment stage in preparation for sulfation roasting and leaching in lithium recovery During calcination, αspodumene (less reactive, monoclinic crystal Effect of calcination on coarse gangue rejection of hard rock lithium ores